Abstract

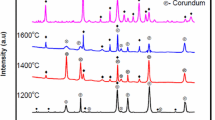

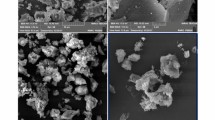

Mullite ceramics were fabricated by reaction sintering using bauxite and kaolin as raw materials and Al(OH)3 as an additive. Enhanced mullite ceramic performance was achieved by optimizing sintering temperature and amount of added Al(OH)3. Results show that higher amount of Al(OH)3 led to increased mullite content. Furthermore, scanning electron microscopy results revealed better interfacial bonding due to interlocking structures of columnar mullite at high sintering temperatures (≥ 1500 °C) in samples prepared with the addition of Al(OH)3. This led to significant improvement in bulk density and mechanical strength of mullite ceramics. Thus, compared with samples prepared without Al(OH)3, the addition of Al(OH)3 was beneficial to formation, growth, and development of mullite. The optimum bulk density of 2.75 g/cm3 was achieved with apparent porosity of 0.79%, and the highest flexural strength of 129.25 MPa was achieved in samples with 12 wt.% Al(OH)3 after sintering at 1550 °C for 3 h.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this article (and its supplementary information files).

References

Cameron, W.E.: Nonstoichiometry in sillimanite: mullite compositions with sillimanite-type superstructures. Phys. Chem. Min. 1, 265–272 (1977)

Sahraoui, T., Belhouchet, H., Heraiz, M., Brihi, N., Guermat, A.: The effects of mechanical activation on the sintering of mullite produced from kaolin and aluminum powder. Ceram. Int. 42, 12185–12193 (2016)

Ananthakumar, S., Jayasankar, M., Warrier, K.G.K.: Microstructural, mechanical and thermal characterisation of sol–gel-derived aluminium titanate–mullite ceramic composites. Acta. Mater. 54, 2965–2973 (2006)

Schneider, H., Schreuer, J., Hildmann, B.: Structure and properties of mullite—A review. J. Eur. Ceram. Soc. 28, 329–344 (2008)

Alves, H.P.A., Silva, J.B., Campos, L.F.A., Torres, S.M., Dutra, R.P.S., Macedo, D.A.: Preparation of mullite based ceramics from clay–kaolin waste mixtures. Ceram. Int. 42, 19086–19090 (2016)

Almeida, R.S.M., Bergmüller, E.L., Eggert, B.G.F., Tushtev, K., Schumacher, T., Lührs, H., Clauß, B., Grathwohl, G., Rezwan, K., Reimanis, I.: Thermal Exposure Effects on the Strength and Microstructure of a Novel Mullite Fiber. J. Am. Ceram. Soc. 99, 1709–1716 (2016)

Zhu, Z., Wei, Z., Shen, J., Zhu, L., Xu, L., Zhang, Y., Wang, S., Liu, T.: Fabrication and catalytic growth mechanism of mullite ceramic whiskers using molybdenum oxide as catalyst. Ceram. Int. 43, 2871–2875 (2017)

Chen, X., Li, T., Ren, Q., Wu, X., Li, H., Dang, A., Zhao, T., Shang, Y., Zhang, Y.: Mullite whisker network reinforced ceramic with high strength and lightweight. J. Alloy. Compd. 700, 37–42 (2017)

Bouchetou, M., Ildefonse, J., Poirier, J., Daniellou, P.: Mullite grown from fired andalusite grains: the role of impurities and of the high temperature liquid phase on the kinetics of mullitization and consequences on thermal shocks resistance. Ceram. Int. 31, 999–1005 (2005)

Rahman, S., Feustel, U., Freimann, S.: Structure description of the thermic phase transformation sillimanite–mullite. J. Eur. Ceram. Soc. 21, 2471–2478 (2001)

Chen, C.Y., Lan, G.S., Tuan, W.H.: Preparation of mullite by the reaction sintering of kaolinite and alumina. J. Eur. Ceram. Soc. 20, 2519–2525 (2000)

Guo, H., Li, W., Ye, F.: Low-cost porous mullite ceramic membrane supports fabricated from kyanite by casting and reaction sintering. Ceram. Int. 42, 4819–4826 (2016)

Xu, X., Lao, X., Wu, J., Zhang, Y., Xu, X., Li, K.: Microstructural evolution, phase transformation, and variations in physical properties of coal series kaolin powder compact during firing. Appl. Clay. Sci. 115, 76–86 (2015)

Sahnoune, F., Chegaar, M., Saheb, N., Goeuriot, P., Valdivieso, F.: Algerian kaolinite used for mullite formation. Appl. Clay. Sci. 38, 304–310 (2008)

Alima, M., Hadda, R., Sihem, B., Afef, A., Yasmina Taïbi, Sabrina, L., Naima, T., Azzedine, G., Sabri, B.: Effect of chamotte on the structural and microstructural characteristics of mullite elaborated via reaction sintering of Algerian kaolin. J. Mater. Res. Technol. 8, 4010–4018 (2019)

Hugo, P.A.A., Rubens, A.J., Liszandra, F.A.C., Ricardo, P.S.D., João, P.F.G., Francisco, J.A.L., Daniel, A.M.: Structural study of mullite based ceramics derived from a mica-rich kaolin waste. Ceram. Int. 43, 3919–3922 (2017)

Ebrahim, K.S., Touradj, E., Esmaeil, S.: Preparation of mullite from alumina/aluminum nitrate and kaolin clay through spark plasma sintering process. Ceram. Int. 44, 21053–21066 (2018)

Ma, J., Ye, F., Zhang, B., **, Y.C., Yang, C., Ding, J., Zhang, H.Q., Liu, Q.: Low-temperature synthesis of highly porous whisker-structured mullite ceramic from kaolin. Ceram. Int. 44, 13320–13327 (2018)

Rashad, M., Balasubramanian, M.: A quantitative analysis of in-situ gases on the properties of porous mullite developed from clay and AlF3·3H2O. Ceram. Int. 45, 1420–1423 (2019)

Maldhure, A.V., Tripathi, H.S., Ghosh, A., Das, S.K.: Mullite-Corundum Composites from Bauxite: Effect of Chemical Composition. T. Indian. Ceram. Soc. 73, 31–36 (2014)

Li, J.H., Ma, H.W., Huang, W.H.: Effect of V2O5 on the properties of mullite ceramics synthesized from high-aluminum fly ash and bauxite. J. Hazard. Mater. 166, 1535–1539 (2009)

Du, X., Wang, Y., Su, X., Li, J.: Influences of pH value on the microstructure and phase transformation of aluminum hydroxide. Powder. Technol. 192, 40–46 (2009)

Yuan, W., Kuang, J., Huang, Z., Yu, M.: Effect of aluminum source on the kinetics and mechanism of mullite preparation from kaolinite. Chem. Phys. Lett. 787, 139242–139248 (2022)

Guo, H., Li, W.: Effects of Al2O3 crystal types on morphologies, formation mechanisms of mullite and properties of porous mullite ceramics based on kyanite. J. Eur. Ceram. Soc. 38, 679–686 (2018)

Liu, Z., **e, N., Zhang, H., Huang, S., Wu, C., He, S., Zhu, J., Liu, Y.: Effect of Al(OH)3 addition on densification mechanism and properties of reaction-sintered mullite-corundum composite ceramics. J. Asian. Ceram. Soc. 10, 703–712 (2022)

Hubbard, C.R., Snyder, R.L.: RIR - Measurement and Use in Quantitative XRD. Powder. Diffr. 3, 74–77 (2013)

Peng, L., Qin, S.: Sintering Behavior and Technological Properties of Low-Temperature Porcelain Tiles Prepared Using a Lithium Ore and Silica Crucible Waste. Minerals-Basel. 9, 731–746 (2019)

Ren, Q., Li, H., Wu, X., Huo, Z., Hai, O., Lin, F.: Effect of the calcining temperatures of low-grade bauxite on the mechanical property of mullite ceramics. Int. J. Appl. Ceram. Tec. 15, 554–562 (2018)

Chen, Y., Wang, M., Hon, M.: Phase transformation and growth of mullite in kaolin ceramics. J. Eur. Ceram. Soc. 24, 2389–2397 (2004)

Li, S., Du, H., Guo, A., Xu, H., Yang, D.: Preparation of self-reinforcement of porous mullite ceramics through in situ synthesis of mullite whisker in flyash body. Ceram. Int. 38, 1027–1032 (2012)

Romero, M., Padilla, I., Contreras, M., López-Delgado, A.: Mullite-Based Ceramics from Mining Waste: A Review. Minerals-Basel. 11, 332–370 (2021)

Yan, M., Li, Y., Sun, Y., Li, L., Tong, S., Sun, J.: Controllable preparation and synthetic mechanism of mullite from the bauxite with Fe-rich oxide content. Mater. Chem. Phys. 202, 245–250 (2017)

Yue, X., Li, Y., Ma, C., Zheng, Q., Wu, X., Li, B.: Novel process for synthesizing fused mullite from titanium-rich medium/low grade or waste bauxite. Ceram. Int. 48, 8228–8234 (2022)

Liu, X., Deng, C., Deng, C., Liu, M., Zhou, K.: Mullite-modified ZrB2-MoSi2 coating for carbon/carbon composites to withstand long term ablation. Ceram. Int. 44, 4330–4337 (2018)

Zhao, D., Wu, D., Shi, J., Niu, F., Ma, G.: Microstructure and mechanical properties of melt-grown alumina-mullite/glass composites fabricated by directed laser deposition. J. Adv. Ceram. 11, 75–93 (2021)

Goren, R., Gocmez, H., Ozgur, C.: Synthesis of cordierite powder from talc, diatomite and alumina. Ceram. Int. 32, 407–409 (2006)

Chen, Y., Wang, Y., Hon, M.: Secondary Mullite Formation in Kaolin–Al2O3 Ceramics. J. Mater. Res. 19, 806–814 (2004)

Chen, Y., Wang, M., Hon, M.: Transformation kinetics for mullite in kaolin–Al2O3 ceramics. J. Mater. Res. 18, 1355–1362 (2003)

Li, J.G., Sun, X.D.: Synthesis and sintering behavior of a nanocrystalline α-alumina powder. Acta. Mater. 48, 3103–3112 (2000)

Rashad, M., Sabu, U., Logesh, G., Srishilan, C., Lodhe, M., Joy, A., Balasubramanian, M.: Mullite phase evolution in clay with hydrated or anhydrous AlF3. J. Eur. Ceram. Soc. 40, 5974–5983 (2020)

Lee, W.E., Jayaseelan, D.D., Zhang, S.: Solid–liquid interactions: The key to microstructural evolution in ceramics. J. Eur. Ceram. Soc. 28, 1517–1525 (2008)

Zhang, J., Ke, C., Wu, H., Zhang, S., Yu, J.: Anisotropic Grain Growth Mechanism of Mullite Derived from Cobalt Oxide Doped Diphasic-Gels. Rare. Metal. Mat. Eng. 44, 323–326 (2015)

Liu, X.Y., Maiwa, K., Tsukamoto, K.: Heterogeneous two-dimensional nucleation and growth kinetics. J. Chem. Phys. 106, 1870–1879 (1997)

Bai, C., Li, Y., Liu, Z., Liu, P., Deng, X., Li, J., Yang, J.: Fabrication and properties of mullite-bonded porous SiC membrane supports using bauxite as aluminum source. Ceram. Int. 41, 4391–4400 (2015)

Acknowledgements

This work was supported by the Scientific Research Foundation for High-level Talents of Anhui University of Science and Technology (Grant No. 2023yjrc57), the National Natural Science Foundation of China (Grant No. 11872001), the Key Technologies R&D Program of Anhui Province of China (Grant No. 202104a05020033), the Foundation of State Key Laboratory of High-efficiency Utilization of Coal and Green Chemical Engineering (Grant No. 2021-K19), the Anhui Provincial Major Science and Technology Special Program (Grant No. 18030901049), the School-enterprise Cooperation Projects (Grant No. HX2021062279), and the College Students Innovation and Entrepreneurship Training Program (Grant No. S202210361144). We would like to thank MogoEdit (https://www.mogoedit.com) for its English editing during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by [Zhenying Liu], [Nan **e], and [Hanxin Zhang]. Conceptualization: [Zhenying Liu]; methodology: [Nan **e]; formal analysis and investigation: [Zhenying Liu], and [Nan **e]; writing-review and editing: [Zhenying Liu], [Nan **e], [Hanxin Zhang], [Shouwu Huang], [Kai Wang], [Kai Cui], [Changguo Xue], [Hongzheng Zhu], and [Yin Liu]; Funding acquisition: [Zhenying Liu], [Kai Cui], [Changguo Xue], [Hongzheng Zhu], and [Yin Liu]; and Supervision: [Changguo Xue], [Hongzheng Zhu], and [Yin Liu]. The first draft of the manuscript was written by [Zhenying Liu] and all authors commented on previous versions of the manuscript. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Z., **e, N., Zhang, H. et al. Effect of Al(OH)3 content on properties, microstructure, and sintering mechanism of mullite ceramics from bauxite. J Aust Ceram Soc 60, 13–23 (2024). https://doi.org/10.1007/s41779-023-00950-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-023-00950-3