Abstract

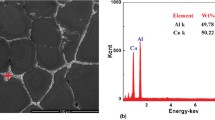

In order to explore the solid solution strengthening mechanism of Al-Si series alloy under semi-solid squeezing casting an experiment was conducted to cast, heat treat, and then characterize the material. OM, SEM, and TEM were selected as tools to characterize the microstructure and mechanical properties of semi-solid extrusion Al–Si–Cu–Mg alloy under different solution times. The results show that the eutectic Si phase fuses, the Al2Cu phase rapidly dissolves into the matrix, and the dislocation density in the matrix slightly decreases at the initial stage of solution. When the solution time reaches 8 h, the spheroidization degree of the eutectic Si phase reaches its optimum shape as measured by aspect ratio and size. The Al2Cu phase is essentially completely dissolved into the matrix, leading to a significant reduction in the dislocation density within the matrix. The alloy reached a relatively high mechanical properties after 1 hour of solid solution at 525 °C. The dissolution of the Cu element in the matrix and the enrichment of dislocation lines around the Si phase together contribute to strengthening the α-Al phase. Additionally, another strength peak emerges at 8 h of solid solution. The second strength peak is mainly attributed to the refinement of the eutectic Si phase and the solution strengthening of the Al2Cu phase.

Similar content being viewed by others

References

X.Y. Jiao, C.F. Liu, Z.P. Guo et al., On the characterization of primary iron-rich phase in a high-pressure die-cast hypoeutectic Al–Si alloy. J Alloy Compd 862, 158580 (2021). https://doi.org/10.1016/j.jallcom.2020.158580

G.D. Ma, L. Li, S.Y. ** et al., Enhanced combination of strength and ductility in the semi-solid rheocast hypereutectic Al Si alloy with the effect of in-situ TiB2 particles. Mater Charact 176, 11143 (2021). https://doi.org/10.1016/j.matchar.2021.111143

A.M. Samuel, M.H. Abdelaziz, H.W. Doty et al., Metallurgical parameters controlling fragmentation and spheroidization processes of eutectic Si particles in Al–Si cast alloys. Inter Metalcast 16, 1709–1731 (2022). https://doi.org/10.1007/s40962-021-00702-8

H. Tahiri, A.M. Samuel, H.W. Doty et al., Effect of Sr–grain refiner–Si Interactions on the microstructure characteristics of Al–Si hypereutectic alloys. Inter Metalcast 12, 307–320 (2018). https://doi.org/10.1007/s40962-017-0164-5

P. Yan, Y. Liu, W. Mao et al., Effect of antimony on the microstructure evolution and mechanical properties of hypereutectic Al–Si rheological high pressure die casting alloy. Inter Metalcast 16, 1733–1744 (2022). https://doi.org/10.1007/s40962-021-00718-0

S.A. Hassasi, M. Abbasi, S.J. Hosseinipour, Parametric investigation of squeeze casting process on the microstructure characteristics and mechanical properties of A390 aluminum alloy. Inter Metalcast 14, 69–83 (2020). https://doi.org/10.1007/s40962-019-00325-0

W.J. Gao, S.M. **ng, G.Y. Yan et al., Effect of oscillation frequency on microstructure of A356 slurry prepared by semi-solid metal forming with flow. J Mater Process T 311, 1–9 (2023). https://doi.org/10.1016/j.jmatprotec.2022.117829

N. Umudee, J. Wannasin, S. Janudom et al., Study of surface segregation defect of 7075 aluminum alloy in semi-solid squeeze casting. A M M 752–753, 3–6 (2015)

H. Liu, L. Li, J. Niu et al., Effect of Mg and Cu additions on microstructure and mechanical properties of squeeze casting Al–Si–Cu–Mg alloy. Mater Sci Forum 850, 511–518 (2016). https://doi.org/10.4028/www.scientific.net/MSF.850.511

J. Hao, B. Yu, J. Bian et al., Comparison of the semisolid squeeze casting and gravity casting process on the precipitation behavior and mechanical properties of the Al–Si–Cu–Mg alloy. Mater Charact 180, 111 (2021). https://doi.org/10.1016/j.matchar.2021.111404

M. Qi, Y. Kang, Q. Qiu et al., Microstructures, mechanical properties, and corrosion behavior of novel high-thermal-conductivity hypoeutectic Al–Si alloys prepared by rheological high-pressure die-casting. J Alloy Compd 749, 487–502 (2018). https://doi.org/10.1016/j.jallcom.2018.03.178

W. Cheng, C.Y. Liu, H.F. Huang et al., High strength and ductility of Al–Si–Mg alloys fabricated by deformation and heat treatment. Mater Charact 178, 111 (2021). https://doi.org/10.1016/j.matchar.2021.111278

S. Beroual, Z. Boumerzoug, P. Paillard et al., Effects of heat treatment and addition of small amounts of Cu and Mg on the microstructure and mechanical properties of Al–Si–Cu and Al–Si–Mg cast alloys. J Alloy Compd 784, 1026–1035 (2019). https://doi.org/10.1016/j.jallcom.2018.12.365

J.A. Taylor, D.H. Stjohn, J. Barresi et al., Influence of Mg content on the microstructure and solid solution chemistry of Al–7%Si–Mg casting alloys during solution treatment. Mater Sci Forum 331, 277–282 (2017). https://doi.org/10.4028/www.scientific.net/MSF.331-337.277

Y.J. Li, S. Brusethaug, A. Olsen et al., Influence of Cu on the mechanical properties and precipitation behavior of AlSi7Mg0.5 alloy during aging treatment. Scripta Mater 54(1), 99–103 (2006). https://doi.org/10.1016/j.scriptamat.2005.08.044

P. Ouellet, F.H. Samuel, Effect of Mg on the ageing behaviour of Al–Si–Cu 319 type aluminium casting alloys. J Mater Sci 34(19), 4671–4697 (1999). https://doi.org/10.1023/A:1004645928886

Y. **ng, Z.H. Jia, J.H. Li, L.P. Ding et al., Microstructure and mechanical properties of foundry Al–Si–Cu–Hf alloy. Mater Sci Eng A 722, 197–205 (2018)

Y.C. Lin, S.C. Luo, L.X. Yin et al., Microstructural evolution and high temperature flow behaviors of a homogenized Sr-modified Al–Si–Mg alloy. J Alloys Compd 739, 590–599 (2018). https://doi.org/10.1016/j.jallcom.2017.12.278

D.L. Zhang, L.H. Zheng, D.H. StJohn, Effect of solution treatment temperature on tensile properties of AI-7Si-0.3Mg (wt-%) alloy. Mater Sci Technol 14, 619–625 (1998). https://doi.org/10.1179/mst.1998.14.7.619

E. Tillová, M. Panuková, Effect of solution treatment on intermetallic phases morphology in AlSi9Cu3 cast alloy. Metalurgija 47(3), 207–210 (2008)

Q. Cai, C.L. Mendis, S. Wang et al., Effect of heat treatment on microstructure and tensile properties of die-cast Al–Cu–Si–Mg alloys. J Alloys Compd 881, 160559 (2021). https://doi.org/10.1016/j.jallcom.2021.160559

H. Yang, S. Ji, W. Yang et al., Effect of Mg level on the microstructure and mechanical properties of die-cast Al–Si–Cu alloys. Mater Sci Eng A 642, 340–350 (2015). https://doi.org/10.1016/j.msea.2015.07.008

M.F. Qi, B. Li, P.F. Zhang et al., Improvement of mechanical properties of Al–Si–Cu alloy diecastings combined with Cd microalloying and semisolid forming. Mater Sci Eng A 861, 144312 (2022). https://doi.org/10.1016/j.msea.2022.144312

K.S. Alhawari, M.Z. Omar, M.J. Ghazali et al., Microstructural evolution during semisolid processing of Al–Si–Cu alloy with different Mg contents. Trans Nonferr Metal Soc 27(7), 1483–1497 (2017). https://doi.org/10.1016/S1003-6326(17)60169-9

S. Nafisi, R. Ghomashchi, Grain refining of conventional and semi-solid A356 Al–Si alloy. J Mater Process Tech 174(1), 371–383 (2006). https://doi.org/10.1016/j.jmatprotec.2006.02.012

M. Haghshenas, H.A. Zarei, S.M. Fatemi et al., The effects of thermo-mechanical parameters on the microstructure of Thixocast A356 aluminum alloy. Mater Sci Eng A 480, 68–74 (2008). https://doi.org/10.1016/j.msea.2007.06.075

Z. Chen, Y. Zhao, Z. Zhang, Theoretical and experimental study of precipitation and coarsening kinetics of θ′ phase in Al–Cu alloy. Vacuum 189(12), 110263 (2021). https://doi.org/10.1016/j.vacuum.2021.110263

C.H. Chiang, Y.A. Chi, Si coarsening of spray-formed high loading hypereutectic Al–Si alloys in the semisolid state. Mater Sci Eng A 396(1), 263–270 (2005). https://doi.org/10.1016/j.msea.2005.01.017

E. Sjölander, S. Seifeddine, Optimisation of solution treatment of cast Al–Si–Cu alloys. Mater Des 31, 44–49 (2010). https://doi.org/10.1016/j.matdes.2009.10.035

B. Niethammer, J.J. Velázquez, Global stability and bounds for coarsening rates within the mean-field theory for domain coarsening. Commun Part Diff Eq 31(11), 1679–1708 (2006). https://doi.org/10.1080/03605300500481533

S. Menargues, E. Martin, M.T. Baile et al., New short T6 heat treatments for aluminium silicon alloys obtained by semisolid forming. Mater Sci Eng A 621(1), 236–242 (2015). https://doi.org/10.1016/j.msea.2014.10.078

H. Wei, Y. Chen, Z. Li et al., Microstructure evolution and dislocation strengthening mechanism of Cu–Ni–Co–Si alloy. Mater Sci Eng A 826, 142023 (2021). https://doi.org/10.1016/j.msea.2021.142023

T.H. Liu, C.W. Pao, C.C. Chang, Effects of dislocation densities and distributions on graphene grain boundary failure strengths from atomistic simulations. Carbon 50(10), 3465–3472 (2012). https://doi.org/10.1016/j.carbon.2012.03.012

Y. Mazaheri, A. Fattah-alhosseini, Y. Mazaheri et al., Effects of grain size and dislocation density on strain hardening behavior of ultrafine grained AA1050 processed by accumulative roll bonding. J Alloys Compd 658, 854–861 (2016). https://doi.org/10.1016/j.jallcom.2015.11.032

Z. Zhu, M.J. Starink, Solution strengthening and age hardening capability of Al–Mg–Mn alloys with small additions of Cu. Mater Sci Eng A 488(1–2), 125–133 (2008). https://doi.org/10.1016/j.msea.2007.12.018

J.Y. Yao, J.A. Taylor, Characterisation of intermetallic particles formed during solution treatment of an Al–7Si–0.4Mg–0.12Fe alloy. J Alloys Compd 519, 60–66 (2012). https://doi.org/10.1016/j.jallcom.2011.12.047

M. Liu, C. Zhang, Z. Meng et al., Atomic diffusion mechanism and interface nanomechanics in the Al/Ti composite structures. Compos Part B Eng 230, 109507 (2022). https://doi.org/10.1016/j.compositesb.2021.109507

Acknowledgement

The author expresses their gratitude to National Natural Science Foundation of China (No. 51974092), Education Department of Guangdong Province (No. 2020ZDZX2058), the Guangdong Basic and Applied Basic Research Foundation (No. 2021B1515120028), Guangdong Basic and Applied Basic Research Foundation (2020A1515110386), the National Natural Science Foundation of China (Grant No. 52001073).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled “Evolution of solid solution microstructure of Al–Si–Cu–Mg alloy formed by semi-solid squeeze casting.”

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hao, J., Chen, B., **a, P. et al. Effect of solid solution treatment on microstructure and mechanical properties of Al–Si–Cu–Mg alloy prepared by semi-solid squeeze casting. Inter Metalcast (2023). https://doi.org/10.1007/s40962-023-01160-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40962-023-01160-0