Abstract

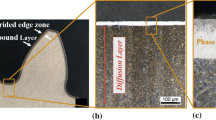

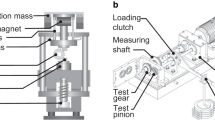

The article investigates the linear static characteristics of a stainless steel gear wheel after thermochemical treatment (nitriding). As a result, the product hardness and wear resistance increase. The experiment has shown that the optimum temperature for the formation of a nitrided case with a hardness of 11 740–12 003 MPa for corrosion-resistant refractory steel 12Kh18N9T is 570–590°C with a nitriding time of 48 h. However, overly high hardness of the nitrided case increases the brittleness of the gear wheel; therefore, deep surface treatment may be required when grinding or polishing. It is shown that, after nitriding, the steel under study has a homogeneous structure with clearly pronounced transition layers; the average thickness of the nitrided case is 60–90 μm. The stress-strain state (SSS) of the product before and after nitriding, which determines the internal stresses and deformation of the wheel tooth, shows that the static characteristics are approximately equal. However, a nitrided wheel has a higher hardness, greater safety margin and less tendency to deform at high loads.

Similar content being viewed by others

REFERENCES

Zorin, V.A., Remont dorozhnykh mashin, avtomobilei i traktorov (Repair of Road Vehicles, Cars, and Tractors), 10th ed., Moscow: Akademiya, 2016. ISBN 978-5-4468-3034-3

Lakhtin, Yu.M. and Arzamasov, B.N., Khimiko-termicheskaya obrabotka metallov (Chemical Heat Treatment of Metals), Moscow: Metallurgiya, 1985.

Kitaev, N.I., Kostin, K.B., and Pichkhidze, S.Ya., Hardening of a highly loaded gear wheel, Proc. 7th Int. Youth Sci.-Pract. Conf. of Southwest State University “Product Quality: Control, Management, Improvement, Planning”, 2020.

Starosel’skii, A.A. and Garkunov, D.N., Dolgovechnost’ trushchikhsya detalei mashin: Proizvodstvenno-prakti-cheskoe izdanie (Durability of rubbing machine parts: Production and practical edition), Moscow: Mashinostroenie, 1967.

Kobeleva, K.V. and Tyktamishev, V.R., Methods of increasing the loadability on aeronautical gear transmissions, Vestn. Permsk. Nats. Issled. Politekh. Univ. Aerokosm. Tekh., 2017, no. 50, pp. 128–138. https://doi.org/10.15593/2224-9982/2017.50.12

Markova, O.A., Prikladnaya mekhanika. Detali mashin. Chast’ I: Uchebnoe Posobie (Applied Mechanics. Machine Parts. Part I: Handbook), Nizhnekamsk: Nizhnekamsk Chem. Technol. Inst. (Branch) “Kazan Nat. Res. Technol. Univ.”, 2013.

Pegashkin, V.F., Obrabotka zubchatykh koles: Uchebnoe posobie (Gear Wheel Processing: Handbook), Nizhny Tagil: Nizhny Tagil Technol. Inst. (Branch) Ural Fed. Univ., 2016.

Kostin, K.B., Gorshkov, N.V., Vikulova, M.A., Luk’yanova, V.O., and Pichkhidze, S.Ya., Investigation of the surface and composition of steel grade 12Kh18N10T with different types of processing, Proc. 28th Int. Sci. Conf. “Trends in the Development of Science and Education”, Samara, Russia, July 31, 2017, Samara: L-Zhurnal, 2017, pp. 15–16. http://ljournal.ru/wp-content/uploads/2016/05/lj31.07.2017_p3.pdf.

Gerasimov, S.A., Kuksenova, L.I., and Lapteva, V.G., Struktura i iznosostoikost’ azotirovannykh konstruktsionnykh stalei i splavov (Structure and Wear Resistance of Nitrided Structural Steels and Alloys), Moscow: Bauman Moscow State Tech. Univ., 2012.

Gura, P.S. and Sysun, V.I., Ion-plasma nitriding of steel surfaces in inductive discharge with planar induction coil, Vestn. Voronezh Gos. Tekn. Univ., 2013, vol. 9, no. 6-1, pp. 82–85.

Borisov, Yu.S., Vikulova, M.A., Kitaev, N.I., and Pichkhidze, S.Ya., Analysis of the possibility of strengthening microsurgical ophthalmic scissors, Nauch. Al’manakh, 2020, no. 7-1 (69), pp. 153–156.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Kolemesin

Rights and permissions

About this article

Cite this article

Kitaev, N.I., Pichkhidze, S.Y. Study of Strength Properties of a Nitrided Gear Wheel. Inorg. Mater. Appl. Res. 13, 211–216 (2022). https://doi.org/10.1134/S207511332201018X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207511332201018X