Abstract

A great part of interest has been paid for fabricating new materials with novel mechanical, optical, and electrical properties. Boron carbon nitride (BCN) ternary system was applied for variable bandgap semiconductors and systems with extreme hardness. The purpose of this literature review is to provide a brief historical overview of B4C and BN, to review recent research trends in the BCN synthesizes, and to summarize the fabrication of BCN thin films by plasma sputtering technique from B4C and BN targets in different gas atmospheres. Pre-set criteria are used to discuss the processing parameters affecting BCN performance which includes the gasses flow ratio and effect of temperature. Moreover, many characterization studies such as mechanical, etching, optical, photoluminescence, XPS, and corrosion studies of the RF sputtered BCN thin films are also covered. We further mentioned the application of BCN thin films to enhance the electrical properties of metal-insulator-metal (MIM) devices according to a previous report of Prakash et al. (Opt. Lett. 41, 4249, 2016).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Sputtering process

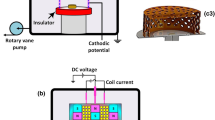

Sputtering technique is a physical vapor deposition technique that is considered a successful technique as a result of its features like a high film deposition rate and low-temperature structures [1]. It is a simple and economical method for producing thin films of alloys, metals, carbides, nitrides, and oxides [2]. The most common approach to this technique is the magnetron sputtering technique that uses a magnetic field to assist the process of depositing thin films onto a substrate. The particles (atoms and ions) are ejected through the transfer of momentum from the Ar ions. In a magnetron sputtering, electrons are confined along the magnetic field lines. A gaseous plasma that confines electrons is generated, and then accelerated to bombardment the target, which will lead to erode the material and eject them in the form of neutral particles and a minor component of ions. Inert gas is typically used as sputter gas like argon or even an active gas like nitrogen. Then, these ejected particles will place onto the substrate and coat a thin film of the target.

The magnetron sputtering technique offers great advantages compared with other techniques like uniform, homogeneity, and great adhesion deposition over the comparatively large area, facility to choose the substrate material and target material with very high melting points, high deposition rate, and also easy of the control of thickness [3]. However, several disadvantages of reactive sputtering for instance target poisoning, poor deposition rates, and arcing causing defects in the thin film [4]. From the other hand, there are main factors used to tune the thickness of the synthesized films in sputtering technique. These factors are the integrated pulse energy, deposition time, [5] chamber pressure, plasma gas, the angle of target and the substrate, and substrate temperature which is important to reduce the dopant redistribution and defect formation related to high-temperature processing [6].

However, different energy sources are required to maintain the plasma state in magnetron sputtering technique while it is losing power inside the chamber such as direct current (DC) for conductive targets for instance aluminum and copper, radio frequency (RF) for nonconductive targets like silicon and manganese dioxide, ion-beam sputtering which can depend only on an ion source without using any magnetic field, ion-assisted deposition reactive sputtering, and high-power impulse magnetron sputtering (HIPIMS) that produce higher energy flux of sputtered comparing with DC magnetron sputtering and ionized atoms are delivered to the growing surface in pulses repeated at certain frequency [5, 7]. Some materials deposited by magnetron sputtering have found applications in energy such as in gas turbine blade coating and solar panels, electronics/microelectronics application in flip-chip backside metallization and sensors, and many other applications in various fields.

1.2 History of boron carbon nitride (BCN) thin film technology

In the recent years, thin film technology was applied in the field of semiconductors science. More interestingly, BCN films represented a potential material as protective and hard coatings for cutting tools and for other wear-resistance uses [8,9,10,11,12,13,14]. Drude in 1889 discussed the earliest fabrication of thin films under vacuum with unique characteristics on the glass of discharge tubes [15]. The principal properties of the materials could be improved by the formation of thin films instead of other structural arrangements. For instance, few numbers of microns of gold material coated onto glass surface make the glass conductive. Furthermore, thin film technology was used to prepare metastable phases at low temperature especially with applying plasma techniques such as sputter deposition and plasma assisted chemical vapor deposition (PACVD) techniques. For example, cubic boron nitride could be prepared easily at lower pressure and temperature than bulk fabrication processes. Moreover, PACVD techniques were employed to prepare polycrystalline diamond at 20 mbar pressure and lower than 1000 K temperature [16]. Thin film technology has been applied to semiconductor and photovoltaic cell technologies [17, 18]. It is well known that elemental solids of group IVA and compounds between IIIA and VA groups were applied in the aforesaid technologies because of their excellent physical and electrical properties. Within the next sections, the unique behaviors of BN and B4C materials will be discussed as well as the promising properties resulting from combining these materials to synthesize BCN thin films.

1.2.1 Boron nitride (BN) thin films

Diamond, c-BN, and boron carbide (B4C) are among the hardest known materials apart from nanocomposites or nano-multilayer materials. The structures of diamond and c-BN are very close to each other. Graphite and h-BN exhibit layered structures with weak van der Waals forces. More interestingly, graphite is a semi-metal while h-BN is an insulator.

Boron nitride material is a dry lubricant with excellent properties, which can be altered with respect to the crystal morphology. BN layers were applied in electron-field emitters, high-temperature dielectrics, tribological devices, and optoelectronic systems [19,20,115]. To investigate the physical and the chemical characteristics of deposited films, graphite, and B4C targets were applied in RF sputtering by Essafti et al. to deposit amorphous CN, amorphous BC, and amorphous BCN thin films on silicon substrates. It was found that carbon atoms bound to nitrogen atoms majorly as sp2 C=N rather than sp3 C–N and exist as C–C bonds in the deposited BCN films. In addition, C=N and B–N bonds were also formed. The films were deposited with varying proportions and diverse bonding forms. The great variation in the shape and the binding energies of the C1s core level XPS spectra indicated the difference in the morphology of the synthesized films [116].

3.8 Corrosion studies

Composites are applied in a wide range of applications because of their promising properties [117,118,119,120,121,122,123,124,125]. To illustrate, the corrosion behavior of BCN films has been attracted a growing attention of researchers to allow their application in different environments. The electrochemical polarization and dissolution rate of a deposited BCN thin film in acidic, neutral, and alkaline mediums were studied by Byon et al. The dissolution rate of B1.0C2.4N1.0 thin film was declined in NaOH < NaCl < HCl solutions (Fig. 5a). In 1 M NaOH medium, it was revealed that as the C ratio increases as the dissolution rate of the BCN film decreases (Fig. 5b). In addition, a B1.0C(3.2–4.4)N1.2 thin film was noticed to exhibit a superior corrosion-resistant performance [126].

Dissolution rate (−Δd/Δt) of a B1.0C2.4N1.0 films in 1 M HCl, 1 M NaCl, and 1 M NaOH mediums, b B1.0C(0.5–4.4)N(0.9–1.2) films in 1 M NaOH medium [126]

3.9 Raman spectroscopy studies

Raman spectroscopy is a technique applied to measure the wavelength and intensities of inelastically scattered light by measuring the change in rotational, electronic or vibrational energy of a molecule. The properties and microstructures of the films can be investigated by Raman spectroscopy [127]. The long-range ordered crystalline structure can be predicted from Raman results. To illustrate, Tsai et al. used pulsed-DC magnetron sputtering technique to deposit BCN films using B4C target under Ar/N2 gas flow. Numerous processing factors were discovered to grow BCN films with high c-BN content [128]. To characterize the composition and phases, Raman spectroscopy with other techniques was used. By changing temperature and substrate bias, the deposited BCN films displayed h-BN, c-BN, wurtzite-BN (w-BN) phases and their mixed phases. By controlling the substrate bias and stage deposition technique, 90% c-BN film was obtained with clear facets and grains [128].

4 Metal-insulator-metal (MIM) devices based on BCN thin films

Prakash A. and Sundaram K. synthesized BCN thin films by RF magnetron sputtering using B4C target at various flow ratios of N2 and Ar gasses and deposition temperatures to study the electrical properties of metal-insulator-metal (MIM) devices. They found that increasing the N2 gas in the BCN film and the substrate temperatures leads to drop the dielectric constant but increasing the dielectric breakdown strength and the resistivity. Moreover, the highest dielectric breakdown strength of 3.4 MV/cm of BCN films achieved with a dielectric constant of 2.13 and resistivity of 3 × 1012 Ω.cm [129]. Another paper conducted by Prakash et al. for MIM devices tested for their potential UV photodetection capability by using BCN films applied in harsh environment applications. They used dual target RF magnetron sputtering, BN target as DC sputtering and B4C as RF magnetron sputtering with N2 and Ar as processing gas to form BCN films. Glass substrate used to produce MIM structure, deposited by aluminum strips as a bottom electrode using a mechanical mask in a thermal evaporation technique and loaded in the sputtering system to deposit a thin film of BCN of a thickness of 100 to 120 nm. The last step ended by creating the top electrode through depositing a number of gold strips over the BCN film, a thin layer of gold fabricated by using thermal evaporation process to form a transparent top electrode for the photo-detector window. Using UV photocurrent measurements, the optoelectronic performance of the BCN MIM device was examined using UV photocurrent measurements. The device achieved a UV photocurrent response of two orders higher with respect to dark current in the range − 3 to 3 V [130].

Table 1 represents different processing parameters used to prepare thin BCN films. This table summarizes the targets used in both of RF and DC powers, deposition gasses, and the various temperatures used during the deposition and the main results.

5 Conclusion

Sputtering technique is considered as an excellent method to synthesize thin films with availability to use various types of substrates and deposit uniform films over a relatively large area. Many studies conducted the synthesis of BCN by RF magnetron sputtering and investigated different properties of the films and the effect of varying deposition parameters. The increase of N2 flow resulted in a significant decrease in the elastic modulus, hardness, and wear resistance and led to reducing the amount of boron and carbon in BCN films. From the other hand, varying the temperature and annealing affected the refractive index and the optical bandgap. Furthermore, even at high annealing temperature at 1000 °C, it has been found that BCN films possess an unlimited vacuum thermal stability. Sputtering power also played a primary role in enhancing the elastic coefficients, hardness and elastic modulus of the synthesized films. Changing the bias voltage and substrate temperature allowed to control the bond contents in the deposited films. The hardness of BCN films can be improved by increasing the substrate temperature. The incorporation of about 20% of N2 leads to producing BCN films with either electrically insulating behavior with a low dielectric constant or high mechanical characteristics. When the nitrogen content in the BCN film was surged, the optical transmission was increased dramatically while increasing the substrate temperature modified the transmission slightly. Furthermore, deposition BCN films at 400 °C offered the highest PL intensity, reducing the deposition temperature reduced the PL intensity. Cu diffusion could be increased by increasing the boron loading of BCN thin films whereas, changing the annealing temperature revealed very small Cu diffusion enhancement. Increasing the N2 content and substrate temperature diminished the dielectric constant of the deposited BCN films. In addition, increasing the substrate temperature increased the breakdown voltage initially then followed by a slight decrease. The resistivity was found to be constant and can be slightly modified with increasing the substrate temperature. Corrosion studies revealed that B1.0C(3.2–4.4)N1.2 thin films provided superior corrosion-resistant properties. BCN MIM devices achieved a UV photocurrent response of two orders higher with respect to dark current in the range − 3 to 3 V.

References

Prakash A. Deposition and characterization studies of boron carbon nitride (BCN) thin films prepared by dual target sputtering (PhD Thesis) 2016

D.R. Gibson, I. Brinkley, E. Waddell, J.M. Walls, Proc. SPIE 7101, 710108 (2008)

E. Pascual, E. Martı, J. Esteve, A. Lousa, Boron carbide thin films deposited by tuned-substrate RF magnetron sputtering. Diam. Relat. Mater. 8, 402–405 (1999)

K. Koski, J. Ho, Voltage controlled reactive sputtering process for aluminium oxide thin films. Thin Solid Films 326, 189–193 (1998)

A. Kossoy, R.L. Magnusson, T.K. Tryggvason, K. Leosson, S. Olafsson, Method to control deposition rate instabilities—high power impulse magnetron sputtering deposition of TiO2. J. Vac. Sci. Technol. A Vac. Surf. Film 33, 21514 (2015)

T. Lohner, M. Serényi, D.K. Basa, N.Q. Khánh, Á. Nemcsics, P. Petrik, et al., Acta Polytech. Hungarica 5, 23 (2008)

D. Depla, S. Mahieu, J. Greene, Handb. Depos. Technol. Film coatings 281, 253 (1991)

P.D. Cuong, H.-S. Ahn, E.-S. Yoon, K.-H. Shin, Effects of relative humidity on tribological properties of boron carbide coating against steel. Surf. Coatings Technol. 201, 4230–4235 (2006)

X. Deng, H. Kousaka, T. Tokoroyama, N. Umehara, Deposition and tribological behaviors of ternary BCN coatings at elevated temperatures. Surf. Coatings Technol. 259, 2–6 (2014)

T. Hirte, R. Feuerfeil, V. Perez-Solorzano, T.A. Wagner, M. Scherge, Influence of composition on the wear properties of boron carbonitride (BCN) coatings deposited by high power impulse magnetron sputtering. Surf. Coatings Technol. 284, 94–100 (2015)

Y. Li, X. Jia, W. Shi, S. Leng, H.A. Ma, S. Sun, F. Wang, N. Chen, Y. Long, The preparation of new “BCN” diamond under higher pressure and higher temperature. Int. J. Refract. Met. Hard Mater. 43, 147–149 (2014)

V.S. Sulyaeva, Y.M. Rumyantsev, V.G. Kesler, M.L. Kosinova, Synthesis and optical properties of BCxNy films deposited from N-triethylborazine and hydrogen mixture. Thin Solid Films 581, 59–64 (2015)

S. Xu, X. Ma, H. Wen, G. Tang, C. Li, Effect of annealing on the mechanical and scratch properties of BCN films obtained by magnetron sputtering deposition. Appl. Surf. Sci. 313, 823–827 (2014)

F. Zhou, Q. Wang, B. Yue, X. Wu, L. Zhuge, X. Cheng, Mechanical properties and bonding structure of boron carbon nitride films synthesized by dual ion beam sputtering. Mater. Chem. Phys. 138, 215–224 (2013)

Drude P Ueber Oberflächenschichten. II. Theil, Ann. Phys. 272, 532 (1889)

R.N. Tiwari, J.N. Tiwari, L. Chang, M. Yoshimura, Enhanced nucleation and growth of diamond film on Si by CVD using a chemical precursor. J. Phys. Chem. C 115, 16063–16073 (2011)

O. Sneh, R.B. Clark-Phelps, A.R. Londergan, J. Winkler, T.E. Seidel, Thin film atomic layer deposition equipment for semiconductor processing. Thin Solid Films 402, 248–261 (2002)

A. Shah, P. Torres, R. Tscharner, N. Wyrsch, H. Keppner, Photovoltaic Technology: The Case for Thin-Film Solar Cells. Science 285, 692–698 (1999)

X. Yang, H. Li, Y. Li, X. Lv, G. Zou, Synthesis and optical properties of purified translucent, orthorhombic boron nitride films. J. Cryst. Growth 312, 3434–3437 (2010)

X. Yang, H. Li, Y. Li, X. Lü, S. Gao, P. Zhu, Q. Zhang, T. Zhang, G. Zou, Dependence of RF power on the phase transformation for boron nitride films deposited on graphite at room temperature. J. Cryst. Growth 311, 3716–3720 (2009)

D. **-**ang, Z. **ao-Kang, Y. Qian, W. Xu-Yang, C. Guang-Hua, H. De-Yan, Chinese Phys. B 18, 4013 (2009)

E. Weißmantel, T. Pfeifer, F. Richter, Electron microscopic analysis of cubic boron nitride films deposited on fused silica. Thin Solid Films 408, 1–5 (2002)

Y. Panayiotatos, P. Patsalas, C. Charitidis, S. Logothetidis, Surf. Coatings Technol. 151–152, 155 (2002)

X.W. Zhang, Y.J. Zou, B. Wang, X.M. Song, H. Yan, G.H. Chen, S.P. Wong, J. Mater. Sci. 36, 1957–1961 (2001)

V. Dimitrov, S. Sakka, Electronic oxide polarizability and optical basicity of simple oxides. I. J. Appl. Phys. 79, 1736–1740 (1996)

K. Teii, S. Matsumoto, Impact of low-energy ions on plasma deposition of cubic boron nitride. Thin Solid Films 576, 50–54 (2015)

A. Schiitze, K. Bewilogua, H. Ltithje, S. Kouptsidis, S. Jager, Surf. Coat. Technol. 75, 717 (1995)

A. Werbowy, J. Szmidt, A. Sokołowska, S. Mitura, RF plasma selective etching of boron nitride films. Diam. Relat. Mater. 9, 609–613 (2000)

I. Bello, C.Y. Chan, W.J. Zhang, Y.M. Chong, K.M. Leung, S.T. Lee, Y. Lifshitz, Deposition of thick cubic boron nitride films: the route to practical applications. Diam. Relat. Mater. 14, 1154–1162 (2005)

K. Bewilogua, M. Keunecke, K. Weigel, E. Wiemann, Thin Solid Films 469–470, 86 (2004)

H. Yang, C. Iwamoto, T. Yoshida, Thin Solid Films 407, 67 (2002)

B. Mårlid, K. Larsson, H. Carlsson J-O, Hydrogen and Fluorine Adsorption on the h-BN (001) Plane. J. Phys. Chem. B 103, 7637–7642 (1999)

B. Wang, Y. Qin, F. **, J.F. Yang, K. Ishizaki, Pulse electric current sintering of cubic boron nitride/tungsten carbide–cobalt (cBN/WC–Co) composites: effect of cBN particle size and volume fraction on their microstructure and properties. Mater. Sci. Eng. A 607, 490–497 (2014)

M.-E. Wang, G.-J. Ma, Dong C and Gong S-L 2014. Chinese Phys. B 23, 66805 (2014)

F. Xu, M.F. Yuen, B. He, C.D. Wang, X.R. Zhao, X.L. Tang, D.W. Zuo, W.J. Zhang, Microstructure and tribological properties of cubic boron nitride films on Si 3 N 4 inserts via boron-doped diamond buffer layers. Diam. Relat. Mater. 49, 9–13 (2014)

H. Yang, A. Chen, F. Qiu, Cubic boron nitride film residual compressive stress relaxation by post annealing. Diam. Relat. Mater. 20, 1179–1182 (2011)

K.P. Loh, M. Nishitani-Gamo, I. Sakaguchi, T. Taniguchi, A.T. Diam, Relat. Mater., 8 (1296)

B. Mårlid, K. Larsson, J.-O. Carlsson, Nucleation ofc−BNon hexagonal boron nitride. Phys. Rev. B 64, 184107 (2001)

H.S. Yang, J.Y. Zhang, A.M. Nie, X.B. Zhang, Chinese Phys. B 17, 3453 (2008)

H.S. Kim, J.K. Park, W.S. Lee, Y.J. Baik, Variation of residual stress in cubic boron nitride film caused by hydrogen addition during unbalanced magnetron sputtering. Thin Solid Films 519, 7871–7874 (2011)

J.-S. Ko, J.-K. Park, W.-S. Lee, Y.-J. Baik, The parameter space of hydrogen content added to Ar–nitrogen sputtering gas and substrate bias voltage for the formation of cubic boron nitride thin film deposited by unbalanced magnetron sputtering method. Surf. Coatings Technol. 223, 75–78 (2013)

I. Konyashin, V. Khvostov, V. Babaev, M. Guseva, J. Bill, F. Aldinger, The influence of excited hydrogen species on the surface state of sp2-hybridized boron nitride. Diam. Relat. Mater. 8, 2053–2058 (1999)

J.K. Park, J.H. Lee, W.S. Lee, Y.J. Baik, Effect of substrate bias and hydrogen addition on the residual stress of BCN film with hexagonal structure prepared by sputtering of a B4C target with Ar/N2 reactive gas. Thin Solid Films 549, 276–280 (2013)

S. Weidner, S. Geburt, S. Milz, J. Ye, S. Ulrich, C. Ronning, Extension of the cubic boron nitride thin film growth phase diagram. Diam. Relat. Mater. 22, 88–91 (2012)

H.-G. Boyen, P. Widmayer, D. Schwertberger, N. Deyneka, P. Ziemann, Appl. Phys. Lett. 76, 709 (2000)

M. Keunecke, E. Wiemann, K. Weigel, S.T. Park, K. Bewilogua, Thick c-BN coatings – preparation, properties and application tests. Thin Solid Films 515, 967–972 (2006)

S. Pat, Anadolu Univ. J. Sci. Technol. Appl. Sci. Eng. 17, 191 (2016)

Zhao Y, Gao W, Xu B, Li Y-A, Li H-D, Gu G-R et al 2016. Chinese Phys. B 25 106801

S. Tuff, J. Dubois, G. Fantozzi, G. Barbier, Densification, microstructure and mechanical properties of TiB2-B4C based composites. Int. J. Refract. Met. Hard Mater. 14, 305–310 (1996)

I. Topcu, H.O. Gulsoy, N. Kadioglu, A.N. Gulluoglu, Processing and mechanical properties of B4C reinforced Al matrix composites. J. Alloys Compd. 482, 516–521 (2009)

K.A. Schwetz, L.S. Sigl, L. Pfau, Mechanical properties of injection molded B4C–C ceramics. J. Solid State Chem. 133, 68–76 (1997)

F. Thévenot, Boron carbide—a comprehensive review. J. Eur. Ceram. Soc. 6, 205–225 (1990)

G. Bonnet, V. Rohr, X. Chen, J. Bernier, R. Chiocca, H. Issard, Pack. Transp. Stor. Secur. Radio. Mater. 20, 98 (2013)

N. Vast, J. Sjakste, E. Betranhandy, Boron carbides from first principles. J. Phys. Conf. Ser. 176, 12002 (2009)

K. Shirai, Electronic structures and mechanical properties of boron and boron-rich crystals (Part I). J. Superhard. Mater. 32, 205–225 (2010)

K. Shirai, Prediction of phase diagrams for hard materials: application to boron crystals. Int. J. Thermophys. 35, 1888–1899 (2014)

A.K. Suri, C. Subramanian, J.K. Sonber, T.S.R.C. Murthy, Synthesis and consolidation of boron carbide: a review. Int. Mater. Rev. 55, 4–40 (2010)

H. Werheit, V. Filipov, U. Kuhlmann, U. Schwarz, M. Armbrüster, A. Leithe-Jasper, T. Tanaka, I. Higashi, T. Lundström, V.N. Gurin, M.M. Korsukova, Raman effect in icosahedral boron-rich solids. Sci. Technol. Adv. Mater. 11, 23001 (2010)

X. Tao, L. Dong, X. Wang, W. Zhang, B.J. Nelson, X. Li, B4C-nanowires/carbon-microfiber hybrid structures and composites from cotton T-shirts. Adv. Mater. 22, 2055–2059 (2010)

M.J. Zhou, S.F. Wong, C.W. Ong, Q. Li, Microstructure and mechanical properties of B4C films deposited by ion beam sputtering. Thin Solid Films 516, 336–339 (2007)

M. Chen, J.J.W. McCauley, K.J.K. Hemker, Science 99, 1563 (2003)

S.P. Dodd, G.A. Saunders, B. James, J. Mater. Sci. 37, 2731–2736 (2002)

R. Ma, Y. Bando, Investigation on the growth of boron carbide nanowires. Chem. Mater. 14, 4403–4407 (2002)

W.Q. Han, Appl. Phys. Lett. 88, 1 (2006)

P. Kohler-Redlich, F. Ernst, M. Rühle, Chem. Mater. 11, 3620 (1999)

J. Wei, B. Jiang, Y. Li, C. Xu, D. Wu, B. Wei, Straight boron carbide nanorods prepared from carbon nanotubes. J. Mater. Chem. 12, 3121–3124 (2002)

M. Renzhi, Y. Bando, Chem. Phys. Lett. 364, 314 (2002)

H.K. Clark, J.L. Hoard, The crystal structure of boron carbide. J. Am. Chem. Soc. 65, 2115–2119 (1943)

V. Domnich, S. Reynaud, R.A. Haber, M. Chhowalla, Boron carbide: structure, properties, and stability under stress. J. Am. Ceram. Soc. 94, 3605–3628 (2011)

A. Prakash, K.B. Sundaram, Optical studies of reactively Co-sputtered BCN thin films. ECS Trans. 61, 51–56 (2014)

Y. **an, R. Qiu, X. Wang, P. Zhang, Interfacial properties and electron structure of Al/B 4 C interface: a first-principles study. J. Nucl. Mater. 478, 227–235 (2016)

T.V. Hynes, M.N. Alexander, Nuclear magnetic resonance study ofβ‐rhombohedral boron and boron carbide. J. Chem. Phys. 54, 5296–5310 (1971)

Thevenot F B 1974 217

Beckel L Mexico 1986 87131

M. Bouchacourt, F. Thevenot, The correlation between the thermoelectric properties and stoichiometry in the boron carbide phase B4C-B10.5C. J. Mater. Sci. 20, 1237–1247 (1985)

J. Lee, H. Youn, K.S. Hong, Phase Transit., 83 (1999)

S. Ulrich, H. Ehrhardt, J. Schwan, R. Samlenski, R. Brenn, Subplantation effect in magnetron sputtered superhard boron carbide thin films. Diam. Relat. Mater. 7, 835–838 (1998)

A.O. Sezer, J.I. Brand, Chemical vapor deposition of boron carbide. Mater. Sci. Eng. B 79, 191–202 (2001)

S. Vepřek, S. Rambert, M. Heintze, F. Mattenberger, M. Jurčik-Rajman, W. Portmann, et al., J. Nucl. Mater. 162–164, 724 (1989)

D. Byun, B.R. Spady, N.J. Ianno, P.A. Dowben, Comparison of different chemical vapor deposition methodologies for the fabrication of heterojunction boron-carbide diodes. Nanostructured Mater. 5, 465–471 (1995)

Winter J, Esser H G, Reimer H, Grobusch L, Von Seggern J and Wienhold P 1990. J. Nucl. Mater. 176–177 486

S. Lee, J. Mazurowski, W.L. O’Brien, Q.Y. Dong, J.J. Jia, T.A. Callcott, Y. Tan, K.E. Miyano, D.L. Ederer, D.R. Mueller, P.A. Dowben, The structural homogeneity of boron carbide thin films fabricated using plasma‐enhanced chemical vapor deposition from B5H9+CH4. J. Appl. Phys. 74, 6919–6924 (1993)

D. Byun, S.D. Hwang, P.A. Dowben, F.K. Perkins, F. Filips, N. Ianno, J 1994. Appl. Phys. Lett. 64 (1968)

F.K. Perkins, R.A. Rosenberg, S. Lee, P.A. Dowben, Synchrotron‐radiation‐induced deposition of boron and boron carbide films from boranes and carboranes: Decaborane. J. Appl. Phys. 69, 4103–4109 (1991)

F.K. Perkins, M. Onellion, S. Lee, D. Li, J. Mazurowski, P.A. Dowben, Appl. Phys. A Mater. Sci. Process. 450, 442 (1992)

U. Jansson, J.O. Carlsson, B. Stridh, S. Söderberg, M. Olsson, Chemical vapour deposition of boron carbides I: Phase and chemical composition. Thin Solid Films 172, 81–93 (1989)

J.C. Oliveira, O. Conde, Deposition of boron carbide by laser CVD: a comparison with thermodynamic predictions. Thin Solid Films 307, 29–37 (1997)

L.G. Vandenbulcke, Theoretical and experimental studies on the chemical vapor deposition of boron carbide. Ind. Eng. Chem. Prod. Res. Dev. 24, 568–575 (1985)

L. Vandenbulcke, G. Vuillard, Composition and structural changes of boron carbides deposited by chemical vapour deposition under various conditions of temperature and supersaturation. J. Less-Common. Met. 82, 49–56 (1981)

M. Olsson, S. Söderberg, B. Stridh, U. Jansson, J.O. Carlsson, Chemical vapour deposition of boron carbides II: morphology and microstructure. Thin Solid Films 172, 95–109 (1989)

J. Rey, G. Male, P. Kapsa, J. Loubet, J. Rey, G. Male, et al., J. Phys. Coll., 50 (1989)

M. Ducarroir, C. Bernard, Thermodynamic domains of the various solid deposits in the B-C-H-Cl vapor system. J. Electrochem. Soc. 123, 136 (1976)

S.V. Deshpande, E. Gulari, S.J. Harris, A.M. Weiner, Filament activated chemical vapor deposition of boron carbide coatings. Appl. Phys. Lett. 65, 1757–1759 (1994)

V.L. Solozhenko, D. Andrault, G. Fiquet, M. Mezouar, D.C. Rubie, Synthesis of superhard cubic BC2N. Appl. Phys. Lett. 78, 1385–1387 (2001)

A.Y. Liu, M.L. Cohen, Prediction of new low compressibility solids. Science 245, 841–842 (1989)

A.Y. Liu, R.M. Wentzcovitch, M.L. Cohen, Atomic arrangement and electronic structure ofBC2N. Phys. Rev. B 39, 1760–1765 (1989)

A. Lousa, J. Esteve, S. Muhl, E. Martínez, BCN thin films near the B 4 C composition deposited by radio frequency magnetron sputtering. Diam. Relat. Mater. 9, 502–505 (2000)

H. Yokomichi, T. Funakawa, A. Masuda, Preparation of boron–carbon–nitrogen thin films by magnetron sputtering. Vacuum 66, 245–249 (2002)

S. Nakao, T. Sonoda, K. Tsugawa, J. Choi, T. Kato, Effects of nitrogen gas ratio on composition and microstructure of BCN films prepared by RF magnetron sputtering. Vacuum 84, 642–647 (2009)

V.O. Todi, B.P. Shantheyanda, R.M. Todi, K.B. Sundaram, K. Coffey, Optical characterization of BCN films deposited at various N2/Ar gas flow ratios by RF magnetron sputtering. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 176, 878–882 (2011)

J. Yue, W. Cheng, X. Zhang, D. He, G. Chen, Ternary BCN thin films deposited by reactive sputtering. Thin Solid Films 375, 247–250 (2000)

T. Tavsanoglu, M. Jeandin, O. Addemir, Synthesis and characterisation of thin films in the B–C–N triangle. Surf. Eng. 32, 755–760 (2016)

M. Lei, Q. Li, Z. Zhou, I. Bello, C. Lee, S. Lee, Characterization and optical investigation of BCN film deposited by RF magnetron sputtering. Thin Solid Films 389, 194–199 (2001)

V.O. Todi, B.P. Shantheyanda, K.B. Sundaram, Influence of annealing on the optical properties of reactively sputtered BCN thin films. Mater. Chem. Phys. 141, 596–601 (2013)

D.H. Kim, E. Byon, S. Lee, J.-K. Kim, H. Ruh, Thin Solid Films 447–448, 192 (2004)

L. Liu, Y. Wang, K. Feng, Y. Li, W. Li, C. Zhao, Y. Zhao, Preparation of boron carbon nitride thin films by radio frequency magnetron sputtering. Appl. Surf. Sci. 252, 4185–4189 (2006)

C. Zhuang, J. Zhao, F. Jia, C. Guan, Z. Wu, Y. Bai, X. Jiang, Tuning bond contents in B–C–N films via temperature and bias voltage within RF magnetron sputtering. Surf. Coatings Technol. 204, 713–717 (2009)

L. Liu, Y. Zhao, Y. Tao, D. Yang, H. Ma, Y. Li, Effects of experimental parameters on composition of boron carbon nitride thin films deposited by magnetron sputtering. Appl. Surf. Sci. 253, 439–443 (2006)

A. Prakash, V. Todi, K.B. Sundaram, S.W. King, Hardness studies of RF sputtered deposited BCN thin films. ECS Trans. 58, 147–153 (2014)

A. Prakash, V. Todi, K.B. Sundaram, L. Ross, G. Xu, M. French, P. Henry, S.W. King, Investigation of the dielectric and mechanical properties for magnetron sputtered BCN thin films. ECS J. Solid State Sci. Technol. 4, N3122–N3126 (2015)

A. Prakash, K.B. Sundaram, ECS J. Solid State Sci. Technol. 5, 35 (2016)

A. Prakash, K.B. Sundaram, A.D. Campiglia, Photoluminescence studies on BCN thin films synthesized by RF magnetron sputtering. Mater. Lett. 183, 355–358 (2016)

A. Prakash, K.B. Sundaram, J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 34, 40603 (2016)

A. Prakash, G. Skaria, K.B. Sundaram, Investigation on electrical properties of RF sputtered deposited BCN thin films. ECS Trans. 53, 53–58 (2013)

A. Prakash, K.B. Sundaram, Deposition and XPS studies of dual sputtered BCN thin films. Diam. Relat. Mater. 64, 80–88 (2016)

A. Essafti, E. Ech-chamikh, M. Azizan, Structural and chemical study of a‐BC, a‐CN, and a‐BCN Thin films prepared by reactive RF sputtering*. Spectrosc. Lett. 41, 57–63 (2008)

E.M. Fayyad, A.M. Abdullah, M.K. Hassan, A.M. Mohamed, G. Jarjoura, Z. Farhat, Recent advances in electroless-plated Ni-P and its composites for erosion and corrosion applications: a review. Emergent Mater. 1, 3–24 (2018)

O.O. Fadiran, N. Girouard, J.C. Meredith, Pollen fillers for reinforcing and strengthening of epoxy composites. Emergent Mater. 1, 95–103 (2018)

A. Nagaraj, D. Govindaraj, M. Rajan, Magnesium oxide entrapped polypyrrole hybrid nanocomposite as an efficient selective scavenger for fluoride ion in drinking water. Emergent Mater. 1, 25–33 (2018)

M. Mrlik, P. Sobolciak, I. Krupa, P. Kasak, Light-controllable viscoelastic properties of a photolabile carboxybetaine ester-based polymer with mucus and cellulose sulfate. Emergent Mater. 1, 35–45 (2018)

A. Popelka, P. Sobol, M. Mrlík, Z. Nogellova, I. Chodák, M. Ouederni, M.A. Al-Maadeed, I. Krupa, Foamy phase change materials based on linear low-density polyethylene and paraffin wax blends. Emergent Mater. 1, 47–54 (2018)

D. Ponnamma, A. Erturk, H. Parangusan, K. Deshmukh, M.B. Ahamed, M.A. Al-Maadeed, Stretchable quaternary phasic PVDF-HFP nanocomposite films containing graphene-titania-SrTiO3 for mechanical energy harvesting. Emergent Mater. 1, 55–65 (2018)

T. Meng, C. Yi, L. Liu, A. Karim, X. Gong, Enhanced thermoelectric properties of two-dimensional conjugated polymers. Emergent Mater. 1, 67–76 (2018)

A. Janson, J. Minier-Matar, E. Al-Shamari, A. Hussain, R. Sharma, D. Rowley, S. Adham, Evaluation of new ion exchange resins for hardness removal from boiler feedwater. Emergent Mater. 1, 77–87 (2018)

N. Abdullah, N. Yusof, A.F. Ismail, F.E.C. Othman, J. Jaafar, L.W. Jye, W.N.W. Salleh, F. Aziz, N. Misdan, Effects of manganese(VI) oxide on polyacrylonitrile-based activated carbon nanofibers (ACNFs) and its preliminary study for adsorption of lead(II) ions. Emergent Mater. 1, 89–94 (2018)

E. Byon, M. Son, N. Hara, K. Sugimoto, Thin Solid Films 447–448, 197 (2004)

Z.F. Zhou, I. Bello, M.K. Lei, K.Y. Li, C.S. Lee, S.T. Lee, Surf. Coat. Technol. 128, 334 (2000)

T.-H. Tsai, T.-S. Yang, C.-L. Cheng, M.-S. Wong, Synthesis and properties of boron carbon nitride (BN:C) films by pulsed-DC magnetron sputtering. Mater. Chem. Phys. 72, 264–268 (2001)

A. Prakash, K.B. Sundaram, Studies on electrical properties of RF sputtered deposited boron carbon nitride thin films. ECS J. Solid State Sci. Technol. 4, N25–N29 (2015)

A. Prakash, S.D. Nehate, K.B. Sundaram, Boron carbon nitride based metal-insulator-metal UV detectors for harsh environment applications. Opt. Lett. 41, 4249 (2016)

Funding

Dr. Talal M. Altahtamouni gratefully acknowledges Qatar University for funding the project: GCC Co-Fund Program Grant GCC-2017-007.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zagho, M.M., Dawoud, H.D., Bensalah, N. et al. A brief overview of RF sputtering deposition of boron carbon nitride (BCN) thin films. emergent mater. 2, 79–93 (2019). https://doi.org/10.1007/s42247-018-0018-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-018-0018-9