Abstract

Prevention of spreading viral respiratory disease, especially in case of a pandemic such as coronavirus disease of 2019 (COVID-19), has been proved impossible without considering obligatory face mask-wearing protocols for both healthy and contaminated populations. The widespread application of face masks for long hours and almost everywhere increases the risks of bacterial growth in the warm and humid environment inside the mask. On the other hand, in the absence of antiviral agents on the surface of the mask, the virus may have a chance to stay alive and be carried to different places or even put the wearers at risk of contamination when touching or disposing the masks. In this article, the antiviral activity and mechanism of action of some of the potent metal and metal oxide nanoparticles in the role of promising virucidal agents have been reviewed, and incorporation of them in an electrospun nanofibrous structure has been considered an applicable method for the fabrication of innovative respiratory protecting materials with upgraded safety levels.

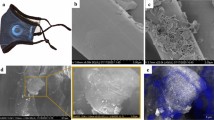

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Human coronaviruses have been considered nonlethal pathogens, which usually cause mild upper respiratory diseases and around 15% of prevalent colds [1]. However, in the past two decades, severe pneumonia and human death have been caused by two animal-transmitted coronaviruses, severe acute respiratory syndrome coronavirus (SARS-CoV) and Middle East respiratory syndrome coronavirus (MERS-CoV) [2]. And lately, in 2019, the prevalence of a novel viral disease, COVID-19, which originated from the same family and officially named after a well-known antecedent, SARS-CoV-2, based on World Health Organization (WHO), as killed over 6.04 million people and infected over 455 million people all around the world which undoubtedly has been the most catastrophic issue of human health in the twenty-first century so far.

Finally, on 12 March 2020, the WHO announced COVID-19 as the fifth recorded pandemic, after Spanish flu (H1N1) in 1918 [3], Asian flu (H2N2) in 1957 [4], Hong Kong flu (H3N2) in 1968 [5], and Swine flu Pandemic (H1N1) in 2009 [6], which respectively led to around 50 million, 1.5 million, 1 million, and 300,000 deaths.

Although the severity and mortality of COVID-19 are less than most of other epidemic coronaviruses (i.e., SARS-CoV and MERS-CoV), it is much more transmissive and can be easily spread via the virus-containing droplets originating from sneezing, coughing, exhalation, or by contacting contaminated materials [7]. The aerosol pathway cannot be neglected as the most critical and dominant way of the virus to spread [8]. Even though a majority of the population in developed and develo** countries have received vaccines, high mutation rates in the genome of COVID-19 [9] have been leading to emergence of new variants (i.e., Omicron [10]) that can cause a whole different type of symptoms, sometimes more severe and long-lasting complications, beyond the immunizing power of the vaccines which were introduced so far. Besides, there are still some unvaccinated populations due to specific beliefs or vaccine hesitancy. Therefore, wearing face masks as the first line of defense is still part of the WHO protocol and the best-recommended strategy for managing the outbreak due to the reduction of the risk of infection and preventing transmission of droplets, small carriers of respiratory viruses, either from the surroundings to the healthy wearer or from the infected wearer to the surroundings [8].

These masks mostly contain a nonwoven layer with a specific pore size to impede the passage of the pathogens, and durability of manufacturing material [11], fitness, flexibility, and comfort are the most important concepts in the design process, which subsequently impact the perception of users and their tendency for using masks [12]. Ideal air filtration materials should also be able to effectively capture the aerosol particles and allow airstream to pass through them simultaneously [13]. Substituting nanofibers for conventional filter media could be a proper approach to fulfilling the abovementioned criteria [14].

The first effort to employ electrospun nanofibers with the aim of air filtration begins in the early 1980s [15]. The outstanding properties of the nanofibers, including small fiber diameter and pore size, high porosity, interconnected pore structure [16], high ratio of surface area to volume, promising mechanical strength, and controllable morphology, are beneficial for improving filtration performance and capturing particles [17]. Besides, less resistance of the nanofibrous media to airflow leads to minimization of leakage and enhances the chance of capturing the particles without needing a perfect seal, which can reduce the exposure levels of wearers considering the case of using ordinary masks [14].

Electrospinning is the most promising technology producing high-efficiency nanofibrous air filters from a vast range of polymers that have been widely used in many fields, including disposable respirators, indoor air purifiers, cleanroom air purification systems, and automotive cabin air filters, among other devices [112].

Besides the effectivity of AgNPs in the early stages of viral infection, their anti-HIV activity in pre-infected Vero cells was reported to be potent. That’s probably because AgNPs inhibit the activity of HIV-1 after entering the host cell by disrupting viral protein functions or by direct attaching to the RNA or DNA structure and reducing the rate of reverse transcription or pro-viral transcription [113]. Furthermore, the direct attachment of AgNPs on the surface of the vaccinia virus (VACV) fusion complex is another potential mechanism of its antiviral effect [114]. Figure 4 illustrates the potential mechanism of action in the use of AgNPs as an antiviral agent.

Lara et al. reported that PVP capped AgNPs with a diameter of 30–50 nm inhibited the replication of HIV in MT-2 cells and evaluation of the viral titer in the infected cervical tissue after 48 h demonstrated that NPs in the concentration of 150 mg. L−1 offered long-lasting protection against HIV without causing any cytotoxicity in the explants. It was claimed that the interaction of AgNPs with HIV glycoproteins placed on the surface of the virus, drastically limits the fusion ability and binding of HIV into the host cells [115].

Castro-Mayorga et al. studied the effectivity of AgNPs for inactivating feline calicivirus (FCV) and murine norovirus (MNV) as the main causes of viral gastroenteritis. It was conducted by employing PHBV3 (poly (3-hydroxybutyrate-co-3-hydroxyvalerate)) films coated with electrospun PHBV18/AgNPs fiber mats to produce active biopolymers with antiviral effects, especially suitable for food preservation and medical contact surfaces. AgNPs showed dose-dependent effectiveness in decreasing FCV and MNV infectivity on CRFK cells (ATCC CCL-94) and RAW 264.7 cells, respectively, and after 24 h exposure to PHBV18/AgNP coated PHBV3 films, no infectious FCV recovered from the samples and MNV titers declined by 0.86 logs. The highest antiviral activity was achieved by employing 7 ± 3 nm-sized AgNPs in the concentration of 21 mg. L−1 [116].

** agents: PVP, a recombinant F protein from RSV (RF 412), and Bovine Serum Albumin (BSA) to study the inhibition of RSV infection in HEp-2 cells. They reported that the PVP-coated AgNPs possess the ability of binding to the RSV surface based on a regular spatial arrangement, interact with G proteins, and distribute on the RSV envelope, and claimed that the small size (4 to 8 nm) and uniformity of PVP-coated AgNPs in comparison with other forms, may cause the effectiveness of the binding. As a result, unlike the PVP-coated AgNPs with 44% inhibition, NPs which were coated by BSA or RF 412 failed to demonstrate any significant anti-RSV properties [119].

Lu et al. analyzed the ability of AgNPs to inhibit HBV replication in HepAD38 cells using different dimensions: 10, 50, and 800 nm. AgNPs with a diameter of 800 nm were determined as highly toxic to consider antiviral while particles with a diameter of 10 nm and 50 nm demonstrated potent anti-HBV activities (80% in 10 nm and 92% in 50 nm) and minimum toxicity. They also compared the inhibitory effect of 10 nm AgNPs with 10 nm AuNPs and reported the significantly higher anti-HBV activity of AgNPs compared to AuNPs [111].

Lara et al. was another research group that confirmed the anti-HIV effectivity of AgNPs at the beginning of viral replication, their ability to disrupt the entrance of the virus, and their virucidal activity. They considered a panel of viral isolates and tested 30–50 nm-sized AgNPs against them reaching the result that IC50 of AgNPs (the concentration at which infectivity was inhibited by 50%) were placed in the domain between 440 and 910 mg. L−1. They employed a human cervical tissue culture model to elucidate the anti-HIV-1 activity of AgNPs only 1 min after the topical treatment and this culture conserved its viral protection for 48 h, showing a long-lasting shielding effect of AgNPs. They claimed that AgNPs are a potent antiviral in the infections of both cell-free (clinical isolates, T and M tropic strains, laboratory strains, and resistant strains) and cell-associated viruses and still is a threat to HIV-1 after its entrance to the host cell [120].

Gaikwad et al. demonstrated the size-dependent interaction of AgNPs with HSV-1 and 2 and HPIV-3. In this study, the effect of some physicochemical characteristics of NPs on their inhibitory activity was evaluated. They synthesized AgNPs using different fungi and claimed that the system of nanoparticle production has a direct impact on its antiviral activity. AgNPs produced by C. indicum and F. oxysporum demonstrated the most potent inhibition, especially against HSV-1 and HPIV-3. Regarding the diameter impact on virucidal ability, they reported that F. oxysporum and Curvularia species-mediated AgNPs, with the diameter of 4–13 nm and 5–23 nm, respectively, demonstrated the most potent inhibition (80%–90%) against HSV-1 and HPIV-3 and had lower cytotoxicity to Vero cells. In contrast, 7–20 nm AgNPs synthesized by Alternaria and Phoma species, had less antiviral activity; so, smaller sized AgNPs were capable of inhibiting the viral replication. They also studied the zeta potential influence on antiviral effectivity. AgNPs synthesized by F. oxysporum and Curvularia species that were more stable (zeta potential = − 32.9 mV and − 22.1 mV) were reported to be more effective antivirals. Although AgNPs produced by Alternaria and Phoma possess higher zeta potential, they are weaker antiviral agents because of their larger size [110].

Elechiguerra and colleagues’ study on the mechanism of interaction between AgNPs and HIV-1, revealed the size-dependent interaction and exclusive attachment of 1–10 nm-sized AgNPs to HIV-1 and introduced the exposed sulfur-containing parts of the glycoprotein knobs of HIV-1 as attractive interaction sites with AgNPs, which inhibit the virus from attaching to the MT-2 cells by preferential attachment to the gp120 glycoprotein knobs. Elechiguerra et al. also observed different trends in HIV-1 inhibition that was because of using different cap** agents in the preparation process. BSA- and PVP-coated NPs, were reported to show less inhibitory effect since the surface of the nanoparticle was directly bonded to the cap** agents [121].

Mori et al. prepared Ag NP/chitosan formulations possessing an average diameter of 3.5, 6.5, and 12.9 nm, with anti-H1N1 activity in MDCK infected cells. Based on the test results of all the samples, anti-H1N1 activity enhanced in a dose-dependent manner with increasing AgNps concentration. They also observed a size-dependent form that AgNPs with smaller diameters were more potent antivirals [122].

Sreekanth et al. employed 5 to 15 nm-sized AgNPs synthesized by the aqueous extract of Panax ginseng roots to investigate their virucidal effects on MDCK cells against the influenza-A virus. The results showed that AgNps were slightly antiviral with an inhibition rate of 5.31%, 4.18%, and 5.97% when used in certain amounts (0.005, 0.01, and 0.15 M). In a concentration-dependent manner, by increasing the amount of AgNPs (0.02 and 0.25 M) the inhibition of H1N1 reached 7.10% and 15.12%. The toxicity assessment of all tested samples demonstrated no threat to uninfected MDCK cells [123].

Huy et al. investigated the cytotoxicity and antiviral activity of pure AgNPs towards poliovirus. AgNPs were synthesized by electrochemical method and had a quasi-spherical shape, sized around 7.1 nm, which is lesser than poliovirus particle size (25–30 nm) facilitating the mobility and free interaction of AgNPs to viral particles, impeding them to bind to host cells. After 48 h, poliovirus infected human rhabdomyosarcoma (RD) cells treated with 3.13 ppm of AgNPs demonstrated up to 98% viability and AgNPs successfully defeated all poliovirus particles. Furthermore, it was reported that the electrochemical method produced less toxic AgNPs compared to the chemical method. Interestingly, even by using 200 ppm of AgNPs, the figures for cell viability remained high: 90% at 24 h, 87% at 48 h, and 83% at 72 h [124].

The research plan of Baram-Pinto et al. was to design mercaptoethane sulfonate-capped AgNPs (Ag-MES) based on the well-known mechanism of the binding and entrance of HSV-1 into the host cells and the interaction of HS placed on the surface of the host cell with glycoproteins of HSV envelope. AgNPs, which had no toxic effects on the host cells, aim at the virus and act as a rival to bind with cellular HS, causing disruption of the viral passage and preventing the subsequent infection. The results of the plaque reduction test in Vero cells showed that HSV-1 was disabled in the presence of Ag- MES and that’s because of the multivalent nature of MES and its organized presence on the surface, which imitates HS of the host membrane and makes NPs interact with HSV-1 and prevent the infection. They also suggested using AgNP that contains numerous functional groups could be a potential way to inhibit more than one virus at a time [125].

Adenovirus type 3 (Ad3) was another target for testing the antiviral effect of AgNPs. Chen et al. revealed that AgNPs with a diameter of about 11.4 nm exhibited remarkable inhibition against Ad3 in vitro. Besides, in HeLa cells infected with AgNPs treated with Ad3 any cytopathic effect (CPE) was not visible. TEM images showed the morphologic changes in Ad3 suggesting that AgNPs altered fiber and capsid proteins and disabled them to trigger endocytosis and the rest of the infection process steps [126].

Rogers et al. ran in vitro tests to evaluate the inhibitory influence of 10–80 nm AgNPs with (Ag-PS) or without polysaccharide coating to combat monkeypox virus (MPV) infection. Among the samples, Ag-PS-25 (polysaccharide-coated, 25 nm) and Ag-NP-55 (non-coated, 55 nm) showed a significant dose-dependent influence on the mean number of plaque-forming units (PFU) and decreased them without any cytotoxicity to host cells. The 10 nm AgNPs restrained MPV infection, and the polysaccharide-coated AgNPs, 10 (AgPS-10), 25 (Ag-PS-25), and 80 (Ag-PS-80) nm nanoparticles, and Ag-PS-10 successfully reduced MPV-induced plaque formation when using in 12.5 to 100 mg. L−1. But finally, they announced 10 nm Ag-PS at all tested concentrations as the most potent anti-MPV agent causing a statistically significant decline in MPV plaque formation [127].

Speshock et al. focused on evaluating the inhibitory effects of AgNPs against TCRV from the arenavirus family. This virus could be transmitted person-to-person by aerosols. This transmission mechanism is similar to COVID-19. Surprisingly in vitro test results demonstrated a significant decline in the TCRV RNA replication and promising infection control after treatment with AgNPs, as long as it is used within the first 2 to 4 h (early phases) of virus replication. Toxicity tests showed that uncoated 10 nm AgNPs were toxic to Vero cells in concentrations higher than 50 mg. L−1 but significantly successful in declining viral production at 25 mg. L−1, while polysaccharide-coated AgNPs at 100 mg. L−1 were toxic to Vero cells, which is not a concern because 50 mg. L−1 is a perfect dose for total inhibition of TCRV replication. Therefore, the polysaccharide coating acted in favor and against the anti-TCRV efficacy of AgNPs while protecting the host from the risk of AgNPs cytotoxicity, possibly impeding the interaction of Ag and virus particles [112].

** and reducing agents [225]. For incorporation of the synthesized NPs into the nanofiber structure, they should be dispersed into the polymeric solution and carefully homogenized to be prepared for the electrospinning process. Choosing an appropriate solvent is a crucial factor for achieving a homogeneous dispersion in the electrospinning solution. The second common method includes an in-situ synthesis of metallic NPs in the electrospinning solution in which the solvent provides the necessities of the reduction process and the polymer chain acts as a stabilizing agent. After achieving a homogenized NP-containing solution, it is loaded into a syringe and will be placed in an electrospinning device in which a high voltage creates an electrically charged jet of polymer solution at the tip of the needle that in case of overcoming the surface tension of the polymer solution will cause the jet stretching out as a narrow polymeric strip which loses its solvent during the way of traveling toward the collector by vaporization and finally forms nanometer-scale metallic NPs-containing fibers [226].

Antiviral Nondimensional Materials

Takayama et al. introduced bioactive compound-loaded nanofibers as functional materials for the production of a surgical mask with antibacterial and antiviral properties. The polymeric material for fabrication of electrospun nanofibers could be selected from a group comprising: Zein, fibroin, collagen, chitosan, chitin, PVA, polyvinyl chloride, PLA, PU, nylon and methoxy methylated nylon, polyester, polystyrene, PAN, polyamide and, PET. The bioactive compound that are the main functional substances in the mask structure may consist of at least one of these natural compounds: persimmon tannin polyphenols, grape seed polyphenols, catechin polyphenols, coffee polyphenols, lemon peel polyphenols, soybean polyphenols, ellagic acid phenyl carboxylic acid and, coumalin. These compounds possess antioxidative, antibacterial, antiviral, and deodorizing effects that are ideal characteristics for a surgical mask. The preferable diameter of electrospun fibers is in the range of 1 to 2,000 nm with a weight per unit area of 0.005 g.m−2 to 10 g.m−2 and air-permeability of 1 cc.cm−2.sec−1 to 1,000 cc.cm−2.sec−1. In the process of producing each test sample, an electrospinning solution containing a mixture of the selected base polymer and the concentration of 20 wt.% bioactive compound prepared, and after the characterization of physical properties (Table 3), all samples were employed for further evaluations.

Besides, two other samples were synthesized in the form of three layer-reinforced nanofibers, one of them comprised catechin polyphenol loaded methoxy methylated nylon non-woven fabric with an average diameter of 150 nm as the base layer and catechin polyphenol-containing PU with the average size of 500 nm was employed as the reinforcing nanofiber and the weight per unit area for this sample was 0.1 g.m−2. In the second sample PVA with an average diameter of 250 nm was the substitute for methoxy methylated nylon. The results of evaluations exhibited that all fabricated samples had strong antimicrobial activity and showed potent filtration efficiency and high trap** performance of more than 99% for both fine particles bigger than 3 µm and 0.1 µm. Furthermore, the air permeability for all of the synthesized face masks was 100 cc.cm−2.s−1 or higher, which enhances the mask wearability along with antioxidative, antimicrobial, antiviral, and deodorizing effects provides favorable properties for an ideal surgical mask [227].

Gabbay invented an antiviral textile containing ionic copper particles that can be used for the production of condom sheaths, surgical gloves, and tubing. The author suggested that different types of natural (i.e., silk, cotton, wool, and linen) and synthetic fibers such as cellulose and cellulose acetate fibers, regenerated protein fibers, PU fibers, acrylic fibers, vinyl fibers, and polyolefin fibers, excluding polyester and nylon fibers, can be used for formation of the textile. After choosing the proper textile material and soaking it in a solution that contains one or more metal cationic species with two or more positive oxidation states, the activated textile will be produced. Then a reduction process needs to happen in contact with the textile leading to the production of a metalized textile.

The chosen textile material in this invention is polyamide, which contains water-insoluble ionic copper particles in powder form that supplies by adding 25 g of a mixture of CuO and Cu2O Powder yielding a 1% mixture. An in vitro antiviral test was performed to evaluate the effectivity of CuO-Cu2O impregnated fibers to inhibit the HIV-1 infection in MT-2 cells. The results exerted that 1% CuO and CuO Fibers showed 26% inhibition, while the suppression for the positive control (CuO and Cu2O powder) was 70%. Then, they impregnated a latex glove with 1% or more Cu2+ ions and after 20 min of exposure, more than 95% of the subsequent virus infectivity of lymphocytes that is known as the main target of HIV-1, was neutralized [228].

Years later Gabbay suggested a practical method of incorporating copper (II) oxide (CuO) particles with the size of 0.5 to 2 µm into the rayon fibers that are manufactured from regenerated cellulosic fiber with the aim of producing antiviral fibers. The antiviral activity of the fibers is the result of releasing Cu2+ ions in the exposure to water or water vapor. The method is comprising these steps: first, the addition of CuO particles to the rayon viscose in the amount of 0.25 and 10% of the initial cellulose dry weight, then the rayon fiber produce using an acid bath containing sulfuric acid by extruding the viscose through a spinneret into the bath, and a group of particles will place on the surface of the fibers and protruding from there. The produced fibers will exhibit antiviral properties [229].

Nanofibrous Air Filters and Face Masks

The aerosol pathway is a critical way of spreading viruses, especially for highly transmittable respiratory infections such as H1N1 [8], which is capable of changing the cluster size of the virus according to temperature, atmospheric pH, and hygroscopicity that can directly influence the movement of virus particles in the nasopharyngeal passages [230]. Furthermore, H1N1 can shape clusters with the size of 400 nm and then they grow larger in the saliva to form aerosols the size of 0.7 mm to 6 µm, which can easily spread in the environment by the change in airflow trajectory during sneezing and coughing [231]. The design process of the respiratory masks performs based on the concepts of material durability, flexibility, fit, and comfortability that theoretical models exhibited that constructing them with smooth, long, smaller than a micron, and circular cross-section fibers lead to increasing the aerosol capture efficiency [232].

Conlon claimed that integration of nanofibers in the middle layer of the mask structure even in the form of one or more discrete layers or strips of melt-blown fibers or spun bound small diameter fibers, can be formed by extruding molten thermoplastic materials and turning them into filaments, reduce the deflection of exhaled air and pressure drop, while enhancing the filtration of airborne particles, such as pathogens (Fig. 7). The author supported the abovementioned claim by performing comparative pressure drop measurements on multilayered facemasks containing non-woven fibers in the inner and outer layer, which can be made of polyethylene or PP and a nanofibrous mat with a fiber diameter of about 150 times smaller than non-woven fibers that is placed in the middle layer for filtration and may contain polytetrafluoroethylene (PTFE). The results demonstrated that the pressure drop in non-containing discrete nanofiber layers is 18 times higher, directly related to the amount of deflected air in the facemask, resulting in less airflow through the facemask. The bidirectional flow of air in nanofibrous masks was enhanced, and they also had greater filtration efficiency than other masks [233].

Electrospun nanofibers are smaller than melt-blown fibers for about 1 to 2 orders of magnitude [234] and the process of electrospinning leads to the generation of smaller micropores, increased surface area, and decreasing the weight of electrospun mat in comparison with melt-blown mat, 0.02–0.5 g.m−2 versus 5–200 g.m−2, respectively [235].

The ideal characteristics of electrospun air filtration materials including small fiber diameter and pore size, guarantee the effective particle capturing and facile passing of airstream through the filter and can be optimized by regulation of electrospinning parameters such as voltage, the distance between the needle tip and the collector, time, concentration of the polymeric solution, etc. [236].

Based on the above-mentioned criteria, Reyes et al. designed a membrane of nongrafted electrospun Nylon-6 fibers with a size of 100 to 150 nm that can be employed to capture virus-containing exhaled breath aerosols to act as a lightweight diagnostic device. The results of the aerosol capture evaluation of a uniformly thick electrospun Nylon-6 fiber membrane with the size of 15 cm × 93 cm in a simulated breathing apparatus demonstrated that they exhibited higher breath capture overall, 39 to 50% higher than commercial woven and nonwoven controls, and 60 to 95% of 0.2 mm to 6 µm sized aerosol droplets were successfully captured by the membrane due to the morphological properties of the electrospun membranes such as high surface area, smaller interfiber pores, and reduced fiber diameter, which despite their less weight (20 times less than the commercial controls) they did not rupture or degraded during the tests [237].

The electrospun nanofibrous mat exhibits great potential to be employed as High-Efficiency Particulate Air (HEPA) and Ultra Low Penetration Air (ULPA) grade filter media, by comparing the filtering efficiency of a nanofibrous mat and melt-blown nonwoven filter media. The very first trials for the formation of air filters were simple fibrous assembly using cotton, wool, and later, polyester, PP, fiberglass, and other proper materials for removing biological agents. Removing almost 99.9998% of Bacillus subtilis moving spores in the airstreams with low velocity employing slag wool with a thickness of 3 inches (7.62 cm) in the survey of Terjesen and Cherry [238], was one of the first trials in this field of air filtration. Decker et al. used a spun-glass fiber mat with a fiber diameter of less than 1.25 µm as a filter with a thickness of 0.5 inches (1.27 cm) along with an electrostatic precipitator for removing 95.7–100% of airborne viruses for removing E. coli [239].

In another survey, Staphylococcus aureus cells in the aerosolized form were retained using a single thickness glass fiber mat as the filter media, capable of holding back 98.5–98.7% of nebulized aerosols [240]. Incorporation of the cell lytic enzymes into the nanocomposites is another way of preventing pathogenic bacteria, such as surface incorporation of endolysin for inhibition of the listeria bacteriophage [241].

Gogotsi et al. [242] suggested a composite matrix as highly flexible material for application in producing membranes to make filtration devices. The composite was comprised of a porous scaffold to support the electrospun nanofibers, which photocatalytic metal oxide particles, were electrosprayed on them and uniformly deposited in the fibrous structure without agglomeration. The candidates for photocatalytic metal oxide particles were TiO2, Zirconium dioxide (ZrO2), ZnO, and Tungsten trioxide (WO3) in the average diameter of about 5 to 50 nm or more preferably, 10 to 30 nm and the amounts of 0.5–20% or more favorably 3–10% of the total suspension weight. The porous scaffold might be synthesized from a single or mixture of polymers including polyethylene, PP, PU, polyester, polyvinyls (i.e. polyvinyl chloride or polyvinyl alcohol), PAN, polyamide, etc., and with the aim of increasing the adhesion of the particles, the scaffold could pass a surface modification step prior to electrospraying, comprising treatment with a proper binder material that may include one or more silica precursors (i.e. tetraethyl orthosilicate (TEOS), tetra-n-propoxysilane, organo alkoxysilanes, etc.) (Fig. 7).

The preferable pH range is 2 to 5 and the binder material may contain inorganic or organic acids such as phosphoric acid, nitric acid hydrochloric acid and, sulfuric acid or acetic acid, dichloroacetic acid, trifluoroacetic acid, and benzene sulfonic acid. The fibers were suggested to be nanosized with a diameter of 500 nm to about 1 µm, and the proper concentration for electrospinning solution is 4 to 20 wt. % of the polymer solution total weight that should be selected to possess the capability of adhering to the porous scaffold, and may comprise polyamides, poly (vinyl acetate), poly(acrylonitrile), poly (Vinylidene fluoride), PEO, PVP, PCL, chitosan, cellulose, cellulose acetate, fibrinogen, collagen, silk, and styrene/isoprene copolymer or polymer blends that are soluble in a common solvent, for example, polylactide-blend-PVP, PEO-blend-poly(methyl methacrylate), polystyrene-blend-polyester, poly (vinylidene fluoride)-blend-poly (methyl methacrylate), etc.

As a practical example, they first washed a PP filter substrate with a mixture of deionized water and polar solvent and employed that as the porous scaffold. Then polyamide nanofibers were deposited on a silica-coated scaffold by electrospinning the solution of polyamide 11 in formic acid/dichloromethane. Then, a suspension of TiO2 NPs (with a diameter of 10–15 nm) in deionized water and ethanol (50:50 w/w) was electrosprayed onto the polyamide nanofibers.

They compared the above method with the process of dip-coating of NPs, found that the particle distribution in the dip-coating process was not uniform and led to agglomeration of TiO2 NPs that because of decreasing the effective surface area, reduced the antimicrobial and antiviral activity in comparison with the same number of smaller particles. Therefore, electrospraying is considered the more appropriate method for the uniform distribution of metal particles, which can preserve the antiviral activity of metallic NPs [242].

Leung suggested a double layer filtration medium comprising a microfibrous coarse layer that is positioned proximal to the airflow direction and attached to a fine layer of nanofibers that can be produced of electrospun or melt-blown polymers and placed distal to the airflow direction. The nanofibrous layer with a fiber diameter of 150 nm to 200 nm enhances the chance of capturing and molecular diffusion through fibers due to the high surface area to volume ratio, which is in the range of 1.3 × 107/meter to 4 × 108/meter. The electrospun nanofibers also carry an electrical charge generated through the electrospinning process that awards them the ability to intercept particles with an opposite electrical charge in the air stream. The microfibrous coarse filter layer with an average fiber diameter of 1 to 30 µm and a thickness of about 0.1 to 20 mm, possesses a high solid holding capacity and larger voids for trap** larger particles, while the nanofibrous layer with smaller voids is appropriate for capturing finer particles. The preferred weight ratio of the nanofibers to microfibers is 10%:90% and the nanofibrous layer can be directly electrospun onto the coarse surface of the non-woven microfibers that could also be placed in a liquid medium and the liquid subsequently be removed under the vacuum and ultimately the two layers form a rigid structure by mechanical compressing by using a trace amount of adhesive substance. The final filtration medium may also include a hydrophobic layer of non-polar polymers such as PTFE, nylon, glass composites, acrylic, and polyethersulfone (PES) to allow free gas exchange and prevent the entrance of virus bearing water droplets. For empowering the filter to antibacterial characteristics, the metallic NPs of MgO, TiO2 with potent ability to produce oxidation reactions under the ultraviolet light, silver (Ag) compounds such as silver nitrate, and organic compounds such as poly (N-benzyl4-vinyl pyridinium chloride) with the strong affinity to virus bacteriophage T4, could be added to the fibrous structure through the electrospinning process or grafting anti-microbial polymers onto the filter surface through atom transfer radical polymerization from an initiating surface, leading to non-leaching covalent attachment of the anti-microbial agents, or even by using initiated condensed vapor deposition (iCVD) technology, which is used for coating anti-microbial substrate on non-woven fibers surface without the risk of blocking the inter-fiber pores [243].

Li et al. developed a face mask using PSU electrospun nanofibers for filtration of PM2.5 (particulate matter with a diameter of 2.5 microns or less) in the polluted air. The PSU solution with the concentration of 18wt.% was prepared using Dimethylacetamide (DMAc)/acetone (9: 1) as the solvent and the process of electrospinning was performed in different time durations. The SEM results indicated that in the time duration of 15 min, the nanofibers showed random orientation and high porosity with a diameter of about 500–800 µm and an interfiber distance of 1–3 µm. The nanofibrous masks exhibited an acceptable rejection efficiency of more than 90%, showing a high PM2.5 rejection capability in comparison with disposable non-woven masks (32.9%). The percentage of PM2.5 rejection enhanced with increasing the time of the electrospinning process resulting in a thicker mat of nanofibers and in the time of 60 min, the rejection capability reaches 99.4%. It is believed that there is a contradictory relationship between air permeability and particle rejection, and with increasing the air permeability, PM2.5 rejection decreases and vice versa. Between the tested samples, the nanofibrous mask produced via 15 min electrospinning, exhibited the highest air permeability and PM2.5 rejection contrast, as well as possessing a great PM2.5 rejection value of 90% and suitable pressure drop and air permeability [244].

Qin et al. reached a dramatic decrease in the pressure drop of the membrane produced by electrospinning of 10 wt.% and 5 wt.% solutions of PAN that were made of thin microsphere loaded nanofibrous scaffold, which their presence in the structure contributed to larger pore size leading to enhancement of the filtration efficiency and capturing of PM2.5 and more importantly reduction of the pressure drop by decreasing the clogging of the membrane [245].

It has proved that the filtration efficiency of electrospun PVA microporous membrane is mathematically proportional to the pore size [236]. Although membranes with smaller pore sizes demonstrate higher filtration efficiency, their tiny pore size generally contributes to easier clogging in the filtration process [246].

Choi et al. designed an air filter comprising polyester and aluminum with the ability to capture and inactivate airborne microorganisms simultaneously. The potent electrostatic interactions of fibers in the filter structure with charged bacteria led to filtration of about 99.99% of Escherichia coli and Staphylococcus epidermidis bacteria with about 10 times lesser pressure drop per thickness in comparison with commercial efficient air filters and this capability was maintained after cyclic washing of the filter, which indicated the reusability of polyester and aluminum filter. The process of adding Al to the fiber structure was performed by dip-coating of a polyester nonwoven filter with a fiber size of 30 μm and porosity of 78.3% into an Al precursor ink, AlH3O(C4H9)2 and the comparative antibacterial test results demonstrated that growing Al nanograins on the fiber structure, improved the inactivation efficiency of the filter from 89.3 to 94.8% for E. coli and from 79.7 to 96.9% for S. epidermidis that considered to be a result of enhancing surface roughness and hydrophobicity after the addition of Al to the filter structure [247].

In another report, a washable nanofibrous membrane composed of PAN/AgNPs nanofibers was designed as an antibacterial mask with the aim of two-way prevention of bacterial passage from person to surroundings and vice versa. The preparation of PAN/AgNPs membrane was performed by dip** the PAN nanofibrous mat in a solution that contained 1000 mg. L−1 silver nitrate and the effect of different dip** cycles on different physicochemical characteristics of the membrane was investigated. The results of TEM demonstrated that the mean size of pure PAN nanofibers was 263 nm and after loading AgNPs, reached 290, 250, and 302 nm for one, two, and three dip** cycles, respectively. The size distributions of AgNPs also ranged from 18 nm to the maximum diameter of 39 nm in the third dip** cycle. The mechanical properties of PAN nanofibers were also improved after loading AgNPs and the tensile strength of the fibers increased even after 120 h washing with deionized water. Based on the release profile of the AgNPs loaded fibrous mat, when the negligible amount of AgNPs (2,247 ppm /gr nanofiber) was loaded into the nanofibers, the nanofibrous mat showed a two-stage release pattern, and the controlled release of Ag from PAN structure during 120 h confirmed that this method is appropriate for preparing washable antibacterial membranes. The antibacterial test results exhibited the effective antibacterial activity of the PAN/AgNPs membrane against Pseudomonas and Staphylococcus bacteria and had more inhibitory effects against Pseudomonas than against Staphylococcus. Although the presence of a high concentration of AgNPs caused by using two and three dip** cycles for loading of AgNPs led to the highest cytotoxicity, the sample with one cycle loaded AgNPs demonstrated the minimum rate of toxicity, as well as the optimal antibacterial properties, while kee** high biocompatibility [248].

Hashmi et al. produced and characterized a membrane made of CuO-loaded PAN electrospun nanofibers for antibacterial face mask application. The authors mentioned that the aim of producing about 60% of nanofibers is biomedical employment and loaded spherical shape CuO NPs with the size of 37 ± 9 nm as a stable and cost-effective antibacterial candidate in four different concentrations on pure PAN nanofibers with the average size of 141 nm and produced PAN nanofibers containing an optimum amount of 1.00% CuO with the size of 197 nm. The incorporation of CuO NPs significantly improved the tensile strength of nanofibers and imparted crystallinity and higher hydrophilicity to the membrane. Surface area is another factor that was found to be proportional to the CuO concentration in the membrane and based on the Brunauer–Emmett–Teller (BET) test results, the PAN nanofibrous mat containing the optimum amount of 1.00% CuO had a higher surface area of 20.63 ± 0.087 m2. g−1 than the neat PAN nanofibrous mat 8.09 ± 0.012 m2. g−1. The results of the breathability test by the upright cup method exhibited that the water uptake and breathability of the membrane are enhanced with the addition of CuO NPs. Furthermore, the presence of CuO in the intrinsically compact structure of neat PAN nanofibrous mat led to a reduction of its high resistance to the airflow by increasing the porosity of the mat and the value of air resistivity (R) declined from 24.05 for neat PAN, to 10.08 for 1.00% CuO containing mat, exhibiting better air permeability of the CuO loaded filter membrane. The results of analyzing the drug release behavior showed that the structure of CuO loaded PAN nanofibers was retained after socking in water for 72 h, that the nanofibers successfully released Cu without the occurrence of fiber dissolution in the aqueous medium, that the quantity of Cu was directly proportional to the CuO concentration in the PAN fibers. Based on the results of the MTT analysis, after passing the incubation period of 120 h more than 50% of the total cells survived. The CuO-loaded PAN nanofibers demonstrated a great antimicrobial effect on both gram-positive and negative bacteria (E. coli and B. subtilis) and the inhibition zone expanded with increasing the amount of CuO, representing the potent intrinsic antibacterial characteristic of CuO [249].

Seo et al. designed a facemask comprising three types of the fibrous membrane, one of them was a built-in adsorptive membrane made by stacking an adsorptive layer produced by accumulating ion-exchange nanofibers forming a mat with a pore size of about 3 µm or less on a supporting layer of woven or nonwoven fabrics, thicker and possessing larger pore size, forming a membrane with the capability of adsorbing ionic and ultrafine substances from the environment and high purification performance. The nanofibers could be either anion or cation exchange and the web shape adsorptive layer preferred to be coated with oil to activate the adsorption process in functional groups on the nanofiber surface. The second fibrous membrane that can be laminated on the first one, was made of electrospun dopamine-loaded nanofibers with the aim of gathering and maintaining the moisture of the breath to a certain degree in the nanofibrous web. The dopamine-loaded nanofibers were also functionalized by attaching active groups to dopamine under UV or plasma irradiation, or by acid or base treatment, to function as a negative charge (SO3H−) or positive charge (NH4+) functional group to adsorb heavy metals, bacteria, and viruses of the passing air. The last fibrous membrane could be formed by electrospinning of a polymeric solution that contains silver nanomaterial (from AgNO3, Ag2SO4, and AgCl) that may be stitched to the supporting layer and the potent antibacterial property of silver enables the facemask to kill the bacteria that may be contained in the airflow. Based on the abovementioned characteristics, this mask can be utilized for medical, industrial, or daily applications with stable breathing and convenient use [250].

Zhang et al. designed a smart face mask that was capable of monitoring human breath in case of emotional changes or during the exercise employing a humidity sensor made of silver nanoparticle-containing alginate fiber that was fabricated by a three-step procedure comprising electrospinning of sodium alginate, ion exchanging of the sodium and silver ions, and ultimately reduction of AgNPs in situ. The mean diameter of alginate nanofibers was 240 nm that the AgNPs were uniformly dispersed throughout the nanofiber that the resultant sensor exhibited appropriate humidity sensitivity in the relative humidity (RH) range of 20% to 80% and was capable of accurately capturing the rate and depth of the respiration [251].

Yang et al. introduced a face mask with thermal management ability consisting of a commercially available nanoporous polyethylene (nanoPE) sheath with 50−1000 nm pores and high infrared (IR) transparency of 92.1% and the nylon-6 nanofibers with a diameter of < 100 nm and transmittance up to 85% on the top of it with potent particulate matter (PM) adhesion and PM2.5 capture efficiency of 99.6% while exhibiting low pressure drop. Since the moist warm environment inside the face masks exposes the wearers to an extra hazard, the evaluation of thermal properties such as conduction or insulation could be a significant factor in the process of design that is conventionally determined by the thickness of the fibers. Manipulation of the thermal properties by changing the fiber thickness which is strongly correlated to the removal capability and air permeability is challenging considering the fact that other thickness-dependent performances could be also affected. Therefore, modification of this filter material using nanoPE, added an excellent radiative cooling effect to the fibrous layer while maintaining the unique characteristics of great PM capture capability and low pressure drop. The authors also found that coating nanoPE substrate with silver has a warming effect that the resultant face mask can keep the user face comfortable, cool in summer, and warm in winter while protecting them from polluted air or infections in case of indoor use in hospitals [252].

Fortifying Nanofibrous Mats for Filtration Applications

While the possibilities of making improvements in the filtration efficiency of the present mainstream fibrous air filtration materials like melt-blown fibers, cellulose fibers, and glass fibers are limited because they comprise microfibers [253], the electrospun nanofibers, are known as a privileged platform for the production of air filtration materials possessing advantages such as packing structure with tunable nano-dimensional fiber diameter [254], highly porous structure and flexibility [255], remarkable electrostatic effect and, the feasibility of producing them from a wide range of raw materials [256]. But for employing nanofibers on the industrial scale some of the structural flaws should amend to fulfill the expectations of a great filtration material (Fig. 8).

The Multilayer Structure

The strategy of employing a multilayer structure is based on the fact that increasing the weight of the electrospun filter membrane leads to improvement of the filtration efficiency [257]. But the practical method cannot be carried out as continuous deposition of nanofibers in the electrospinning process because the airflow channels which have formed in the structure of the membrane will be partly clogged, leading to an increase in the pressure drop. Besides, the pore size distribution of the membranes that were fabricated from the electrospinning of one polymer is usually narrow, which negatively impacts the filtration efficiency in the case of targeting particles of various sizes. Therefore, a multilayer structure is fabricated from the layers with the same composition and porosity, arranged alongside each other to improve filtration efficiency and simultaneously alleviate the enhancement of pressure drop (Fig. 9).

Zhang et al. designed a multilayer filter made of three layers of membranes from PSU fibers with a diameter of about 1 μm, PAN nanofibers with a size of about 200 nm, and the finest layer with the polyamide-6(PA-6) fibers with a size of about 20 nm. This integrated filter demonstrated a low-pressure drop of 118 Pa and a high filtration efficiency with capability of filtration of numerous particles with different sizes which made possible by removing particles larger than 2 μm with PSU layer, capturing particles bigger than 0.5 μm within PAN nanonet, and finally, sieving 0.3 μm sized particles and more by PA-6 membrane [258].

Cellulose derivatives have been generally used for producing comfortable inner layers in commercial face masks comprising multilayers of non-woven fabrics. Furthermore, they can also be deposited on the surface of the outer layer in fiber/particle form or could be added to air filtration equipment as a separate layer before or after the filter layer. For instance, Asper et al. designed a filter paper made entirely from pure cellulose nanofibers with a diameter of 20–30 nm produced by Cladophora sp. Algae and employed it for viral removal. The results of retention tests demonstrated that the nanocellulose filter is capable of removing xenotropic murine leukemia virus and Swine Influenza A virus with high removal capacity [259].

Currently, most the air filtration respirators are designed based on the multilayer structure and comprise an electret filter that is composed of polymeric fibers such as PP, PTFE, poly-butylene terephthalate, and polycarbonate, forming a nonwoven mat which possesses electrostatic charge and placed in the central position of the layered structure [260]. The mechanism of particle trap** in the electret membranes was not limited to the porous structure and they have the ability to capture the particles in an active manner with more attraction distance. Besides, there is no need to provide a high density of small pores and thick filters, and as a result, the appropriate removal efficiency can be achieved in the condition of continuous airflow with a low pressure drop. Through the process of formation of the nanofibrous membranes, electrospinning favorably provides in-situ electrostatic charge by introducing charge storage enhancers to electrospinning polymeric solutions [32].

Lamination

The nanofibrous web of chitosan possesses unique properties such as biocompatibility, being non-toxic, biodegradability, and special physical and chemical characteristics that enable chitosan to capture and neutralize toxic materials in the liquids or air and destroy the structure of bacteria or viruses. Considering the shortcomings of the fibrous web of chitosan in the filtration process like poor mechanical stability, Mohammadian et al. investigated a method of remediation to strengthen this structure. They laminated the chitosan nanofibrous web into a multilayer system employing cotton fabric and an adhesive via the hot-melt method. In the process of electrospinning, an aluminum-covered collector was covered by polypropylene spun bond nonwoven (PPSN), which is a web form hot-melt adhesive, and the 10 wt.% solutions of chitosan and multiwalled nanotubes (MWNTs) used for the production of the nanofibers, and after removing them from the collector, another layer of PPSN attached on it and after that, the whole three layers placed in the middle of two cotton weft-warp fabrics and then, hot-melt laminating carried out by a flat iron at various temperatures to study the impact of laminating temperature on the multilayer structures. The authors found that the images of optical microscope (and not the cross-sectional SEM) were more applicable for observation of the structural changings, they also used an air permeability tester below 125 Pa air pressure for measurement of the air transport properties. The results showed that as long as the laminating temperature was under the melting point of PPSN, the nanofibrous web remained approximately unchained, but with increasing the temperature, the adhesive force among the layers was improved and gradually, PPSN was flattened between layers, and transformed to film-like structure, and by reaching to the temperatures above the PPSN melting point, the nanofiber web began to damage. On the other hand, increasing the laminating temperature contributed to the reduction of air permeability because of impeding the convective airflow by the adhesive layer. In the temperatures above the melting point, the reduction of airflow was a result of adhesive penetration to other layers (because of the more surface junction with nanofibers, PPSN has more penetration into the nanofibrous web than the fabric) that led to blockage of the nanofibrous porosity and prevention of passing the air during the experiment [261].

Lee et al. developed a membrane filter media using electrospun polybenzimidazole (PBI) nanofibers for application in dust-proof face masks to capture the particulate matters (PMs). The nanofiber layer was formed on a polyester mesh and for improving the mechanical stability against bending or other stresses, was laminated with another polyester mesh at the temperature of 140 °C and PBI fibers were immobilized between the two layers of polyester. PBI nanofibers are capable of making intermolecular electrostatic interactions that are the result of the high electric dipole moment of PBI polymer and made them an appropriate platform for the production of the efficient filter membrane. Based on the observations, the PBI filter kept its inherent function after cleaning and provided the filtering efficiency of about 98.5% at a very lower pressure drop (130 Pa) than commercial masks (386 Pa) with the similar filtering efficiencies, as well as a threefold higher quality factor (∼0.032) compared to the commercial ones (∼0.011) [262].

Hung et al. mentioned that although the higher weight of the filter membranes can lead to an increase in the filtration efficiency, the quality factor of the filters does not improve because of the unwanted enhancement in the pressure drop [263].

Increasing the Surface Area

Another method for increasing the specific surface area and improving the efficiency of particle capture is manipulating some features of the electrospun fibers considering two opposite design concepts of “addition” and “subtraction” [264]. The addition of nano-protrusions on the electrospun fibers by incorporation of nanoparticles such as PAN/SiO2 [265], PAN/ TiO2 [266], PSU/TiO2 [267], and so on, leads to increasing the specific surface area and as a result, the chance of capturing the particles enhances. Besides, the presence of these regions on the structure of fibers that possess low air resistance enhances the friction force between fibers and particles and reduces the probability of slip** and moving the captured particles by the shear flow of air [265].

Another way of achieving a higher specific surface area and filtration performance is by constructing porous fibers. Pan et al. generated densely distributed nano-pores on PLA electrospun fibers by regulating RH during the process of electrospinning and obtained the highest quality factor of 0.0276 on RH of 45% [268].

Face Masks for Viral Filtration

Ren et al. provided information about employing nanoparticles in a formula that contained a compound of metallic nanoparticles along with non-metallic or anionic groups in a fibrous structure with the aim of preventing transmission of the viruses, especially by inhalation of infected droplets. The preferred diameter of the fiber filaments could be around 7 µm and the different forms are nanoparticles such as dry powders, liquids, sol–gels, or nanotubes with a preferred average size up to 100 nm that can be incorporated into protective clothing made of natural (such as wool, cotton, cellulose, silk, etc.) or artificial fabrics (polyester, polyethylene, PP, rayon, nylon, polyimide, Kevlar R, carbon, etc.). The antiviral activity of the formula was evaluated by Hemagglutination assay and reported based on the percentage of viral titer reduction. In the first group of trials, nanoparticles with the concentration of 0.1 to 1 wt.% were tested for inhibitory effects against different strains of flu viruses such as B/GDAL444 and VC1/256 on turkey red blood cells (TRBC’s), and based on the obtained results, the authors marked nano-Ag and TiO2 as “poor”, ZnO and Alumina as “good”, and compounds related to Al (Al-phosphates), Ca2+ (Ca phosphates, Ca-silicates and Ca-carbonates), Si (SiO2 and SiC), Cu and Cu oxides, P (Al-phosphates) and active carbons marked as “highly virucidal” by demonstrating over 90% virucidal rates. In another trial, the antiviral activity of different nanoparticles with diameters of 5 nm to 100 nm toward avian H5N1 Influenza NIBRG-14 was evaluated in MDCK cells. The results after 30 min of incubation demonstrated that Tungsten carbide (WC) exhibited the highest viral reduction percentage of 99.992% in the second place, titanium carbide (TiC) and titanium carbonitride (TiC0.5N0.5) were the most efficient nanoparticle with the viral reduction of 99.223% and the least reduction belonged to silicon (IV)nitride (Si3N4) with the reduction rate of 83.400% [269].

Another sample of antiviral fibers for air filtration applications can be produced by loading monovalent copper compounds such as CuCl, CuOOCCH3, CuBr, and CuI particles with the least amount of 0.2% by mass concerning the weight of the fiber. The results of the cellular evaluation of the antiviral properties of the fibers against two model enveloped (influenza A / Kitakyushu / 159/93 (H3N2)) and non-enveloped (FCV (F9 strain)) viruses exhibited that copper (I) iodide and copper (I) chloride powder were the most potent antiviral compounds with the capability of inactivating viruses in a short time of 1 min in MDCK and CrFK cells, respectively [270].

Stewart et al. evaluated the inhibitory influence of four types of multilayer fabrics on Influenza B (B/Lee/40) virus in vitro. The findings showed that adding 2% copper acetate and 2% zinc acetate to the structure of spun-bond nonwoven or melt-blown PP fabric containing 2% citric acid, 2% PVA, and 0.5% polyoxyethylene (20) sorbitan boosted the antiviral activity of the fabric resulting in an appropriate material for making a facial mask to decrease the transmission of human pathogens [271].

Smith et al. designed a face mask that was intended to have antiviral and antibacterial activity and a lower pressure differential as well as offering superior comfort. The face mask comprised of an activated carbon cloth impregnated with silver which had a protective PP membrane on it and they both were placed in the middle of two inner and outer layers. The combination of the abovementioned layers is designed to draw the viruses from a static and mobile environment and capture them into the cloth assembly to be held and destroyed there.

Although activated carbon cloth is intrinsically antibacterial, it is supposed that it’s not capable to capture very small particulates of viruses. But impregnation of activated carbon cloth with antiviral metals, such as silver, equipped the cloth with antiviral and virucidal properties. In this process which is called carbonization and activation, the metal salt is sequentially converted to metal oxide and metal and then located in the structure of cloth in any fashion: placed between the fibers, attached to the fibers, or embedded into them, leading to the formation of a microporous structure that has the ability to attract and capture molecules. In this project, the amount of impregnated silver was 0.3% by weight, the thickness of the silver-impregnated activated carbon cloth was 0.2 to 2 mm, and employing an MS-2 coliphage that in comparison with an FFP3 (filtering facepieces with at least 99% particle filtration efficiency at 0.3 microns) facemask, the filtration ability and pressure drop, as well as the virus capture, retention, and elimination efficiency of the cloth were tested.

The results exerted that surprisingly, the activated carbon cloth had virucidal properties, both with and without silver, but the presence of AgNPs in the cloth structure significantly increased the virucidal activity, and had no adverse effect on the efficiency of virus capture, which increased with the enhancement of the weight of the membrane layer, for example, it was 98.26% in case of using a 22 g.m−2 membrane and reaches to 99.88% viral capture employing a 60 g.m−2 one. However, there is an optimum point for increasing the weight of the membrane because, after that, the permeability will be limited, so here, the membrane weighed 60 g.m−2, and the weight of the outer and inner layers were 50 g.m−2 and 30 g.m−2, respectively. The retention capability of the cloth, which is the number of remaining viruses in the cloth after capture, was 99.9998%. This composite represented a facemask with a lower pressure differential and reasonable cost [272].

A major problem of applicating face masks for viral protection is the accumulation of viral particles on the surface of the filtration membranes or within the membrane fibers, remaining alive and infectious for a relatively long period [273]. To defeat this shortcoming, Davison designed a four-layered filter composed of a central melt-blown PP filtration layer surrounded by an inner spun-bond PP and two layers with antiviral characteristics: the first layer composed of copper and zinc ions incorporated into cellulose/polyester and the second one (outer layer) is another spun-bond PP coated with a hydrophilic plastic coating that acidified with citric acid. Therefore, the infectious droplets and viral particles are absorbed in the outer layer and denatured by the citric acid then the damaged viruses are eliminated by divalent metal cations in the second layer [274].

Even though N95 class face masks demonstrated a greater level of protection compared with surgical/medical masks during the pandemic crisis, such as SARS in 2003 [275], their application has some serious flaws including low breathability, overall discomfort, excessive heat and humidity, malodorousness, facial pressure, skin irritation and, diminished visual, vocal, or auditory acuity, which reduce the favorability of the mask in general applications and more importantly, interfere with occupational duties of the health care employees [276]. Therefore, combining the advantages of each type, low air resistance of surgical/medical face masks, and high protection of N95 respirators leads to manufacturing the most desirable face mask. Besides, the protection level of a mask is dependent on two criteria, possessing the ability to filtration of hazardous particles in a wide diameter range from nanometers to micrometers and perfect sealing to avoid any leakage.

Tong et al. presented a novel face mask with expected antibacterial properties and potent filtration efficiency (more than 95%) with high breathability and also great face seal, including three to four nonwoven layers in the main body, comprising nanofibers with a diameter of 10–99 nm interweaved with partially gelled submicron fibers in the size range of 100–1000 nm. The layers can be attached by ultrasonic welding and the fibers were made of selected polymers such as PU or PHBV and CuO employed as a biocide agent in the concentration of 2% -50% (w /w), which can be incorporated into the structure of submicron and nanosized electrospun fibers by encapsulation into the fibers, or attaching onto the fiber surface, or can be physically trapped in the fiber structure or crosslinked to the fibers.

In the first trial, an electrospun microfibrous PU mat containing 2% (w/w) of CuO with a surface density of 0 0.12 g.m−2 and thickness of 230 µm was tested for evaluation of particulate filter penetration using sodium chloride (NaCl) aerosols. In another trial, the same evaluation was performed on electrospun CuO -incorporated PHBV fibers with submicron diameter. Both masks conformed to The National Institute for Occupational Safety and Health (NIOSH) N95 criteria in breathability and filtration efficiency. At an airflow rate of around 85 L.min−1, 95–99.999% of NaCl aerosols with a diameter of about 260 nm were successfully filtered. The protective masks exhibited more than 99% reduction of gram-negative bacteria, Pseudomonas aeruginosa, within 5 min because of the oligodynamic effect of CuO [277].

Discussion

There have been some comparative studies with the aim of designating the most promising metallic particle for antiviral applications. For instance, Mallikarjun tested the antiviral properties of Cu (II), Ni (II), and Zn (II) complexed with four groups of ligands: 3-(phenyl)-1-(2’-hydroxynaphthyl)—2—propen—1—one (PHPO), 3—(4-chlorophenyl)—1- (2’-hydroxynaphthyl)–2–propen—1—one (CPHPO), 3—(4 -methoxyphenyl) -1-(2’-hydroxynaphthyl)-2-propen-1-one(MPHPO) and, 3—(3,4-dimethoxyphenyl)–1-(2’-hydroxynaphthyl) —2—propen—1—one (DMPHPO) and declared the effectivity of them in order against tobacco ringspot virus(TRSV). All of them were examined in amounts of 250 ppm to 1500 ppm. The results demonstrated that the antiviral activities of the tested complexes were as follows: Cu (DMPHO)2 > Zn (DMPHO)2 > Ni (DMPHO)2 > Cu (PHPO)2 > Zn (PHPO)2 > Ni (PHPO)2 > Cu (MPHPO)2 > Zn (MPHPO)2 > Ni (MPHPO)2 > Cu (CPHPO)2 > Zn (CPHPO)2 > Ni (CPHPO)2. The author mentioned that the most toxic complexes toward the virus have greater solution stability and higher lipid solubility and the toxicity might be due to the interference of metal ions in regular cell proliferation [278]. In another study, Mastro et al. showed that treatment of peripheral blood mononuclear cells with Cu, Ag and, Ag+ Cu resulted in HIV-1 inhibitory degree of 43.82%, 37.15% and, 51.97%, respectively, which demonstrates the ascendancy of copper in viral inhibition [279]. Furthermore, Sagripanti et al. reported that the required amount of Cu (II) ions for achieving a 70% reduction in the titer of cell-free HIV-1 in a solution, is much less than Fe (III): 1.6 mM Cu (II) to 18 mM Fe (III). The required number of copper atoms for the inactivation of HIV-1 is approximately 1011 per infectious virus particle [280]. Minoshima et al. also reported that solid-state Cu2O possesses the superior inhibitory ability against both enveloped and nonenveloped viruses (influenza A and bacteriophage Q) in comparison with silver compounds, due to its unique viral inactivation mechanism via direct contact of Cu2O with viral cells, which disrupts recognition of host by destroying the structure of viral surface proteins and as a result, inactivates the viruses regardless of the viral envelope [281]. Nakano et al. employed highly photocatalytic WO3 microparticles with 0.5 mass % of CuO powder to design an antiviral composite material. The in vitro antiviral evaluation was performed by inoculating two low and high pathogenic viruses, influenza virus (H9N2) and avian influenza virus (H5N1) into the MDCK cells exposed to the irradiation of visible light by the wavelength of 380 nm and illuminance of 6000 Lx for 24 h. Inactivation effect R is a parameter that is used for evaluation of the inhibitory effect of the target particles, which is formulated as [R = log C−log A], where C denotes the virus concentration of the particle-free visible irradiated sample after 24 h that A denotes the virus concentration of the particle-containing sample that received the same irradiation treatment. The WO3 particles exhibited relatively low antiviral performance; however, making a composition of WO3 with CuO resulted in an increase in the inactivation effect value after 24 h of irradiation in the same condition. Compared to WO3 alone, the Inactivation effect ® was significantly increased from 1.9 to 4.7 [282].

In addition to the fact that the existence of various and feasible methods to synthesize CuNPs has made them a very practical option for widespread application [225], another advantage of employing them as antiviral agent is their synergistic effect in viral inactivation when used along with other metallic particles. Broglie et al. designed a core–shell structure placing Au in the core and Copper (II) Sulfide (CuS) in the shell of the NPs with a diameter of 2–5 nm and evaluated their antiviral properties against norovirus GI.1. The results of the in vitro antiviral test demonstrated that Au/CuS NPs can inactivate 50% of the viruses in the minimum concentration of 0.083 μM by damaging the structure of capsid proteins, which can reach complete viral inhibition by increasing the NPs concentration to 0.83 μM. In another survey, a hybrid coating impregnated with copper, zinc, and silver cations was produced by radical polymerization through a sol–gel process and in vitro evaluations demonstrated the ability of this coating for viral titer reduction: 98–100% after 120 min exposure to HIV-1 and slower virucidal kinetics for other enveloped viruses in the exposure time of 240 min: 97% for DENV, 100% for HSV-1, 77% for influenza and only marginal reduction in viral titer for the non-enveloped coxsackie B3 virus [283]. Kanovsky tested the anti-HIV-1 properties of active polymeric fibers containing varying amounts and ratios of Cu2O and tetrasilver tetroxide (Ag4O4). The antiviral test was performed on MT-2 cells and the measurement of the concentration of p24 (HIV-1 capsid protein) was the basis of virus proliferation determination. No cytotoxicity was observed for the combination of Ag4O4 and Cu2O and the results of antiviral tests showed that using the amount of 1% wt. of Ag4O4 alone, results in 76% inhibition while the presence of Cu2O in the composite led to achieving the ability to inactivate 96% of the viral titer [284].

Shimabuku et al. reported that granular activated carbon in the water filtration device was not capable of inactivating T4 bacteriophage after incorporation of minimum concentration (0.5 and 1.0 w/w (%)) of Ag into the structure, but the synergistic effect of CuO NPs in viral inactivation with the particle size of 22 to 37 nm and the concentration of 1.0 w/w (%) along with 0.5 w/w (%) of 25 to 40 nm-sized Ag NPs, caused 5.53 log reduction in T4 bacteriophage titer [285].

The application of nanofibers as a substitute for conventional material for producing filtration devices can reduce mask airflow resistance significantly and direct more airflow through the mask, which leads to enhancement of the filtration efficiency. The improvement of the fit, is the only way of increasing the filtration efficiency and reduction of receiver exposure in existing commercial face masks, while this solution also results in increasing the airflow resistance in the face mask, because of forcing a greater part of the airstream to passage the mask. But in the case of employing nanofibers, the intrinsic decrease in mask airflow resistance minimizes leaking around the mask and provides a better chance for passing particles through the filter and capturing them without the requirement of a perfect seal, and ultimately reduces the receiver exposure levels in comparison with conventional face masks. With the incorporation of nanoparticles in the structure of nanofibers, the electrospun mat will benefit from increasing the surface area and at the same time, will be equipped with potent antiviral agents [286].

In the end, having a brief glimpse of three commercial face masks can feasibly declare the potent effectivity and applicability of using copper compounds in the structure of face masks with the aim of viral inhibition of respiratory viruses. Three face masks made by BioFriend™ BioMask™, Cufitec® Surgical Mask, and Innonix Anti-Influenza Child’s Mask possess the ability to inactivate 99.99% of various types of influenza viruses and their active ingredients are: citric acid 2% wt. (in the outer layer) and copper 1.6% wt. and zinc 1.6% wt. (in the 2nd layer) for BioFriend™ BioMask™ and Innonix Anti-Influenza Child’s Mask, CuI in the amount of 0.5% wt. (in the outer and inner layers) for Cufitec® Surgical Mask.

Copper compounds are low-cost and feasibly applicable as promising antiviral agents and can also be combined with other biocidal metallic particles to intensify the overall antiviral effect, especially when placed in the structure of face masks with the aim of protecting the wearers against lethal pathogens such as COVID-19.

Conclusion

Wearing protective masks is still the most powerful strategy for preventing viral transmission and managing the outbreak of COVID-19. Designing the innovative face masks, equipped with antiviral agents, can be a great step forward to enhance the security level of the mask wearers. The metal and metal oxide NPs as potent candidates possessing antiviral activity have been studied for years. The majority of the essays on the antiviral properties of these NPs are limited to in vitro and cellular studies on human cell lines, and the number of in vivo experiments is considerably fewer. Based on these reports, a number of metal and metal oxide NPs have shown propitious antiviral activity, especially against respiratory viruses and a bright future is visible for their application in the structure of anti-virus masks.

The nanofibrous layers, on the other hand, were reviewed as the most promising material for develo** face masks with great filtration qualities. The non-hazardous nature and intrinsic antiviral properties of the polymers, as well as the most practicable methods for improving the structural and filtration characteristics of the nanofibrous mats with the aim of using them in face masks fabrication, have been introduced and examples of patents and products which have been developed based on the abovementioned criteria were mentioned. In the end, this field of study has been shown to possess a vast potential for making innovations at both experimental and industrial levels with the aim of fulfilling the need for safe antiviral respiratory protecting materials.

The most challenging issue in the application of metal nanoparticles is their cytotoxicity on human cells (especially through inhalation), which makes the necessity to determine the accurate effective and safe dose of metal NPs for loading into nanofibrous layers more prominent. On the other hand, according to the potentials of this field, the upcoming researches in the field of proving the antiviral properties of metal NPs should change direction from in vitro and cellular studies to in vivo and clinical ones. The ease of use and accessibility of metal NPs-loaded face masks should be studied clinically as well. The combination of this field of nanotechnology with superior technologies based on artificial intelligence in the context of interdisciplinary collaborations will provide the possibility of making a wide variety of innovations in the fabrication of multi-layer face masks to finally approach the most suitable face mask in terms of reaching the maximum protection, applicability and, the possibility of monitoring the face mask's functionality from biological and technical aspects, which will upgrade the application of face masks from a protection-only device to an ever-growing biosensing tool.

Data Availability

Data sharing not applicable to this review article as no datasets were generated or analysed during the current study.

References

Yin Y, Wunderink RG. MERS, SARS and other coronaviruses as causes of pneumonia. Respirology. 2018;23:130.

Sekimukai H, Iwata-Yoshikawa N, Fukushi S, Tani H, Kataoka M, Suzuki T, Hasegawa H, Niikura K, Arai K, Nagata N. Gold nanoparticle-adjuvanted S protein induces a strong antigen-specific IgG response against severe acute respiratory syndrome-related coronavirus infection, but fails to induce protective antibodies and limit eosinophilic infiltration in lungs. Microbiol Immunol. 2020;64:33.

Johnson NP, Mueller J. Updating the accounts: global mortality of the 1918–1920" Spanish" influenza pandemic. Bulletin of the History of Medicine. 2002, 105.

Viboud C, Simonsen L, Fuentes R, Flores J, Miller MA, Chowell G. Global mortality impact of the 1957–1959 influenza pandemic. J Infect Dis. 2016;213:738.

Simonsen L, Clarke MJ, Schonberger LB, Arden NH, Cox NJ, Fukuda K. Pandemic versus epidemic influenza mortality: a pattern of changing age distribution. J Infect Dis. 1998;178:53.

Kain T, Fowler R. Preparing intensive care for the next pandemic influenza. Crit Care. 2019;23:1.

Raj VS, Mou H, Smits SL, Dekkers DH, Müller MA, Dijkman R, Muth D, Demmers JA, Zaki A, Fouchier RA. Dipeptidyl peptidase 4 is a functional receptor for the emerging human coronavirus-EMC. Nature. 2013;495:251.

Joseph J, Baby HM, Zhao S, Li XL, Cheung KC, Swain K, Agus E, Ranganathan S, Gao J, Luo JN, editors. Role of bioaerosol in virus transmission and material‐based countermeasures. Exploration; 2022: Wiley Online Library.

Kaushik A, Mostafavi E. To manage long COVID by selective SARS-CoV-2 infection biosensing. Innovation. 2022;3: 100303.

Mostafavi E, Dubey AK, Teodori L, Ramakrishna S, Kaushik A. SARS-CoV-2 Omicron variant: a next phase of the COVID-19 pandemic and a call to arms for system sciences and precision medicine. MedComm. 2022;3: e119.

Tebyetekerwa M, Xu Z, Yang S, Ramakrishna S. Electrospun nanofibers-based face masks. Adv Fiber Mat. 2020;2:161.

Jefferson T, Foxlee R, Del Mar C, Dooley L, Ferroni E, Hewak B, Prabhala A, Nair S, Rivetti A. Physical interventions to interrupt or reduce the spread of respiratory viruses: systematic review. BMJ. 2008;336:77.

Cho D, Naydich A, Frey MW, Joo YL. Further improvement of air filtration efficiency of cellulose filters coated with nanofibers via inclusion of electrostatically active nanoparticles. Polymer. 2013;54:2364.

Skaria SD, Smaldone GC. Respiratory source control using surgical masks with nanofiber media. Ann Occup Hyg. 2014;58:771.

Larrondo L, John MR. Electrostatic fiber spinning from polymer melts. II. Examination of the flow field in an electrically driven jet. J Polymer Sci. 1981;19:921.

Cui H, Li Y, Zhao X, Yin X, Yu J, Ding B. Multilevel porous structured polyvinylidene fluoride/polyurethane fibrous membranes for ultrahigh waterproof and breathable application. Compos Commun. 2017;6:63.

Chaudhary V, Gautam A, Silotia P, Malik S, de Oliveira HR, Khalid M, Khosla A, Kaushik A, Mishra YK. Internet-of-nano-things (IoNT) driven intelligent face masks to combat airborne health hazard. Mater Today. 2022;2:2.

Lv D, Zhu M, Jiang Z, Jiang S, Zhang Q, **ong R, Huang C. Green electrospun nanofibers and their application in air filtration. Macromol Mater Eng. 2018;303:1800336.

Kaushik AK, Dhau JS. Photoelectrochemical oxidation assisted air purifiers; perspective as potential tools to control indoor SARS-CoV-2 Exposure. Appl Surf Sci Adv. 2022;9: 100236.

Saghati S, Akbarzadeh A, Del Bakhshayesh A, Sheervalilou R, Mostafavi E. Electrospinning and 3D printing: prospects for market opportunity. Electrospinning. 2018;2:136.

Hosseini S, Tafreshi HV. On the importance of fibers’ cross-sectional shape for air filters operating in the slip flow regime. Powder Technol. 2011;212:425.

Brown TD, Dalton PD, Hutmacher DW. Melt electrospinning today: An opportune time for an emerging polymer process. Prog Polym Sci. 2016;56:116.

Yun KM, Hogan CJ Jr, Matsubayashi Y, Kawabe M, Iskandar F, Okuyama K. Nanoparticle filtration by electrospun polymer fibers. Chem Eng Sci. 2007;62:4751.

Komur B, Bayrak F, Ekren N, Eroglu M, Oktar FN, Sinirlioglu Z, Yucel S, Guler O, Gunduz O. Starch/PCL composite nanofibers by co-axial electrospinning technique for biomedical applications. Biomed Eng Online. 2017;16:1.

Lu P, Ding B. Applications of electrospun fibers. Recent Pat Nanotechnol. 2008;2:169.

Qin XH, Wang SY. Electrospun nanofibers from crosslinked poly (vinyl alcohol) and its filtration efficiency. J Appl Polym Sci. 2008;109:951.

Wang N, Wang X, Ding B, Yu J, Sun G. Tunable fabrication of three-dimensional polyamide-66 nano-fiber/nets for high efficiency fine particulate filtration. J Mater Chem. 2012;22:1445.

Kim GT, Ahn YC, Lee JK. Characteristics of Nylon 6 nanofilter for removing ultra fine particles. Korean J Chem Eng. 2008;25:368.