Abstract

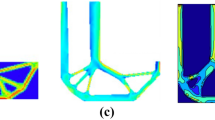

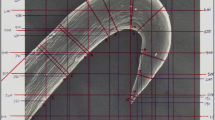

This research reports on numerical and experimental methods for the use of post-tensioning with brittle ceramic extrusions. It proposes a novel construction approach, including new joint typologies, and demonstrates the viability of ceramic as a primary structural material in a bending-active context through two pavilion-scale prototypes. The research proceeded in three distinct phases. First, relevant material properties —compressive strength, bending strength, modulus—were determined experimentally. Next, several post-tensioned beam prototypes were tested to examine the interaction between post-tensioning steel and ceramic, understand failure modes, and refine construction details. Finally, two post-tensioned prototypes were designed based on these findings, the Vierendeel Arch and the Hypar Tower. The design process for each prototype involved a novel digital workflow that utilized multiple parametric models to generate and analyze global design geometry, link to structural analysis software, discretize the forms into components based on available stock sizes, accommodate for assembly tolerances, and generate component cut lists. The prototypes behaved as predicted, demonstrating that post-tensioning can successfully control bending stresses in ceramic extrusions, and introducing entirely new applications for the material.

Similar content being viewed by others

Notes

We will use the term post-tensioning for the work presented here, since the forces in the tendon are induced after the assembly of the member, much as in concrete systems with unbonded tendons. Mechanically speaking prestressing and post-tensioning can have very similar effects.

Unpublished data provided by Cerámica Mayor S.A. via email 5/25/2018

Bending stresses were calculated as follows: M = [(w L2) / 8] + [(P L) / 4] with w = 0.832 N/mm; L = 2140 mm for beams A and C, L = 1365 mm for beam B; the largest positive moment in the beams A and C at maximum point load was 0.166 kNm. Maximum tensile bending stresses can be found with: f = [M / S] – [F / A] with M the maximum moment, F the post-tensioning force, S the section modulus, and A the cross-sectional area of the profile. A positive number indicates the amount of residual tensile stresses, a negative number indicates that the tensile zone is subject to compressive stress due to post-tensioning stress overriding the tensile bending stresses.

References

Shushkewich KW (2012) Eugène Freyssinet—invention of Prestressed concrete and precast segmental construction. Struct Eng Int 22(3):415–420. https://doi.org/10.2749/101686612X13363869853338

Bechthold M (2015) Ceramic material systems: in architecture and interior design. Birkhäuser, Basel

Lourenço PB, Vasconcelos G (2015) The design and mechanical performance of high-performance perforated fired masonry bricks. In: Pacheco-Torgal F, Lourenço PB, Labrincha JA, Kumar S, Chindaprasirt P (eds) Eco-efficient masonry bricks and blocks, vol 2. Woodhead Publishing, Oxford, pp 13–44. https://doi.org/10.1016/B978-1-78242-305-8.00002-4

Brand S (1994) How buildings learn: what happens after they’re built. Viking, New York

Bechthold M (2016) Ceramic prototypes – design, computation, and digital fabrication. Informes de la Construccion 68(544):e167–e167. https://doi.org/10.3989/ic.15.170.m15

King N, Bechthold M, Kane A, Michalatos P (2014) Robotic tile placement: tools, techniques and feasibility. https://doi.org/10.1016/J.AUTCON.2013.08.014

Weston, M. (2013). Prime Negatives: Parametric Sponge-Forming and Slip Casting for Ceramics. In Proceedings of the XVII Conference of the Iberoamerican Society of Digital Graphics - SIGraDi: Knowledge-based Design (pp. 396–399). Presented at the XVII Conference of the Iberoamerican Society of Digital Graphics - SIGraDi: Knowledge-based Design, Valparaiso, Chile: Editora Edgard Blücher. https://doi.org/10.5151/despro-sigradi2013-0075

Kwon H (2002). Experimentation and analysis of contour crafting (CC) process using uncured ceramic materials (Unpublished PhD Dissertation). University of Southern California

Seibold Z, Hinz K, Garcia del Castillo López, J. L., Martinez Alonso N, Mhatre S, & Bechthold M (2018). Ceramic Morphologies. Precision and control in paste-based additive manufacturing. In ACADIA // 2018: Recalibration. On imprecisionand infidelity. [Proceedings of the 38th Annual Conference of the Association for Computer Aided Design in Architecture (ACADIA) ISBN 978–0–692-17729-7] Mexico City, Mexico 18–20 October, 2018, pp. 350–357. CUMINCAD. Accessed October 27, 2021 Retrieved from http://papers.cumincad.org/cgi-bin/works/paper/acadia18_350

AlOthman S, Im HC, Jung F, Bechthold M (2018) Spatial print trajectory: controlling material behavior with print speed, feed rate, and complex print path. In: In robotic fabrication in architecture, art and design 2018. Springer International Publishing, Cham, pp 167–180. https://doi.org/10.1007/978-3-319-92294-2_13

Seibold Z, Mhatre S, Alhadidi S, García del Castillo López JL, & Bechthold M (2019). Janus Printing: Coextrusion based Multi-material Additive Manufacturing for Ceramics. In ACADIA 19:UBIQUITY AND AUTONOMY [Proceedings of the 39th Annual Conference of the Association for Computer Aided Design in Architecture (ACADIA) ISBN 978–0–578-59179-7] (The University of Texas at Austin School of Architecture, Austin, Texas 21–26 October, 2019) pp. 576–585. CUMINCAD. Accessed October 27, 2021 Retrieved from http://papers.cumincad.org/cgi-bin/works/paper/acadia19_576

Händle F (2007) Extrusion in ceramics. Springer, Berlin. https://doi.org/10.1007/978-3-540-27102-4_2

Ugarte-Urzúa, J. P., Mhatre, S., Bechthold, M., & Norman, S. (2020). Extruded Tessellations: A novel structural ceramic system at the intersection of industrial ceramic extrusion and CNC fabrication. In Blucher Design Proceedings (pp. 326–333). Presented at the Congreso SIGraDi 2020, Medellín, Colombia: Editora Blucher. https://doi.org/10.5151/sigradi2020-45

Overall S, Rysavy JP, Miller C, Sharples W, Sharples C, Kumar S et al (2018) Made-to-measure: automated drawing and material craft. Technol Archit Des 2(2):172–185. https://doi.org/10.1080/24751448.2018.1497365

Seibold Z, Mesa O, Stavric M, Bechthold M (2018) Ceramic tectonics: tile grid Shell. Proc IASS Annual Symp 2018(8):1–8

Dorjpalam, S., Kawase, H., & Yamaguchi, K. (2008). EXPERIMENTAL AND NUMERICAL STUDY ON DYNAMIC PROPERTIES OF FRICTION-RESISTANT DRY-MASONRY STRUCTURES. In 14th World Conference on Earthquake Engineering (第十四届国际地震工程会议) (p. A-X). **地震学会

Hubmer, P., & Bscheider, E. (2015). MODULAR CERAMIC CONSTRUCTION SYSTEM (p. 12)

Bechthold M (2008) Innovative surface structures: technologies and applications. Taylor & Francis, Abingdon, Oxon; New York

Alini L (2011) CCCloud Casalgrande Ceramic Cloud. Dalla produzione al progetto/CCCloud Casalgrande Ceramic Cloud. From production to project. Techne 1:130–137

Schodek D L, & Bechthold M (2014). Structures (7th edition / Daniel L. Schodek, Martin Bechtold.). Boston: Pearson

Anderegg FO (1937) Super-ceramic building members*. J Am Ceram Soc 20(1–12):77–79. https://doi.org/10.1111/j.1151-2916.1937.tb19865.x

Johnston RD, Chipman RD, Knapp WJ (1953) Prestressed ceramics as a structural material. J Am Ceram Soc 36(4):121–126. https://doi.org/10.1111/j.1151-2916.1953.tb12848.x

Shanley FR, Knapp WJ, & Kurtz P Jr. (1966). An Investigation of Ceramics as Structural Materials (NASA Contractor Report No. NASA-CR-632) (p. 21). University of California. Retrieved from https://ntrs.nasa.gov/citations/19660029462

Devalapura RK, Krause GL, Sweeney SC, Littler D, Staab E (1997) Construction productivity advancement research (CPAR) program. In: Development of an innovative post-tensioning system for Prestressed clay brick masonry walls. CONSTRUCTION ENGINEERING RESEARCH LAB (ARMY), CHAMPAIGN Accessed October 27, 2021 Retrieved from https://apps.dtic.mil/sti/citations/ADA327657

Wrana S, Cervenkova N, Miroslav K (2015). Green Vee System: Planted Ceramic Modular Load-Bearing System. In Proceedings of IASS Annual Symposia. Presented at the IASS Conference, Amsterdam

Brick masonry material properties (no. 3A). (1992) (p. 10). Accessed October 27, 2021 Retrieved from https://www.gobrick.com/docs/default-source/read-research-documents/technicalnotes/3a-brick-masonry-material-properties.pdf?sfvrsn=0

Rutten D (2013) Galapagos: on the logic and limitations of generic solvers. Archit Des 83(2):132–135. https://doi.org/10.1002/ad.1568

Kalina RD, Lean SM, & Breen JE (2011). Comparative Study of Mechanical and Corrosion Resistance Properties of Bridge Post-Tensioning Strands. Accessed October 27, 2021 Retrieved from https://trid.trb.org/view/1144043

McCool GE (2010). Evaluation of corrosion resistance of new and upcoming post-tensioning materials after long-term exposure testing (thesis). Accessed October 27, 2021 Retrieved from https://repositories.lib.utexas.edu/handle/2152/ETD-UT-2010-12-2541

Acknowledgements

The authors thank ASCER Tile of Spain for their continuing support. Cevisama 2019 and 2020 provided additional support for the exhibition of the design prototypes. Javier Mira from the Instituto de Tecnología Cerámica as well as Groupo on Market helped realize the design. Windmill Structural Consultants S.L.P. provided the structural peer review. Simpson Gumpertz & Heger assisted with compression testing. TriPyramid Structures Inc. designed and fabricated hardware for the construction-scale prototype beams. We would also like to thank Natalia Bechthold and Olga Mesa for their contributions during the prototype design process.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bechthold, M., Seibold, Z. & Mhatre, S. Post-tensioned ceramic structures: design, analysis and prototy**. Archit. Struct. Constr. 2, 165–182 (2022). https://doi.org/10.1007/s44150-022-00025-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s44150-022-00025-0