Abstract

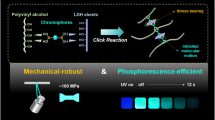

The development of high-power white light-emitting diodes demands highly efficient and stable all-inorganic color converters. In this respect, phosphor-glass/ceramic composites show great promise as they could combine the merits of high quantum efficiency of phosphors and high chemical and thermal stabilities of glass/ceramic matrices. However, strong interfacial reaction between phosphors and matrices at high temperature results in quantum efficiency loss of the embedded phosphors, and traditional solutions rely on high-pressure consolidation techniques. Here we report the intrinsic inhibition of interfacial reaction by using silica glass rather than multicomponent glasses as the matrix. The embedment of phosphors is achieved via a pressureless sintering method, rendering these color-tunable phosphor-glass composites not only accessible to three-dimensional printing technique, but also highly efficient (internal quantum efficiency >90.0%), thermally stable at 1200 °C and hydrothermally stable at 200 °C. Our results provide a facile and general strategy for develo** all-inorganic functional composites.

Similar content being viewed by others

Introduction

Color converters that can emit light of desired wavelengths after absorbing incident light play a key role in light-emitting1,2,3 and -detecting4 devices as well as photovoltaics5,6. However, conventional color converters with luminescent particles embedded in transparent organic polymers are notoriously easy to degrade during exposure to heat, moisture and short-wavelength radiation, leading to much shorter lifetime of the devices than expected7,8. Recently, the so-called phosphor-converted white light-emitting diodes (pc-WLEDs) have been widely used in general lighting and display backlighting, but their extension to high-power and high-brightness lighting fields such as street lighting, automotive headlamp and large-size display, is extremely sluggish1,2,3,1,2,3,40, and then YAG:Ce powders are added to obtain the final composite slurry where YAG:Ce particles can be well suspended (Fig. 1a). The slurry is then polymerized into transparent flat-plate green bodies within 30 s under high-power UV light. Green bodies with complex 3D structure can be also rapidly produced from the developed photocurable slurry with stereolithography (SLA) 3D printing (Supplementary Fig. 2), by which Kotz et al have recently fabricated various silica glass structure parts41,42. After two-step heat treatment for debinding and densifying (Methods), the green bodies become porous and then are fully densified into transparent pure silica glass or translucent yellow YAG:Ce-PiSG (Fig. 1a,b), where for PiSG doped with 1 wt% YAG:Ce (1 wt% YAG:Ce-PiSG) the linear shrinkage is 4.7 and 27.9% after debound and densified, respectively.

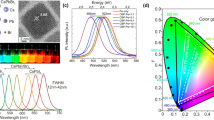

a Amorphous silica nanoparticles are first dispersed into UV-curable monomer, and then YAG:Ce powders are mixed with the UV-curable dispersion to form the slurry, which is put into the mould and polymerized into flat discs under high-power 365 nm light. After debound and sintered, they are fully densified into bulk composite (1.8 cm in diameter). Note that the resultant slurry shows no obvious phosphor settlement after siting for 30 min. b Flat discs of YAG:Ce-PiSG with various YAG:Ce contents (from left to right: 0, 1, 3, 5 and 7 wt%, 1.8 cm in diameter and 1.0 mm in thickness). c Total transmittance of YAG:Ce-PiSG with various YAG:Ce contents (1.0 mm in thickness). d Fluorescence microscope images of YAG:Ce/silica composite after polymerized, debound and densified (scale bar, 100 μm). e Surface CLSM image of 3 wt% YAG:Ce-PiSG (scale bar, 100 μm). f 3D reconstruction CLSM image of 3 wt% YAG:Ce-PiSG (scale bar, 100 μm). g Examples of printed and sintered 3 wt% YAG:Ce-PiSG (scale bar, 1 cm).

As shown in Fig. 1c, pure silica glass exhibits excellent transparency with a total transmittance of 80.5% at the wavelength of 450 nm (86.2% at 600 nm), implying that full densification is achieved. With incorporating YAG:Ce into silica glass, the as-synthesized samples become translucent, accompanied by intense yellow emission upon 450 nm excitation (Fig. 1b). Transparency reduction is mainly attributed to the enhanced light scattering due to the different refractive indices of YAG:Ce (1.84) and silica glass (1.46); nevertheless, moderate light scattering is beneficial to the color uniformity and the light extraction of high-power pc-WLED, especially when laser diodes (LDs) are used as the excitation sourceFull size image

Solid-state nuclear magnetic resonance (NMR) spectroscopy is a powerful tool to provide atomic structural information in material science. Figure 3d shows the 27Al magic angle spinning NMR (MAS-NMR) spectra of YAG:Ce powder and YAG:Ce-PiSG. The single-peak signal at 1.5 ppm and the well-defined quadrupolar peak at 71.3 ppm can be clearly resolved, where the former represents six-coordinated Al (AlVI) and the latter four-coordinated Al (AlIV). The maximum peak positions, i.e. the average isotropic chemical shifts (δiso), as well as the peak shapes of the two aluminum species show no difference in both spectra, indicating that the local environment of these polyhedrons remains nearly the same after YAG:Ce are embedded into silica glass. The ratios of the integrated signal intensities of AlIV and AlVI species from YAG:Ce powder and YAG:Ce-PiSG are estimated to be 42.3:57.8 and 41.5:58.5, respectively, both of which agree well with the expected 2:3 ratio for YAG crystal. In addition, the 29Si MAS-NMR spectra of pure silica glass and YAG-PiSG (Supplementary Fig. 6) are almost identical, which is consistent with the results from 27Al MAS-NMR spectra. Moreover, the long-term (10 h) high-temperature stability of YAG:Ce-PiSG at 1200 °C also reflect the intrinsically inhibited interfacial reaction between YAG:Ce and silica glass. Our results unambiguously confirm that interfacial reaction between YAG:Ce and silica glass matrix is very limited even at 1250 °C for 3 h.

Versatile phosphor-silica glass composites

The extremely small diffusion rate of highly charged Si4+ and the absence of non-bridging oxygens18,28 largely improve the activation energy (namely the required temperature) for the interfacial reaction of phosphor with silica glass, as compared with multicomponent glasses. Moreover, a reduction atmosphere is employed not only to assist the densification process, but also to preserve Ce3+ and Eu2+, two most widely used activators in phosphors, which otherwise would be oxidized into luminescence killers (Ce4+ and Eu3+) at high temperature. Using amorphous silica nanoparticles lower the required temperature to only 1250 °C, but, nevertheless, the structure of most phosphors including oxides and oxynitrides are thermally stable at this temperature. Therefore, the proposed strategy can generally be applied to achieve color tunable emission in silica glass based composites.

As shown in Fig. 4, not only garnet-type phosphors including Lu3Al5O12:Ce (LuAG:Ce, blue-green), (Gd,Y)3Al5O12:Ce (GdAG:Ce, orange) as well as YAG:Ce (yellow), but other well-known phosphors such as BaMgAl10O17:Eu (BAM:Eu, blue), β-SiAlON:Eu (β-Sialon:Eu, green) and Al2O3:Cr (far-red) were particularly incorporated into silica glass for exemplification (Fig. 4). As expected, all the as-synthesized phosphor-glass composites are highly efficient with limited IQE loss except the β-Sialon:Eu doped one (Supplementary Table 3). Unlike α-sialon, β-sialon is structurally unstable at high temperature due to N2 evaporation43, resulting in large IQE loss. Using smaller amorphous silica nanoparticles (<15 nm) or tetramethoxysilane as the precursor43,50 could reduce the required temperature to lower than 1100 °C. It is thus anticipated that more kinds of phosphors could be incorporated into silica glass without obvious IQE loss. However, the densifying temperature of silica glasses is still too high for red nitride phosphors, and this limitation cannot be well circumvented until novel oxide or oxynitride red phosphors with high thermal stability are developed. Finally, silica glass acts as an effective buffer for the embedded phosphors against oxidation at high temperature (Supplementary Fig. 4), which will endow them with better performance as the thermographic phosphor for high-temperature (>1000 °C) thermometry36.