Abstract

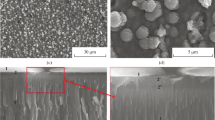

TiN coatings are deposited onto AISI430 stainless-steel substrates in an Ar + N2 atmosphere, under a constant total pressure of 0.5 Pa, at a variable nitrogen-flow rate of f(N2) = 0.5–10 cm3/min and magnetron-sputtering currents of I m = 10, 30, and 100 A. The dependences of the coating microhardness, macrostress, and growth rate on f(N2) and I m are obtained. Two microharndess maxima at f(N2) = 1 and 4 cm3/min and I m = 30 A are found. The maximum microhardness of the coatings reaches 32 ± 5 GPa at a maximum macrostress of 7 GPa.

Similar content being viewed by others

References

H. Pierson, Handbook of Refractory Carbides and Nitrides (Noyes Publ., Park Ridge, NJ, 1996).

J. T. Gudmundsson, Vacuum 84, 1360 (2010).

A. S. Mamaev and A. S. Kaigorodov, J. Surf. Invest.: X-ray, Synchrotr. Neutron Techn. 8, 1119 (2014). doi: 10.7868/S0207352814110109.

I. Petrov, P. B. Barna, L. Hultman, and J. E. Greene, J. Vac. Sci. Technol. A 21 (5), 117 (2003).

A. P. Ehiasarian, A. Vetushka, Y. A. Gonzalvo, G. Saf-ran, L. Szekely, et al., J. Appl. Phys. 109, 104314 (2011).

F. Vaz, J. Ferreira, E. Ribeiro, et al., Surf. Coat. Tech-nol. 191, 317 (2005).

J. Musil, S. Kadlec, and J. Vyskocil, Thin Solid Films 167, 107 (1988).

N. V. Gavrilov and A. I. Men’shakov, Instrum. Exp. Tech. 54, 732 (2011).

W. Oliver and G. Pharr, J. Mater. Res. 7, 1564 (1992).

A. Anders, Surf. Coat. Technol. 205, S1 (2011).

U. Helmersson, M. Lattemann, J. Bohlmark, A. P. Ehi-asarian, and J. Gudmundsson, Thin Solid Films 513, 1 (2006).

A. Cavaleiro, Nanostructured Coatings, Nanostructure Science and Technology (Springer, Berlin, Heidelberg, 2006; Moscow, Tekhnosfera, 2011).

A. P. Ehiasarian, Y. A. Gonzalvo, and T. D. Whitmore, Plasma Process. Polym. 4, S309 (2007).

M.-J. Chou, G. J.-P. Yu, and J.-H. Huang, Surf. Coat. Technol. 149, 7 (2002).

C. T. Chen, Y. C. Song, G.-P. Yu, and J.-H. Huang, J. Mater. Eng. Perf. 7, 324 (1998).

P. Martin, A. Bendavid, and T. Kinder, IEEE Trans. Plasma Sci. 25, 675 (1997).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.S. Mamaev, A.V. Chukin, 2015, published in Poverkhnost’. Rentgenovskie, Sinkhrotronnye i Neitronnye Issledovaniya, 2015, No. 10, pp. 12–15.

Rights and permissions

About this article

Cite this article

Mamaev, A.S., Chukin, A.V. Effect of the nitrogen flow rate on the microhardness and microstructure of TiN coatings deposited by high power pulsed magnetron sputtering. J. Surf. Investig. 9, 980–983 (2015). https://doi.org/10.1134/S1027451015050365

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451015050365