Abstract

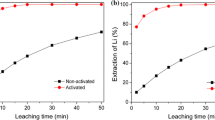

Growing demand for valuable battery materials and environmental issues from battery disposal make the recycling of spent lithium-ion batteries (LIBs) essential. Specifically, the green approaches using organic reagents have garnered many attentions for battery recycling. In this study, a synergetic organic leaching system using methanesulfonic acid (MSA) of strong organic acid and citric acid (CA) with good chelating ability was investigated to extract valuable metals from LiCoO2. Hydrogen peroxide was used as a reducing agent to enhance leaching kinetics. Cobalt extraction of 98% and lithium extraction of 97 % were achieved in the optimized condition; 2.4M MSA, 1.6M CA, 1.0 vol% H2O2, S/L ratio 80 g/L, 85 °C, and 1 h. The optimal leaching condition of the MSA-CA mixed leaching system exhibited good applicability to various cathode scraps, such as LiCoO2, LiNixMnyCo1-x-yO2, and LiNixCoyO2. The dissolved Co and Li ions in the MSA-CA leachate were selectively recovered with high recovery efficiencies of 99 % and 97 % as Co3O4 and Li3PO4, respectively. The recovered Co3O4 and Li3PO4 were utilized to regenerate cathode materials. LiCoO2 and LiFePO4 were also synthesized through a solid-state reaction and hydrothermal method. The recycling process based on the MSA-CA-H2O2 synergetic leaching system was proposed, and it might be applied as a green and economical organic leaching system for the recycling of various types of spent LIBs.

Similar content being viewed by others

References

Gil-Alana LA, Monge M (2019) Lithium: production and estimated consumption. Evidence of persistence. Resources Policy 60:198–202

Reddy TB, Linden D (2011) Linden’s Handbook of Batteries, 4th edn. McGraw-Hill Professional Publishing

Asadi Dalini E, Karimi G, Zandevakili S, Goodarzi M (2020) A review on environmental, economic and hydrometallurgical processes of recycling spent lithium-ion batteries. Miner Process Extr Metall Rev 42(7):451–472

Liu Y, **ng P, Liu J (2017) Environmental performance evaluation of different municipal solid waste management scenarios in China. Resources, Conservation and Recycling 125:98–106

**e R, Zhu Y, Liu J, Li Y, Wang X, Shumin Z (2020) Research status of spodumene flotation: a review. Mineral Processing and Extractive Metallurgy Review 42(5):321–334

Engel H, Hertzke P, Siccardo G (2019) Second-life EV batteries: the newest value pool in energy storage. McKinsey & Company

Choi Y, Rhee SW (2020) Current status and perspectives on recycling of end-of-life battery of electric vehicle in Korea (Republic of). Waste Manag 106:261–270

Sommerville R, Zhu P, Rajaeifar MA, Heidrich O, Goodship V, Kendrick E (2021) A qualitative assessment of lithium ion battery recycling processes. Resources, Conservation and Recycling 165:105219

Okonkwo EG, Wheatley G, He Y (2021) The role of organic compounds in the recovery of valuable metals from primary and secondary sources: a mini-review. Resources, Conservation and Recycling 174:105813

Lv W, Wang Z, Cao H, Sun Y, Zhang Y, Sun Z (2018) A critical review and analysis on the recycling of spent lithium-ion batteries. ACS Sustainable Chemistry & Engineering 6(2):1504–1521

Jha MK, Kumari A, Jha AK, Kumar V, Hait J, Pandey BD (2013) Recovery of lithium and cobalt from waste lithium ion batteries of mobile phone. Waste Manag 33(9):1890–1897

Chen X, Ma H, Luo C, Zhou T (2017) Recovery of valuable metals from waste cathode materials of spent lithium-ion batteries using mild phosphoric acid. J Hazard Mater 326:77–86

Peng C, Hamuyuni J, Wilson BP, Lundstrom M (2018) Selective reductive leaching of cobalt and lithium from industrially crushed waste Li-ion batteries in sulfuric acid system. Waste Manag 76:582–590

Wang B, Lin XY, Tang Y, Wang Q, Leung MK, Lu XY (2019) Recycling LiCoO2 with methanesulfonic acid for regeneration of lithium-ion battery electrode materials. J Power Sources 436:226828

Fu Y, He Y, Qu L, Feng Y, Li J, Liu J, Zhang G, **e W (2019b) Enhancement in leaching process of lithium and cobalt from spent lithium-ion batteries using benzenesulfonic acid system. Waste Manag 88:191–199

Gao W, Liu C, Cao H, Zheng X, Lin X, Wang H, Zhang Y, Sun Z (2018) Comprehensive evaluation on effective leaching of critical metals from spent lithium-ion batteries. Waste Manag 75:477–485

Golmohammadzadeh R, Rashchi F, Vahidi E (2017) Recovery of lithium and cobalt from spent lithium-ion batteries using organic acids: process optimization and kinetic aspects. Waste Manag 64:244–254

Li L, Dunn JB, Zhang XX, Gaines L, Chen RJ, Wu F, Amine K (2013) Recovery of metals from spent lithium-ion batteries with organic acids as leaching reagents and environmental assessment. J Power Sources 233:180–189

Li L, Qu W, Zhang X, Lu J, Chen R, Wu F, Amine K (2015) Succinic acid-based leaching system: a sustainable process for recovery of valuable metals from spent Li-ion batteries. J Power Sources 282:544–551

Meng Q, Zhang Y, Dong P (2017) Use of glucose as reductant to recover Co from spent lithium ions batteries. Waste Manag 64:214–218

Zhang Y, Meng Q, Dong P, Duan J, Lin Y (2018) Use of grape seed as reductant for leaching of cobalt from spent lithium-ion batteries. Journal of Industrial and Engineering Chemistry 66:86–93

Wu Z, Soh T, Chan JJ, Meng S, Meyer D, Srinivasan M, Tay CY (2020b) Repurposing of fruit peel waste as a green reductant for recycling of spent lithium-ion batteries. Environ Sci Technol 54(15):9681–9692

Chen X, Luo C, Zhang J, Kong J, Zhou T (2015a) Sustainable recovery of metals from spent lithium-ion batteries: a green process. ACS Sustain Chem Eng 3(12):3104–3113

Golmohammadzadeh R, Faraji F, Rashchi F (2018) Recovery of lithium and cobalt from spent lithium ion batteries (LIBs) using organic acids as leaching reagents: a review. Resour Conserv Recycl 136:418–435

Xu M, Kang S, Jiang F, Yan X, Zhu Z, Zhao Q, Teng Y, Wang Y (2021) A process of leaching recovery for cobalt and lithium from spent lithium-ion batteries by citric acid and salicylic acid. RSC Adv 11(44):27689–27700

Chen X, Fan B, Xu L, Zhou T, Kong J (2016) An atom-economic process for the recovery of high value-added metals from spent lithium-ion batteries. J Clean Prod 112:3562–3570

Meng F, Liu Q, Kim R, Wang J, Liu G, Ghahreman A (2020) Selective recovery of valuable metals from industrial waste lithium-ion batteries using citric acid under reductive conditions: leaching optimization and kinetic analysis. Hydrometallurgy 191:105160

Fu Y, He Y, Chen H, Ye C, Lu Q, Li R, **e W, Wang J (2019a) Effective leaching and extraction of valuable metals from electrode material of spent lithium-ion batteries using mixed organic acids leachant. J Ind Eng Chem 79:154–162

Nayaka GP, Zhang Y, Dong P, Wang D, Pai KV, Manjanna J, Santhosh G, Duan J, Zhou Z, **ao J (2018) Effective and environmentally friendly recycling process designed for LiCoO2 cathode powders of spent Li-ion batteries using mixture of mild organic acids. Waste Manag 78:51–57

Ahn J, Wu J, Lee J (2019) Investigation on chalcopyrite leaching with methanesulfonic acid (MSA) and hydrogen peroxide. Hydrometallurgy 187:54–62

Gernon MD, Wu M, Buszta T, Janney P (1999) Environmental benefits of methanesulfonic acid: comparative properties and advantages. Green Chem 1:127–140

Wu J, Ahn J, Lee J (2020a) Kinetic and mechanism studies using shrinking core model for copper leaching from chalcopyrite in methanesulfonic acid with hydrogen peroxide. Mineral Processing and Extractive Metallurgy Review 42(1):38–45

Wu Z, Dreisinger DB, Urch H, Fassbender S (2014) Fundamental study of lead recovery from cerussite concentrate with methanesulfonic acid (MSA). Hydrometallurgy 142:23–35

Li L, Ge J, Wu F, Chen R, Chen S, Wu B (2010b) Recovery of cobalt and lithium from spent lithium ion batteries using organic citric acid as leachant. J Hazard Mater 176(1-3):288–293

Zhao Y, Yuan X, Jiang L, Wen J, Wang H, Guan R, Zhang J, Zeng G (2020) Regeneration and reutilization of cathode materials from spent lithium-ion batteries. Chem Eng J 383:123089

Wu J (2021) Application of green lixiviants in metal extraction from primary and secondary metal resources” (Doctoral dissertation,. The University of Arizona)

Vanysek P (2000) Electrochemical series. CRC handbook of chemistry and physics 8:8–33

Zhang X, Cao H, **e Y, Ning P, An H, You H, Nawaz F (2015) A closed-loop process for recycling LiNi1/3Co1/3Mn1/3O2 from the cathode scraps of lithium-ion batteries: process optimization and kinetics analysis. Sep Purif Technol 150:186–195

Zhuang L, Sun C, Zhou T, Li H, Dai A (2019) Recovery of valuable metals from LiNi0.5Co0.2Mn0.3O2 cathode materials of spent Li-ion batteries using mild mixed acid as leachant. Waste Manag 85:175–185

Sokić MD, Marković B, Živković D (2009) Kinetics of chalcopyrite leaching by sodium nitrate in sulphuric acid. Hydrometallurgy 95(3-4):273–279

Habashi F (1999) Kinetics of metallurgical processes. Métallurgie Extractive Québec, Québec, QC, Canada

Shi G, Liao Y, Su B, Zhang Y, Wang W, ** J (2020) Kinetics of copper extraction from copper smelting slag by pressure oxidative leaching with sulfuric acid. Sep Purif Technol 241:116699

Kim S, Bang J, Yoo J, Shin Y, Bae J, Jeong J, Kim K, Dong P, Kwon K (2021) A comprehensive review on the pretreatment process in lithium-ion battery recycling. J Clean Prod 294:126329

Song Y, Zhao Z (2018) Recovery of lithium from spent lithium-ion batteries using precipitation and electrodialysis techniques. Sep Purif Technol 206:335–342

Chen X, Xu B, Zhou T, Liu D, Hu H, Fan S (2015b) Separation and recovery of metal values from leaching liquor of mixed-type of spent lithium-ion batteries. Sep Purif Technol 144:197–205

Shin DJ, Joo SH, Lee D, Shin SM (2022) Precipitation of lithium phosphate from lithium solution by using sodium phosphate. Can J Chem Eng 2022:1–8

Bao L, Xu G, Wang M (2019) Controllable synthesis and morphology evolution of hierarchical LiFePO4 cathode materials for Li-ion batteries. Mater Charact 157:109927

Ma Z, Shao G, Fan Y, Wang G, Song J, Liu T (2014) Tunable morphology synthesis of LiFePO4 nanoparticles as cathode materials for lithium ion batteries. ACS Appl Mater Interfaces 6(12):9236–9244

Robinson JP, Koenig GM Jr (2015) Tuning solution chemistry for morphology control of lithium-ion battery precursor particles. Powder Technol 284:225–230

Acknowledgements

Data from this manuscript had been presented in the Symposium in Honor of Patrick R. Taylor at the MINEXCHANGE 2023 SME Annual Conference & Expo, held in Denver, CO, February 26 to March 1, 2023.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, JY., Wu, J., Kim, EW. et al. Recycling for Recovery of Critical Metals from LiCoO2 Cathode Material Through Methanesulfonic Acid-Citric Acid Organic Leaching System. Mining, Metallurgy & Exploration 40, 1455–1467 (2023). https://doi.org/10.1007/s42461-023-00837-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-023-00837-8