Abstract

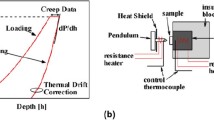

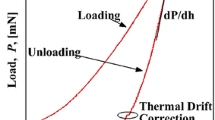

This investigation reports the nanomechanical properties of shallow water shrimp exoskeleton at temperatures ranging from 30 °C to 80 °C measured using nanoindentation experiments. Scanning Electron Microscopy (SEM) measurements suggest that the shrimp exoskeleton has the Bouligand structure in its layers, a key characteristic of the crustaceans. The thickness of the layers and packing density are found to be different from that of lobsters and crabs reported earlier in the literature. Mechanical properties at high temperatures are determined using micro materials nanoindentation test set up combined with the hot stage. The properties measured during nanoindentation test are corrected for the creep and thermal drift during the experiments. The reduced modulus values are found to be around 28 GPa at 30 °C that reduces to approximately 24 GPa at 80 °C. The hardness values also decrease from 1.6 GPa at 30 °C to around 1.2 GPa at 80 °C. The indentation size effect is found to be absent at all temperatures. Creep mechanisms of polymers like materials and its temperature dependence are discussed to give more insight into the deformation mechanism.

Similar content being viewed by others

References

Boßelmann F, Romano P, Fabritius H, Raabe D, Epple M. The composition of the exoskeleton of two crustacea: The American lobster Homarus americanus and the edible crab Cancer pagurus. Thermochimica Acta, 2007, 463, 65–68.

Raabe D, Romano P, Sachs C, Fabritius H, Al-Sawalmih A, Yi S-B, Servos G, Hartwig H G. Microstructure and crystallographic texture of the chitin-protein network in the biological composite material of the exoskeleton of the lobster Homarus americanus. Materials Science and Engineering: A, 2006, 421, 143–153.

Raabe D, Sachs C, Romano P. The crustacean exoskeleton as an example of a structurally and mechanically graded biological nanocomposite material. Acta Materialia, 2005, 53, 4281–4292.

Seki Y, Schneider M S, Meyers M A. Structure and mechanical behavior of a toucan beak. Acta Materialia, 2005, 53, 5281–5296.

Lian J, Wang J. Microstructure and mechanical properties of dungeness crab exoskeletons. In: Proulx T, ed., Mechanics of Biological Systems and Materials, Springer, New York, 2011, 93–99.

Melnick C A, Chen Z, Mecholsky J J. Hardness and toughness of exoskeleton material in the stone crab, Menippe mercenaria. Journal of Materials Research, 1996, 11, 2903–2907.

Mayer G. New classes of tough composite materials-Lessons from natural rigid biological systems. Materials Science and Engineering: C, 2006, 26, 1261–1268.

Mayer G. New toughening concepts for ceramic composites from rigid natural materials. Journal of the Mechanical Behavior of Biomedical Materials, 2011, 4, 670–681.

Hepburn H R, Joffe I, Green N, Nelson K J. Mechanical properties of a crab shell. Comparative Biochemistry and Physiology Part A: Physiology, 1975, 50, 551–IN13.

Barthelat F, Rim J E, Espinosa H D. A review on the structure and mechanical properties of mollusk shells-perspectives on synthetic biomimetic materials. Applied Scanning Probe Methods XIII, Springer, 2009, 17–44.

Bouligand Y. Twisted fibrous arrangements in biological materials and cholesteric mesophases. Tissue and Cell, 1972, 4, 189–217.

Giraud-Guille M M. Fine structure of the chitin-protein system in the crab cuticle. Tissue and Cell, 1984, 16, 75–92.

Chen P Y, Lin AY-M, McKittrick J, Meyers M A. Structure and mechanical properties of crab exoskeletons. Acta Bio-materialia, 2008, 4, 587–596.

Chen B, Peng X, Wang J G, Wu X. Laminated microstructure of Bivalva shell and research of biomimetic ceramic/polymer composite. Ceramics International, 2004, 30, 2011–2014.

Shahidi F, Synowiecki J. Isolation and characterization of nutrients and value-added products from snow crab (Chionoecetes opilio) and shrimp (Pandalus borealis) processing discards. Journal of Agricultural and Food Chemistry, 1991, 39, 1527–1532.

Islam M, Masum S, Rahman M, Moll M, Shaikh A, Roy S. Preparation of chitosan from shrimp shell and investigation of its properties. International Journal of Basic and Applied Sciences, 2011, 11, 116–30.

Rødde R H, Einbu A, Vårum K M. A seasonal study of the chemical composition and chitin quality of shrimp shells obtained from northern shrimp (Pandalus borealis). Carbohydrate Polymers, 2008, 71, 388–393.

Ibrahim H M, Salama M F, El-Banna H A. Shrimp’s waste: Chemical composition, nutritional value and utilization. Food/Nahrung, 1999, 43, 418–423.

Weaver J, Milliron G W, Miserez A, Evans-Lutterodt K, Herrera S, Gallana I, Mershon W J, Swanson B, Zavattieri P, Dimasi E, Kisailus D. The Stomatopod Dactyl club: A Formidable damage-tolerant biological hammer. Science, 2012, 336, 1275–1280.

Andresen I L, Smidsørod O. Temperature dependence of the elastic properties of alginate gels. Carbohydrate Research, 1977, 58, 271–279.

Lagakos N, Jarzynski J, Cole J, Bucaro J. Frequency and temperature dependence of elastic moduli of polymers. Journal of applied physics, 1986, 59, 4017–4031.

Wang W Y, Liu B, Kodur V. Effect of temperature on strength and elastic modulus of high-strength steel. Journal of Materials in Civil Engineering, 2013, 25, 174–182.

Zacharias J. The temperature dependence of Young’s modulus for nickel. Physical Review, 1933, 44, 116.

Farraro R, McLellan R. Temperature dependence of the Young’s modulus and shear modulus of pure nickel, platinum, and molybdenum. MTA, 1977, 8, 1563–1565.

Young G, Garofalo R, Peters S, Harmer O. The effect of temperature on soft contact lens modulus and diameter. Eye & Contact Lens, 2011, 37, 337–341.

Latella B A, Humphries S R. Young’s modulus of a 2.25Cr-1Mo steel at elevated temperature. Scripta materialia, 2004, 51, 635–639.

Wang C A, Huang Y, Zan Q, Guo H, Cai S. Biomimetic structure design-a possible approach to change the brittleness of ceramics in nature. Materials Science and Engineering: C, 2000, 11, 9–12.

Zhou B L. Bio-inspired study of structural materials. Materials Science and Engineering: C, 2000, 11, 13–18.

Luz G M, Mano J F. Biomimetic design of materials and biomaterials inspired by the structure of nacre. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2009, 367, 1587–1605.

Oliver W C, Pharr G M. Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. Journal of Materials Research, 1992, 7, 1564–1583.

Pharr G. Measurement of mechanical properties by ultra-low load indentation. Materials Science and Engineering: A, 1998, 253, 151–159.

Gan M, Tomar V. Scale and temperature dependent creep modeling and experiments in materials. JOM Journal of the Minerals, Metals, and Materials Society, 2011, 63, 27–34.

Gan M, Tomar V. Role of length scale and temperature in indentation induced creep behavior of polymer derived Si-C-O ceramics. Materials Science and Engineering: A, 2010, 527, 7615–7623.

Feng G, Ngan A. The effects of creep on elastic modulus measurement using nanoindentation. Materials Research Society, Boston, MA, 2001.

Ngan A, Tang B. Viscoelastic effects during unloading in depth-sensing indentation. Journal of Materials Research, 2002, 17, 2604–2610.

Feng G, Ngan A. Effects of creep and thermal drift on modulus measurement using depth-sensing indentation. Journal of materials research, 2002, 17, 660–668.

Koyanagi J, Yoneyama S, Nemoto A, Melo JDD. Time and temperature dependence of carbon/epoxy interface strength. Composites Science and Technology, 2010, 70, 1395–1400.

Tilton Jr R F, Dewan J C, Petsko G A. Effects of temperature on protein structure and dynamics: X-ray crystallographic studies of the protein ribonuclease-A at nine different temperatures from 98 to 320 K. Biochemistry, 1992, 31, 2469–2481.

Frauenfelder H, Petsko G A, Tsernoglou D. Temperature-dependent X-ray diffraction as a probe of protein structural dynamics. Nature, 1979, 280, 558–563.

Bull H B, Breese K. Thermal stability of proteins. Archives of Biochemistry and Biophysics, 1973, 158, 681–686.

Bischof J C, He X. Thermal stability of proteins. Annals of the New York Academy of Sciences, 2006, 1066, 12–33.

Sherby O D, Burke P M. Mechanical behavior of crystalline solids at elevated temperature. Progress in Materials Science, 1968, 13, 323–390.

Tuttle M E, Brinson H F. Prediction of the long-term creep compliance of general composite laminates. Experimental Mechanics, 1986, 26, 89–102.

Raghavan J, Meshii M. Creep of polymer composites. Composites Science and Technology, 1998, 57, 1673–1688.

Saheb D N, Jog J. Natural fiber polymer composites: A review. Advances in polymer technology, 1999, 18, 351–363.

Ma C C M, Tai N H, Wu S H, Lin S H, Wu J F, Lin J M. Creep behavior of carbon-fiber-reinforced polyetheretherketone (PEEK) [±45] 4s laminated composites (I). Composites Part B: Engineering, 1997, 28, 407–417.

Schoeck G. The activation energy of dislocation movement. Physica Status Solidi (b), 1965, 8, 499–507.

Shanholtz E R, LaSalvia J C. Investigation of the Indentation-Size Effect (ISE) in a commercial SiAlON: Multifractal scaling analysis and underlying mechanisms. Journal of the American Ceramic Society, 2013, 96, 2607–2614.

Li H, Bradt R C. The indentation load/size effect and the measurement of the hardness of vitreous silica. Journal of Non-Crystalline Solids, 1992, 146, 197–212.

Saha R, Nix W D. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Materialia, 2002, 50, 23–38.

Gamonpilas C, Busso E P. On the effect of substrate properties on the indentation behaviour of coated systems. Materials Science and Engineering: A, 2004, 380, 52–61.

Bolshakov A, Oliver W, Pharr G. Finite element studies of the influence of pile-up on the analysis of nanoindentation data. Materials Research Society Symposium Proceedings, Cambridge University Press, 1997, 141–146.

Bolshakov A, Pharr G. Influences of pileup on the measurement of mechanical properties by load and depth sensing indentation techniques. Journal of Materials Research, 1998, 13, 1049–1058.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Verma, D., Tomar, V. Structural-nanomechanical property correlation of shallow water shrimp (Pandalus platyceros) exoskeleton at elevated temperature. J Bionic Eng 11, 360–370 (2014). https://doi.org/10.1016/S1672-6529(14)60049-4

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(14)60049-4