Abstract

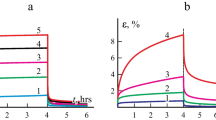

A generalization of a physically nonlinear Maxwell-type viscoelastoplastic constitutive equation with four material functions is formulated, whose general properties and range of applicability were discussed in a series of our previous studies. In order to expand the range of rheological effects and materials that can be described by the equation, it is proposed to add a third strain component expressed by a linear integral Boltzmann–Volterra operator with arbitrary functions of shear and volumetric creep. For generality and for the convenience of using the model, as well as for fitting the model to various materials and simulated effects, a weight factor (degree of nonlinearity) is introduced into the constitutive equation, which allows combining the original nonlinear equation and the linear viscoelastic operator in arbitrary proportions to control the degree of different effects modeled. Equations are derived for families of creep curves (volumetric, shear, longitudinal, and transverse) generated by the proposed constitutive equation with six arbitrary material functions, and an expression is obtained for the Poisson ratio as a function of time. Their general properties and dependence on loading parameters and characteristics of all material functions are studied analytically and compared with the properties of similar relations produced by two combined constitutive equations separately. New qualitative effects are identified which can be described by the new constitutive equation in comparison with the original ones, and it is verified that the generalization eliminates some shortcomings of the Maxwell-type viscoelastoplastic constitutive equation, but retains its valuable features. It is confirmed that the proposed constitutive equation can model sign alternation, monotonic and nonmonotonic changes in transverse strain and Poisson’s ratio under constant stress, and their stabilization over time. Generally accurate estimates are obtained for the variation range, monotonicity and nonmonotonicity conditions of Poisson’s ratio, and its negativity criterion over a certain time interval. It is proven that neglecting volumetric creep (the postulate of bulk elasticity), which simplifies the constitutive equation, greatly limits the range of possible evolution scenarios of Poisson’s ratio in time: it increases and cannot have extremum and inflection points. The analysis shows that the proposed constitutive equation provides ample opportunities for describing various properties of creep and recovery curves of materials and various Poisson’s ratio evolution scenarios during creep. It can significantly expand the range of described rheological effects, the applicability of the Maxwell-type viscoelastoplastic equation, and deserves further research and application in modeling.

Similar content being viewed by others

REFERENCES

Khokhlov, A.V., Two-Sided Estimates for the Relaxation Function of the Linear Theory of Heredity via the Relaxation Curves during the Ramp-Deformation and the Methodology of Identification, Mech. Solids, 2018, vol. 53, pp. 307–328. https://doi.org/10.3103/S0025654418070105

Khokhlov, A.V., Analysis of Properties of Ramp Stress Relaxation Curves Produced by the Rabotnov Non-Linear Hereditary Theory, Mech. Compos. Mater., 2018, vol. 54, no. 4, pp. 473–486. https://doi.org/10.1007/s11029-018-9757-1

Khokhlov, A.V., Properties of the Set of Strain Diagrams Produced by Rabotnov Nonlinear Equation for Rheonomous Materials, Mech. Solids, 2019, vol. 54, pp. 384–399. https://doi.org/10.3103/S002565441902002X

Khokhlov, A.V., Long-Term Strength Curves Generated by the Nonlinear Maxwell-Type Model for Viscoelastoplastic Materials and the Linear Damage Rule under Step Loading, Vestn. Samar. Gos. Tekhn. Univ., Ser. Fiz.-Mat. Nauki, 2016, vol. 20, no. 3, pp. 524–543. http://dx.doi.org/10.14498/vsgtu1512

Khokhlov, A.V., The Nonlinear Maxwell-Type Model for Viscoelastoplastic Materials: Simulation of Temperature Influence on Creep, Relaxation and Strain–Stress Curves, Vestn. Samar. Gos. Tekhn. Univ., Ser. Fiz.-Mat. Nauki, 2017, vol. 21, no. 1, pp. 160–179. https://doi.org/10.14498/vsgtu1524

Khokhlov, A.V., A Nonlinear Maxwell-Type Model for Rheonomic Materials: Stability under Symmetric Cyclic Loadings, Moscow Univ. Mech. Bull., 2018, vol. 73, no. 2, pp. 39–42. https://doi.org/10.3103/S0027133018020036

Khokhlov, A.V., Applicability Indicators and Identification Techniques for a Nonlinear Maxwell-Type Elasto-Viscoplastic Model Using Multi-Step Creep Curves, Vestn. MGTU Baumana. Ser. Estestv. Nauki, 2018, no. 6, pp. 92–112. https://doi.org/10.18698/1812-3368-2018-6-92-112

Khokhlov, А.V., Applicability Indicators and Identification Techniques for a Nonlinear Maxwell-Type Elastoviscoplastic Model Using Loading–Unloading Curves, Mech. Compos. Mater., 2019, vol. 55, no. 2, pp. 195–210. https://doi.org/10.1007/s11029-019-09809-w

Khokhlov, A.V., Possibility to Describe the Alternating and Non-Monotonic Time Dependence of Poisson’s Ratio during Creep Using a Nonlinear Maxwell-Type Viscoelastoplasticity Model, Russ. Metallurgy (Metally), 2019, no. 10, pp. 956–963. https://doi.org/10.1134/S0036029519100136

Khokhlov, A.V., Shaporev, A.V., and Stolyarov, O.N., Loading–Unloading–Recovery Curves for Polyester Yarns and Identification of the Nonlinear Maxwell-Type Viscoelastoplastic Model, Mech. Compos. Mater., 2023, vol. 59, no. 1, pp. 129–146. https://doi.org/10.1007/s11029-023-10086-x

Rabotnov, Yu.N., Creep Problems in Structural Members, Amsterdam–London: North-Holland Pub. Co., 1969.

Bugakov, I.I., Creep of Polymer Materials, Moscow: Nauka, 1973.

Malinin, N.N., Creep Calculations for Elements of Mechanical Engineering Structures, Moscow: Mashinostroeniye, 1981.

Gokhfeld, D.A. and Sadakov, O.S., Plasticity and Creep of Structural Members under Repeated Loading, Moscow: Mashinostroeniye, 1984.

Nikitenko, A.F., Creep and Long-Term Strength of Metallic Materials, Novosibirsk: NGASU, 1997.

Betten, J., Creep Mechanics, Berlin: Springer-Verlag, 2008. https://doi.org/10.1007/b138749

Lokoshchenko, A.M., Creep and Long-Term Strength of Metals, Boca Raton, FL: CRC Press, Taylor & Francis Group, 2018.

Lakes, R.S., Viscoelastic Materials, Cambridge: Cambridge Univ. Press, 2009. https://doi.org/10.1017/CBO9780511626722

Bergstrom, J.S., Mechanics of Solid Polymers. Theory and Computational Modeling, William Andrew, Elsevier, 2015. https://doi.org/10.1016/c2013-0-15493-1

Vinogradov, G.V. and Malkin, A.Ya., Rheology of Polymers, Moscow: Khimiya, 1977.

Larson, R.G., Constitutive Equations for Polymer Melts and Solutions, Boston: Butterworth, 1988. https://doi.org/10.1016/c2013-0-04284-3

Gupta, R.K., Polymer and Composite Rheology, New York: Marcel Dekker, 2000.

Malkin, A.Y. and Isayev, A.I., Rheology: Conceptions, Methods, Applications, Toronto: Chem. Tec. Publ., 2012.

Brinson, H.F. and Brinson, L.C., Polymer Engineering Science and Viscoelasticity, Springer, 2008. https://doi.org/10.1007/978-0-387-73861-1

Kalinnikov, A.E. and Vakhrushev, A.V., Creep of Materials of Different Tensile and Compressive Strengths under Variable Loads, Mech. Comp. Mater., 1982, vol. 18, pp. 267–272.

Fatemi, A. and Yang, L., Cumulative Fatigue Damage and Life Prediction Theories: A Survey of The State of the Art for Homogeneous Materials, Int. J. Fatigue, 1998, vol. 20, no. 1, pp. 9–34.

Launay, A., Maitournam, M.H., Marco, Y., Raoult, I., and Szmytka, F., Cyclic Behaviour of Short Glass Fibre Reinforced Polyamide: Experimental Study and Constitutive Equations, Int. J. Plasticity, 2011, vol. 27, pp. 1267–1293. https://doi.org/10.1016/j.ijplas.2011.02.005

Darabi, M.K., Al-Rub, R.K.А., Masad, E.A., Huang, C.-W., and Little, D.N., A Modified Viscoplastic Model to Predict the Permanent Deformation of Asphaltic Materials under Cyclic-Compression Loading at High Temperatures, Int. J. Plasticity, 2012, vol. 35, pp. 100–134.

Takagi, H., Dao, M., and Fujiwara, M., Prediction of the Constitutive Equation for Uniaxial Creep of a Power-Law Material through Instrumented Microindentation Testing and Modeling, Mater. Trans., 2014, vol. 55, no. 2, pp. 275–284.

Chinh, N.Q. and Szommer, P., Mathematical Description of Indentation Creep and Its Application for the Determination of Strain Rate Sensitivity, Mater. Sci. Eng. A, 2014, vol. 611, pp. 333–336.

Petukhov, D.S. and Keller, I.E., Dual Plane Problems for Cree** Flow of Power-Law Incompressible Medium, Vestn. Samar. Gos. Tekhn. Univ., Ser. Fiz.-Mat. Nauki, 2016, vol. 20, no. 3, pp. 496–507.

Kaibyshev, O.A., Superplasticity of Commercial Alloys, Moscow: Metallurgiya, 1984.

Nieh, T.G., Wadsworth, J., and Sherby, O.D., Superplasticity in Metals and Ceramics, Cambridge: Cambridge Univ. Press, 1997. https://doi.org/10.1017/CBO9780511525230

Padmanabhan, K.A., Vasin, R.A., and Enikeev, F.U., Superplastic Flow: Phenomenology and Mechanics, Berlin: Springer-Verlag, 2001. https://doi.org/10.1007/978-3-662-04367-7

Segal, V.M., Beyerlein, I.J., Tome, C.N., Chuvil’deev, V.N., and Kopylov, V.I., Fundamentals and Engineering of Severe Plastic Deformation, New York: Nova Science Pub. Inc., 2010.

Zhilayev, A.P. and Pshenichnyuk, A.I., Superplasticity and Grain Boundaries in Ultrafine-Grained Materials, Cambridge: Cambridge Int. Sci. Publ., 2010.

Cao, Y., Determination of the Creep Exponent of a Power-Law Creep Solid Using Indentation Tests, Mech. Time-Depend. Mater., 2007, vol. 11, pp. 159–172.

Megahed, M., Ponter, A.R.S., and Morrison, C.J., An Experimental and Theoretical Investigation into the Creep Properties of a Simple Structure of 316 Stainless Steel, Int. J. Mech. Sci., 1984, vol. 26, no. 3, pp. 149–164.

Enikeev, F.U., Experimental Assessment of the Strain Rate Sensitivity of a Superplastic Material with a Highly Inhomogeneous Stress–Strain State, Zavodsk. Laborator. Diagnostika Mater., 2007, vol. 73, no. 10, pp. 44–50.

Mochugovskiy, A.G., Mosleh, A.O., Kotov, A.D., Khokhlov, A.V., Kaplanskaya, L.Y., and Mikhaylovskaya, A.V., Microstructure Evolution, Constitutive Modelling, and Superplastic Forming of Experimental 6XXX-Type Alloys Processed with Different Thermomechanical Treatments, Materials, 2023, vol. 16, no. 1-445, pp. 1–18. https://doi.org/10.3390/ma16010445

Eglit, M.E., Yakubenko, A.E., and Zaiko, Yu.S., Mathematical Modeling of Slope Flows of Non-Newtonian Media, Trudy Matem. Inst. Steklova, 2018, vol. 300, pp. 229–239.

Radchenko, V.P. and Shapievskii, D.V., Mathematical Model of Creep for a Microinhomogeneous Nonlinearly Elastic Material, J. Appl. Mech. Tech. Phys., 2008, vol. 49, no. 3, pp. 478–483. https://doi.org/10.1007/s10808-008-0064-9

Naumenko, K., Altenbach, H., and Gorash, Y., Creep Analysis with a Stress Range Dependent Constitutive Model, Arch. Appl. Mech., 2009, vol. 79, pp. 619–630. https://doi.org/10.1007/s00419-008-0287-5

Lu, L.Y., Lin, G.L., and Shih, M.H., An Experimental Study on a Generalized Maxwell Model for Nonlinear Viscoelastic Dampers Used in Seismic Isolation, Eng. Struct., 2012, vol. 34, no. 1, pp. 111–123.

Monsia, M.D., A Simplified Nonlinear Generalized Maxwell Model for Predicting the Time Dependent Behavior of Viscoelastic Materials, World J. Mech., 2011, no. 1, pp. 158–167. https://doi.org/10.4236/wjm.2011.13021

Stolin, A.M. and Khokhlov, A.V., Nonlinear Model of Shear Flow of Thixotropic Viscoelastoplastic Continua Taking into Account the Evolution of the Structure and Its Analysis, Moscow Univ. Mech. Bull., 2022, vol. 77, no. 5, pp. 127–135. https://doi.org/10.3103/S0027133022050065

Khokhlov, A.V. and Gulin, V.V., Analysis of the Properties of a Nonlinear Model for Shear Flow of Thixotropic Media Taking into Account the Mutual Influence of Structural Evolution and Deformation, Phys. Mesomech., 2023, vol. 26, no. 6, pp. 621–642. https://doi.org/10.1134/S1029959923060036

Gorodtsov, V.A. and Leonov, A.I., On the Kinematics, Nonequilibrium Thermodynamics, and Rheological Relationships in the Nonlinear Theory of Viscoelasticity, J. Appl. Math. Mech., 1968, vol. 32, no. 1, pp. 62–84. https://doi.org/10.1016/0021-8928(68)90148-2

Leonov, A.I., Lipkina, E.Ch., Paskhin, E.D., and Prokunin, A.N., Theoretical and Experimental Investigations of Shearing in Elastic Polymer Liquids, Rheol. Acta., 1976, vol. 15, no. 7/8, pp. 411–426. https://doi.org/10.1007/BF01574496

Palmov, V.A., Rheological Models in Nonlinear Solid Mechanics, Uspekhi Mekh., 1980, vol. 3, no. 3, pp. 75–115.

Prokunin, A.N., On the Non-Linear Maxwell-Type Defining Equations for Describing the Motions of Polymer Liquids, J. Appl. Math. Mech., 1984, vol. 48, no. 6, pp. 699–706. https://doi.org/10.1016/0021-8928(84)90037-6

Leonov, A.I. and Prokunin, A.N., Non-Linear Phenomena in Flows of Viscoelastic Polymer Fluids, London: Chapman and Hall, 1994. https://doi.org/10.1007/978-94-011-1258-1

Leonov, A.I., Constitutive Equations for Viscoelastic Liquids: Formulation, Analysis and Comparison with Data, Rheology Series, 1999, vol. 8, pp. 519–575. https://doi.org/10.1016/S0169-3107(99)80040-9

Khokhlov, A.V., Analysis of Creep Curves Produced by the Linear Viscoelasticity Theory under Cyclic Stepwise Loadings, Vestn. Samar. Gos. Tekhn. Univ., Ser. Fiz.-Mat. Nauki, 2017, vol. 21, no. 2, pp. 326–361. https://doi.org/10.14498/vsgtu1533

Khokhlov, A.V., Applicability Indicators and Identification Technique for a Nonlinear Maxwell-Type Elastoviscoplastic Model Using Repeated Creep Recovery Tests, Problem. Prochnost. Polzuchest., 2021, vol. 83, no. 4, pp. 443–450.

Moskvitin, V.V., Resistance of Viscoelastic Materials (As Applied to Solid Propellant Rocket Motor Charges), Moscow: Nauka, 1972.

Ainbinder, S.B., Tyunina, E.L., and Tsirule, K.I., Properties of Polymers in Various Stress States, Moscow: Khimiya, 1981.

Gol’dman, A.Ya., Bulk Deformation of Plastics, Leningrad: Mashinostroeniye, 1984.

Gol’dman, A.Ya., Prediction of the Deformation Properties of Polymeric and Composite Materials, Washington, DC: American Chemical Society, 1994.

Mileiko, S.T., Metal and Ceramic Based Composites, Amsterdam: Elsevier, 1997.

Moshev, V.V., Svistkov, A.L., Garishin, O.K., et al., Structural Mechanisms of Formation of Mechanical Properties of Granular Polymer Composites, Yekaterinburg: Izd-vo UrO RAN, 1997.

Bazhenov, S.L., Berlin, A.A., Kulkov, A.A., and Oshmyan, V.G., Polymer Composites: Strength and Technology, Moscow: Izd-vo Intellekt, 2009.

Brekhova, V.D., Investigation of the Poisson’s Ratio of Certain Crystalline Polymers under a Constant Compressive Load, Polymer Mech., 1965, vol. 1, pp. 23–24. https://doi.org/10.1007/BF00858886

Dzene, I.Y. and Putans, A.V., Poisson’s Ratio of Polyethylene in One-Dimensional Creep, Polymer Mech., 1967, vol. 3, pp. 626–627. https://doi.org/10.1007/BF00859258

Dzene, I.Y., Kregers, A.F., and Vilks, U.K., Characteristic Features of the Deformation Process on Creep and Secondary Creep of Polymers under Conditions of Monaxial Tensioning. Part I, Polymer Mech., 1974, vol. 10, pp. 337–342. https://doi.org/10.1007/BF00865585

Shcherbak, V.V. and Gol’dman, A.Ya., Volume Changes in Particle-Reinforced Composites in Creep Test Conditions, Mekh. Kompozit. Mater., 1982, no. 3, pp. 549–552.

Kalinnikov, A.E. and Vakhrushev, A.V., The Ratio of Transverse to Longitudinal Strain under Uniaxial Creep of Materials with Different Strengths, Mekh. Kompozit. Mater., 1985, no. 2, pp. 351–354.

Knauss, W.G. and Emri, I., Volume Change and the Nonlinearly Thermoviscoelastic Constitution of Polymers, Polym. Eng. Sci., 1987, vol. 27, pp. 86–100.

Tschoegl, N.W., Time Dependence in Material Properties: An Overview, Mech. Time-Depend. Mater., 1997, vol. 1, no. 1, pp. 3–31. https://doi.org/10.1023/A:1009748023394

Ozupek, S. and Becker, E.B., Constitutive Equations for Solid Propellants, J. Eng. Mater. Technol., 1997, vol. 119, no. 2, pp. 125–132. https://doi.org/10.1115/1.2805983

Hilton, Н.Н., Implications and Constraints of Time-Independent Poisson’s Ratios in Linear Isotropic and Anisotropic Viscoelasticity, J. Elast., 2001, vol. 63, pp. 221–251. https://doi.org/10.1023/A:1014457613863

Tschoegl, N.W., Knauss, W.G., and Emri, I., Poisson’s Ratio in Linear Viscoelasticity—A Critical Review, Mech. Time-Depend. Mater., 2002, vol. 6, no. 1, pp. 3–51. https://doi.org/10.1023/A:1014411503170

Arzoumanidis, G.A. and Liechti, K.M., Linear Viscoelastic Property Measurement and Its Significance for Some Nonlinear Viscoelasticity Models, Mech. Time-Depend. Mater., 2003, vol. 7, no. 3, pp. 209–250. https://doi.org/10.1023/B:MTDM.0000007357.18801.13

Lomakin, E.V., Mechanics of Media with Stress-State Dependent Properties, Phys. Mesomech., 2007, vol. 10, no. 5–6, pp. 255–265.

Savinykh, A.S., Garkushin, G.V., Razorenov, S.V., and Kanel, G.I., Longitudinal and Bulk Compressibility of Soda-Lime Glass at Pressures to 10 GPa, Tech. Phys., 2007, vol. 52, pp. 328–332. https://doi.org/10.1134/S1063784207030073

Pandini, S. and Pegoretti, A., Time, Temperature, and Strain Effects on Viscoelastic Poisson’s Ratio of Epoxy Resins, Polym. Eng. Sci., 2008, vol. 48, no. 7, pp. 1434–1441. https://doi.org/10.1002/pen.21060

Bykov, D.L. and Peleshko, V.A., Constitutive Relations for Strain and Failure of Filled Polymer Materials in Dominant Axial Tension Processes under Various Barothermal Conditions, Mech. Solids, 2008, vol. 43. no. 6, pp. 870–891. https://doi.org/10.3103/S0025654408060058

Shekhar, H. and Sahasrabudhe, A.D., Longitudinal Strain Dependent Variation of Poisson’s Ratio for HTPB Based Solid Rocket Propellants in Uni-Axial Tensile Testing, Propellants Explosives Pyrotech., 2011, vol. 36, no. 6, pp. 558–563. https://doi.org/10.1002/prep.200900079

Tscharnuter, D., Jerabek, M., Major, Z., and Lang, R.W., Time-Dependent Poisson’s Ratio of Polypropylene Compounds for Various Strain Histories, Mech. Time-Dependent Mater., 2011, vol. 15, no. 1, pp. 15–28. https://doi.org/10.1007/s11043-010-9121-x

Grassia, L., D’Amore, A., and Simon, S.L., On the Viscoelastic Poisson’s Ratio in Amorphous Polymers, J. Rheology, 2010, vol. 54, no. 5, pp. 1009–1022. https://doi.org/10.1122/1.3473811

Cui, H.R., Tang, G.J., and Shen, Z.B., Study on Viscoelastic Poisson’s Ratio of Solid Propellants Using Digital Image Correlation Method, Propellants Explosives Pyrotech., 2016, vol. 41, no. 5, pp. 835–843. https://doi.org/10.1002/prep.201500313

Lakes, R., Foam Structure with a Negative Poisson’s Ratio, Science, 1987, vol. 235, pp. 1038–1040. https://doi.org/10.1126/science.235.4792.1038

Friis, E.A., Lakes, R.S., and Park, J.B., Negative Poisson’s Ratio Polymeric and Metallic Materials, J. Mater. Sci., 1988, vol. 23, pp. 4406–4414. https://doi.org/10.1007/BF00551939

Berlin, A.A., Rothenburg, L., and Bathurst, R.J, Peculiarities of Deformation of Disordered Polymeric and Nonpolymeric Bodies, Polymer Sci., 1992, vol. 34, no. 7, pp. 559–573.

Milton, G.W., Composite Materials with Poisson’s Ratios Close to –1, J. Mech. Phys. Solids, 1992, vol. 40, pp. 1105–1137. https://doi.org/10.1016/0022-5096(92)90063-8

Lakes, R.S. and Elms, K., Indentability of Conventional and Negative Poisson’s Ratio Foams, J. Compos. Mater., 1993, vol. 27, pp. 1193–1202. https://doi.org/10.1177/002199839302701203

Caddock, B.D. and Evans, K.E., Negative Poisson Ratios and Strain-Dependent Mechanical Properties in Arterial Prostheses, Biomaterials, 1995, vol. 16, pp. 1109–1115.

Chan, N. and Evans, K.E., Indentation Resilience of Conventional and Auxetic Foams, J. Cell. Plastics, 1998, vol. 34, pp. 231–260. https://doi.org/10.1177/0021955X9803400304

Alderson, K.L., Fitzgerald, A., and Evans, K.E., The Strain Dependent Indentation Resilience of Auxetic Microporous Polyethylene, J. Mater. Sci., 2000, vol. 35, pp. 4039–4047. https://doi.org/10.1023/A:1004830103411

Konyok, D.A., Wojciechowski, K.W., Pleskachevsky, Y.M., and Shilko, S.V., Materials with Negative Poisson’s Ratio (Review), Mekh. Kompozits. Mater. Konstrukts., 2004, vol. 10, no. 1, pp. 35–69.

Greer, A.L., Lakes, R.S., Rouxel, T., and Greaves, G.N., Poisson’s Ratio and Modern Materials, Nat. Mater., 2011, vol. 10, no. 11, pp. 823–837. https://doi.org/10.1038/NMAT3177

Khokhlov, A.V., Applicability Indicators of the Linear Viscoelasticity Theory Using Creep Curves under Tensile Load Combined with Constant Hydrostatic Pressure, Mekh. Kompozits. Mater. Konstrukts., 2019, vol. 25, no. 2, pp. 259–280. https://doi.org/10.33113/mkmk.ras.2019.25.02.259_280.09

Khokhlov, A.V., Analysis of the Bulk Creep Influence on Stress–Strain Curves under Tensile Loadings at Constant Rates and on Poisson’s Ratio Evolution Based on the Linear Viscoelasticity Theory, Vestn. Samar. Gos. Tekhn. Univ., Ser. Fiz.-Mat. Nauki, 2019, vol. 23, no. 4, pp. 671–704. https://doi.org/10.14498/vsgtu1710

Khokhlov, A.V., Simulation of Hydrostatic Pressure Influence on Creep Curves and Poisson’s Ratio of Rheonomic Materials under Tension Using the Rabotnov Non-Linear Hereditary Relation, Mekh. Kompozits. Mater. Konstrukts., 2018, vol. 24, no. 3, pp. 407–436. https://doi.org/10.33113/mkmk.ras.2018.24.03.407_436.07

Khokhlov, А.V., On the Capability of Linear Viscoelasticity Theory to Describe the Effect of Extending Region of Material Linearity as the Hydrostatic Pressure Grows, Moscow Univ. Mech. Bull., 2021, vol. 76, no. 1, pp. 7–14. https://doi.org/10.3103/S0027133021010040

Khokhlov, A.V., Fading Memory Effect and Asymptotic Commutativity under Multi-Step Loadings in the Linear Viscoelasticity Theory, Komposit. Nanostruktur., 2022, vol. 14, no. 4, pp. 208–232. https://doi.org/10.36236/1999-7590-2022-14-4-208-232

Funding

The work was supported by the Ministry of Science and Higher Education of the Russian Federation under the program of the Moscow Center of Fundamental and Applied Mathematics under Agreement No. 075-15-2022-284.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author of this work declares that he has no conflicts of interest.

Additional information

Publisher's Note. Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khokhlov, A.V. Hybridization of a Linear Viscoelastic Constitutive Equation and a Nonlinear Maxwell-Type Viscoelastoplastic Model, and Analysis of Poisson’s Ratio Evolution Scenarios under Creep. Phys Mesomech 27, 229–255 (2024). https://doi.org/10.1134/S1029959924030020

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959924030020