Abstract

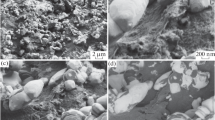

Highly disperse and reactive (HfB2–SiC)@(Ta2O5–HfO2–C) composite powders were manufactured by sol–gel technology where Ta2O5–HfO2–C amorphous components were nanostructured and distributed in each other as uniformly as possible. The reactive sintering of the prepared composite powders at a relatively low temperature (1800°С) with an exposure time of 30 min and the pressure 30 MPa yielded (HfB2–30 vol % SiC)–xTa4HfC5 ultra-high temperature ceramics (UHTCs), where x = 5, 10, and 15 vol %, with a relative density of 75–78%. X-ray powder diffraction proved the complete conversion of tantalum and hafnium oxides to complex carbide Ta4HfC5. The average grain size as determined by scanning electron microscopy did not exceed 2–3 µm in HfB2 and 30–60 nm for the Ta4HfC5 phase. Thermal analysis in flowing air showed that, in the temperature range 20–1400°С, the increasing percentage of tantalum–hafnium carbide (the least oxidation resistant phase) leads to a systematic increase in oxidation-induced weight gain; however, a tendency to saturation is observed. The microstructural specifics of the oxidized surface are noticed depending on the composition of HfB2–SiC–Ta4HfC5 ceramics.

Similar content being viewed by others

REFERENCES

E. P. Simonenko, D. V. Sevast’yanov, N. P. Simonenko, et al., Russ. J. Inorg. Chem. 58, 1669 (2013). https://doi.org/10.1134/S0036023613140039

C. Piriou, O. Rapaud, S. Foucaud, et al., Ceram. Int. 45, 1846 (2019). https://doi.org/10.1016/j.ceramint.2018.10.075

J. Binner, M. Porter, B. Baker, et al., Int. Mater. Rev. (2019). https://doi.org/10.1080/09506608.2019.1652006

A. Radhi, V. Iacobellis, and K. Behdinan, Compos. B: Eng. 175, 107129 (2019). https://doi.org/10.1016/j.compositesb.2019.107129

E. P. Simonenko, N. P. Simonenko, A. N. Gordeev, et al., J. Sol–Gel Sci. Technol. 92, 386 (2019).https://doi.org/10.1134/S0036023618110177

E. P. Simonenko, N. P. Simonenko, A. N. Gordeev, et al., Russ. J. Inorg. Chem. 64, 1681 (2019). https://doi.org/10.1134/S0036023619130084

E. P. Simonenko, N. P. Simonenko, A. S. Mokrushin, et al., Russ. J. Inorg. Chem. 64, 1849 (2019). https://doi.org/10.1134/S0036023619140109

E. P. Simonenko, N. P. Simonenko, A. N. Gordeev, et al., Russ. J. Inorg. Chem. 63, 1484 (2018). https://doi.org/10.1134/S0036023618110177

E. P. Simonenko, N. P. Simonenko, A. N. Gordeev, et al., Russ. J. Inorg. Chem. 63, 1345 (2018). https://doi.org/10.1134/S0036023618100170

H. Zhang, D. D. Jayaseelan, I. Bogomol, et al., J. Alloys Compd. 785, 958 (2019). https://doi.org/10.1016/j.jallcom.2019.01.208

N. Liao, D. Jia, Z. Yang, et al., J. Phys. Chem. Solids 136, 109153 (2020). https://doi.org/10.1016/j.jpcs.2019.109153

S. Ghadami, E. Taheri-Nassaj, and H. R. Baharvandi, J. Alloys Compd. 809, 151705 (2019). https://doi.org/10.1016/j.jallcom.2019.151705

A. Purwar, S. Ariharan, B. Basu, et al., Int. J. Refract. Met. Hard Mater. 84, 104972 (2019). https://doi.org/10.1016/j.ijrmhm.2019.104972

L. Silvestroni, S. Mungiguerra, D. Sciti, et al., Corros. Sci., Art. 108125 (2019). https://doi.org/10.1016/j.corsci.2019.108125

C. Li, Y. Niu, X. Zhong, et al., J. Eur. Ceram. Soc. 39, 4565 (2019). https://doi.org/10.1016/j.jeurceramsoc.2019.07.01

K. S. Cissel and E. Opila, J. Am. Ceram. Soc. 101, 1765 (2018). https://doi.org/10.1111/jace.15298

D. Bannykh, A. Utkin, and N. Baklanova, Int. J. Refract. Met. Hard Mater. 84, 105023 (2019). https://doi.org/10.1016/j.ijrmhm.2019.105023

E. P. Simonenko, N. P. Simonenko, V. G. Sevastyanov, and N. T. Kuznetsov, Russ. J. Inorg. Chem. 63, 1772 (2018). https://doi.org/10.1134/S003602361814005X

S. Zhou, Z. Wang, X. Sun, and J. Han, Mater. Chem. Phys. 122, 470 (2010). https://doi.org/10.1016/j.matchemphys.2010.03.028

X. Sun, X. Zhang, Z. Wang, et al., Key Eng. Mater. 434—435, 185 (2010). www.scientific.net/KEM.434-435.185

W.-M. Guo, Y. You, G.-J. Zhang, et al., J. Eur. Ceram. Soc. 35, 1985 (2015). https://doi.org/10.1016/j.jeurceramsoc.2014.12.026

X. Zhang, Z. Wang, X. Sun, et al., Mater. Lett. 62, 4360 (2008). https://doi.org/10.1016/j.matlet.2008.07.027

H. **, S. Meng, Q. Yang, and Y. Zhu, Ceram. Int. 39, 5591 (2013). https://doi.org/10.1016/j.ceramint.2012.12.074

X. H. Zhang, Z. Wang, P. Hu, et al., Scr. Mater. 61, 809 (2009). https://doi.org/10.1016/j.scriptamat.2009.07.001

AslM. Shahedi, M. J. Zamharir, Z. Ahmadi, and S. Parvizi, Mater. Sci. Eng. A: Struct. 716, 99 (2018). https://doi.org/10.1016/j.msea.2018.01.038

F. Yang, X. Zhang, J. Han, and S. Du, Mater. Lett. 62, 2925 (2008). https://doi.org/10.1016/j.matlet.2008.01.076

F. Yang, X. Zhang, J. Han, and S. Diu, J. Compos. Mater. 44, 953 (2010). https://doi.org/10.1177/0021998309346545

F. Yang, X. Zhang, J. Han, and S. Du, J. Alloys Compd. 472, 395 (2009). https://doi.org/10.1016/j.jallcom.2008.04.092

J. Lin, Y. Huang, H. Zhang, et al., Ceram. Int. B 41, 15261 (2015). https://doi.org/10.1016/j.ceramint.2015.07.207

A. Nisar, S. Ariharan, and K. Balani, Ceram. Int. 43, 13483 (2017). https://doi.org/10.1016/j.ceramint.2017.07.053

A. Nisar and K. Balani, Coatings 7 (8), 110 (2017). https://doi.org/10.3390/coatings7080110

A. M. Shahedi and K. M. Ghassemi, Mater. Sci. Eng. A: Struct. 625, 385 (2015). https://doi.org/10.1016/j.msea.2014.12.028

X. Zhang, Y. An, J. Han, et al., RSC Adv. 5, 47060 (2015). https://doi.org/10.1039/C5RA05922D

Y. An, X. Xu, and K. Gui, Ceram. Int. 42, 14066 (2016). https://doi.org/10.1016/j.ceramint.2016.06.014

B. Zhang, X. Zhang, C. Hong, et al., ACS Appl. Mater. Interfaces 8, 11675 (2016). https://doi.org/10.1021/acsami.6b00822

S. K. Thimmappa, B. R. Golla, P. V. Bhanu, et al., Ceram. Int. A 45, 9061 (2019). https://doi.org/10.1016/j.ceramint.2019.01.243

M. Mallik, K. K. Ray, and R. Mitra, Coatings 7, 92 (2017). https://doi.org/10.3390/coatings7070092

P. Wang, H. Li, J. Kong, et al., Corros. Sci. 159, (2019). https://doi.org/10.1016/j.corsci.2019.108119

Z. Balak, AslM. Shahedi, M. Azizieh, et al., Ceram. Int. 43, 2209 (2017). https://doi.org/10.1016/j.ceramint.2016.11.005

Carmen Carney, Anish Paul, Saranya Venugopal, et al., J. Eur. Ceram. Soc. 34, 1045 (2014). https://doi.org/10.1016/j.jeurceramsoc.2013.11.018

M. Mashhadi, M. Shambuli, and S. Safi, J. Mater. Res. Technol. 5, 200 (2016). https://doi.org/10.1016/j.jmrt.2015.10.003

E. P. Simonenko, N. P. Simonenko, V. G. Sevastyanov, and N. T. Kuznetsov, Russ. J. Inorg. Chem. 64, 1697 (2019). https://doi.org/10.1134/S0036023619140079

F. Adibpur, S. A. Tayebifard, M. Zakeri, and AslM. Shahedi, Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2019.08.243

R. Inoue, Y. Arai, Y. Kubota, et al., J. Alloys Compd. 731, 310 (2018). https://doi.org/10.1016/j.jallcom.2017.10.034

X. Wang, W. Ji, J. Hu, et al., Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2019.09.001

H.-L. Liu, J.-X. Liu, H.-T. Liu, and G.-J. Zhang, Scr. Mater. 107, 140 (2015). https://doi.org/10.1016/j.scriptamat.2015.06.005

X. Zhang, Q. Qu, J. Han, et al., Scr. Mater. 59, 753 (2008). https://doi.org/10.1016/j.scriptamat.2008.06.004

W.-W. Wu, G.-J. Zhang, Y.-M. Kan, and P.-L. Wang, J. Am. Ceram. Soc. 91, 2501 (2008). https://doi.org/10.1111/j.1551-2916.2008.02507.x

M. **ang, J. Gu, W. Ji, et al., Ceram. Int. 44, 8417 (2018). https://doi.org/10.1016/j.ceramint.2018.02.035

L. Silvestroni, H.-J. Kleebe, W. G. Fahrenholtz, and J. Watts, Sci. Rep. 7, 40730 (2017). https://doi.org/10.1038/srep40730

J. Zou, G.-J. Zhang, C.-F. Hu, et al., J. Am. Ceram. Soc. 95, 874 (2012). https://doi.org/10.1111/j.1551-2916.2011.05062.x

D.-W. Ni, J.-X. Liu, and G.-J. Zhang, J. Eur. Ceram. Soc. 32, 3627 (2012). https://doi.org/10.1016/j.jeurceramsoc.2012.05.001

J. Zou, G.-J. Zhang, Y.-M. Kan, and P.-L. Wang, Scr. Mater. 59, 309 (2008). https://doi.org/10.1016/j.scriptamat.2008.03.029

J. Zou, G.-J. Zhang, Y.-M. Kan, and P.-L. Wang, J. Am. Ceram. Soc. 92, 2838 (2009). https://doi.org/10.1111/j.1551-2916.2009.03293.x

Y. Wang, B. Ma, L. Li, and L. An, J. Am. Ceram. Soc. 95, 374 (2012). https://doi.org/10.1111/j.1551-2916.2011.04945.x

C. Peng, X. Gao, M. Wang, et al., Appl. Phys. Lett. 114, 011905 (2019). https://doi.org/10.1063/1.5054954

O. Cedillos-Barraza, S. Grasso, N. Al Nasiri, et al., J. Eur. Ceram. Soc. 36, 1539 (2016). https://doi.org/10.1016/j.jeurceramsoc.2016.02.009

L. Feng, J.-M. Kim, S.-H. Lee, and S.-J. Park, J. Am. Ceram. Soc. 99, 1129 (2016). https://doi.org/10.1111/jace.14144

C. Zhang, A. Gupta, S. Seal, et al., J. Am. Ceram. Soc. 100, 1853 (2017). https://doi.org/10.1111/jace.14778

V. V. Kurbatkina, E. I. Patsera, E. A. Levashov, and A. N. Timofeev, Ceram. Int. 44, 4320 (2018). https://doi.org/10.1016/j.ceramint.2017.12.024

C. Agte and H. Alterthum, Z. Techn. Phys., No. 6, 182 (1930).

R. A. Andrievskii, N. S. Strel’nikova, N. I. Poltoratskii, et al., Sov. Powder Metall. 6, 65 (1967). https://doi.org/10.1007/BF00773385

A. I. Savvatimskiy, S. V. Onufriev, and S. A. Muboyadzhyan, J. Eur. Ceram. Soc. 39, 907 (2019). https://doi.org/10.1016/j.jeurceramsoc.2018.11.030

C. Zhang, A. Loganathan, B. Boesl, and A. Agarwal, Coatings 7, Article 111 (2017). https://doi.org/10.3390/coatings7080111

C. Zhang, B. Boesl, and A. Agarwal, Ceram. Int. 3, 14798 (2017). https://doi.org/10.1016/j.ceramint.2017.07.227

E. P. Simonenko, N. P. Simonenko, V. G. Sevastyanov, and N. T. Kuznetsov, Russ. J. Inorg. Chem. 61, 1483 (2016). https://doi.org/10.1134/S0036023616120172

E. P. Simonenko, N. P. Simonenko, E. K. Papynov, et al., Russ. J. Inorg. Chem. 63, 1 (2018). https://doi.org/10.1134/S0036023618010187

E. P. Simonenko, N. P. Simonenko, D. V. Sevastyanov, et al., Russ. J. Inorg. Chem. 61, 1649 (2016). https://doi.org/10.1134/S0036023616130039

V. G. Sevast’yanov, E. P. Simonenko, N. A. Ignatov, et al., Inorg. Mater. 46, 495 (2010). https://doi.org/10.1134/S0020168510050109

V. G. Sevastyanov, E. P. Simonenko, N. A. Ignatov, et al., Russ. J. Inorg. Chem. 56, 661 (2011). https://doi.org/10.1134/S0036023611050214

E. P. Simonenko, N. A. Ignatov, N. P. Simonenko, et al., Russ. J. Inorg. Chem. 56, 1681 (2011). https://doi.org/10.1134/S0036023611110258

E. P. Simonenko, N. P. Simonenko, Yu. S. Ezhov, et al., Phys. Atom. Nucl. 78, 1357 (2015). https://doi.org/10.1134/S106377881512011X

E. P. Simonenko, N. P. Simonenko, M. I. Petrichko, et al., Russ. J. Inorg. Chem. 63, 1317 (2019). https://doi.org/10.1134/S0036023619110196

F. M. Spiridonov, M. N. Mulenkova, V. I. Tsyrel’nikov, and L. N. Komissarova, Zh. Neorg. Khim. 26, 922 (1981).

H. Holleck, J. Nucl. Mater. 21, 14 (1967). https://doi.org/10.1016/0022-3115(67)90724-6

R. W. G. Wyckoff, Cryst. Struct. 1, 85 (1963).

W. Wong-Ng and C. Hubbard, Powder Diffr. 2, 242 (1987). https://doi.org/10.1017/S0885715600012884

T. Kawamura, Mineral. J. 4, 333 (1965). https://doi.org/10.2465/minerj1953.4.333

H. U. Hummel, R. Fackler, and P. Remmert, Chem. Ber. 125, 551 (1992). https://doi.org/10.1002/cber.19921250304

H. Jehn and E. Olzi, J. Less-Common Met. 27, 297 (1972). https://doi.org/10.1016/0022-5088(72)90062-8

Funding

The study was supported by the Russian Scientific Foundation (project no. 17-73-20181).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Fedorova

Rights and permissions

About this article

Cite this article

Simonenko, E.P., Simonenko, N.P., Lysenkov, A.S. et al. Reactive Hot Pressing of HfB2–SiC–Ta4HfC5 Ultra-High Temperature Ceramics. Russ. J. Inorg. Chem. 65, 446–457 (2020). https://doi.org/10.1134/S0036023620030146

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036023620030146