Abstract

Bacillus cereus (B. cereus) is observed to have varying effects on the stress corrosion cracking (SCC) sensitivity of different microstructures in the simulated heat-affected zone (HAZ) of X80 steel. At open circuit potential (OCP), the SCC sensitivity of different microstructures increased from 3.40–7.49% in an abiotic medium to 10.22–15.17% in a biotic medium. At −0.9 V (SCE), it increased from 22.81–26.51% to 35.76–39.60%. The increment in SCC sensitivity upon exposure to B. cereus was highest in the coarse-grained HAZ (7.68 and 16.79% at OCP and −0.9 V, respectively), followed by the intercritical and fine-grained HAZs. Owing to differences in the phase composition, grain boundary type, dislocation density, and surface volta potential, the initial adhesion number and position of B. cereus in the microstructure of the HAZ were differed, resulting in different sensitivities to SCC.

Similar content being viewed by others

Introduction

The X80 pipeline steel is widely accepted as one of the most economical seamless and welded pipeline steels owing to its high resistance, strength, and weldability. Although corrosion accidents are minimized in pipes, which are manufactured and operated in compliance with regulations, they are not completely eliminated owing to the special microstructure of welded joints1,2,3. The change in the local microstructure during the welding thermal cycle is attributed to the corrosion behavior of the corresponding weld region4,5,6. The heat-affected zone (HAZ) deserves special attention for its role in corrosion resistance as the physical, mechanical, and chemical properties of the alloy therein differ from those observed in the parent metal area. In conventional steels, the HAZ can be broken down into three crucial components: the intercritical HAZ (ICHAZ), fine-grained HAZ (FGHAZ), and coarse-grained HAZ (CGHAZ), with each component exhibiting a distinct microstructure.

Over the past several decades, a significant number of studies on the corrosion of welded joints have focused on galvanic, stress, and fatigue corrosions in ocean atmosphere, soil solution, and other environments7,8,9. Recently, microbiologically influenced corrosion (MIC) of welded joints has attracted the attention of researchers10,11,12. Arun et al.13 investigated the microstructural changes in stainless steel, including the formation of secondary and intergranular austenite in weld seams that reduced the levels of alloying elements and resulted in MIC. Antony et al.14 reported sulfate-reducing bacteria (SRB) attack to occur preferentially in the ferrite phase of a 2205 duplex stainless steel weldment, while being restricted to the austenite phase of the parent metal. Liduino et al.15 conducted a comparative study on the welding area of X65 steel and observed the welding region to be more prone to biofilm development, which is primarily related to the surface roughness. Evidently, the microstructure of stainless or carbon steel substantially affects the corrosion sensitivity and its underlying mechanisms.

Most equipments are subjected to stress during service. Subsequently, the relationship between microorganisms and stress corrosion is being studied16,17,18. SRB enhances the brittle fracture characteristics of carbon steel by facilitating hydrogen recombination and the diffusion of atomic hydrogen into the metal19. SRB has different control mechanisms for stress corrosion cracking (SCC) of 980 steel at different culture times by hydrogen permeation, which is also closely related to that under a cathodic potential20. Under a cathodic potential, SRB-assisted pitting and promotion of hydrogen permeation into steel facilitate crack initiation and propagation, responsible for the increase in SCC susceptibility14a2–c2) reflects the density of the geometrically necessary dislocations, and the corresponding results suggest that the ICHAZ stress is evenly distributed, whereas the FGHAZ and IGHAZ stresses are obvious and concentrated. The subsequent 30 min immersion test topography (Fig. 14a3–c3) shows that B. cereus in different quantities can be detected on the surface of the sample, with some attached independently and some in clusters.

To further elucidate the bacterial distribution behaviors under stress, the cells were manually marked in situ in the KAM phase map**, and the corresponding results are shown in Fig. 15. The locally magnified maps clearly demonstrate the distribution of B. cereus in the low-stress, high-stress, or adjacent areas on different HAZ. Thus, we statistically analyzed the cell numbers and clusters in the whole marked region and normalized the B. cereus distribution. The corresponding results are listed in Table 1.

It is observed that 2.98% of the cells are distributed in the high stress region, 16–29% in the low stress region, and the remaining (i.e., more than half) occupy the adjacent transition region. These results show that the bacteria were preferentially distributed in the high/low-stress adjacent transition region. It is well known that the geometrically necessary dislocations in the high-stress regions are higher than those in the low-stress regions, increasing electrochemical activity. Thus, the initial adhesion selection of bacteria may be related to this property39.

Based on the above analysis, the following conclusions can be drawn: (1) Compared with ICHAZ and FGHAZ, B. cereus had the most evident corrosion in CGHAZ. The CGHAZ surface allowed the adhesion of more bacteria in the early stages, which was ascribed to its higher surface thermodynamics. There were several dislocation-plugging and large-angle grain boundaries inside the microstructure, which provided active dissolution sites. (2) B. cereus increased the SCC sensitivity of different microstructures in the HAZ. The SCC of different microstructures in abiotic/biotic medium increased from 3.40–7.49% to 10.22–15.17% at OCP and from 22.81–26.51% to 35.76–39.60% at −0.9 V. Compared with ICHAZ and FGHAZ, B. cereus exhibited the greatest SCC sensitivity to CGHAZ. At −0.9 V, both ICHAZ and FGHAZ exhibited ductile fracture characteristics, while CGHAZ exhibited brittle fracture characteristics. (3) Different KAM values affected the initial bacterial adhesion. Compared to the high- and low-stress regions, 61–80% of B. cereus preferentially adhered to the high-/low-stress adjacent region.

Methods

Material and HAZ microstructures

The material investigated in this study, X80 pipeline steel, was provided by Baoshan Iron & Steel Co. Ltd. The chemical composition of this pipeline steel was (wt%): 0.07 C, 0.24 Si, 2.16 Mn, 0.31 Cr, 0.35 Mo, 0.41 Ni, 0.25 Cu, 0.15 Nb, and Fe balance. The obtained microstructure was a typical granular bainite structure with a yield strength of 754 MPa. Typical HAZ microstructures were produced using a thermodynamic simulation tester (DIS; Gleeble 3500). The sample size was 80 × 10 × 10 mm, and the energy of the test line was set to 17 kJ cm−1. The preset and actual heating and cooling rates are shown in Fig. 16. After air cooling to room temperature, weld HAZ with different microstructures were formed.

By observing the microstructure, the characteristics of CGHAZ, FGHAZ, and ICHAZ were distinguished. Subsequently, the three microstructures were replicated via heat treatment. Andrews predicted the initial and complete austenitizing temperatures (Ac1 and Ac3, respectively) for determining the appropriate peak temperatures of ICHAZ and FGHAZ microstructures, respectively, and their corresponding empirical formulae were expressed as:

where ω denotes the mass fraction of each element. Several pieces of X80 steel were cut to dimensions of 20 mm × 10 mm × 3 mm for the heat treatment. Combined with the T-C curve, for ICHAZ, FGHAZ, and CGHAZ, appropriate temperatures were selected at AC1-AC3, AC3-1100 °C, and 1100–1320 °C, respectively. The cut X80 steel pieces were kept in a muffle furnace (HF-Ke**g, KSL-1400X) at the corresponding temperature for 10 min and then cooled to room temperature. The pieces were then finely polished and etched with a 4% nital solution The subsequent microstructure was observed using a scanning electron microscope (SEM, XL30-FEG) until it was the same as that of the HAZ simulated by Gleeble. The peak temperatures of ICHAZ, FGHAZ, and CGHAZ in this study were observed to be 750, 900, and 1300 °C, respectively.

All the specimens were progressively abraded with 150–2000 grit SiC papers, cleaned with deionized water and anhydrous ethanol, and finally dried in a cold air stream. All the samples were sterilized with glutaraldehyde and then exposed to UV light for at least 30 min prior to the test to ensure that they were not contaminated.

Bacteria and culture medium

B. cereus, a typical NRB, was isolated from the surrounding soil of an X80 pipeline steel specimen (100 mm × 75 mm × 5 mm) that had been buried for two years in Bei**g soil (NL 39°79, EL 116°35, average temperature 12.9°C, moisture 14.38, salinity 0.198%, pH 6.96). Evolutionary trees and their nitrate reducibility were analyzed as described in our previous study40. The composition of the near-neutral pH solution was (g·L−1): 0.5 yeast extract, 1 tryptone, 1 NaCl, 1 NaNO3, 0.483 NaHCO3, 0.122 KCl, 0.137 CaCl2, and 0.131 MgSO4⋅7H2O. Before the experiment, the medium was sterilized at 121 °C for 20 min, and cooled under a continuous stream of 5% CO2 balanced with N2 for 2 h to achieve an anaerobic and near-neutral pH condition.

For the biotic medium, bacterial seeds were cultured in the above solution at 30 °C for 24 h at a ratio of 1:100 (v/v). For the abiotic medium, the culture medium was not inoculated with any bacteria, ensuring that the whole experimental process was uncontaminated. All the experiments were sealed and performed at 30 °C without oxygen, unless otherwise specified.

Electrochemical test

HAZ specimens with dimensions of 10 mm × 10 mm × 2 mm were connected to a copper wire and sealed with epoxy resin, leaving 1 cm2 as the working electrode (WE). A platinum sheet and saturated calomel electrode (SCE) were used as the counter and reference electrodes, respectively.

The electrochemical tests were performed through a workstation (Gamry, Reference 600+) using a typical three-electrode system. After inoculation, electrochemical impedance spectroscopy (EIS) was performed for 1, 3, 7, and 14 d at a sinusoidal voltage signal of 10 mV in the frequency range of 10−2–104 Hz. Fast and slow sweep potential polarization curves were determined for the specimens after they were immersed in the inoculation medium for 3 d. The scanning range of the polarization curves was from −1.3 to 0 V (vs. Ref), while the scanning rates for the fast and slow potential curves were 0.5 and 50 mV s−1, respectively. The EIS data and polarization curves were analyzed using the Zsimpwin software (Scribner) and Echem Analyst (Gamry), respectively.

Morphology analysis

After completing the 14-day EIS, the samples were carefully removed and immersed in a 2.5% glutaraldehyde solution for 8 h at 4 °C in a refrigerator. The specimens were then dehydrated with ethanol (50%, 60%, 70%, 80%, 90%, and 100% (v/v) consecutively) for 8 min, followed by drying naturally. The morphology was observed via SEM with a beam voltage of 25 kV. The corrosion product elements and their structures were analyzed via energy-dispersive X-ray spectroscopy (EDX). After observation, the samples were cleaned in acetone followed by immersion in a derusting solution (3.5 g hexamethylenetetramine was added to 500 mL hydrochloric acid and 500 mL deionized water) to remove any corrosion products. Next, the morphology of the corrosion pits was observed via confocal laser scanning microscopy (CLSM, Keyence VK-X250).

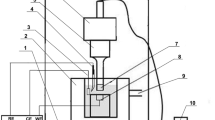

Slow strain rate tensile

Tensile specimens and experimental devices were used in the experiment, as shown in Fig. 17 a and b, respectively. After polishing and UV irradiation, the tensile specimen were sealed with silica gel, installed in a sealed box containing CE and RE, and subjected to UV irradiation for at least 30 min. The solution inoculated with B. cereus was injected into the device and kept at OCP or −0.9 V for 3 d. The solution cell with the tensile samples was then fixed on a tensile testing machine (Letry, WDML-30 kN). A pre-force of 1000 N was added to eliminate the crevice inside the machine and fixture gap. The strain rate was set to 1 × 10−6 s−1, the same order of magnitude as that of a typical SCC crack propagation rate.

Previous studies27 have shown the B. cereus system to have the maximum effect on the SCC sensitivity of X80 steel at −0.9 V. attributed to the potential having an effect on both the hydrogen embrittlement and physiological activities of B. cereus. Therefore, the same test parameters were used to investigate the effects of B. cereus on HAZ.

After the SSRT test, the decrease in the reduction in area (Iψ) was calculated using the following equation to evaluate the fracture susceptibility of X80 steel.

where ψs and ψ0 are the percentage reductions in area in the test environment and air, respectively. The fracture specimens were cut to remove the excess part, corrosion products were cleaned as described in morphology analysis, and fracture and lateral surfaces of the specimens were observed via SEM.

Microscopic surface analysis

The samples for electron backscatter diffraction (EBSD) and scanning Kelvin probe force microscopy (SKPFM) were prepared as follows: three different HAZ tensile specimens were subjected to SSRT testing at 2% plastic strain. The most central 10 mm length was then cut to 10 mm × 6 mm × 2 mm specimens. After a series of mechanical polishing, electrolytic etching, and position marking procedures, the EBSD and SKPFM samples were prepared. The subsequent EBSD data was acquired using TSL data acquisition software integrated with JSM-6301. Kernel average misorientation (KAM) map** was performed using the 1st nearest neighbor method. SKPFM tests were performed using an atomic force microscope (Bruker, Multimode VIII) in ScanAsyst-air mode to obtain the topologies and Volta potentials of the surface, which were analyzed using the NanoScope Analysis software.

Data availability

All data needed to evaluate the conclusions in the paper are presented in the paper. Additional data related to this paper are available from the corresponding author upon reasonable request.

References

Qiao, Q. et al. Failure analysis of corrosion at an inhomogeneous welded joint in a natural gas gathering pipeline considering the combined action of multiple factors. Eng. Failure Anal. 64, 126–143 (2016).

Shirinzadeh, M., Mohammadi, J., Behnamian, Y., Eghlimi, A. & Mostafaei, A. Metallurgical investigations and corrosion behavior of failed weld joint in AISI 1518 low carbon steel pipeline. Eng. Failure Anal. 53, 78–96 (2015).

Sahraoui, Y., Benamira, M., Nahal, M., Nouadria, F. & Chateauneuf, A. The effect of welded joint repair on a corroded pipeline reliability subjected to the hardness spatial variability and soil aggressiveness. Eng. Failure Anal. 118, 104854 (2020).

Mohammadi, F., Eliyan, F. F. & Alfantazi, A. Corrosion of simulated weld HAZ of API X-80 pipeline steel. Corros. Sci. 63, 323–333 (2012).

Li, Y. et al. Effect of cathodic potential on stress corrosion cracking behavior of different heat-affected zone microstructures of E690 steel in artificial seawater. J. Mater. Sci. Technol. 64, 141–152 (2021).

Wang, L. W. et al. In situ corrosion characterization of simulated weld heat affected zone on API X80 pipeline steel. Corros. Sci. 85, 401–410 (2014).

Ma, H. C. et al. Comparative study on corrosion fatigue behaviour of high strength low alloy steel and simulated HAZ microstructures in a simulated marine atmosphere. Int. J. Fatigue 137, 105666 (2020).

Wu, W., Liu, Z. Y., Li, X. G., Du, C. & Cui, Z. Influence of different heat-affected zone microstructures on the stress corrosion behavior and mechanism of high-strength low-alloy steel in a sulfurated marine atmosphere. Mater. Sci. Eng. A 759, 124–141 (2019).

Zhu, J. Y. et al. Galvanic corrosion of a welded joint in 3Cr low alloy pipeline steel. Corros. Sci. 111, 391–403 (2016).

Dao, V. H., Ryu, H. K. & Yoon, K. B. Leak failure at the TP316L welds of a water pipe caused by microbiologically influenced corrosion. Eng. Failure Anal. 122, 105244 (2021).

Ress, J. et al. Microbiologically influenced corrosion of welded AISI 304 stainless steel pipe in well water. Eng. Failure Anal. 116, 104734 (2020).

Devendranath, R. K. et al. Microstructure, mechanical properties and biocorrosion behavior of dissimilar welds of AISI 904L and UNS S32750. J. Manuf. Process 30, 27–40 (2017).

Arun, D., Vimala, R. & Devendranath Ramkumar, K. Investigating the microbial-influenced corrosion of UNS S32750 stainless-steel base alloy and weld seams by biofilm-forming marine bacterium Macrococcus equipercicus. Bioelectrochemistry 135, 107546 (2020).

Antony, P. J., Singh Raman, R. K., Kumar, P. & Raman, R. Corrosion of 2205 duplex stainless steel weldment in chloride medium containing sulfate-reducing bacteria. Metall. Mater. Trans. A 39, 2689–2697 (2008).

Liduino, V. S., Lutterbach, M. T. S. & Sérvulo, E. F. C. Biofilm activity on corrosion of API 5L X65 steel weld bead. Colloids Surf. B. Biointerfaces 172, 43–50 (2018).

Stipaničev, M., Rosas, O., Basseguy, R. & Turcu, F. Electrochemical and fractographic analysis of microbiologically assisted stress corrosion cracking of carbon steel. Corros. Sci. 80, 60–70 (2014).

Wei, B. X. et al. Effect of uniaxial elastic stress on corrosion of X80 pipeline steel in an acidic soil solution containing sulfate-reducing bacteria trapped under disbonded coating. Corros. Sci. 193, 109893 (2021).

Guo, L. et al. Multidimensional insights into the corrosion inhibition of 3,3-dithiodipropionic acid on Q235 steel in H2SO4 medium: a combined experimental and in silico investigation. J. Colloid Interface Sci 570, 116–124 (2020).

Javaherdashti, R., Raman, R., Panter, C. & Pereloma, E. Microbiologically assisted stress corrosion cracking of carbon steel in mixed and pure cultures of sulfate reducing bacteria. Int. Biodeterior. Biodegrad. 58, 27–35 (2006).

Lv, M., Chen, X., Li, Z. & Du, M. Effect of sulfate-reducing bacteria on hydrogen permeation and stress corrosion cracking behavior of 980 high-strength steel in seawater. J. Mater. Sci. Technol. 92, 109–119 (2021).

Sun, D. X., Wu, M. & **e, F. Effect of sulfate-reducing bacteria and cathodic potential on stress corrosion cracking of X70 steel in sea-mud simulated solution. Mater. Sci. Eng. A 721, 135–144 (2018).

Liu, B., Li, Z. Y., Yang, X. J., Du, C. & Li, X. Microbiologically influenced corrosion of X80 pipeline steel by nitrate reducing bacteria in artificial Bei**g soil. Bioelectrochemistry 135, 107551 (2020).

Mulla, A. et al. Diversity of culturable nitrate-reducing bacteria from the Arabian Sea oxygen minimum zone. Deep Sea Res. Part II Top. Stud. Oceanogr 156, 27–33 (2018).

Huang, Y. et al. Responses of soil microbiome to steel corrosion. npj Biofilms Microbiomes 7, 6 (2021).

Al-Nabulsi, K. M., Al-Abbas, F. M., Rizk, T. Y. & Salameh, A. a. E. M. Microbiologically assisted stress corrosion cracking in the presence of nitrate reducing bacteria. Eng. Failure Anal. 58, 165–172 (2015).

Liu, B. et al. Corrosion mechanism of nitrate reducing bacteria on X80 steel correlated to its intermediate metabolite nitrite. Constr. Build. Mater. 303, 124454 (2021).

Liu, B., Liu, M. H., Liu, Z. Y., Du, C. & Li, X. Nitrate-reducing-bacteria-assisted hydrogen embrittlement of X80 steel in a near-neutral pH solution. Corros. Sci. 202, 110317 (2022).

Song, L., Liu, Z., li, X. & Du, C. Stress corrosion cracking of simulated weld heat-affected zone on X100 pipeline steel in carbonate/bicarbonate solution. J. Mater. Eng. Perform. 29, 2574–2585 (2020).

Liu, Z. Y., Li, X. G. & Cheng, Y. F. Mechanistic aspect of near-neutral pH stress corrosion cracking of pipelines under cathodic polarization. Corros. Sci. 55, 54–60 (2012).

Liu, Z., li, X., Du, C. & Cheng, Y. Local additional potential model for effect of strain rate on SCC of pipeline steel in an acidic soil solution. Corros. Sci. 51, 2863–2871 (2009).

Yang, K. et al. Bacterial anti-adhesion surface design: surface patterning, roughness and wettability: a review. J. Mater. Sci. Technol. 99, 82–100 (2022).

Chinnaraj, S. B. et al. Modelling the combined effect of surface roughness and topography on bacterial attachment. J. Mater. Sci. Technol. 81, 151–161 (2021).

Javed, M. A., Neil, W. C., Stoddart, P. & Wade, S. Influence of carbon steel grade on the initial attachment of bacteria and microbiologically influenced corrosion. Biofouling 32, 109–122 (2016).

Xu, D. K. & Gu, T. Y. Carbon source starvation triggered more aggressive corrosion against carbon steel by the Desulfovibrio vulgaris biofilm. Int. Biodeterior. Biodegrad. 91, 74–81 (2014).

Uneputty, A. et al. Strategies applied to modify structured and smooth surfaces: a step closer to reduce bacterial adhesion and biofilm formation. Colloids Interface Sci. Commun. 46, 100560 (2022).

Kreve, S. & Reis, A. C. D. Bacterial adhesion to biomaterials: what regulates this attachment? Jpn. Dent. Sci. Rev. 57, 85–96 (2021).

Moteshakker, A. & Danaee, I. Microstructure and corrosion resistance of dissimilar weld-joints between duplex stainless steel 2205 and austenitic stainless steel 316L. J. Mater. Sci. Technol. 32, 282–290 (2016).

Daughney, C. J., Fein, J. B. & Yee, N. A comparison of the thermodynamics of metal adsorption onto two common bacteria. Chem. Geol. 144, 161–176 (1998).

Yang, X. J. et al. Stress-assisted microbiologically influenced corrosion mechanism of 2205 duplex stainless steel caused by sulfate-reducing bacteria. Corros. Sci. 173, 108746 (2020).

Liu, B., Sun, M. H., Lu, F. Y., Du, C. & Li, X. Study of biofilm-influenced corrosion on X80 pipeline steel by a nitrate-reducing bacterium, Bacillus cereus, in artificial Bei**g soil. Colloids Surf. B. Biointerfaces 197, 111356 (2021).

Acknowledgements

Many thanks to Ms. Yanning Liu for her assistance with Gleeble thermal simulation, and we are also grateful to Dr. Zhaoliang Li for sharing his expertise on scanning Kelvin probe force microscopy. Lastly, we are also immensely grateful for the financial support of the National Natural Science Foundation of China (No. 51871026) and the China Postdoctoral Science Foundation (No. 2022M710348).

Author information

Authors and Affiliations

Contributions

B.L.: Conceptualization, methodology, investigation, and writing. J.Y.: Conceptualization, methodology, and investigation. C.D.: Project administration and conceptualization. Z.L.: Review and editing. W.W.: Formal analysis. Supervision. X.L.: Resources.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, B., Yang, J., Du, C. et al. Stress corrosion cracking of X80 steel heat-affected zone in a near-neutral pH solution containing Bacillus cereus. npj Mater Degrad 7, 27 (2023). https://doi.org/10.1038/s41529-023-00333-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-023-00333-w

- Springer Nature Limited

This article is cited by

-

Improving HIC resistance of pipe-steel by Ti/Mg treatment with insights into hydrogen migration

npj Materials Degradation (2024)

-

Enhancement resistance to microbiologically influenced stress corrosion of Cu-bearing steel against Bacillus cereus

npj Materials Degradation (2024)