Abstract

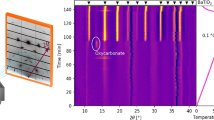

The refractory nature of BaTiO3 leads to limited densification and grain growth for films processed at low temperatures and a modest nonlinear dielectric response due to a marked sensitivity to physical scale and material quality. Adding liquid-forming sintering aids, common in bulk ceramics, to thin films enhances mass transport, leading to enhanced grain growth at lower temperatures. This work explores the effectiveness of a sputtered CuO buffer layer with BaO–B2O3 (BBO) fluxes to engineer the microstructure of BaTiO3 films. Grain size and homogeneity increase in the presence of even a ∼1 nm CuO layer. In general, grain size increases from 75 to 370 nm with an addition of 2.2% BBO and 8 nm CuO. Room temperature capacitance in fluxed films increases by a factor of 5 over pure films, and ferroelectric phase transitions are clearly observable in dielectric measurements. CuO–BBO proves effective on (0001) Al2O3 and (100) MgO substrates, although all microstructures are notably finer for the latter.

Similar content being viewed by others

References

S.M. Aygün, J.F. Ihlefeld, W.J. Borland, and J-P. Maria: Permittivity scaling in Ba1− xSrxTiO3 thin films and ceramics. J. Appl. Phys. 109, 034108 (2011).

M.H. Frey, Z. Xu, P. Han, and D.A. Payne: The role of interfaces on an apparent grain size effect on the dielectric properties for ferroelectric barium titanate ceramics. Ferroelectrics 206, 337–353 (1998).

T.M. Shaw, Z. Suo, M. Huang, E. Liniger, R.B. Laibowitz, and J.D. Baniecki: The effect of stress on the dielectric properties of barium strontium titanate thin films. Appl. Phys. Lett. 75, 2129 (1999).

S.K. Streiffer, C. Basceri, C.B. Parker, S.E. Lash, and A.I. Kingon: Ferroelectricity in thin films: The dielectric response of fiber-textured (BaxSr1− x)Ti1+ yO3+ z thin films grown by chemical vapor deposition. J. Appl. Phys. 86, 4565 (1999).

G. Arlt, D. Hennings, and G. de With: Dielectric properties of fine-grained barium titanate ceramics. J. Appl. Phys. 58, 1619 (1985).

Z. Zhao, V. Buscaglia, M. Viviani, M. Buscaglia, L. Mitoseriu, A. Testino, M. Nygren, M. Johnsson, and P. Nanni: Grain-size effects on the ferroelectric behavior of dense nanocrystalline BaTiO3 ceramics. Phys. Rev. B: Condens. Matter Mater. Phys. 70, 024107 (2004).

H. Kishi, Y. Mizuno, and H. Chazono: Base-metal electrode-multilayer ceramic capacitors: Past, present and future perspectives. Jpn. J. Appl. Phys. 42, 1–15 (2003).

D. Prakash, B.P. Sharma, T.R. Rama Mohan, and P. Gopalan: Flux additions in barium titanate: Overview and prospects. J. Solid State Chem. 155, 86–95 (2000).

R. Takahashi, Y. Yonezawa, M. Ohtani, M. Kawasaki, K. Nakajima, T. Chikyow, H. Koinuma, and Y. Matsumoto: Perfect Bi4Ti3O12 single-crystal films via flux-mediated epitaxy. Adv. Funct. Mater. 16, 485–491 (2006).

J.F. Ihlefeld, W.J. Borland, and J-P. Maria: Enhanced dielectric and crystalline properties in ferroelectric barium titanate thin films. Adv. Funct. Mater. 17, 1199–1203 (2007).

D.T. Harris, M.J. Burch, J.F. Ihlefeld, P.G. Lam, J. Li, E.C. Dickey, and J-P. Maria: Realizing strain enhanced dielectric properties in BaTiO3 films by liquid phase assisted growth. Appl. Phys. Lett. 103, 012904 (2013).

D.T. Harris, P.G. Lam, M.J. Burch, J. Li, B.J. Rogers, E.C. Dickey, and J-P. Maria: Ultra-high tunability in polycrystalline Ba1− xSrxTiO3 thin films. Appl. Phys. Lett. 105, 072904 (2014).

I. Burn: Flux-sintered BaTiO3 dielectrics. J. Mater. Sci. 17, 1398–1408 (1982).

D. Hennings and H. Schreinemacher: Method of producing a dielectric with perowskite structure and containing a copper oxide, United States Patent Office. U.S. Patent No. US4222885A, 1980.

D. Hennings and H. Schreinemacher: Method of producing a dielectric with perowskite structure and containing a copper oxide, United States Patent Office. U.S. Patent No. US4244830A, 1981.

T. Li, K. Yang, R. Xue, Y. Xue, and Z. Chen: The effect of CuO do** on the microstructures and dielectric properties of BaTiO3 ceramics. J. Mater. Sci.: Mater. Electron. 22, 838–842 (2010).

C-F. Yang: The influence of CuO–BaO mixture addition on the grain growth and dielectric characteristics of BaTiO3 ceramics. Ceram. Interfaces 24, 341–346 (1998).

ASTM International: ASTM E112-13, Standard Test Methods for Determining Average Grain Size (ASTM International, West Conshohocken, PA, 2013).

W. Zhang, K. Osamura, and S. Ochiai: Phase diagram of the BaO–CuO binary system. J. Am. Ceram. Soc. 73, 1958–1964 (1990).

E.M. Levin and H.F. McMurdie: The system BaO–B2O3. J. Am. Ceram. Soc. 32, 99–105 (1949).

M.J. Burch, J. Li, D.T. Harris, J-P. Maria, and E.C. Dickey: Mechanisms for microstructure enhancement in flux-assisted growth of barium titanate on sapphire. J. Mater. Res. 29, 843–848 (2014).

D.T. Harris, M.J. Burch, J. Li, E.C. Dickey, and J-P. Maria: Low-temperature control of twins and abnormal grain growth in BaTiO3. J. Am. Ceram. Soc. 98, 2381–2387 (2015).

S. Derling, T. Müller, and H. Abicht: Copper oxide as a sintering agent for barium titanate based ceramics. J. Mater. Sci. 36, 1425–1431 (2001).

J-B. Lim, S. Nahm, H-T. Kim, J-H. Kim, J-H. Paik, and H-J. Lee: Effect of B2O3 and CuO on the sintering temperature and microwave dielectric properties of the BaTi4O9 ceramics. J. Electroceram. 17, 393–397 (2006).

M-H. Kim, Y-H. Jeong, S. Nahm, H-T. Kim, and H-J. Lee: Effect of B2O3 and CuO additives on the sintering temperature and microwave dielectric properties of Ba(Zn1/3Nb2/3)O3 ceramics. J. Eur. Ceram. Soc. 26, 2139–2142 (2006).

A.M.M. Gadalla and J. White: Equilibrium relationships in the system CuO–Cu2O–Al2O3. Trans. Br. Ceram. Soc. 63, 57 (1964).

D. McCauley, R.E. Newnham, and C.A. Randall: Intrinsic size effects in a barium titanate glass-ceramic. J. Am. Ceram. Soc. 81, 979–987 (1998).

J.F. Ihlefeld, P.R. Daniels, S.M. Aygün, W.J. Borland, and J-P. Maria: Property engineering in BaTiO3 films by stoichiometry control. J. Mater. Res. 25, 1064–1071 (2010).

J.K. Lee, K.S. Hong, and J.W. Jang: Roles of Ba/Ti ratios in the dielectric properties of BaTiO3 ceramics. J. Am. Ceram. Soc. 84, 2001–2006 (2001).

D.C. Lupascu, Y. Genenko, and N. Balke: Aging in ferroelectrics. J. Am. Ceram. Soc. 89, 224–229 (2006).

Y.Q. Tan, J.L. Zhang, and C.L. Wang: Aging behaviours of CuO modified BaTiO3 ceramics. Adv. Appl. Ceram. 113, 223–227 (2014).

H.T. Langhammer, T. Müller, R. Böttcher, and H-P. Abicht: Crystal structure and related properties of copper-doped barium titanate ceramics. Solid State Sci. 5, 965–971 (2003).

U. Robels and G. Arlt: Domain wall clam** in ferroelectrics by orientation of defects. J. Appl. Phys. 73, 3454 (1993).

A. Young, G. Hilmas, S.C. Zhang, and R.W. Schwartz: Effect of liquid-phase sintering on the breakdown strength of barium titanate. J. Am. Ceram. Soc. 90, 1504–1510 (2007).

Z.H. Wu, H.X. Liu, M.H. Cao, Z.Y. Shen, Z.H. Yao, H. Hao, and D.B. Luo: Effect of BaO–Al2O3–B2O3–SiO2 glass additive on densification and dielectric properties of Ba0.3Sr0.7TiO3 ceramics. J. Ceram. Soc. Jpn. 116, 345–349 (2008).

V. Krasevec, M. Drofenik, and D. Kolar: Genesis of the (111) twin in barium titanate. J. Am. Ceram. Soc. 73, 856–860 (1990).

V. Krasevec, M. Drofenik, and D. Kolar: Topotaxy between BaTiO3 and Ba6Ti17O40. J. Am. Ceram. Soc. 70, C–193–C–195 (1987).

B. Lee, S. Chung, and S-J.L. Kang: Grain boundary faceting and abnormal grain growth in BaTiO3. Acta Mater. 48, 1575–1580 (2000).

B-K. Lee and S-J.L.L. Kang: Second-phase assisted formation of {111} twins in barium titanate. Acta Mater. 49, 1373–1381 (2001).

B. Lee, S. Chung, and S.L. Kang: Necessary conditions for the formation of {111} twins in barium titanate. J. Am. Ceram. Soc. 83, 2858–2860 (2004).

R.C. DeVRIES: Observations on growth of BaTiO3 crystals from KF solutions. J. Am. Ceram. Soc. 42, 547–558 (1959).

O. Eibl, P. Pongratz, and P. Skalicky: Crystallography of (111) twins in BaTiO3. Philos. Mag. Part B 57, 521–534 (1988).

O. Eibl, P. Pongratz, P. Skalicky, and H. Schmelz: Formation of (111) twins in BaTiO3 ceramics. J. Am. Ceram. Soc. 70, C–195–C–197 (1987).

ACKNOWLEDGMENTS

This material is based upon work supported by the NSF Center for Dielectrics and Piezoelectrics (NSF 1361503), the National Science Foundation Graduate Research Fellowship (NSF DGE-0946818), and the Army Research Office contract (W911NF1410285). Any opinion, findings, and conclusions or recommendations expressed in this material are those of the authors(s) and do not necessarily reflect the views of the National Science Foundation. The authors acknowledge the use of the Analytical Instrumentation Facility (AIF) at North Carolina State University, which is supported by the State of North Carolina and the National Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Harris, D.T., Burch, M.J., Mily, E.J. et al. Microstructure and dielectric properties with CuO additions to liquid phase sintered BaTiO3 thin films. Journal of Materials Research 31, 1018–1026 (2016). https://doi.org/10.1557/jmr.2016.89

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.89