Abstract

The study of dislocation plasticity mediated by semi-coherent interfaces can aid in the design of certain heterostructured materials, such as nanolaminates. The evolution of interface misfit patterns under complex stress fields arising from dislocation pileups can influence local dislocation/interface interactions, including effects of multiple incoming dislocations. This work utilizes the Concurrent Atomistic-Continuum modeling framework to probe the evolution of misfit structures at semi-coherent Ni/Cu and Cu/Ag interfaces im**ed by dislocation pileups generated via nanoindentation. A continuum microrotation metric is computed at various stages of the indentation process and used to visualize the evolution of the interface misfit dislocation pattern. The stress state from approaching dislocations induces mixed contraction and expansion of misfit dislocation structures at the interface. A lower number of misfit nodes per unit interface area coincides with greater localized deformation with regard to atoms near misfit nodes for Ni/Cu. The decreased misfit node spacing for Cu/Ag alternatively distributes the restructuring associated with plastic deformation over a larger percentage of atoms at the interface. Interface sliding facilitated by misfit dislocation motion is found to facilitate deformation extending into the bulk lattices centered on misfit nodes. The depth of penetration of those fields is found to be greater for Ni/Cu than for Cu/Ag.

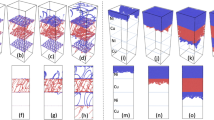

Graphic abstract

The study of dislocation plasticity mediated by semi-coherent interfaces can aid in the design of certain heterostructured materials, such as nanolaminates. The evolution of interface misfit patterns under complex stress fields arising from dislocation pileups can influence local dislocation/interface interactions, including effects of multiple incoming dislocations. This work utilizes the Concurrent Atomistic-Continuum modeling framework to probe the evolution of misfit structures at semi-coherent Ni/Cu and Cu/Ag interfaces im**ed by dislocation pileups generated via nanoindentation. A continuum microrotation metric is computed at various stages of the indentation process and used to visualize the evolution of the interface misfit dislocation pattern. The stress state from approaching dislocations induces mixed contraction and expansion of misfit dislocation structures at the interface. A lower number of misfit nodes per unit interface area coincides with greater localized deformation with regard to atoms near misfit nodes for Ni/Cu. The decreased misfit node spacing for Cu/Ag alternatively distributes the restructuring associated with plastic deformation over a larger percentage of atoms at the interface. Interface sliding facilitated by misfit dislocation motion is found to facilitate deformation extending into the bulk lattices centered on misfit nodes. The depth of penetration of those fields is found to be greater for Ni/Cu than for Cu/Ag.

Similar content being viewed by others

References

X. Wu, P. Jiang, L. Chen, F. Yuan, Y.T. Zhu, Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. 111(20), 7197–7201 (2014)

X. Wu, M. Yang, F. Yuan, G. Wu, Y. Wei, X. Huang, Y. Zhu, Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. 112(47), 14501–14505 (2015)

J. Moering, X. Ma, G. Chen, P. Miao, G. Li, G. Qian, S. Mathaudhu, Y. Zhu, The role of shear strain on texture and microstructural gradients in low carbon steel processed by surface mechanical attrition treatment. Scripta Mater. 108, 100–103 (2015)

A. Misra, 7—mechanical behavior of metallic nanolaminates, in Nanostructure control of materials. ed. by R.H.J. Hannink, A.J. Hill (Woodhead Publishing, Sawston, 2006), pp. 146–176

N.A. Mara, I.J. Beyerlein, Interface-dominant multilayers fabricated by severe plastic deformation: stability under extreme conditions. Cur. Opin. Solid State Mater Sci. 19(5), 265–276 (2015)

C.C. Tasan, M. Diehl, D. Yan, M. Bechtold, F. Roters, L. Schemmann, C. Zheng, N. Peranio, D. Ponge, M. Koyama et al., An overview of dual-phase steels: advances in microstructure oriented processing and micromechanically guided design. Annu. Rev. Mater. Res. 45, 391–431 (2015)

A. Sáenz-Trevizo, A.M. Hodge, Nanomaterials by design: a review of nanoscale metallic multilayers. Nanotechnology 31(29), 292002 (2020)

B.M. Clemens, H. Kung, S.A. Barnett, structure and strength of multilayers. MRS Bull. 24(2), 20–26 (1999)

Q. Zhou, J.Y. **e, F. Wang, P. Huang, K.W. Xu, T.J. Lu, The mechanical behavior of nanoscale metallic multilayers: a survey. Acta Mech. Sin. 31(3), 319–337 (2015)

R.G. Hoagland, R.J. Kurtz, C.H. Henager, Slip resistance of interfaces and the strength of metallic multilayer composites. Scripta Mater. 50(6), 775–779 (2004)

I.N. Mastorakos, H.M. Zbib, D.F. Bahr, Deformation mechanisms and strength in nanoscale multilayer metallic composites with coherent and incoherent interfaces. Appl. Phys. Lett. 94(17), 173114 (2009)

M. **ang, Y. Liao, K. Wang, G. Lu, J. Chen, Shock-induced plasticity in semi-coherent 111 cu-ni multilayers. Int J. Plast. 103, 23–38 (2018)

S. Shao, J. Wang, I.J. Beyerlein, A. Misra, Glide dislocation nucleation from dislocation nodes at semi-coherent 1 1 1 Cu–Ni interfaces. Acta Mater. 98, 206–220 (2015)

X.Y. Chen, X.F. Kong, A. Misra, D. Legut, B.N. Yao, T.C. Germann, R.F. Zhang, Effect of dynamic evolution of misfit dislocation pattern on dislocation nucleation and shear sliding at semi-coherent bimetal interfaces. Acta Mater. 143, 107–120 (2018)

H. Yang, L. Zhu, R. Zhang, J. Zhou, Z. Sun, Influence of high stacking-fault energy on the dissociation mechanisms of misfit dislocations at semi-coherent interfaces. Int J. Plast. 126, 102610 (2020)

R.F. Zhang, T.C. Germann, X.Y. Liu, J. Wang, I.J. Beyerlein, Layer size effect on the shock compression behavior of fcc–bcc nanolaminates. Acta Mater. 79, 74–83 (2014)

R. Dikken, M. Khajeh Salehani, Edge dislocation im**ement on interfaces between dissimilar metals (2017)

A. Couret, J. Crestou, S. Farenc, G. Molenat, N. Clement, A. Coujou, D. Caillard, In situ deformation in T.E.M: recent developments. Microsc. Microanal. Microstruct. 4(2–3), 153–170 (1993)

S. Shao, J. Wang, A. Misra, R.G. Hoagland, Spiral patterns of dislocations at nodes in (111) semi-coherent FCC interfaces. Sci. Rep. (2013). https://doi.org/10.1038/srep02448

H. Yang, L. Zhu, R. Zhang, J. Zhou, Z. Sun, Shearing dominated by the coupling of the interfacial misfit and atomic bonding at the FCC (111) semi-coherent interfaces. Mate Des. 186, 108294 (2020)

S. Shao, J. Wang, A. Misra, Energy minimization mechanisms of semi-coherent interfaces. J. Appl. Phys. 116(2), 023508 (2014)

E.B. Tadmor, M. Ortiz, R. Phillips, Quasicontinuum analysis of defects in solids. Philos. Mag. A 73(6), 1529–1563 (1996)

E.B. Tadmor, F. Legoll, W.K. Kim, L.M. Dupuy, R.E. Miller, Finite-temperature quasi-continuum. Appl. Mech. Rev. (2013). https://doi.org/10.1115/1.4023013

L.E. Shilkrot, R.E. Miller, W.A. Curtin, Coupled atomistic and discrete dislocation plasticity. Phys. Rev. Lett. (2002). https://doi.org/10.1103/PhysRevLett.89.025501

G. Anciaux, T. Junge, M. Hodapp, J. Cho, J.-F. Molinari, W.A. Curtin, The coupled atomistic/discrete-dislocation method in 3d part I: Concept and algorithms. J. Mech. Phys. Solids 118, 152–171 (2018)

D.L. McDowell, Multiscale modeling of interfaces, dislocations, and dislocation field plasticity, in Mesoscale models. ed. by S. Mesarovic, S. Forest, H. Zbib (Springer, Cham, 2018)

M. Dewald, W.A. Curtin, Analysis and minimization of dislocation interactions with atomistic/continuum interfaces. Model. Simul. Mater. Sci. Eng.. 14(3), 497–514 (2006)

T. Shimokawa, T. Kinari, S. Shintaku, Interaction mechanism between edge dislocations and asymmetrical tilt grain boundaries investigated via quasicontinuum simulations. Phys. Rev. B. (2007). https://doi.org/10.1103/PhysRevB.75.144108

Y. Chen, S. Shabanov, D.L. McDowell, Concurrent atomistic-continuum modeling of crystalline materials. J. Appl. Phys. 126(10), 101101 (2019)

S. Xu, R. Che, L. **ong, Y. Chen, D.L. McDowell, A quasistatic implementation of the concurrent atomistic-continuum method for FCC crystals. Int J. Plast. 72, 91–126 (2015)

S. Xu, D.L. McDowell, I.J. Beyerlein, Sequential obstacle interactions with dislocations in a planar array. Acta Mater. 174, 160–172 (2019)

L. **ong, D.L. McDowell, Y. Chen, Nucleation and growth of dislocation loops in Cu, Al and Si by a concurrent atomistic-continuum method. Scripta Mater. 67(7–8), 633–636 (2012)

S. Xu, L. **ong, Y. Chen, D.L. McDowell, Sequential slip transfer of mixed-character dislocations across Σ3 coherent twin boundary in FCC metals: a concurrent atomistic continuum study. npj Comput. Mater. 2(1), 15016 (2016)

S. Xu, L. **ong, Y. Chen, D.L. McDowell, Comparing EAM potentials to model slip transfer of sequential mixed character dislocations across two symmetric tilt grain boundaries in Ni. JOM 69(5), 814–821 (2017)

S. Xu, Y. Li, and Y. Chen: Si/Ge (111) semicoherent interfaces: Responses to an in-plane shear and interactions with lattice dislocations. Physica Status Solidi (b). 257, 2000274 (2020).

Y. Li, Z. Fan, W. Li, D.L. McDowell, Y. Chen, A multiscale study of misfit dislocations in PbTe/PbSe(001) heteroepitaxy. J. Mater. Res. 34(13), 2306–2314 (2019)

H. Chen, S. Xu, W. Li, R. Ji, T. Phan, L. **ong, A spatial decomposition parallel algorithm for a concurrent atomistic-continuum simulator and its preliminary applications. Comput. Mater. Sci. 144, 1–10 (2018)

W.-R. Jian, M. Zhang, S. Xu, I.J. Beyerlein, Atomistic simulations of dynamics of an edge dislocation and its interaction with a void in copper: A comparative study. Modell. Simul. Mater. Sci. Eng. 28(4), 045004 (2020)

G.H. Vineyard, Frequency factors and isotope effects in solid state rate processes. J. Phys. Chem. Solids 3(1–2), 121–127 (1957)

A.F. Voter, J.D. Doll, Transition state theory description of surface self-diffusion: comparison with classical trajectory results. J. Chem. Phys. 80(11), 5832–5838 (1984)

S. Ryu, K. Kang, W. Cai, Predicting the dislocation nucleation rate as a function of temperature and stress. J. Mater. Res. 26(18), 2335–2354 (2011)

G. Henkelman, B.P. Uberuaga, H. Jónsson, A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113(22), 9901–9904 (2000)

X. Zhang, B. Zhang, Y. Mu, S. Shao, C.D. Wick, B.R. Ramachandran, W.J. Meng, Mechanical failure of metal/ceramic interfacial regions under shear loading. Acta Mater. 138, 224–236 (2017)

G.J. Tucker, J.A. Zimmerman, D.L. McDowell, Continuum metrics for deformation and microrotation from atomistic simulations: application to grain boundaries. Int. J. Eng. Sci. 49(12), 1424–1434 (2011)

I. Wang, Atomistic simulations of dislocation pileup: grain boundaries interaction. JOM 67(7), 1515–1525 (2015)

M. Dodaran, J. Wang, Y. Chen, W.J. Meng, S. Shao, Energetic, structural and mechanical properties of terraced interfaces. Acta Mater. 171, 92–107 (2019)

E. Bitzek, P. Koskinen, F. Gähler, M. Moseler, P. Gumbsch, Structural relaxation made simple. Phys. Rev. Lett. 97(17), 170201 (2006)

S. Yang, Y. Chen, Concurrent atomistic and continuum simulation of bi-crystal strontium titanate with tilt grain boundary. Proc. R. Soc. A Math. Phys. Eng. Sci. 471(2175), 20140758 (2015)

X. Tian, J. Cui, M. Yang, K. Ma, M. **ang, Molecular dynamics simulations on shock response and spalling behaviors of semi-coherent 111 Cu-Al multilayers. Int. J. Mech. Sci. 172, 105414 (2020)

C. Ruestes, I. Alhafez, H. Urbassek, C.J. Ruestes, I.A. Alhafez, H.M. Urbassek, Atomistic studies of nanoindentation—a review of recent advances. Curr. Comput.-Aided Drug Des. 7(10), 293 (2017)

S.Z. Chavoshi, S. Xu, Nanoindentation/scratching at finite temperatures: Insights from atomistic-based modeling. Prog. Mater Sci. 100, 1–20 (2019)

E. Tadmor, Modeling Materials: Continuum, Atomistic, and Multiscale Techniques (Cambridge University Press, Cambridge, New York, 2011).

B. Onat, S. Durukanoglu, An optimized interatomic potential for Cu-Ni alloys with the embedded-atom method. J. Phys. Condens. Matter (2014). https://doi.org/10.1088/0953-8984/26/3/035404

P.L. Williams, Y. Mishin, J.C. Hamilton, An embedded-atom potential for the Cu–Ag system. Modell. Simul. Mater. Sci. Eng. 14(5), 817–833 (2006)

S. Xu, T.G. Payne, H. Chen, Y. Liu, L. **ong, Y. Chen, D.L. McDowell, PyCAC: The concurrent atomistic-continuum simulation environment. J. Mater. Res. 33(7), 857 (2018)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Modell. Simul. Mater. Sci. Eng. 18(1), 015012 (2009)

A. Stukowski, K. Albe, Dislocation detection algorithm for atomistic simulations. Modell. Simul. Mater. Sci. Eng. 18(2), 025016 (2010)

D. Faken, H. Jónsson, Systematic analysis of local atomic structure combined with 3D computer graphics. Comput. Mater. Sci. 2(2), 279–286 (1994)

I.A. Zimmerman, D.J. Bammann, H. Gao, Deformation gradients for continuum mechanical analysis of atomistic simulations. Int. J. Solids Struct. 46(2), 238–253 (2009)

G.J. Tucker, J.A. Zimmerman, D.L. McDowell, Shear deformation kinematics of bicrystalline grain boundaries in atomistic simulations. Modell. Simul. Mater. Sci. Eng. 18(1), 015002 (2009)

Acknowledgments

This work is based on research supported by the National Science Foundation under the Grants CMMI-1761553 and CMMI-1761512. All presented simulations were conducted using XSEDE resources under allocation TG-MSS150010.

Author information

Authors and Affiliations

Corresponding author

Additional information

David McDowell was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Rights and permissions

About this article

Cite this article

Selimov, A., Xu, S., Chen, Y. et al. Lattice dislocation induced misfit dislocation evolution in semi-coherent {111} bimetal interfaces. Journal of Materials Research 36, 2763–2778 (2021). https://doi.org/10.1557/s43578-021-00184-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00184-8