Abstract

Globally, nitrogen (N) fertilizer demand is expected to reach 112 million tonnes to support food production for about 8 billion people. However, more than half of the N fertilizer is lost to the environment with impacts on air, water and soil quality, and biodiversity. Importantly, N loss to the environment contributes to greenhouse gas emissions and climate change. Nevertheless, where N fertilizer application is limited, severe depletion of soil fertility has become a major constraint to sustainable agriculture. To address the issues of low fertilizer N use efficiency (NUE), biochar-based N fertilizers (BBNFs) have been developed to reduce off-site loss and maximize crop N uptake. These products are generally made through physical mixing of biochar and N fertilizer or via coating chemical N fertilizers such as prilled urea with biochar. This review aims to describe the manufacturing processes of BBNFs, and to critically assess the effects of the products on soil properties, crop yield and N loss pathways.

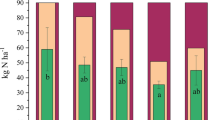

Graphical Abstract

Highlights

-

A comprehensive review of technology has been undertaken from biochar-based nitrogen fertilizers (BBNFs).

-

Kinetics and mechanisms of the slow-release of N from BBNFs are revealed.

-

BBNFs enhanced soil properties, N retention in soil and crop yield, and improved N use efficiency.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

For most agricultural systems, nitrogen (N) is the most limiting nutrient for productivity, thus compromising economic sustainability. To address this limitation, synthetic N fertilizers are applied to about 135 million Ha of agricultural land. However, these synthetic N inputs also have a range of environmental consequences including the contamination of groundwater resources (Wang et al. 2019), surface water contamination leading to eutrophication (Ayele and Atlabachew 2021), damage to reefs (Lapointe et al. 2019), gaseous losses contributing to acid rainfall (Penuelas et al. 2020) and greenhouse gas emissions (Puga et al. 2020). It has been reported that about 50 million tonnes of reactive N are released per year into the environment (Bodirsky et al. 2014).

Nitrogen use efficiency (NUE) has been broadly defined as the amount of fertilizer N that is utilized by plants in both the current and subsequent seasons (Hirose 2011). Delivering increased NUE is of paramount importance to ensure food security for a diminished area of arable land (Zhang et al. 2015) while minimizing off-site environmental impacts.

One of the key strategies to achieve greater NUE is to improve the synchrony between N supply and crop demand (Fageria and Baligar 2005). Slow-release N fertilizer has been shown to achieve this outcome (Wen et al. 2017). Some novel enhanced efficiency fertilizers such as nano structured slow-release fertilizer (Gurusamy et al. 2017), slow-release fertilizer hydrogel (Ramli 2019), lignin-based controlled release fertilizer (Chen et al. 2020a, b), brown coal based slow-release N fertilizer (Saha et al. 2021), and carbon-based slow-release fertilizer (Rashid et al. 2021), have shown benefits to crop production with lower impacts on the environment.

While the production and environmental benefits of enhanced efficiency N fertilizers (EENFs) are well demonstrated, the economic efficiency should also be taken into consideration. There is a paucity of information on the economic costs or benefits of EENFs, however, Khakbazan et al. (2013) have shown that the controlled release urea products typically have a lower net revenue of production compared to conventional urea application. To address this consideration, a body of literature is emerging on the use of biochar as a cost-effective and environmentally friendly carrier for N fertilizer. Biochar is a stable carbon (C)-rich material that is highly porous with a large surface area (Bolan et al. 2022; Chen et al. 2022b), possessing many functional groups (Zhang et al. 2022). Therefore, biochar has become a versatile material for removing contaminants from water (Niazi et al. 2018; Yin et al. 2021; Chen et al. 2022a) and air (Zhang et al. 2019, 2021b), enhancing soil productivity (Li et al. 2018; Sun et al. 2019; Chen et al. 2015), sepiolite (Shi et al. 2020) and kaolin (Chen et al. 2018a) are added to help the pelletization of BBNFs and enhance the direct binding of N fertilizer to biochar. With the addition of bentonite, the mechanical strength of BBNFs can be increased and the granular structure can be protected from collapse due to the association between N–H of fertilizer and Al–OH of bentonite (Shi et al. 2020). The use of bentonite can also promote beneficial microorganisms when added to a clay loam soil (Yao et al. 2015) and contribute to higher water-holding capacity (WHC%) and water-retention (Wen et al. 2017). Moreover, Wen et al. (2017) found that lamellar bentonite could be exfoliated to form a complicated physical network, which can further prolong the diffusion path of N release from the BBNF. The interaction between Mg-OH of sepiolite and N–H of N fertilizer was also found to be effective in reducing N leaching from BBNFs (Shi et al. 2020). Kaolin has also been used as a binding agent during pelletization of BBNFs (Chen et al. 2018a). Kaolinite in the soil can enhance the stability of biochar by reducing chemical oxidation and biological degradation, which promotes long-term C sequestration (Yang et al. 2018). Biochar can also be activated to increase its surface area or surface functional groups. In the preparation of a BBNF product, barley straw-based biochar was physically activated using CO2 and then mixed with N, P, K and micro-nutrients resulting in lower N losses from a sandy clay loam soil (by up to 63%) compared to either urea or NH4NO3 (González-Cencerrado et al. 2020).

2.2 Coating of fertilizers with biochar

Biochar coating of chemical fertilizers is a promising approach in the development of controlled release fertilizers, having been shown to limit N loss pathways and associated environmental problems (Wang et al. 2015; Naz and Sulaiman 2016). Coating of chemical N fertilizers with polymer films composited with biochar has been shown to further improve N release characteristics. Waterborne polymer (polyacrylate) (Zhou et al. 2015), waterborne copolymer (made of PVA (polyvinyl alcohol) and polyvinylpyrrolidone (PVP)) (Chen et al. 2018b), the water-retention polymer (acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid) (Wen et al. 2017), and biodegradable polymers (such as starch, and ethyl cellulose) (González et al. 2015) were applied to synthesize biochar-based polymer coating for BBNFs.

Considering the low-cost and minimal environmental impact, waterborne polymers (i.e., water-soluble) have been developed as coatings to produce BBNFs. For example, controlled release of nutrients over 12 months was achieved with the inclusion of biochar in a polyacrylate coating and the product had no significant impact on the dominant soil bacterial community (Zhou et al. 2015). Chen et al. (2018b) developed BBNFs using biochar-based waterborne copolymers to coat urea, resulting in a slow-release formulation that released 65% of the total N over 22 days. Due to the cross-linking networks between biochar and copolymers, BBNFs with biochar-based waterborne copolymer films showed low water absorbency and were more effective in retaining N than copolymers (Chen et al. 2018b). In another coating technology, biochar was mixed with humic acid, bentonite and modified starch (Dong et al. 2020). The SEM and FT-IR observations revealed that an effective dense layer was formed that slowed N release from the granule.

Water supply plays a key role in agricultural production, and thus polymers that improve soil water retention and water holding capacity can play a role in improving the functionality of BBNFs. Acrylic acid (AA), 2-acrylamide-2-methylpropanesulfonic acid (AMPS), bentonite and NH4+-loaded biochar were utilized to synthesize BBNFs. SEM analysis verified that biochar embedded in BBNFs could hold a substantial quantity of water due to its highly porous structure. The results showed BBNFs at 2% (w/w) application rate increase the water holding capacity of soil from 29 to 61%, compared to the treatment without BBNFs. Moreover, the soil without the samples lost all its absorbed water after 12 days, whereas BBNFs still retained 10.6% of the soil moisture on the 30th day (Wen et al. 2017). It should be noted, however, that most of the reported biochar-based BBNFs can only marginally change soil water retention. Therefore, the development of biochar-based BBNFs with high water retention represents a significant opportunity.

Another formulation of BBNF was produced whereby biochar was impregnated by urea in a batch reactor (150 ± 5 °C) at atmospheric pressure and then encapsulated using biodegradable polymers including sodium alginate (SA), cellulose acetate (CA) and ethyl cellulose (EC) (González et al. 2015). For soil columns planted with wheat, leaching of urea-N was greatest with urea (4.1 mg/kg dry soil) while BBNF lowered this to 2.4 mg/kg (dry soil). The BBNF products were shown to retard urea hydrolysis, another mechanism that may explain the higher NUE.

2.3 Exploitation of sorptive properties of biochar

Porosity and reactive surfaces contribute to the adsorptive nature of biochar, which have been exploited to develop controlled release fertilizer formulations. Various articles describe processes such as solid liquid adsorption and infiltration to develop these products.

For example, Khan et al. (2008) fabricated BBNF by placing charcoal in a rotary vacuum evaporator with N fertilizer solution and then rotating for 24 h at 100 °C. This resulted in a BBNF with a significantly retarded release of N into soil leachate. A similar BBNF preparation method using biochar pyrolyzed at 200 °C and (NH4)2SO4 showed that more than 90% of the NH4+ was retained after a 21-day desorption experiment (Cai et al. 2016). Biochar made from rice husks was put into urea-hydrogen peroxide (UHP) solution to prepare BBNFs via an adsorption method. As compared to urea, more C–O and C=O groups could be obtained in the products due to the oxidation of carbonized surfaces by H2O2, contributing to the improved slow-release of N (Chen et al. 2018a). A BBNF (An et al. 2020) was made by incorporating biochar into semi-interpenetrating polymer networks through graft co-polymerization with superabsorbent hydrogels. The product exhibited a high water-retention capacity of 73% after 25 days, which was far greater than fertilizer without the incorporation of biochar. It showed the incorporation of biochar can significantly improve the pore structure of BBNFs and create more cross-linking points.

In another approach, molten urea (about 155 °C) was used as both a binder and N source to synthesize BBNFs (** more effective enhanced biochar fertilisers for improvement of pepper yield and quality. Pedosphere 25:703–712. https://doi.org/10.1016/S1002-0160(15)30051-5 " href="/article/10.1007/s42773-022-00160-3#ref-CR87" id="ref-link-section-d277406080e3186">2015). Even with a 20% reduction of fertilization application, the biomass of vegetable (oilseed rape) obtained was higher (about 10%) under BBNF treatment compared to urea treatment (Jia et al. 2021). When maize yield was normalized by mass of N fertilizers (N agronomic efficiency, AEN), the improvement observed with BBNFs was further increased to above 40% (Zheng et al. 2017). An increased tea yield (10%) was also achieved with the application of BBNFs (He et al. 2019).

In addition to crop yield, other plant growth processes such as germination rate and seedling growth parameters could also be enhanced by BBNFs. Cottonseed treated with BBNFs showed a higher germination rate (about 94%) than that treated with NH4Cl (about 84%) (Wen et al. 2017). On the other hand, turnip germination rate was lowered (Amaro et al. 2016). Further studies are required to determine the key effects of BBNFs on plant seed germination.

It is reported that the biomass and crop yield generally increased with the application of BBNFs to the soil, while belowground productivity exhibited no significant response to biochar addition, according to a meta-analysis (Biederman and Harpole 2013). The root length of cotton plants under BBNF treatments increased by 26% compared to the use of NH4Cl (Wen et al. 2017). Similarly, the biomass and volume of roots—under BBNFs increased by 26% and 38%, increased, compared to the use of related to urea fertilizers, possibly indicating enhanced plant growth in dryland agriculture (Shi et al. 2020) and under drought conditions (Bruun et al. 2014; Li and Tan 2021). Significantly less N fertilizer (58 kg N/t grain) was consumed in the BBNF treatments than conventional inorganic compound fertilizers (85 kg N/t grain), implying a higher plant NUE, lower N pollution, and higher economic output (Zheng et al. 2017).

5 Conclusions and perspectives

While there is strong evidence that BBNFs can improve N use efficiency, there is still a need for an improved understanding of their optimal application rates, and how these affect their economic feasibility compared to conventional fertilizers. Across about 20 studies in the literature, BBNFs showed 15–69% delay in cumulative N release and 25–65% improvement in fertilizer use efficiency over traditional chemical fertilizers. The future challenge is to enhance the N efficiency of BBNFs, with the associated reduction in environmental pollution, while maintaining their cost-effectiveness by minimizing cost of their production.

There are several mechanisms by which BBNFs can improve nutrient use efficiency and lower fertilizer N loss to the environment. Modelling approaches to understand the kinetics of fertilizer nutrient release, as well as additional studies using isotope techniques will allow a detailed understanding of the benefits of BBNFs. By linking this knowledge with an understanding of soil properties, crop fertilizers demand, and climate (rainfall and temperature) forecasts for the season, it may be possible to produce BBNFs formulations to provide optimum N release characteristics for a specific crops and environments. Essentially, it is better to design BBNFs based on the optimal N absorption rate by crops or plants to keep balance between N release rate and N absorption. Further work is required to establish the relationship between N-release control of BBNFs and N absorption by plants. The long-term effects of large-scale application of BBNFs on the environment, and the corresponding ecological risks to biodiversity and ecosystem balance also require consideration. In conclusion, evidence suggests that BBNFs can result in improved fertilizer use efficiency, while providing other benefits to soil, such as increasing SOC. The use of biochar as a carrier for fertilizers will have other benefits compared to conventional polymer coating, especially related to avoiding the entry of plastics and microplastics into the environment.

This review shows that BBNFs possess considerable potential as improved N fertilizers. The contribution of BBNFs to sustainable agriculture includes economic benefits, and reduced energy consumption and greenhouse gas emissions. Although some biochar modification methods seem to be very costly, BBNFs may still be economically feasible due to the relatively low mass fraction of biochar in BBNFs (~ 29%) (Jia et al. 2020), increased economic output (Cen et al. 2021), and ecological and economic benefits arising from lowered eutrophication. Biochar systems could deliver emission reductions of 3.4–6.3 PgCO2e (Lehmann et al. 2021), partly due to the energy gained during biochar production and also the stable C stored in soil. This could be further enhanced through other greenhouse gas (GHG) benefits when introduced into BBNFs. The GHG intensity can be effectively reduced (e.g., 10 kg CO2-eq emission per ton maize grain) after replacing chemical fertilizer with BBNF (Zheng et al. 2017). Roberts et al. (2010) estimated the energy, climate change impacts and the economics of biochar systems by life cycle assessment (LCA). They found that biochar returned to the soil could reduce 800–900 kg CO2 equivalent emissions per tonne of dry feedstock pyrolyzed. Using an LCA approach, González-Cencerrado et al. (2020) showed that BBNFs compared to conventional fertilizers have the lowest impact on acidification, terrestrial and aquatic eutrophication. Thus, the use of BBNFs has the potential to contribute to carbon sequestration, reduced N use and increased farmer income. Our review has highlighted the key benefits and challenges related to the development of enhanced efficiency N fertilizers based on biochar technologies. A framework for the systematic assessment of new products will allow the technology to be fast-tracked to commercial adoption, which will facilitate a wide range of economic and environmental benefits, including the broader goal of carbon neutrality in primary industries.

Availability of data and materials

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Amaro A, Bastos AC, Santos MJG, Verheijen FGA, Soares AMVM, Loureiro S (2016) Ecotoxicological assessment of a biochar-based organic N-fertilizer in small-scale terrestrial ecosystem models (STEMs). Appl Soil Ecol 108:361–370. https://doi.org/10.1016/j.apsoil.2016.09.006

An XF, Yu JL, Yu JZ, Tahmasebi A, Wu ZS, Liu XC, Yu B (2020) Incorporation of biochar into semi-interpenetrating polymer networks through graft co-polymerization for the synthesis of new slow-release fertilizers. J Clean Prod 272:122731. https://doi.org/10.1016/j.jclepro.2020.122731

Ayele HS, Atlabachew M (2021) Review of characterization, factors, impacts, and solutions of Lake eutrophication: lesson for lake Tana, Ethiopia. Environ Sci Pollut Res 28:14233–14252. https://doi.org/10.1007/s11356-020-12081-4

Basak BB, Sarkar B, Saha A, Sarkar A, Mandal S, Biswas JK, Wang H, Bolan NS (2022) Revam** highly weathered soils in the tropics with biochar application: what we know and what is needed. Sci Total Environ 822:153461. https://doi.org/10.1016/j.scitotenv.2022.153461

Biederman LA, Harpole WS (2013) Biochar and its effects on plant productivity and nutrient cycling: a meta-analysis. GCB Bioenergy 5:202–214. https://doi.org/10.1111/gcbb.12037

Bodirsky BL, Popp A, Lotze-Campen H, Dietrich JP, Rolinski S, Weindl I, Schmitz C, Müller C, Bonsch M, Humpenöder F, Biewald A, Stevanovic M (2014) Reactive nitrogen requirements to feed the world in 2050 and potential to mitigate nitrogen pollution. Nat Commun 5:3858. https://doi.org/10.1038/ncomms4858

Bolan N, Hoang SA, Beiyuan J, Gupta S, Hou D, Karakoti A, Joseph S, Jung S, Kim K-H, Kirkham MB, Kua HW, Kumar M, Kwon EE, Ok YS, Perera V, Rinklebe J, Shaheen SM, Sarkar B, Sarmah AK, Singh BP, Singh G, Tsang DCW, Vikrant K, Vithanage M, Vinu A, Wang H, Wijesekara H, Yan Y, Younis SA, Van Zwieten L (2022) Multifunctional applications of biochar beyond carbon storage. Int Mater Rev 67(2):150–200. https://doi.org/10.1080/09506608.2021.1922047

Brentrup F, Küsters J, Lammel J, Kuhlmann H (2000) Methods to estimate on-field nitrogen emissions from crop production as an input to LCA studies in the agricultural sector. Int J Life Cycle Assess 5:349. https://doi.org/10.1007/BF02978670

Bruun EW, Petersen CT, Hansen E, Holm JK, Hauggaard-Nielsen H (2014) Biochar amendment to coarse sandy subsoil improves root growth and increases water retention. Soil Use Manage 30:109–118. https://doi.org/10.1111/sum.12102

Cai Y, Qi H, Liu Y, He X (2016) Sorption/desorption behavior and mechanism of NH4+ by biochar as a nitrogen fertilizer sustained-release material. J Agric Food Chem 64:4958–4964. https://doi.org/10.1021/acs.jafc.6b00109

Cayuela ML, Jeffery S, van Zwieten L (2015) The molar H:Corg ratio of biochar is a key factor in mitigating N2O emissions from soil. Agric Ecosyst Environ 202:135–138. https://doi.org/10.1016/j.agee.2014.12.015

Cen Z, Wei L, Muthukumarappan K, Sobhan A, Mcdaniel R (2021) Assessment of a biochar-based controlled release nitrogen fertilizer coated with polylactic acid. J Soil Sci Plant Nut 21:2007–2019. https://doi.org/10.1007/s42729-021-00497-x

Chen L, Chen QC, Rao PH, Yan LL, Shakib A, Shen GQ (2018a) Formulating and optimizing a novel biochar-based fertilizer for simultaneous slow-release of nitrogen and immobilization of cadmium. Sustainability 10:2740. https://doi.org/10.3390/su10082740

Chen S, Yang M, Ba C, Yu S, Jiang Y, Zou H, Zhang Y (2018b) Preparation and characterization of slow-release fertilizer encapsulated by biochar-based waterborne copolymers. Sci Total Environ 615:431–437. https://doi.org/10.1016/j.scitotenv.2017.09.209

Chen W, Meng J, Han X, Lan Y, Zhang W (2019a) Past, present, and future of biochar. Biochar 1:75–87. https://doi.org/10.1007/s42773-019-00008-3

Chen Y, Jiang Z, Wu D, Wang H, Li J, Bi M, Zhang Y (2019b) Development of a novel bio-organic fertilizer for the removal of atrazine in soil. J Environ Manage 233:553–560. https://doi.org/10.1016/j.jenvman.2018.12.086

Chen H, Yang X, Wang H, Sarkar B, Shaheen SM, Gielen G, Bolan N, Guo J, Che L, Sun H, Rinklebe J (2020a) Animal carcass- and wood-derived biochars improved nutrient bioavailability, enzyme activity, and plant growth in metal-phthalic acid ester co-contaminated soils: a trial for reclamation and improvement of degraded soils. J Environ Manage 261:110246. https://doi.org/10.1016/j.jenvman.2020.110246

Chen J, Fan X, Zhang L, Chen X, Sun S, Sun RC (2020b) Research progress in lignin-based slow/controlled release fertilizer. Chemsuschem 13:4356–4366. https://doi.org/10.1002/cssc.202000455

Chen H, Gao Y, El-Naggar A, Niazi NK, Sun C, Shaheen SM, Hou D, Yang X, Tang Z, Liu Z, Hou H, Chen W, Rinklebe J, Pohořelý M, Wang H (2022a) Enhanced sorption of trivalent antimony by chitosan-loaded biochar in aqueous solutions: characterization, performance and mechanisms. J Hazard Mater 425:127971. https://doi.org/10.1016/j.jhazmat.2021.127971

Chen H, Gao Y, Li J, Fang Z, Bolan NS, Bhatnagar A, Gao B, Hou DY, Wang SS, Song H, Yang X, Shaheen SM, Meng J, Chen W, Rinklebe J, Wang H (2022b) Engineered biochar for environmental decontamination in aquatic and soil systems: a review. Carbon Res. https://doi.org/10.1007/s44246-022-00005-5

Chen Q, Lan P, Wu M, Lu M, Pan B, **ng B (2022c) Biochar mitigates allelopathy through regulating allelochemical generation from plants and accumulation in soil. Carbon Res. https://doi.org/10.1007/s44246-022-00003-7

Cui Z, Chen X, Zhang F (2010) Current nitrogen management status and measures to improve the intensive Wheat-Maize system in China. AMBIO 39(5–6):376–384. https://doi.org/10.1007/s13280-010-0076-6

Domene X, Mattana S, Hanley K, Enders A, Lehmann J (2014) Medium-term effects of corn biochar addition on soil biota activities and functions in a temperate soil cropped to corn. Soil Biol Biochem 72:152–162. https://doi.org/10.1016/j.soilbio.2014.01.035

Dong D, Wang C, Van Zwieten L, Wang H, Jiang P, Zhou M, Wu W (2020) An effective biochar-based slow-release fertilizer for reducing nitrogen loss in paddy fields. J Soils Sediments 20(8):3027–3040. https://doi.org/10.1007/s11368-019-02401-8

El Sharkawi HM, Tojo S, Chosa T, Malhat FM, Youssef AM (2018) Biochar-ammonium phosphate as an uncoated-slow release fertilizer in sandy soil. Biomass Bioenergy 117:154–160. https://doi.org/10.1016/j.biombioe.2018.07.007

Fageria NK, Baligar VC (2005) Enhancing nitrogen use efficiency in crop plants. Adv Agron 88:97–185. https://doi.org/10.1016/S0065-2113(05)88004-6

Fang Z, Hu Y, Wu X, Qin Y, Cheng J, Chen Y, Tan P, Li H (2018) A novel magnesium ascorbyl phosphate graphene-based monolith and its superior adsorption capability for bisphenol A. Chem Eng J 334:948–956. https://doi.org/10.1016/j.cej.2017.10.067

González ME, Cea M, Medina J, González A, Diez MC, Cartes P, Monreal C, Navia R (2015) Evaluation of biodegradable polymers as encapsulating agents for the development of a urea controlled-release fertilizer using biochar as support material. Sci Total Environ 505:446–453. https://doi.org/10.1016/j.scitotenv.2014.10.014

González-Cencerrado A, Ranz JP, Jiménez MTL, Gajardo BR (2020) Assessing the environmental benefit of a new fertilizer based on activated biochar applied to cereal crops. Sci Total Environ 711:134668. https://doi.org/10.1016/j.scitotenv.2019.134668

Grutzmacher P, Puga AP, Bibar MPS, Coscione AR, Packer AP, Andrade CA (2018) Carbon stability and fertilizer induced N2O emissions mitigation in soil treated with biochar. Sci Total Environ 625:1459–1466. https://doi.org/10.1016/j.scitotenv.2017.12.196

Gurusamy UM, Rajan R, Sundaram VB, Selvaraj RCA, Mala R (2017) Evaluation of nano structured slow release fertilizer on the soil fertility, yield and nutritional profile of Vigna radiata. Recent Pat Nanotechnol 11:50–62. https://doi.org/10.2174/1872210510666160727093554

Harter J, Krause HM, Schuettler S, Ruser R, Fromme M, Scholten T, Kappler A, Behrens S (2014) Linking N2O emissions from biochar-amended soil to the structure and function of the N-cycling microbial community. ISME J 8:660–674. https://doi.org/10.1038/ismej.2013.160

He T, Yuan J, Luo J, Liu D, Wang W (2019) Organic fertilizers have divergent effects on soil N2O emissions. Biol Fertil Soils 55:685–699. https://doi.org/10.1007/s00374-019-01385-4

Hirose T (2011) Nitrogen use efficiency revisited. Oecologia 166:863–867. https://doi.org/10.1007/s00442-011-1942-z

Hossain MZ, Bahar MM, Sarkar B, Donne SW, Ok YS, Palansooriya KN, Kirkham MB, Chowdhury S, Bolan N (2020) Biochar and its importance on nutrient dynamics in soil and plant. Biochar 2(4):379–420. https://doi.org/10.1007/s42773-020-00065-z

Jia Y, Hu Z, Mu J, Zhang W, **e Z, Wang G (2020) Preparation of biochar as a coating material for biochar-coated urea. Sci Total Environ 731:139063. https://doi.org/10.1016/j.scitotenv.2020.139063

Jia YM, Hu ZY, Ba YX, Qi WF (2021) Application of biochar-coated urea controlled loss of fertilizer nitrogen and increased nitrogen use efficiency. Chem Biol Technol Agric 8:3. https://doi.org/10.1186/s40538-020-00205-4

Keller A, Steiger BV, Zee S, Schulin R (2001) A stochastic empirical model for regional heavy-metal balances in agroecosystems. J Environ Qual 30:1976–1989. https://doi.org/10.2134/jeq2001.1976

Khajavi-Shojaei S, Moezzi A, Norouzi M, Taghavi M (2020) Synthesis modified biochar-based slow-release nitrogen fertilizer increases nitrogen use efficiency and corn (Zea mays L.) growth. Biomass Convers Bioref 10:10. https://doi.org/10.1007/s13399-020-01137-7

Khakbazan M, Grant CA, Finlay G, Wu R, Harker KN (2013) An economic study of controlled release urea and split applications of nitrogen as compared with non-coated urea under conventional and reduced tillage management. Can J Plant Sci 93:523–534. https://doi.org/10.4141/CJPS2012-107

Khan MA, Kim KW, Wang M, Lim BK, Lee WH, Lee JY (2008) Nutrient-impregnated charcoal: an environmentally friendly slow-release fertilizer. Environmentalist 28:231–235. https://doi.org/10.1007/s10669-007-9133-5

Lapointe BE, Brewton RA, Herren LW, Porter JW, Hu C (2019) Nitrogen enrichment, altered stoichiometry, and coral reef decline at Looe Key, Florida Keys, USA: a 3-decade study. Mar Biol 166:108. https://doi.org/10.1007/s00227-019-3538-9

Lee JW, Hawkins B, Li X, Day DM (2013) Biochar fertilizer for soil amendment and carbon sequestration. In: Advanced biofuels and bioproducts, Springer, New York, pp 57–68

Lehmann J, Cowie A, Masiello CA, Kammann C, Woolf D, Amonette JE, Cayuela ML, Camps-Arbestain M, Whitman T (2021) Biochar in climate change mitigation. Nat Geosci 14:883–892. https://doi.org/10.1038/s41561-021-00852-8

Li H, Tan ZX (2021) Preparation of high water-retaining biochar and its mechanism of alleviating drought stress in the soil and plant system. Biochar 3(4):579–590. https://doi.org/10.1007/s42773-021-00107-0

Li Y, Hu S, Chen J, Müller K, Li Y, Fu W, Lin Z, Wang H (2018) Effects of biochar application in forest ecosystems on soil properties and greenhouse gas emissions: a review. J Soils Sediments 18(2):546–563. https://doi.org/10.1007/s11368-017-1906-y

Liao JY, Liu XR, Hu A, Song HX, Zhang ZH (2020) Effects of biochar-based controlled release nitrogen fertilizer on nitrogen-use efficiency of oilseed rape (Brassica napus L.). Sci Rep-UK 10:11063. https://doi.org/10.1038/s41598-020-67528-y

Liu XR, Liao JY, Song HX, Yang Y, Guan CY, Zhang ZH (2019) A biochar-based route for environmentally friendly controlled release of nitrogen: urea-loaded biochar and bentonite composite. Sci Rep-UK 9:9548. https://doi.org/10.1038/s41598-019-46065-3

Lu K, Yang X, Shen J, Robinson B, Huang H, Liu D, Bolan N, Pei J, Wang H (2014) Effect of bamboo and rice straw biochars on the bioavailability of Cd, Cu, Pb and Zn to Sedum plumbizincicola. Agric Ecosyst Environ 191:124–132. https://doi.org/10.1016/j.agee.2014.04.010

Lu X, Li Y, Wang H, Singh BP, Hu S, Luo Y, Li J, **ao Y, Cai X, Li Y (2019) Responses of soil greenhouse gas emissions to different application rates of biochar in a subtropical Chinese chestnut plantation. Agric for Meteorol 271:168–179. https://doi.org/10.1016/j.agrformet.2019.03.001

Ma R, Zou J, Han Z, Yu K, Wu S, Li ZF, Liu SW, Niu SL, Horwath WR, Zhu-Barker X (2021) Global soil-derived ammonia emissions from agricultural nitrogen fertilizer application: a refinement based on regional and crop-specific emission factors. Glob Change Biol 27:855–867. https://doi.org/10.1111/gcb.15437

Mandal S, Donner E, Vasileiadis S, Skinner W, Smith E, Lombi E (2018) The effect of biochar feedstock, pyrolysis temperature, and application rate on the reduction of ammonia volatilisation from biochar-amended soil. Sci Total Environ 627:942–950. https://doi.org/10.1016/j.scitotenv.2018.01.312

Naz MY, Sulaiman SA (2016) Slow release coating remedy for nitrogen loss from conventional urea: a review. J Control Release 225:109–120. https://doi.org/10.1016/j.jconrel.2016.01.037

Nguyen T, Xu CY, Tahmasbian I, Che R, Xu Z, Zhou X, Wallace HM, Bai SH (2017) Effects of biochar on soil available inorganic nitrogen: a review and meta-analysis. Geoderma 288:79–96. https://doi.org/10.1016/j.geoderma.2016.11.004

Niazi NK, Bibi I, Shahid M, Ok YS, Shaheen SM, Rinklebe J, Wang H, Murtaza B, Islam E, Farrakh Nawaz M, Lüttge A (2018) Arsenic removal by Japanese oak wood biochar in aqueous solutions and well water: investigating arsenic fate using integrated spectroscopic and microscopic techniques. Sci Total Environ 621:1642–1651. https://doi.org/10.1016/j.scitotenv.2017.10.063

Nie T, Yang X, Chen H, Müller K, Shaheen SM, Rinklebe J, Song H, Xu S, Wu F, Wang H (2021) Effect of biochar aging and co-existence of diethyl phthalate on the mono-sorption of cadmium and zinc to biochar-treated soils. J Hazard Mater 408:124850. https://doi.org/10.1016/j.jhazmat.2020.124850

Oh TK, Shinogi Y, Lee SJ, Choi BS (2014) Utilization of biochar impregnated with anaerobically digested slurry as slow-release fertilizer. J Plant Nutr Soil Sci 177:97–103. https://doi.org/10.1002/jpln.201200487

Oladele S, Adeyemo A, Adegaiye A, Awodun M (2019) Effects of biochar amendment and nitrogen fertilization on soil microbial biomass pools in an Alfisol under rain-fed rice cultivation. Biochar 1(2):163–176. https://doi.org/10.1007/s42773-019-00017-2

Pan H, Yang X, Chen H, Sarkar B, Bolan N, Shaheen SM, Wu F, Che L, Ma Y, Rinklebe J, Wang H (2021) Pristine and iron-engineered animal- and plant-derived biochars enhanced bacterial abundance and immobilized arsenic and lead in a contaminated soil. Sci Total Environ 763:144218. https://doi.org/10.1016/j.scitotenv.2020.144218

Park MH, Jeong S, Kim JY (2019) Adsorption of NH3-N onto rice straw-derived biochar. J Environ Chem Eng 7:103039. https://doi.org/10.1016/j.jece.2019.103039

Peng JH, Zhang L, Meulien ES, Bi XTT, Lim JC, Chen WH (2021) Waste plastics as an effective binder for biochar pelletization. Energ Fuel 35(17):13840–13846. https://doi.org/10.1021/acs.energyfuels.1c01884

Penuelas J, Gargallo-Garriga A, Jannssens I, Ciais P, Obersteiner M, Klem K, Urban O, Sardans J (2020) Could global intensification of nitrogen fertilisation increase immunogenic proteins and favour the spread of coeliac pathology? Foods 9:1602. https://doi.org/10.2139/ssrn.3463292

Puga AP, Queiroz MCD, Ligo MAV, Carvalho CS, Pires AMM, Marcatto JDO, Andrade CAD (2019) Nitrogen availability and ammonia volatilization in biochar-based fertilizers. Arch Agron Soil Sci 66:992–1004. https://doi.org/10.1080/03650340.2019.1650916

Puga AP, Grutzmacher P, Cerri C, Ribeirinho VS, Andrade C (2020) Biochar-based nitrogen fertilizers: greenhouse gas emissions, use efficiency, and maize yield in tropical soils. Sci Total Environ 704:135375. https://doi.org/10.1016/j.scitotenv.2019.135375

Qian L, Chen L, Joseph S, Pan GX, Li LQ, Zheng JW, Zhang XH, Zheng JF, Yu XY, Wang JF (2014) Biochar compound fertilizer as an option to reach high productivity but low carbon intensity in rice agriculture of China. Carbon Manag 5:145–154. https://doi.org/10.1080/17583004.2014.912866

Qin P, Wang H, Yang X, He L, Müller K, Shaheen SM, Xu S, Rinklebe J, Tsang DCW, Ok YS, Bolan N, Song Z, Che L, Xu X (2018) Bamboo- and pig-derived biochars reduce leaching losses of dibutyl phthalate, cadmium, and lead from co-contaminated soils. Chemosphere 198:450–459. https://doi.org/10.1016/j.chemosphere.2018.01.162

Ramli RA (2019) Slow release fertilizer hydrogels: a review. Polym Chem-UK 10:6073–6090. https://doi.org/10.1039/C9PY01036J

Rashid M, Hussain Q, Khan KS, Alwabel MI, Hayat R, Akmal M, Ijaz SS, Alvi S (2021) Carbon-based slow-release fertilizers for efficient nutrient management: synthesis, applications, and future research needs. J Soil Scie Plant Nutr 21:1144–1169. https://doi.org/10.1007/s42729-021-00429-9

Ravishankara AR, Daniel JS, Portmann RW (2009) Nitrous oxide (N2O): the dominant ozone-depleting substance emitted in the 21st century. Science 326:123–125. https://doi.org/10.1126/science.1176985

Roberts K, Gloy BA, Joseph S, Scott NR, Lehmann J (2010) Life cycle assessment of biochar systems: estimating the energetic, economic, and climate change potential. Environ Sci Technol 44:827–833. https://doi.org/10.1021/es902266r

Saha BK, Rose MT, Van Zwieten L, Wong VNL, Patti AF (2021) Slow release brown coal-urea fertilizer potentially influences greenhouse gas emissions, nitrogen use efficiency, and sweet corn yield in oxisol. ACS Agric Sci Technol 1(5):469–478. https://doi.org/10.1021/acsagscitech.1c00082

Shi YL, Liu XR, Zhang QW (2019) Effects of combined biochar and organic fertilizer on nitrous oxide fluxes and the related nitrifier and denitrifier communities in a saline-alkali soil. Sci Total Environ 686:199–211. https://doi.org/10.1016/j.scitotenv.2019.05.394

Shi W, Ju YY, Bian RJ, Li L, Pan G (2020) Biochar bound urea boosts plant growth and reduces nitrogen leaching. Sci Total Environ 701:134424. https://doi.org/10.1016/j.scitotenv.2019.134424

Siedt M, Schaeffer A, Smith KEC, Nabel M, Nickoll MR, Dongen JT (2021) Comparing straw, compost, and biochar regarding their suitability as agricultural soil amendments to affect soil structure, nutrient leaching, microbial communities, and the fate of pesticides. Sci Total Environ 751:141607. https://doi.org/10.1016/j.scitotenv.2020.141607

Song Y, Li Y, Cai Y, Fu S, Luo Y, Wang H, Liang C, Lin Z, Hu S, Li Y, Chang SX (2019) Biochar decreases soil N2O emissions in Moso bamboo plantations through decreasing labile N concentrations, N-cycling enzyme activities and nitrification/denitrification rates. Geoderma 348:135–145. https://doi.org/10.1016/j.geoderma.2019.04.025

Steiner C, Das KC, Melear N, Lakly D (2010) Reducing nitrogen loss during poultry litter composting using biochar. J Environ Qual 39(4):1236. https://doi.org/10.2134/jeq2009.0337

Sun H, Dan A, Feng Y, Vithanage M, Mandal S, Shaheen SM, Rinklebe J, Shi W, Wang H (2019) Floating duckweed mitigated ammonia volatilization and increased grain yield and nitrogen use efficiency of rice in biochar amended paddy soils. Chemosphere 237:124532. https://doi.org/10.1016/j.chemosphere.2019.124532

Sun H, Zhang Y, Yang Y, Chen Y, Jeyakumar P, Shao Q, Zhou Y, Ma M, Zhu R, Qian Q, Fan Y, **ang S, Zhai N, Li Y, Zhao Q, Wang H (2021) Effect of biofertilizer and wheat straw biochar application on nitrous oxide emission and ammonia volatilization from paddy soil. Environ Pollut 275:116640. https://doi.org/10.1016/j.envpol.2021.116640

Wang Z, Zheng H, Luo Y, Deng X, Herbert S, **ng B (2013) Characterization and influence of biochars on nitrous oxide emission from agricultural soil. Environ Pollut 174:289–296. https://doi.org/10.1016/j.envpol.2012.12.003

Wang HH, Zheng-Yi HU, Zhu XQ (2015) Comparison of nitrogen loss after biochar coated urea and common urea fertilization in vegetable soil at Chaihe catchment of Dianchi Lake. J Anhui Agric Sci 43:104–107. https://doi.org/10.1111/gcb.14514

Wang Y, Ying H, Yin Y, Zheng H, Cui Z (2019) Estimating soil nitrate leaching of nitrogen fertilizer from global meta-analysis. Sci Total Environ 657:96–102. https://doi.org/10.1016/j.scitotenv.2018.12.029

Wen P, Wu Z, Han Y, Cravotto G, Wang J, Ye BC (2017) Microwave-assisted synthesis of a novel biochar-based slow-release nitrogen fertilizer with enhanced water-retention capacity. ACS Sustain Chem Eng 5:7374–7382. https://doi.org/10.1021/acssuschemeng.7b01721

**ang AH, Qi RY, Wang MF, Zhang K, Jiang EC, Ren YZ, Hu ZW (2020) Study on the infiltration mechanism of molten urea and biochar for a novel fertilizer preparation. Ind Crop Prod 153:112558. https://doi.org/10.1016/j.indcrop.2020.112558

Yang F, Xu Z, Yu L, Gao B, Xu XY, Zhao L, Cao XD (2018) Kaolinite enhances the stability of the dissolvable and undissolvable fractions of biochar via different mechanisms. Environ Sci Technol 52:8321–8329. https://doi.org/10.1021/acs.est.8b00306

Yang X, Pan H, Shaheen SM, Wang H, Rinklebe J (2021) Immobilization of cadmium and lead using phosphorus-rich animal-derived and iron-modified plant-derived biochars under dynamic redox conditions in a paddy soil. Environ Int 156:106628. https://doi.org/10.1016/j.envint.2021.106628

Yang X, Shaheen SM, Wang J, Hou D, Ok YS, Wang S-L, Wang H, Rinklebe J (2022) Elucidating the redox-driven dynamic interactions between arsenic and iron-impregnated biochar in a paddy soil using geochemical and spectroscopic techniques. J Hazard Mater 422:126808. https://doi.org/10.1016/j.jhazmat.2021.126808

Yao C, Joseph S, Lianqing LI, Pan G, Lin Y, Munroe P, Pace B (2015) Develo** more effective enhanced biochar fertilisers for improvement of pepper yield and quality. Pedosphere 25:703–712. https://doi.org/10.1016/S1002-0160(15)30051-5

Ye ZX, Zhang LM, Huang QY, Tan ZX (2019) Development of a carbon-based slow release fertilizer treated by bio-oil coating and study on its feedback effect on farmland application. J Clean Prod 239:118085. https://doi.org/10.1016/j.jclepro.2019.118085

Yin G, Tao L, Chen X, Bolan NS, Sarkar B, Lin Q, Wang H (2021) Quantitative analysis on the mechanism of Cd2+ removal by MgCl2-modified biochar in aqueous solutions. J Hazard Mater 420:126487. https://doi.org/10.1016/j.jhazmat.2021.126487

Yoo G, Kim H, Chen J, Kim Y (2014) Effects of biochar addition on nitrogen leaching and soil structure following fertilizer application to rice paddy soil. Soil Sci Soc Am J 78:852–860. https://doi.org/10.2136/sssaj2013.05.0160

Zhang X, Davidson EA, Mauzerall DL, Searchinger TD, Dumas P, Shen Y (2015) Managing nitrogen for sustainable development. Nature 528:51–59. https://doi.org/10.1038/nature15743

Zhang W, Jiang L, Xu C, He X, Geng Z (2018) Biochar and biochar-based nitrogenous fertilizers: short-term effects on chemical properties of soils. Int J Agric Biol 20:1555–1561. https://doi.org/10.17957/IJAB/15.0669

Zhang X, Gao B, Fang J, Zou W, Dong L, Cao C, Zhang J, Li Y, Wang H (2019) Chemically activated hydrochar as an effective adsorbent for volatile organic compounds (VOCs). Chemosphere 218:680–686. https://doi.org/10.1016/j.chemosphere.2018.11.144

Zhang X, Miao X, **ang W, Zhang J, Cao C, Wang H, Hu X, Gao B (2021a) Ball milling biochar with ammonia hydroxide or hydrogen peroxide enhances its adsorption of phenyl volatile organic compounds (VOCs). J Hazard Mater 403:123540. https://doi.org/10.1016/j.jhazmat.2020.123540

Zhang X, Zheng HH, Wu J, Chen W, Chen YQ, Xuezhi G, Yang HP, Chen HP (2021b) Physicochemical and adsorption properties of biochar from biomass-based pyrolytic polygeneration: effects of biomass species and temperature. Biochar 3(4):657–670. https://doi.org/10.1007/s42773-021-00102-5

Zhang X, Wells M, Niazi NK, Bolan N, Shaheen S, Hou D, Gao B, Wang H, Rinklebe J, Wang Z (2022) Nanobiochar-rhizosphere interactions: implications for the remediation of heavy-metal contaminated soils. Environ Pollut 299:118810. https://doi.org/10.1016/j.envpol.2022.118810

Zheng J, Han J, Liu Z, **a W, Zhang X, Li L, Liu X, Bian R, Cheng K, Zheng J (2017) Biochar compound fertilizer increases nitrogen productivity and economic benefits but decreases carbon emission of maize production. Agric Ecosyst Environ 241:70–78. https://doi.org/10.1016/j.agee.2017.02.034

Zhou ZJ, Du CW, Li T, Shen YZ, Zeng Y, Du J, Zhou JM (2015) Biodegradation of a biochar-modified waterborne polyacrylate membrane coating for controlled-release fertilizer and its effects on soil bacterial community profiles. Environ Sci Pollut Res 22:8672–8682. https://doi.org/10.1007/s11356-014-4040-z

Zhou J, Qu T, Li Y, Zwieten L, Wang H, Chen J, Song X, Lin Z, Zhang X, Luo Y, Cai Y, Zhong Z (2021) Biochar-based fertilizer decreased while chemical fertilizer increased soil N2O emissions in a subtropical Moso bamboo plantation. CATENA 202:105257. https://doi.org/10.1016/j.catena.2021.105257

Zhu X, Chen B, Zhu L, **ng B (2017) Effects and mechanisms of biochar-microbe interactions in soil improvement and pollution remediation: a review. Environ Pollut 227:98–115. https://doi.org/10.1016/j.envpol.2017.04.032

Funding

This work was supported by the National Natural Science Foundation of China (21876027), Science and Technology Innovation Project Guangdong Province (2019KQNCX169), the Key Scientific and Technological Project of Foshan City, China (2120001008392), and the Science and Technology Innovation Project of Foshan, China (1920001000083).

Author information

Authors and Affiliations

Contributions

Yurong Gao: Conceptualization, data curation, investigation, writing—original draft. Zheng Fang: data curation, writing—original draft. Lukas Van Zwieten: formal analysis, writing—review and editing. Nanthi Bolan: writing—review and editing. Da Dong: writing—review and editing. Bert F. Quin: writing—review and editing. Jun Meng: writing—review and editing. Fangbai Li: writing—review and editing. Fengchang Wu: writing—review and editing. Hailong Wang: conceptualization, supervision, writing—review and editing. Wenfu Chen: conceptualization, writing—review and editing.

Corresponding authors

Ethics declarations

Competing interests

The authors have no conflicts of interest to disclose, financial or otherwise.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gao, Y., Fang, Z., Van Zwieten, L. et al. A critical review of biochar-based nitrogen fertilizers and their effects on crop production and the environment. Biochar 4, 36 (2022). https://doi.org/10.1007/s42773-022-00160-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42773-022-00160-3