Abstract

The purpose of this article is to receive environmental assessments of combustion of different types of coal fuel depending on the preparation (unscreened, size-graded, briquetted and heat-treated) in automated boilers and boilers with manual loading. The assessments were made on the basis of data obtained from experimental methods of coal preparation and calculated methods of determining the amount of pollutant and greenhouse gas emissions, as well as the mass of ash and slag waste. The main pollutants from coal combustion are calculated: particulate matter, benz(a)pyrene, nitrogen oxides, sulfur dioxide, carbon monoxide. Of the greenhouse gases carbon dioxide is calculated. As a result of conducted research it is shown that the simplest preliminary preparation (size-graded) of coal significantly improves combustion efficiency and environmental performance: emissions are reduced by 13% for hard coal and up to 20% for brown coal. The introduction of automated boilers with heat-treated coal in small boiler facilities allows to reduce emissions and ash and slag waste by 2–3 times. The best environmental indicators correspond to heat-treated lignite, which is characterized by the absence of sulfur dioxide emissions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The relevance of this study is determined by the need to form energy-efficient directions of development of the energy sector of Russia in order to improve the quality, reliability, and environmental friendliness of supplying heat to consumers of social and industrial sectors.

An important feature of the Asian part of Russia is the high share of coal in the fuel balance, while in the European part, natural gas accounts for the great bulk of it (Fortescue 2016). This fact is due to the large reserves of coal that ensure its low cost (compared to other fossil fuels) and ease of use (Gorbacheva and Sovacool 2015). Another feature is that there is a significant share of heating by small sources, which include boiler houses with boilers up to 1 MW and individual heating boilers. This trend is particularly acute in Eastern Siberia and the Russian Far East, where small heat sources account for as much as 80%–90%. A similar situation is observed in places of special nature use, including protected natural areas, in the ecological zones of the Baikal natural area (Borisov 2020; Maysyuk 2020).

Moreover, there are extensive areas of decentralized heating. Their existence is due to the economic inexpediency of creating district heating systems in areas with low density of heat loads. First of all, this applies to rural areas and urban areas with low-rise buildings (Kozhageldi et al. 2022). The reorientation of housing programs towards the construction of low-rise individual housing at an accelerated pace and the increase in the welfare of the population suggest that the scale of decentralized heating will be maintained, and perhaps even increased. These are exactly the trends that take place in developed countries abroad (Bellos et al. 2022). According to a number of studies, the combustion of coal in small heat sources is recognized as a significant source of air pollution, especially in severely continental climate zones. This fact is due to unfavorable conditions of atmospheric diffusion (low temperatures and height of the planetary boundary layer) (Zhou et al. 2020). Air pollution is also associated with low combustion efficiency, the use of some types of coal and types of boilers, as well as the low emission height (up to 10–30 m) in the absence of means of cleaning flue gases from pollutants (Cheng et al. 2017). It is worth noting that in the case of large heat sources there are various technologies for treatment of flue gases, methods of CO2 capture and storage, as well as methods of removal of nitrogen and sulfur compounds from gas (Hong 2022; Tian et al. 2022). The emission reduction methods used are cost-effective only in the case of large power plants. Research experience in the field of small-capacity heating systems shows that, despite the emergence of new, more up-to-date technologies that allow one to increase the efficiency of heat generation and obtain better environmental performance (Pavlović et al. 2022), implementation of these technologies in real-world heating systems fails to take place due to significant capital expenditures, which turns out to be economically unprofitable for small boilers houses (Jaworek et al. 2021).

There are studies (**gchao et al. 2019) that show that it is also possible to solve environmental problems by switching from low-quality to high-quality coals, or by introducing a new type of furnace.

However, in our opinion, for small boiler plants an alternative way to reduce air pollutants is the development of rational directions of use of existing methods for preparation of coal for combustion (size-grading, briquetting, heat-treatment) (Das et al. 2022; Çınar 2009). It is worth noting that similar issues of using coal in small boilers exist not only in Russia but also in such countries as Canada, China, and some European countries (Zhao et al. 2021; Wyrzykowska et al. 2009).

For example, China has started to actively implement CCT (Clean Coal Technology) since the 2020s. This technology takes into account the properties of local coals (Wang et al. 2019). In addition, "clean coal" technologies imply a wider sense of efficient use of low-emission coal: from extraction to final consumption. The "clean coal" technologies also may include aspects of coal cleaning assessment, geophysics, hydrogeology, mining geology, mine reclamation, coal preparation, coal conversion, and clean coal use (Wang et al. 2020).

Coal preparation, which can be called cleaning or reprocessing, is essentially the modernization of coal raw material in order to improve its properties and minimize the impact on the environment. This issue has been discussed for quite a long time and mainly on the scale of large coal preparation plants, factories and mines, when the modernization of coal raw materials occurs after mining and before transporting it to the consumer (Luttrell and Honaker 2020). Typically, all technologies have high costs, but interest in them has not decreased.

It is necessary to note that in Russia, calculation methods are used to determine the amount of pollutant emissions into the atmosphere. This is explained by the difficulty of obtaining reliable information about the performance of boilers, especially difficult for hot-water boilers of small capacity.

In other countries, data from periodic measurements of concentrations in exhaust gases using special emission factors are used for this purpose.

Thus, the purpose of the study is an environmental performance assessment of the combustion of different types of coal, depending on the preparation (unscreened coal, size-graded coal, coal briquettes, and heat-treated coal) in automated boilers and hand-fed boilers.

Calculations of emissions were made for the main pollutants from coal combustion: particulate matter, benz(a)pyrene, nitrogen oxides, sulfur dioxide, carbon monoxide. Calculation of greenhouse gas emissions is given for carbon dioxide.

Application of the findings of this research contribution will allow one to address the main issues of heat sources of small capacity and produce a system-wide effect:

-

(1)

reduce emissions of pollutants into the atmosphere, primarily sulfur oxides;

-

(2)

increase the efficiency of heat generation by reducing fuel consumption;

-

(3)

reduce slag and ash generation by reducing fuel consumption (up to 1.5 times);

-

(4

enable the use of modern technologies with a high degree of automation of fuel combustion processes;

-

(5)

make it economically feasible to replace inefficient heat sources with more modern ones that are more economical and environmentally friendly.

2 Prerequisites for the use of size-graded coal, coal briquettes, and heat-treated coal

In the course of numerous thermal energy surveys by the staff of the Melentiev Energy Systems Institute, SB RAS, it was found that the actual gross efficiency of a small-capacity boiler is 32%–62%. At the same time, the standard values should be 76%–80%. For example, the boiler plant KVr-100 K was examined, which is a boiler of standard design with hand-fed fuel. A distinct feature of this boiler is the formation of a high fuel bed, the lack of convective heating surfaces, i.e., heat transfer is carried out only by radiation. Table 1 shows the values of heat loss and efficiency of this boiler (Filippov et al. 2005).

The main reason for the low efficiency of the operation of surveyed boilers is that in the stoker they burn ROM coal of a wide size range from 0 to 300 mm with a clear predominance of fines. Significant amounts of fines contribute to increased airflow, and with the presence of various leaks and the uncontrolled nature of the air supply, the optimum airflow factor is exceeded by many times. As a consequence, there is a significant increase in heat loss due to exhaust gases. In addition, combustion of coal with a high content of fines forms a dense, poorly blown bed. As a result, the heating and pyrolysis stages are prolonged for a long time, which contributes to the formation of extensive zones with a reducing atmosphere. This fact, in turn, causes the low temperature values in the bed and its slow growth. All this leads to an increase in incomplete combustion and unburned carbon as well as the formation of pollutants (Comparative combustion of coals from Eastern Siberia in heating boilers of low power and house stoves: scientific report 1998).

The existing coal-fired boilers are characterized by low efficiency of heat generation. This is mainly due to three factors:

-

(1)

the use of low-quality run-of-mine fuel;

-

(2)

the use of boilers with low efficiency;

-

(3)

significant impact of the human factor.

Solving any one or even two of these issues usually does not lead to the desired increase in the efficiency of heat generation. The effect of using prepared fuel is offset by poor boiler designs and poorly qualified personnel who maintain operating conditions that do not correspond to high efficiency. High-efficiency automated boilers cannot be used for run-of-mine fuel whose lump sizes vary greatly. Therefore, for decades there has been no change for the better in heat generation with fuel-bed coal combustion (Maysyuk and Kozlov 2019).

Improving the efficiency of coal combustion in small boiler houses and individual boilers can be achieved by taking measures to prepare the coal for combustion: size-grading, briquetting, and heat treatment (Maysyuk and Kozlov 2020). Figure 1 shows the appearance of coal depending on the type of preparation.

Simple size-grading of coal up to a size of 15–50 mm contributes to the fact that the fuel bed is well permeable to air. If the fuel enters the hot furnace, the devolatilization occurs within a short period of time, which helps accelerate the combustion of coal.

However, it should be borne in mind that a number of lignites is ill-fitted for storing outdoors and after 3–4 weeks begins to decompose, so that such coal must be used up during this period. To do this, one should establish a system of its regular deliveries and quality storage at the customers (closed ventilated warehouse). Arranging of size-grading in the case of regular deliveries to the consumer can be organized directly at the mine, or at the sites of large consumers who have pulverized coal boilers, for which the fine size-graded fraction will serve as the feedstock (Zakharov et al. 2019).

Another method of coal preparation is briquetting. As a rule, the raw material for briquettes is the carbon-containing waste obtained after beneficiation. At the same time, this waste cannot be effectively used for combustion in power plants. Coal briquettes are produced by grinding the carbon-containing raw material to dust, then it is dried and then pressed. The shape of briquettes can vary significantly: ellipsoid, semi-ellipsoid, sphere, cylinder, etc. (Zhuo et al. 2019) A binder may be added during this process. It is worth noting that depending on the type of binder, combustion may produce pollutants in addition to those produced by burning the coal itself. Inorganic additives such as CaO, red mud, aluminum production waste, etc. are also often used in briquetting. These additives react with sulfur-containing components of the gas mixture (SO2, H2S) to form sulfates (Zhang et al. 2020, 2018).

Table 2 shows the results of the proximate analysis of coal briquettes and raw coal. A binder was used in the manufacture of the coal briquette. Proximate and ultimate analysis of coal briquettes and coal was made by the authors of the article using ASTM standards and the methodology described in Kozlov et al. (2015).

Analyzing the values presented in Table 2, we can conclude that the technical specifications of the raw coal and coal briquettes are approximately the same. A slight difference in the briquette is the presence of a binder, which slightly changes its composition. The moisture content of coal is much lower than that usually found in coal combustion in stoker-fired boilers. This is due to the fact that the analytical sample of coal was heavily dried before the study. The moisture content of coal briquettes is within the operating range for this type of fuel.

Despite the fact that the technical specifications of the raw coal and briquettes do not differ drastically, the use of briquettes has several advantages. Firstly, carbon-containing waste is recycled, and secondly, it is transported in bags of small volume or in big bags, which contributes to the preservation of briquettes without loss of quality. The use of this type of fuel is especially relevant for individual fuel-fired boilers, because the same size briquettes form an air-permeable layer with good combustion performance. It is important to note that the widespread introduction of coal briquettes for individual heating of gers in Mongolia has been underway since 2019. There has been a noticeable decrease in the air content of pollutants from coal combustion.

Heat treatment is also a good way to prepare coal for use. The technology of heat treatment is as follows: the raw coal is heated to a certain temperature without exposure to air. As a result of heat treatment, most of the volatile substances, including sulfur- and nitrogen-containing compounds, are removed from the coal, and the semi-coke gets improved technical and reactivity properties compared to the raw coal. The semi-coke is subsequently sent for briquetting.

Briquetting is carried out under pressure and high temperature. The same briquette size ensures efficient combustion, which reduces fuel consumption and, consequently, the formation of ash compounds (Knigawka et al. 2022).

Currently, the Siberian Coal Energy Company (SUEK) has established the production of coal briquettes at the Berezovsky open pit in the Sharypovsky district of Krasnoyarsk Krai. These briquettes are successfully used in Krasnoyarsk Krai in individual household stoves. Briquettes are packed in 20 kg bags and big bags of 550 kg.

Coal briquettes are characterized by the following characteristics (Stepanov et al. 2020):

-

size = 10–40 mm;

-

ash content = 16%–22%;

-

heat of combustion = 18.4–19.4 kJ/kg;

-

moisture content = no more than 7%.

Thus, heat treatment of coal provides almost complete removal of fuel compounds of nitrogen and sulfur, which significantly reduces or completely eliminates emissions of oxides of these substances into the atmosphere, and by reducing fuel consumption by 1.5 times partially reduces emissions of particulate matter, and, accordingly, reduces the amount of slag and ash due to a more complete combustion of fuel (Maysyuk and Kozlov 2020).

Fuel preparation enables improving the environmental performance of coal-fired boilers.

The cost of such fuel increases 2–2.2 times compared to conventional coal. But due to higher combustion heat and increased efficiency of heat production, fuel consumption is reduced and the cost of its delivery is reduced. As a result, fuel costs at the boiler house as a whole are reduced.

Centralized fuel preparation provides a comprehensive solution to the problem of low efficiency of boiler plants with fuel-bed combustion of coal. With prepared fuel, it is possible to use automated boilers, which have high efficiency ratings and do not require human intervention to control and maintain operating conditions. That is, all three causes of low efficiency of boiler plants are eliminated at once (Saneev et al. 2019).

When switching to the use of prepared fuel with its combustion in automated boilers, the structure of the cost of heat produced changes. This ensures the economic feasibility of such a transition. The efficiency of heat generation increases significantly up to 85%–90%. Fuel consumption is reduced by about 30%–35% and, accordingly, the volume of fuel transportation and transportation costs. The payroll gets significantly reduced.

One successful case is the introduction of Thermorobot automated coal boilers with boilers of capacities ranging from 60 to 800 kW. These boilers run on prepared fuel. The efficiency of Thermorobot boilers is about 87%. At the same time, as shown by the study, incomplete combustion and unburned carbon are as small as possible. However, high quality size-graded coal with the grain size of about 50 mm was used (moisture content—21.7%, ash content—9.1%, volatile matter yield—42%, sulfur content—0.5%, calorific value per as-received basis—19.5 kJ/kg). These automated boilers are actively being introduced in the Asian part of Russia, in particular in protected natural areas, such as the Baikal Natural Area (Maysyuk 2019).

3 Methodological guidelines and approaches to the assessment of environmental performance metrics

Calculation of pollutant emissions into the atmosphere was performed in accordance with the "Methodology for determining the emissions of pollutants when burning fuel in boilers with a capacity of less than 30 tons of steam per hour or less than 20 Gcal per hour" (1999; Guidance letter of the Research Institute of Atmosphere 2000).

This methodology is designed to determine the amount of pollutant emissions into the atmosphere based on measurements of concentrations in flue gases. In European countries, as well as in Australia, the amount of emissions from energy facilities is estimated using data on periodic measurements of concentrations of pollutants in flue gases and taking into account special emission factors (National Pollutant Inventory 2011; EEA Report No 2019).

However, due to the difficulty of obtaining reliable information on direct measurements, especially in small capacity hot water boilers, computational methods are used (Methodology for determining the emissions of pollutants when burning fuel in boilers with a capacity of fewer than 30 tons of steam per hour or less than 20 Gcal per hour 1999; Guidance letter of the Research Institute of Atmosphere 2000).

Computational methods allow one to determine the emissions of major pollutants: particulate matter, sulfur dioxide (SO2), nitrogen oxides (NO), carbon monoxide (CO) and benz(a)pyrene (B[a]P), taking into account the burning of different types of fuel, including solid fuel.

For example, to calculate the amount of particulate emissions (MPM) in t/year, formula (1) is used:

where, B is the fuel consumption, t/year; Ar is the ash content of fuel in as-received basis, %; afa is the fraction of ash in the fly ash; q4 is the heat loss due to mechanical incomplete combustion of fuel, %; LHV is the lower calorific value of fuel, kJ/kg; η is the degree of ash purification, %.

As can be seen from Eq. (1), the amount of particulate emissions depends on the qualitative composition of fuel, its quantity (fuel consumption), the conditions of combustion in boiler plants, and the operation of purification equipment. A similar conclusion holds for the calculations of sulfur and carbon oxides (Methodology for determining the emissions of pollutants when burning fuel in boilers with a capacity of fewer than 30 tons of steam per hour or less than 20 Gcal per hour 1999; Guidance letter of the Research Institute of Atmosphere 2000).

However, the mathematical description for calculating emissions of nitrogen oxides and B[a]P is much more complicated, for which one needs to consider the recommendations and specific data of the equipment installed in the boiler house.

It is recommended to calculate the amount of nitrogen oxides emissions during fuel-bed combustion of solid fuel by (2):

where, Bp is th estimated fuel consumption, determined depending on the mechanical incomplete combustion of fuel in the boiler, t/year; \(\beta_{\text{r}}\) is the dimensionless factor that accounts for the influence on the formation of nitrogen oxides of recirculation of flue gases fed in mixture with blowing air under the grate; αt is the equivalence ratio in the furnace for small-capacity boilers with fixed grate and hand-fed fuel, which is recommended to choose according to the standard method of boiler plant analysis (Thermal analysis of boilers, standard method 1998); R6 is the characteristic of the particle size distribution of coal, the residue on the screen with a mesh size of 6 mm; \(q_{\text{R}}\) is the thermal stress of the fuel-burning area, which is determined depending on the fuel-burning area of the boiler and the actual heat output with respect to the heat introduced into the furnace, MW/m2; \(k_{\text{f}}\) is the conversion factor in determining the emissions, t/year.

(3) is recommended for calculating B[a]P emissions:

where, CB[a]P is the mass concentration of B[a]P in dry flue gases at a standard equivalence ratio of 1.4 and normal conditions (temperature = 273 K and pressure = 101.3 kPa) is determined by the formula (4); \(V_{\text{DG}}\) is the volume of dry flue gases produced during the complete combustion of 1 kg of fuel under normal conditions.

Concentration of benzo(a)pyrene in dry flue gases of small-capacity boilers at fuel-bed combustion of solid fuels in mg/nm3, reduced to the excess air of 1.4 is recommended to calculate as follows:

where, A is the coefficient characterizing the type of grate and type of fuel; R is the factor, characterizing the temperature level of screens depending on tn is the water temperature at the boiler outlet for hot-water boilers (Thermal analysis of boilers, standard method 1998); \(K_{\text{l}}\) is the boiler load factor is determined through the ratio of the rated load of the boiler to the actual load; \(K_{\text{ac}}\) is the factor that takes into account the degree of benzo(a)pyrene capture by the ash collector and depends on the type of ash collectors and the temperature of the gases upstream of the ash collector.

When calculating B[a]P emissions, it should be taken into account that when the boiler is operated at loads less than the rated load, the concentration of B[a]P in the flue gases increases. Therefore, the maximum emissions of benzo(a)pyrene are determined both during operation of the boiler at the maximum actual load and during operation at the minimum actual load in order to comprehensively assess atmospheric air pollution.

An important environmental performance metric is the assessment of the mass of ash and slag waste (ASW) produced as a result of solid fuel combustion. As a rule, the quantitative assessment of ASW is associated with the standard method, which is based on accounting the content of pollutants in ash and slag and maximum permissible concentrations (MPC) of these substances (Methodological recommendations on the development of draft standards for the maximum waste disposal for thermal power plants, heat and power plants, industrial and heating boiler houses. 1998). However, calculation of the amount of ASW from small-capacity boiler plants is possible using the method based on the material balance of the boiler, when the ASW mass (Masw) is the sum of slag (Msl) and the mass of fly ash captured in the ash collector.

A detailed analysis of existing methods for quantitative assessment of ash and slag waste from power facilities is presented in Maysyuk et al. (2019).

Basic guidelines for calculating the number of ash-and-slag mixtures are presented in Nazmeev (2002).

When there are no ash collection systems, the calculation of the amount of slag can be carried out by the Eq. (5), t/year:

In light of active climate research, environmental assessments of fossil fuel combustion should include estimates of greenhouse gas emissions. In the case of energy generation facilities, it is carbon dioxide (CO2) emissions. The methodological basis for calculating the amount of CO2 emissions is presented by both foreign and domestic developments. In general, the mass of carbon dioxide emissions depends on the fuel consumption and the CO2 emission factor for each particular fuel, which are developed in accordance with the methodology of the Intergovernmental Panel on Climate Change (IPCC) (IPCC Guidelines for National Greenhouse Gas Inventories).

The inputs are the actual data characterizing the enterprise's activities during the reporting period (consumption of fuel by type, consumption of carbon-containing materials), greenhouse gas emission factors, and design ratios of carbon content in the fuel.

The amount of CO2 emissions from stationary fuel combustion is calculated for individual sources, groups of sources, or the enterprise as a whole as per Eq. (6):

where \(E_{{{\text{CO}}_{2,y} }}\) is CO2 emissions from stationary combustion of fuel during the period y, tCO2; \(FC_{j,y}\) is the consumption of fuel j during the period y, thous. m3, or t, or tce, or TJ; \(EF_{{{\text{CO}}_{2} j,y}}\) is the factor of CO2 emissions from combustion of the fuel j during the period y, tCO2/unit; \(OF_{j,y}\) is the fuel oxidation factor j, fraction; j is type of fuel used for combustion; n is the number of fuels used during the period y.

When calculating the amount of CO2 emissions, it is necessary to consider the consumption of all types of used gaseous, liquid, and solid fuels, of both natural and man-made origin, burned in stationary sources during the reporting period.

Fuel consumption should be determined in units corresponding to the emission factor adopted (tCO2/t, tCO2/tce).

In the methodology adopted in Russia, CO2 emission factors are presented in sufficient detail and take values from 1.59 for natural gas to 2.96 tCO2/tce for lignites, whereas the IPCC methodology indicates the upper and lower limits of CO2 emission factors.

Table 3 shows the values of conversion factors into energy units and emission factors for some types of fuel, including the coal varieties studied in this paper. These coal varieties are mainly used in the Asian part of Russia, including Eastern Siberia, and in particular in the Baikal Natural Area.

According to the guidelines for calculating CO2 emissions, the carbon oxidation factor \(OF_{j,y}\), which takes into account the incomplete oxidation of carbon during its combustion, is, on average, close to one. In the absence of the necessary data on the deposits of coal consumed, it is possible to use emission factors for run-of-mine coal varieties of the respective types (hard coal, lignite, anthracite).

A review of existing methods for assessing the impact of energy facilities on elements of the natural environment is conducted by the authors in Maysyuk and Ivanova (2018), and detailed algorithms for calculating environmental indicators for both large energy facilities and boiler houses are presented in Maysyuk et al. (2021) and Vorozhtsova et al. (2020).

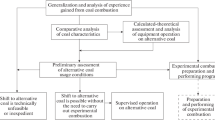

In this study, it can be limited to a simpler scheme that corresponds to the objectives of the study. In general, the calculation of environmental indicators based on the above techniques and mathematical dependencies can be presented in the form of a flowchart, Fig. 2. Initial data for calculating all environmental indicators are data from the "Fuel" and "Equipment" block: emissions of pollutants (5 ingredients), carbon dioxide emissions and ash and slag waste mass. Depending on the fuel consumption (in this study per unit of heat energy production (Gcal)) and qualitative characteristics of coal, taking into account the method of its preparation before combustion, as well as the characteristics of the furnace equipment using Eq. (1–6) the calculation of environmental indicators in the "Waste and emissions calculation" block is made.

4 Input data for the calculation of environmental performance metrics

Environmental performance assessment in this study was carried out for Mugunsky deposit lignite and Cheremkhovsky deposit hard coal assuming their different preparation before combustion in small-capacity boilers of KVr-0.5 (0.5 MW) (Fig. 3) and Termorobot 0.6 (0.6 MW) types (Fig. 4). These types of coal were chosen as raw coal for several reasons: (1) Mugunsky deposit coal (grade 3BR) is a typical representative of low-sulfur lignites and suitable for various methods of its preparation for use in boilers of different types; (2) Cheremkhovsky deposit hard coal is sulfurous and coking coal and cannot be used in automated boilers without preliminary preparation. The study presents the results of calculations for using coal prepared at different temperatures (500, 600, 700 °C). The semi-coking temperature was chosen so as to determine the optimal coke composition for further use. More details on semi-coking of Cheremkhovsky deposit coal are presented in Maysyuk and Kozlov (2020). Input data on the proximate and ultimate analysis of unscreened, size-graded, briquetted, and heat-treated coals (Table 4) were determined experimentally using certified methods and the method for determining the ultimate analysis set out in Kozlov et al. (2015), Maysyuk et al. 2018). In addition, Table 4 presents the calculated values of the volumes of flue gases (theoretical and dry) based on the data on the content of oxygen, hydrogen, and carbon in the fuel.

Analysis of Table 4 shows that the composition of lignite and hard coal compared to sorted coals does not change. Briquetting of coals leads to a slight decrease in hydrogen, oxygen, sulfur and nitrogen content, but the carbon content increases, causing a significant increase in the heat of combustion. As a result, there is little incomplete combustion and the amount of pollutants is reduced. However, it is worth noting that the amount of SOx produced will be the same compared to burning coal. The reason is that the mechanism of formation of sulfur oxides is different from that of NOx, CO, and soot (Das et al. 2022; Lu et al. 2020).

Thermal treatment of lignite makes it possible to completely remove sulfur from the composition. Depending on the temperature of the thermal treatment of hard coals it is also possible to reduce the sulfur and nitrogen content significantly.

Despite a significant increase in ash content in briquetting and thermal preparation of coals, their use in boilers provides more efficient combustion characteristics (Table 5), which leads to a high efficiency (Table 6).

The selected types of boilers have a standard design and are widely used in small heating systems. The boiler KVr-0.5 is a hot water boiler with hand-feeding of coal. The boiler Thermorobot-0.6 is an automated boiler.

For the considered small-capacity hand-fed boilers and fuel-bed combustion the basic technical specifications are systematized on the basis of the data of the manufacturers of such boilers, in which the recommended furnace specifications of boiler plants (b/p) are given (Table 5). Table 5 does not show the degree of flue gas recirculation, because the design of small-capacity boilers in most cases lack a recirculation system.

The calculations of the values of environmental performance metrics are made using the resources of the "High-Temperature Circuit" shared research facilities center (Project No. 13.CKP.21.0038).

All of the boilers covered by this study have no flue gas treatment systems, and hence the degree of ash collection is zero. In the case of the KVr boiler, environmental performance assessments were conducted only for unscreened and size-graded coal. The reason is that the use of briquetted and heat-treated coal in hand-fed boilers is not economically feasible.

Fuel consumption in the calculations of pollutant emissions for each coal variety is assumed in accordance with the technical recommendations for the boiler plants, taking into account the efficiency of existing boilers in produce 1 Gcal of thermal energy, Table 6.

As shown by calculations of coal consumption, the largest amount of fuel to produce 1 Gcal of heat is required for a KVr-type hand-fed boiler when burning lignite. The smallest value is that for the automated boiler of the Thermorobot type when burning hard coal heat-treated at a temperature of 500 °C.

5 Results of calculations of environmental performance metrics

Based on the above methodological recommendations and approaches, we performed calculations of pollutant emissions for five harmful ingredients (particulate matter, sulfur oxides, nitrogen, carbon oxides, and B[a]P), ASW weight, and CO2 emissions from combustion of variously prepared hard coal and lignites in hand-fed boiler plants and with automated fuel-feeding (Table 7). Calculations of environmental indicators were carried out on the basis of mathematical dependencies based on data on the proximate and ultimate analysis of the fuel. The error in these calculations is explained by the error in determining the proximate and ultimate of the corresponding fuels (Table 4).

The results of calculations are given per unit of produced thermal energy of 1 Gcal in kg of pollutant, which allows for comparative estimates. First of all, the predominance of particulate matter should be noted in all calculated values of emissions: from 55% for hard coal briquette combustion in Thermorobot-type boiler plants to 74%—for combustions of heat-treated lignite in a Termorobot-type boiler. Such values of particulate emissions are due to a fairly high ash content in the feedstock fuel.

In general, among the coal varieties covered the highest values of total pollutant emissions correspond to combustion of unprepared coal, both hard coal and lignite in KVr-type hand-fed boilers. Next, by the decrement of calculated total emissions, we can distinguish the group of hard coal varieties prepared for combustion. The lowest values of calculated emissions come from lignites, prepared for combustion in automated Thermorobot boilers.

Preliminary size-grading of coal during combustion in hand-fed boilers of the KVr type compromises environmental performance insignificantly—by 11%–15%. This is caused by the fact that the sorted coals, although they have the same qualitative composition and combustion conditions as ordinary coals, but the process of combustion is more effective due to the properly aired bad. At that, the same environmental performance advantage of lignites over hard coal varieties is preserved, as well as when used in the run-of-mine form (Fig. 5). This is explained by the initial qualitative composition of the fuel (low ash content).

The transition to automated lignite boilers will significantly improve environmental performance. A positive point in this case is the absence of sulfur dioxide emissions (Fig. 6). Combustion of prepared lignites in automated boilers significantly improves the environmental performance in terms of almost all pollutants as compared to the KVr-type hand-fed boilers, even when coal size-grading takes place.

According to the ingredient structure of the calculated emissions, it is clear that the coal varieties that have undergone heat-treatment also have the lowest values for sulfur dioxide and nitrogen emissions, as well as those of carbon oxides. Heat-treated hard coal during combustion in the Thermorobot is characterized by the lowest emission of B[a]P, which is the most dangerous carcinogenic substance, lignite prepared for Thermorobot has approximately the same values. As a result, the lowest values of calculated emissions come from the lignite treated for combustion in automated Thermorobot boilers, which is explained by the improved quality characteristics of the fuel.

Among hard coal types, the best environmental performance is delivered by heat-treated coal (Fig. 7). The figure shows the results of calculations of emissions into the atmosphere during combustion of hard coal varieties, both in hand-fed boilers (KVr) and in an automated boiler (Thermorobot). The highest values of calculated emissions correspond to combustion in hand-fed boilers of run-of-mine and size-graded coal varieties. And the preliminary size-grading of coal during combustion in the hand-fed boiler fail to produce a tangible environmental effect. When switching to the combustion of hard coal briquettes and heat-treated hard coal in automated boilers, the values of environmental performance metrics are reduced by 1.5–3 times. At the same time, a decrease by a factor of 1.3–1.5 is observed in calculated B[a]P emissions.

Considering coal combustion in automated boilers (Thermorobot), in which only coal varieties prepared for combustion are used (from size-graded to heat-treated coal varieties), it is possible to identify the group of heat-treated hard coal varieties having the highest emission of particulate matter and sulfur dioxide, compared with the lignites prepared for combustion (Fig. 8). Calculated emissions of carbon monoxide and nitrogen oxides for hard coal and lignites are about the same. In this case, lignite is environmentally friendly. For combustion of hard coal, it is advisable to provide ash collection systems.

As can be seen from Fig. 8, B[a]P emissions are the largest when burning heat-treated lignite, and the smallest for heat-treated hard coal as well as for size-graded lignite. B[a]P emissions from the other coal varieties studied in this group range from 11.8 to 13.2 µg per Gcal of thermal energy.

As the analysis of research findings demonstrates, coal prepared for combustion has emission values 2–3 times lower than unprepared coal.

Analysis of the calculated values of carbon dioxide emissions showed that the lowest CO2 emission is observed at combustion of heat-treated coal in automated boilers such as Thermorobot. And specific emission per Gcal of thermal energy is lower when burning hard coal rather than lignite—492 kg CO2/Gcal against 529 kg CO2/Gcal (Table 7).

Ash-and-slag waste weight is characterized by the highest yield when burning hard heat-treated coal in automated boilers of the Thermorobot type. The smallest weight of ASW is formed during combustion of size-graded lignites and lignite briquettes in automated boilers (Table 7).

6 Conclusions

Environmental performance metrics largely depend on the following: (1) the qualities of the raw coal, even for the same coal given the availability of different methods of its preparation for combustion; (2) conditions of its combustion: in hand-fed boilers or automated boiler plants, which can greatly affect the change in fuel consumption. Thus, coal pre-treatment significantly improves the efficiency and environmental friendliness of the combustion process. Even simple size-grading of coal before burning in hand-fed boilers widespread enough in the Asian part of Russia, including coastal areas of Lake Baikal (zone of special nature management), will allow the following:

-

(1)

for lignites: to reduce emissions of particulate matter, carbon oxides, and B[a]P by 13%–17%, and sulfur dioxide by 25%;

-

(2)

for hard coal, the reduction in the values of all metrics is estimated at 10%–13%.

The environmental effect of the introduction of automated boilers and coal heat-treated for combustion is estimated as the reduction of all environmental indicators by 2–3 times.

An important conclusion is that changes in fuel preparation technologies before combustion significantly affect environmental performance and lead to various environmental effects. For example, lignites are recommended to be burned both in size-graded and heat-treated form in automated boilers of the Thermorobot type. At the same time, it is recommended to burn hard coal with thermal pre-treatment, but with the installation of ash collection equipment in automated boilers, since these coal types are characterized by significant emissions of particulate matter. In the absence of ash collectors, heat-treated lignites should be preferred. The smallest amount of CO2 emissions occurs during combustion of heat-treated hard coal. The formation of ASW is the least during combustion of size-graded lignite briquettes in automated boilers.

Furthermore, the environmental assessment of the use of various coal types that have undergone preliminary preparation allows the development of certain recommendations to improve the environmental situation.

When using prepared fuel, in addition to improving the environmental performance of the boiler plant, one succeeds in addressing the three fundamental issues of boiler plants with fuel-bed combustion that hinder the improvement the efficiency of heat generation: the use of low-quality run-of-mine coal, the use of boilers with low efficiency, the significant impact of the human factor. Addressing these issues makes it possible to justify the economic feasibility of introducing automated boilers and high-quality prepared (briquetted and heat-treated) fuel.

Additional economic effect will take place due to the reduction of fuel consumption and the corresponding decrease in the volume of fuel transportation and transportation costs, which is especially important for isolated and remote areas. Moreover, the economic effect of the transition to automated boilers will reduce the operating staff and thus the payroll, which currently accounts for a significant share in the structure of the cost price of heat produced by small-capacity boilers.

Availability of data and materials

The data that support the findings of this study are available on request from the corresponding author.

References

Bellos E, Iliadis P, Papalexis C, Rotas R, Nikolopoulos N, Kosmatopoulos E, Halmdienst C (2022) Dynamic investigation of centralized and decentralized storage systems for a district heating network. J Energy Storage 56:106072

Borisov GO (2020) The problems and prospects of energy development in Buryatia. Probl Econ Transit 62(7–9):491–503

Cheng M et al (2017) Air pollutant emission from the underestimated households’ coal consumption source in China. Sci Total Environ 580:641–650

Çınar M (2009) Floatability and desulfurization of a low-rank (Turkish) coal by low-temperature heat treatment. Fuel Process Technol 90(10):1300–1304

Comparative combustion of coals from Eastern Siberia in heating boilers of low power and house stoves: scientific report: ESI SB RAS; Filippov, S.P.—Irkutsk (1998)

Das D, Qadri A, Tak P, Gupta T (2022) Effect of processing on emission characteristics of coal briquettes in cookstoves. Energy Sustain Dev 69:77–86

EEA Report No 13/2019 Technical guidance to prepare national emission inventories. The joint EMEP/EEA air pollutant emission inventory guidebook 2019. https://www.eea.europa.eu/ru/publications/rukovodstvo-emep-eaos-po-inventarizaciivybrosov-2019

Filippov SP, Naumov YV, Ermakov MV (2005) Effect of excess air on the output and efficiency of boilers with stoker combustion of low-grade coals. Therm Eng 52(2):116–121

Fortescue S (2016) Russia’s economic prospects in the Asia Pacific Region. J Eurasian Stud 7(1):49–59

Gorbacheva NV, Sovacool BK (2015) Pain without gain? Reviewing the risks and rewards of investing in Russian coal-fired electricity. Appl Energy 154:970–986

Guidance letter of the Research Institute of Atmosphere No. 335/33-07 dated May 17, 2000, "On the calculation of emissions of harmful substances to the atmosphere according to the" Methodology for determining emissions of pollutants when burning fuel in boilers with a capacity of fewer than 30 tons of steam per hour or less 20 Gcal per hour ” (1999). Research Institute of Atmosphere, St. Petersburg, p 20 (2000)

Hong WY (2022) A techno-economic review on carbon capture, utilisation and storage systems for achieving a net-zero CO2 emissions future. Carbon Capture Sci Technol 3:100044

IPCC Guidelines for National Greenhouse Gas Inventories—vol. 2. https://www.ipcc-nggip.iges.or.jp/public/2006gl/russian/pdf/2_Volume2/V2_2_Ch2_Stationary_Combustion.pdf

Jaworek A, Sobczyk AT, Marchewicz A, Krupa A, Czech T (2021) Particulate matter emission control from small residential boilers after biomass combustion. A review. Renew Sustain Energy Rev 137:110446

**gchao Z, Kotani K, Saijo T (2019) Low-quality or high-quality coal? Household energy choice in rural Bei**g. Energy Econ 78:81–90

Knigawka P, Pianko-Oprych P, Krpec K, Kuboňová L (2022) Comparison of emissions from smokeless coal combustion in a household heating boiler used in Central Europe. Int J Environ Sci Technol 19(8):7151–7164

Kozhageldi BZ, Tulenbayev ZS, Orynbayev S, Kuttybaev G, Abdlakhatova N, Minazhova S (2022) Development of integrated solutions for the decentralisation of electricity supply to power-hungry regions. Electr J 35(4):107108

Kozlov A, Svishchev D, Donskoy I, Shamansky V, Ryzhkov A (2015) A technique proximate and ultimate analysis of solid fuels and coal tar. J Therm Anal Calorim 122(3):1213–1220

Lu G, Shen Q, Cheng F (2020) Sulfur fixation characteristics of single coal briquette particle during the process of combustion in different atmospheres. J Clean Prod 270:122392

Luttrell GH, Honaker RQ (2020) Coal preparation. Fossil Energy XVIII:357–386. https://doi.org/10.1007/978-1-4939-9763-3

Maysyuk E, Ivanova I (2018) Analysis of existing methods for assessing the impact of energy objects on the environment. Inf Math Technol Sci Manag. https://doi.org/10.25729/2413-0133-2018-4-12

Maysyuk E, Kozlov A, Ivanova I (2018) Influence of technical characteristics of solid fuels at estimation of emissions from small boiler plants. Energy Syst Res 1(2):43–50

Maysyuk E (2019) Measures to prevent emissions of pollutants when burning coals in small-capacity boilers in the central ecological area of the Baikal natural territory. In: E3S web of conferences, vol 77. EDP Sciences, p 04007

Maysyuk EP, Kozlov AN (2019) Environmental problems of solid fuel combustion in house furnaces and small boilers and ways their solution. In: IOP conference series: earth and environmental science, vol 272, no. 2. IOP Publishing, p 022192

Maysyuk E, Ivanova I, Izhbuldin A (2019) Impact of critical energy facilities on the components of the environment. In: VIth international workshop 'critical infrastructures: contingency management, intelligent, agent-based, cloud computing and cyber security'(IWCI 2019). Atlantis Press, pp 201–205

Maysyuk EP (2020) Increased environmental requirements for energy objects in the central ecological area of the Baikal Natural Territory: problems and condition for implementation. In: E3S web of conferences, vol 209. EDP Sciences, p 05011

Maysyuk EP, Kozlov AN (2020) Technology of thermal preparation of coal for ecologically pure combustion of fuel in small boilers. In: Journal of physics: conference series, vol 1565, no 1. IOP Publishing, p 012059

Maysyuk E, Ivanova I, Ivanov R (2021) Information content of models for determining the environmental characteristic of the energy facilities functioning. Inf Math Technol Sci Manag. https://doi.org/10.38028/ESI.2021.23.3.005

Methodological instructions and guidelines for the quantitative determination of greenhouse gas emissions by organizations engaged in economic and other activities in the Russian Federation. Approved by order of the Ministry of Natural Resources of Russia dated June 30, 2015. http://sro150.ru/metodiki/371-metodika-rascheta-vybrosov-parnikovykh-gazov. Accessed 27 Jul 2022

Methodological recommendations on the development of draft standards for the maximum waste disposal for thermal power plants, heat and power plants, industrial and heating boiler houses. St. Petersburg, 1998. http://docs.cntd.ru/document/1200043975. Accessed 24 Oct 2018

Methodology for determining the emissions of pollutants when burning fuel in boilers with a capacity of fewer than 30 tons of steam per hour or less than 20 Gcal per hour: M.: State Committee on Environmental Protection of the Russian Federation (with the participation of Integral, p 53 (1999)

National Pollutant Inventory (2011) Emission estimation technique manual for combustion in boilers. Version 3.6. Australian Government, Department of Sustainability, Environment, Water, Population and Communities—[S. l.]

Nazmeev Yu G (2002) Ash and slag removal systems of thermal power plants. Publishing House MPEI, M., p 572

Pavlović B, Ivezić D, Živković M (2022) Transition pathways of household heating in Serbia: analysis based on an agent-based model. Renew Sustain Energy Rev 163:112506

Saneev B, Ivanova Y, Maysyuk P, Izhbuldin A (2019) The main directions of solving energy-related environmental problems in the central ecological zone of the Baikal natural territory. In: IOP conference series: earth and environmental science, vol 381, no 1. IOP Publishing, p 012082

Stepanov S, Mikhalev I, Evtushenko E, Loginov DA, Demenchuk S (2020) Smokeless domestic fuel: Krasnoyarsk experience. Russ Coal J 12:56–62

Thermal analysis of boilers, standard method (third edition, revised and enlarged). SPb., VTI and NPO TsKTI (1998)

Tian S, Yang S, Wang J, Li Q, Li C, Cui X, Ning P (2022) Integrated strategy for efficient simultaneous desulfurization and denitrification of flue gas and high value conversion of sulfur and nitrogen resources. J Hazard Mater 440:129827

Vorozhtsova T, Maysyuk E, Ivanova I (2020) Ontological engineering for methodological support of research into energy-related anthropogenic impact of the environment. In E3S Web of Conferences, vol 209. EDP Sciences, p 02031

Wang G, Xu Y, Ren H (2019) Intelligent and ecological coal mining as well as clean utilization technology in China: review and prospects. Int J Min Sci Technol 29(2):161–169

Wang X, Tang Y, Wang S, Schobert H (2020) Clean coal geology in China: research advance and its future. Int J Coal Sci Technol 7:299–310

Wyrzykowska B, Hanari N, Orlikowska A, Yamashita N, Falandysz J (2009) Dioxin-like compound compositional profiles of furnace bottom ashes from household combustion in Poland and their possible associations with contamination status of agricultural soil and pine needles. Chemosphere 76(2):255–263

Zakharov V, Kozlov A, Donskoy I (2019) Modeling of changes in the heating value of coal transported to Russia’s far north regions on the example of the republic of Sakha (Yakutia). Izvestiia Rossiiskoi Akademii Nauk Energetika 6:132–141

Zhang G, Sun Y, Xu Y (2018) Review of briquette binders and briquetting mechanism. Renew Sustain Energy Rev 82:477–487

Zhang Y, Shen Z, Zhang B, Sun J, Zhang T, Wang X, Wang T, Xu H, Liu P, Wang T (2020) Carbonaceous aerosols emission reduction by using red mud additive in coal briquette. Fuel Process Technol 199:106290

Zhao N, Li B, Li H, Li G, Wu R, Hong Q, Mperejekumana P, Liu S, Zhou Y, Ahmad R, Zayan AMI, Pemberton-Pigott C, Dong R (2021) The potential co-benefits for health, economy and climate by substituting raw coal with waste cooking oil as a winter heating fuel in rural households of northern China. Environ Res 194:110683

Zhou Y et al (2020) Impact of rural residential coal combustion on air pollution in Shandong, China. Chemosphere 260:127517

Zhuo Y, Li C, Wu C, Shen Y (2019) A combined numerical and experimental approach to study the carbonization of low-rank coal ellipsoidal briquettes. Chem Eng Sci 204:76–90

Acknowledgements

The research was carried out under State Assignment Projects (FWEU-2021-0004, FWEU-2021-0005) of the Fundamental Research Program of Russian Federation 2021-2030.

Author information

Authors and Affiliations

Contributions

Conceptualization: AK, EM; supervision: II; investigation: EM, AK; formal analysis: II, writing (original draft): EM, AK.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kozlov, A.N., Maysyuk, E.P. & Ivanova, I.Y. Environmental performance assessments of different methods of coal preparation for use in small-capacity boilers: experiment and theory. Int J Coal Sci Technol 10, 63 (2023). https://doi.org/10.1007/s40789-023-00623-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-023-00623-3