Abstract

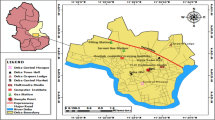

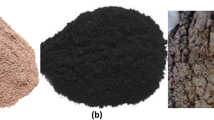

As a result of environmental issues, the use waste residue has gained much attention in the field of soil re-engineering, this is because of the feasibility of using waste derivatives in soil amelioration protocols. This necessitated the current study to deal with the utilization of an industrial residue termed as cement kiln dust (CKD) in enhancing the mechanical performance of black expansive clayey material. The amelioration protocols were as a result of the poor engineering performance of black cotton soil thereby becoming a road cancer material. The extreme vertex design (EVD) is a flexible approach and was adopted for the mixture experimental design and modelling of the mechanical properties of problematic black cotton soil—cement kiln dust blend. The statistical analyses and or approaches engaged in course of this study were carried out using Minitab 18 and Design Expert statistical software. In the current study, the responses considered include California bearing ratio (soaked and unsoaked) and unconfined compressive strength test. The corresponding experimental responses were then achieved in the laboratory and used for analysis and model development. Statistical diagnostics and influence tests carried out on the developed model showed a good correlation with the actual results. However, using the EVD design of experiment approach, the peak performance of soil-CKD was achieved at the mixture combination of 0.45, 0.443 and 0.107% for soil, CKD and water, respectively. The strength outcomes indicate that cement kiln dust could be useful in ameliorating expansive soil for sub-base material of low trafficked roads and as well reduce cost of cement kiln dust residue disposal.

Similar content being viewed by others

Change history

13 June 2021

Due to an unfortunate mistake during the correction process the author portraits have been interchanged.

References

Mamatha, K. M., & Dinesh, S. V. (2017). Resilient modulus of black cotton soil. International Journal of Pavement Research, 10(2), 171–184. https://doi.org/10.1016/j.ijprt.2017.01.008

Sudharani, K., Abhishek, S. K., Adarsh, N., Harish, T., & Manjunath. (2017). Stabilization of black cotton soil using brick dust and bagasse ash. International Journal for Scientific Research and Development, 5(5), 140–144.

Gidigasu, S. S. R., & Gawu, S. K. Y. (2013). The mode of formation, nature and geotechnical characteristics of black cotton soils—a review. Standard Scientific Research and Essays, 1(14), 377–390

Etim, R. K., Eberemu, A. O., & Osinubi, K. J. (2017). Stabilization of black cotton soil with lime and iron ore tailings admixture. Journal of Transportation Geotechnic, 10, 85–95. https://doi.org/10.1016/j.trgeo.2017.01.002

Moses, G., Etim, R. K., Sani, J. E., & Nwude, M. (2019). Desiccation-induced volumetric shrinkage characteristics of highly expansive tropical black clay treated with groundnut shell ash for barrier consideration. Civil and Environmental Research, 11(8), 58–74. https://doi.org/10.7176/CER/11-8-06

Etim, R. K., Attah, I. C., Eberemu, A. O., & Yohanna, P. (2019). Compaction behaviour of periwinkle shell ash treated lateritic soil for use as road sub-base construction material. Journal of GeoEngineering, 14(3), 179–190. https://doi.org/10.6310/jog.201909_14(3).7

Attah, I. C., Agunwamba, J. C., Etim, R. K., & Ogarekpe, N. M. (2019). Modelling and predicting of CBR values of lateritic soil treated with metakaolin for road material. ARPN Journal of Engineering and Applied Sciences, 14(20), 3606–3618

Etim, R. K., Attah, I. C., & Yohanna, P. (2020). Experimental study on potential of oyster shell ash in structural strength improvement of lateritic soil for road construction. International Journal of Pavement Research Technology, Chinese Society of Pavement Engineering, 13(4), 341–351. https://doi.org/10.1007/s42947-020-0290-y

Attah, I. C., Okafor, F. O., & Ugwu, O. O. (2021). Optimization of California bearing ratio of tropical black clay soil treated with cement kiln dust and metakaolin blend. International Journal of Pavement Research and Technology, 14(6), 655–667. https://doi.org/10.1007/s42947-020-0003-6

Attah, I. C., Etim, R. K., Yohanna, P., & Usanga, I. N. (2021). Understanding the effect of compaction energies on the strength indices and durability of oyster shell ash-lateritic soil mixtures for use in road works. Engineering and Applied Science Research, 48(2), 151–160

Etim, R. K., Attah, I. C., Ogarekpe, N. M., & Robert, E. E. (2018). Geotechnical behaviour of lateritic soil—oyster shell ash mixtures. Proceedings of 16th International Conference and Annual General Meeting 2018 of Nigerian Institution of Civil Engineers. Theme: Transforming National Economy through Sustainable Civil Engineering Infrastructure, Paradise 2018. Calabar Intl. Convention Centre, Cal., Cross River State. 24–26 October, 2018, pp. 45–52

Etim, R. K., Attah, I. C., Yohanna, P., & Eshiet, S. J. (2018). Geotechnical properties of lateritic soil treated with periwinkle shell ash. Proceedings of 16th International Conference and Annual General Meeting 2018 of Nigerian Institution of Civil Engineers. Theme: Transforming National Economy through Sustainable Civil Engineering Infrastructure, Paradise 2018. Calabar Intl. Convention Centre, Cal., Cross River State. 24–26 October, 2018, pp. 148–156

Attah, I. C., Okafor, F. O., Ugwu, O. O. (2021). Experimental and optimization study of unconfined compressive strength of ameliorated tropical black clay. Engineering and Applied Science Research. 48(3), 238–248. https://doi.org/10.14456/easr.2021.26

Attah, I. C., Etim, R. K., & Usanga, I. N. (2021). Potentials of cement kiln dust and rice husk ash blend on strength of tropical soil for sustainable road construction material. IOP Conference Series: Materials Science and Engineering, 1036, 012072. https://doi.org/10.1088/1757-899X/1036/1/012072

Ekpo, D. U., Fajobi, A. B., Ayodele, A. L., & Etim, R. K. (2021). Potentials of cement kiln dust-periwinkle shell ash blends on plasticity properties of two selected tropical soils for use as sustainable construction materials. IOP Conference Series: Material Science and Engineering, 1036, 012033. https://doi.org/10.1088/1757-899X/1036/1/012033

Miller, G. A., & Zaman, M. (2000). Field and laboratory evaluation of cement kiln dust as a soil stabilizer. Transportation Research Record, 1714, 25–32

Salahudeen, A. B., Eberemu, O. A., & Osinubi, K. J. (2014). Assessment of cement kiln dust-treated expansive soil for the construction of flexible pavements. Geotechnical and Geological Engineering, Springer, 32(4), 923–931

Maslehuddin, M., Al-Amoudi, O. S. B., Shameema, M., Rehmana, M. K., & Ibrahim, M. (2008). Usage of cement kiln dust in cement products—Research review and preliminary investigations. Construction and Building Materials, 22, 2369–2375

Shoaib, M. M., Balaha, M. M., & Abdel-Rahman, A. G. (2000). Influence of cement kiln dust substitution on the mechanical properties of concrete. Cement and Concrete Research, 30, 337–371

Sreekrishnavilasam, A., King, S., & Santagata, M. (2006). Characterization of fresh and landfilled cement kiln dust for reuse in construction applications. Engineering Geology, 85, 165–173

Salahudeen, A. B., Ijimdiya, T. S., Eberemu, A. O., & Osinubi, K. J. (2018). Artificial neural networks prediction of compaction characteristics of black cotton soil stabilized with cement kiln dust. Journal of Soft Computing in Civil Engineering, 2(3), 53–74

PCA: The Portland Cement Association. (1992). An analysis of selected trace metals in cement kiln dust. PCA.

El-Attar, M. M., Sadek, D. M., & Salah, A. M. (2017). Recycling of high volumes of cement kiln dust in bricks industry. Journal of Cleaner Production, 143, 506–515

Chaunsali, P., & Peethamparan, S. (2013). Influence of the composition of cement kiln dust on its interaction with fly ash and slag. Cement and Concrete Research, 54, 106–113. https://doi.org/10.1016/j.cemconres.2013.09.001

Alaneme, G. U., Onyelowe, K. C., Onyia, M. E., Van Bui, D., Mbadike, E. M., Dimonyeka, M. U., Attah, I. C., Ogbonna, C., Iro, U. I., Kumari, S., Firoozi, A. A., & Oyagbola, I. (2020). Modelling of the swelling potential of soil treated with quicklime-activated rice husk ash using fuzzy logic. Umudike Journal of Engineering and Technology, 6(1), 1–22

Fityus, S., & Buzzi, O. (2009). The place of expansive clays in the framework of unsaturated soil mechanics. Applied Clay Science, 43, 150–155. https://doi.org/10.1016/j.clay.2008.08.005

Miao, L. C., & Liu, S. Y. (2001). Engineering characteristics of expansive soil and engineering measures. Advances in Science and Technology of Water Resource, 48(2), 37–40 in Chinese.

Olubanwo, A. O., & Karadelis, J. N. (2015). Applied mixture optimization techniques for paste design of bonded roller-compacted fiber reinforced polymer modified concrete (BRCFRPMC) overlays. Materials and Structures, 48, 2023–2042. https://doi.org/10.1617/s11527-014-0291-x

Mishra, B. (2015). A study on engineering behavior of black cotton soil and its stabilization by use of lime. International Journal of Science and Research, 4(11), 290–294

Oja, J., & Gundaliya, P. (2012). Study of black cotton soil characteristics with cement waste dust and lime. In Proceedings of the Nirma University International Conference on Engineering (NUiCONE 2012), pp. 110–118, Gujarat, India, December 2013.

Scheffé, H. (1958). Experiments with mixtures. Journal of the Royal Statistical Society Series B., 20, 344–360

Onyelowe, K. C., Alaneme, G. U., Van Bui, D., Van Nguyen, M., Ezugwu, C., Amhadi, T., Sosa, F., Orji, F., & Ugorji, B. (2019). Generalized review on EVD and constraints simplex method of materials properties optimization for civil engineering. Civil Engineering Journal, 5(3), 729–749

Wangkananon, W., Phuaksaman, C., Koobkokkruad, T., & Natakankitkul, S. (2018). An extreme vertices mixture design approach to optimization of tyrosinase inhibition effects. Engineering Journal, 22(1), 175. https://doi.org/10.4186/ej.2018.22.1.175

Jian-Tong, D., Pei-Yu, Y., Shu-Lin, L., & **-Quan, Z. (1999). Extreme vertices design of concrete with combined mineral admixtures. Cement and Concrete Research, 29(6), 957–960. https://doi.org/10.1016/S0008-8846(99)00069-1

Cornell, J. A. (2011). Experiments with mixtures: Designs, models and the analysis of mixture data. (3rd ed.). John Wiley & Sons.

McLean, R. A., & Anderson, V. L. (1966). Extreme vertices design of mixture experiments. Technometrics, 8(3), 447–454. https://doi.org/10.1080/00401706.1966.10490377

Scheffé, H. (1963). The simplex-centroid design for experiments with mixtures. Journal of the Royal Statistical Society: Series B, 25, 235–263

Segad, M., Jönsson, B., Åkesson, T., & Cabane, B. (2010). Ca/Na montmorillonite: Structure, forces and swelling properties. American Chemical Society, Langmuir, 26(8), 5782–5790. https://doi.org/10.1021/la9036293

British Standard (BS) 1377. (1990). Method of testing soils for civil engineering purpose. British Standards Institution, London.

British Standard (BS) 1924. (1990). Method of testing for stabilized soils. British Standard Institution, London.

Chen, F. H. (1988). Foundations on expansive soils. (2nd ed.). Elsevier Services Publications.

Onyelowe, K. C. (2017). Mathematical advances in soil bearing capacity. Electronic Journal of Geotechnical Engineering, 22(12), 4735–4743

Onyelowe, K. C., Alaneme, G. U., Igboayaka, C., Orji, F., Ugwuanyi, H., Van Bui, D., & Van Nguyen, M. (2019). Scheffe optimization of swelling California bearing ratio, compressive strength, and durability potentials of quarry dust stabilized soft clay soil. Materials Science for Energy Technologies, 2(1), 67–77. https://doi.org/10.1016/j.mset.2018.10.005

Alaneme, G. U., & Mbadike, E. M. (2019). Optimization of flexural strength of palm nut fibre concrete using Scheffe’s theory. Materials Science for Energy Technologies, 2, 272–287. https://doi.org/10.1016/j.mset.2019.01.006

Amhadi, T. S., & Assaf, G. J. (2018). Overview of soil stabilization methods in road construction. GeoMEast, 21–33, 2019. https://doi.org/10.1007/978-3-030-01911-2_3

Eriksson, L. (2008). Design of experiments: Principles and applications. MKS Umetrics AB.

Kumar, R. G., & Sanghvi, I. (2015). Optimization techniques: An overview for formulation development. Asian Journal of Pharmaceutical Research, 5, 217–221

Schwartz, J., Merck, S., & Dohme, R. L. (1981). Optimization techniques in product formulation. Journal of the Society of Cosmetic Chemists, 32, 287–301

Design expert 11. (2018). Design of experiment software. Stat-Ease Inc.

Minitab 18. (2018). Minitab statistical software. Minitab Inc.

Snee, R. D. (1979). Experiment design for mixture systems with multicomponent constraints. Communications in Statistics – Theory and Methods, 17, 149–159

Standard Specifications for Transportation, Material and Method of Sampling and Testing. (1986). 14th Edition, American Association of State Highway and Transportation Official (AASHTO), Washington D.C.

American Standard for Testing Material. (1992). Annual book of standards Vol. 04.08. American Society for Testing and Materials.

Alaneme, G. U., Onyelowe, K. C., Onyia, M. E., Van Bui, D., Mbadike, E. M., Ezugwu, C. N., Dimonyeka, M. U., Attah, I. C., Ogbonna, C., Abel, C., Ikpa, C. C., & Udousoro, I. M. (2020). Modeling volume change properties of hydrated-lime activated rice husk ash (HARHA) modified soft soil for construction purposes by artificial neural network (ANN). Umudike Journal of Engineering and Technology, 6(1), 88–110

Warren, K. W., & Kirby, T. M. (2004). Expansive clay soil: A widespread and costly geohazard. (pp. 24–28). Geostrata: Geo-Institute of the American Society Civil Engineers.

Salahudeen, A. B., & Sadeeq, J. A. (2019). California bearing ratio prediction of modified black clay using artificial neural networks. In S. Laryea, & E. Essah (Eds.), Proceedings West Africa Built Environment Research (WABER) Conference (pp. 268–281). 5–7 August 2019 Accra: Ghana. https://doi.org/10.33796/waberconference2019.19

Brereton, R. G. (2003). Chemometrics: Data analysis for the laboratory and chemical plant. John Wiley & Sons.

Alaneme, G. U., & Mbadike, E. M. (2019). Modelling of the mechanical properties of concrete with cement ratio partially replaced by aluminium waste and sawdust ash using artificial neural network. SN Applied Sciences. https://doi.org/10.1007/s42452-019-1504-2

Atkinson, A. C., Donev, A. N., & Tobias, R. D. (2007). Optimal experimental design with SAS. Oxford University Press.

Smith, W. F. (2005). Experimental design for formulation. The American Statistical Association and the Society for Industrial and Applied Mathematics.

Shobha, R., Hiremath, R., & Vanaja, K. (2016). Optimization techniques in pharmaceutical formulation and processing. Textbook of Industrial Pharmacy. Drug Delivery Systems, Cosmetic and Herbal Drug Technology, pp. 158–168.

Borkowski, J. J. (2003). Using genetic algorithm to generate small exact response surface designs. Journal of Probability and Statistical Science, 1, 65–88

Stahle, L., & Wold, S. (1989). Analysis of variance (ANOVA). Chemometrics and Intelligent Laboratory Systems, 6, 259–272. https://doi.org/10.1155/2018/9308580

Marquardt, D. W., & Snee, R. D. (1974). Test statistics for mixture models. Technometrics, 14, 533–537

Bolton, S. (1997). Optimization techniques in pharmaceutical statistics. Practical and clinical applications. (3rd ed.). Marcel Dekker.

Cox, D. R. (1971). A note on polynomial response functions for mixtures. Biometrika, 58, 155–159. https://doi.org/10.1093/biomet/58.1.155

Box, G. E. P., & Draper, N. R. (1959). A basis for the selection of a response surface design. Journal of American Statistical Association, 54, 622–654

Damiri, S., Pouretedal, H. R., & Bakhshi, O. (2016). An extreme vertices mixture design approach to the optimization of methylal production process using p-toluenesulfonic acid as catalyst. Chemical Engineering Research and Design, 112, 155–162. https://doi.org/10.1016/j.cherd.2016.06.012

Snee, R. D., & Marquardt, D. W. (1974). Extreme vertices designs for linear mixture models. Technometrics, 16(3), 399–408

Smith, W. F. (1931). Experimental design for formulation. American Statistical Association and Society for Industrial and Applied Mathematics.

Simon, M. J., Lagergreen, E. S., & Synder, K. A. (1997). Concrete mixture optimization using statistical mixture design methods. In: Proceedings of the PCI/FHWA International symposium on high performance concrete, New Orleans, pp. 230–244.

Attah, I. C., Etim, R. K., Alaneme, G. U., & Bassey, O. B. (2020). Optimization of mechanical properties of rice husk ash concrete using Scheffe’s theory. SN Applied Science. https://doi.org/10.1007/s42452-020-2727-y

Fedorov, V. V. (1972). Theory of optimal experiments. Academic press.

Alaneme, G. U., Dimonyeka, M. U., Ezeokpube, G. C., Uzoma, I. I., & Udousoro, I. M. (2021). Failure assessment of dysfunctional flexible pavement drainage facility using fuzzy analytical hierarchical process. Innovative Infrastructure Solutions. https://doi.org/10.1007/s41062-021-00487-z

Coetzer, R., & Haines, L. M. (2017). The construction of D- and I-optimal designs for mixture experiments with linear constraints on the components. Chemometrics and Intelligent Laboratory Systems, 171, 112–124

Esbensen, K. H., Guyot, D., Westad, F., & Houmoller, L. P. (2002). Multivariate data analysis, in practice: An introduction to multivariate data analysis and experimental design. Aalborg University.

Gorman, J. W. (1970). Fitting equations to mixture data with restraints on compositions. Journal of Quality Technology, 2, 186–194

Mitchell, T. J. (1974). An algorithm for the construction of D-optimal experimental designs. Technometrics, 16, 203–210

Alaneme, G. U., Mbadike, E. M., Iro, U. I., Udousoro, I. M., & Ifejimalu, W. C. (2021). Adaptive neuro-fuzzy inference system prediction model for the mechanical behaviour of rice husk ash and periwinkle shell concrete blend for sustainable construction. Asian Journal of Civil Engineering. https://doi.org/10.1007/s42107-021-00357-0

Ozol-Godfrey, A., Anderson-Cook, C. M., & Montgomery, D. C. (2005). Fraction of design space plots for examining model robustness. Journal of Quality Technology, 37, 223–235

Ding, J. T., Yan, P. Y., Liu, S. L., & Zhu, J. Q. (1999). Extreme vertices design of concrete with combined mineral admixtures. Cement and Concrete Research, 29(6), 957–960. https://doi.org/10.1016/S0008-8846(99)00069-1

Hardin, R. H., & Sloane, N. J. A. (1993). A new approach to construction of optimal designs. Journal of Statistical and Planning Inference, 37, 339–369

Syafitri, U., Sartono, B., & Goos, P. (2015). I-optimal design of mixture experiments in the presence of ingredient availability constraints. Journal of Quality Technology, 47, 220–234

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alaneme, G.U., Attah, I.C., Etim, R.K. et al. Mechanical Properties Optimization of Soil—Cement Kiln Dust Mixture Using Extreme Vertex Design. Int. J. Pavement Res. Technol. 15, 719–750 (2022). https://doi.org/10.1007/s42947-021-00048-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-021-00048-8