Abstract

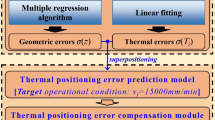

The positioning error of the linear feed system has a great impact on the fabrication quality of the parts. The main error sources contain the geometric error fundamentally determined by the machining capacity and the assembly performance and the thermal error resulted from the temperature rise caused by internal and external heat sources in the manufacturing process. The error compensation method is an effective and economical way to improve the positioning accuracy whose core issue is to establish an error mathematical model with high prediction accuracy and strong robustness. In this paper, a genetic algorithm parameter-optimized support vector machine regression (GA-SVR) modeling method is used to map an intrinsic relationship between location and temperature rise as inputs and synthetic positioning error as output, in which the positioning error collected by a laser interferometer is decomposed into geometrical error and thermal error that is employed to sift the temperature-sensitive points with hierarchical clustering method and gray correlation analysis. The thermal characteristic experiments at different feed speeds were carried out to validate the developed synthetic positioning error model of the X-axis feed system in the machining center. The results showed that the model can accurately reflect the synthetic positioning error change trend of the feeding axis under various operating conditions and has practical availability to perform real-time synthetic error compensation.

Similar content being viewed by others

References

Bryan J (1990) International status of thermal error research. CIRP Ann Manuf Technol 39(2):645–656. https://doi.org/10.1016/S0007-8506(07)63001-7

Postlethwaite SR, Allen JP, Ford DG (1999) Machine tool thermal error reduction—An appraisal. Proc Inst Mech Eng Part B J Eng Manuf 13(1):1–9. https://doi.org/10.1177/095440549921300101

Ferreira PM, Liu CR (1986) An analytical quadratic model for the geometric error of a machine tool. J Manuf Syst 5(1):51–63. https://doi.org/10.1016/0278-6125(86)90067-1

Donmez MA, Blomquist DS, Hocken RJ, Liu CR, Barash MM (1986) A general methodology for machine tool accuracy enhancement by error compensation. Precis Eng 8(4):187–196. https://doi.org/10.1016/0141-6359(86)90059-0

Zhong G, Wang C, Yang S, Ge Y (2015) Position geometric error modeling, identification and compensation for large 5-axis machining center prototype. Int J Mach Tool Manuf 89:142–150. https://doi.org/10.1016/j.ijmachtools.2014.10.009

Yun WS, Kim SK, Cho DW (1999) Thermal error analysis for a CNC lathe feed drive system. Int J Mach Tool Manuf 39(7):1087–1101. https://doi.org/10.1016/S0890-6955(98)00073-X

Xu ZZ, Liu XJ, Kim HK, Shin JH, Lyu SK (2011) Thermal error forecast and performance evaluation for an air-cooling ball screw system. Int J Mach Tool Manuf 51:605–611. https://doi.org/10.1016/j.ijmachtools.2011.04.001

Jiang SY, Mao HB (2010) Investigation of variable optimum preload for a machine tool spindle. Int J Mach Tool Manuf 50:19–28. https://doi.org/10.1016/j.ijmachtools.2009.10.001

Turek P, Jdrzejewski J, Modrzycki W (2010) Methods of machine tool error compensation. J Mach Eng 10(4):5–25

Yang S, Yuan J, Ni J (1996) Accuracy enhancement of a horizontal machining center by real-time error compensation. J Manuf Syst 15(2):113–124. https://doi.org/10.1016/0278-6125(96)82336-3

Mou J (1997) A method of using neural networks and inverse kinematics for machine tool error estimation and correction. ASME Trans J Manuf Sci Eng 119:247–254

Zapłata J, Pajor M (2019) Piecewise compensation of thermal errors of a ball screw driven CNC axis. Precis Eng 60:160–166. https://doi.org/10.1016/j.precisioneng.2019.07.011

Mareš M, Horejš O, Havlík L (2020) Thermal error compensation of a 5-axis machine tool using indigenous temperature sensors and CNC integrated Python code validated with a machined test piece. Precis Eng 66:21–30. https://doi.org/10.1016/j.precisioneng.2020.06.010

Shik YA, Han YX, Rong ZJ, Lee C-Y, Hsieh W-H (2018) DOE-FEM based design improvement to minimize thermal errors of a high speed spindle system. Therm Sci Eng Prog 8:525–536. https://doi.org/10.1016/j.tsep.2018.10.011

Thiem X, Kauschinger B, Ihlenfeldt S (2019) Online correction of thermal errors based on a structure model. Int J Mach Tools Manuf 2(1):49–62. https://doi.org/10.1504/IJMMS.2019.097852

Ma C, Liu J, Wang S (2020) Thermal error compensation of linear axis with fixed-fixed installation. Int J Mech Sci 175(2):105531. https://doi.org/10.1016/j.ijmecsci.2020.105531

Liu J, Ma C, Wang S (2020) Data-driven thermal error compensation of linear x-axis of worm gear machines with error mechanism modeling. Mech Mach Theory 153:104009. https://doi.org/10.1016/j.mechmachtheory.2020.104009

Liu J, Ma C, Wang S (2020) Data-driven thermally-induced error compensation method of high-speed and precision five-axis machine tools. Mech Syst Signal Process 138(2):106538. https://doi.org/10.1016/j.ymssp.2019.106538

Li Y, Zhao J, Ji S (2018) Thermal positioning error modeling of machine tools using a bat algorithm-based back propagation neural network. Int J Adv Manuf Technol 97(5–8):2575–2586. https://doi.org/10.1007/s00170-018-1978-x

Li Y, Zhao J, Ji S, Liang F (2019) The selection of temperature-sensitivity points based on K-harmonic means clustering and thermal positioning error modeling of machine tools. Int J Adv Manuf Technol 100(9):2333–2348. https://doi.org/10.1007/s00170-018-2793-0

Sun J, Xu Y, Liu X (2014) Thermal error compensation and modeling for CNC boring and milling center. Adv Mater Res 945–949:1665–1668

Pahk H, Lee SW (2002) Thermal error measurement and real time compensation system for the CNC machine tools incorporating the spindle thermal error and the feeding axis thermal error. Int J Adv Manuf Technol 20(7):487–494. https://doi.org/10.1007/s001700200182

Fu J, Chen Z (2004) Research on modeling thermal dynamic errors of precision machine based on fuzzy logic and artificial neural network. J Zhejiang Univ Sci 38(6):742–746

Lin W, Fu J, XuChen Y (2008) Thermal error modeling & compensation of numerical control machine tools based on on-line least squares support vector machine. Jisuanji Jicheng Zhizao **tong Comput Integr Manuf Syst 14(2):295–299

Miao E, Gong Y, Niu P, Ji C, Chen H (2013) Robustness of thermal error compensation modeling models of CNC machine tools. Int J Adv Manuf Technol 69(9–12):2593–2603. https://doi.org/10.1007/s00170-013-5229-x

Lin CJ (2001) On the convergence of the decomposition method for support vector machines. IEEE Trans Neural Netw 12(6):1288–1298. https://doi.org/10.1109/72.963765

Vapnik V, Golowich SE, Smola A (2008) Support vector method for function approximation, regression estimation, and signal processing. Adv Neural Inf Process Syst 9:281–287

Shen H, Fu J, He Y, Yao X (2012) On-line Asynchronous Compensation Methods for static/quasi-static error implemented on CNC machine tools. Int J Mach Tool Manuf 60:14–26. https://doi.org/10.1016/j.ijmachtools.2012.04.003

Li Z, Li G, Xu K, Tang X, Dong X (2021) Temperature-sensitive point selection and thermal error modeling of spindle based on synthetical temperature information. Int J Adv Manuf Technol 113(3–4):1–15. https://doi.org/10.1007/s00170-021-06680-9

Shi Y, Li Q, Meng X, Zhang T, Shi J (2020) On time-series InSAR by SA-SVR algorithm: prediction and analysis of mining subsidence. J Sensors. https://doi.org/10.1155/2020/8860225

Guo Q, Xu R, Yang T, He T, Cheng X, Li Z (2016) Application of GRAM and AFSACA-BPN to thermal error optimization modeling of CNC machine tools. Int J Adv Manuf Technol 83:995–1002. https://doi.org/10.1007/s00170-015-7660-7

Huang Y, Zhang J, Li X, Tian L (2014) Thermal error modeling by integrating GA and BP algorithms for the high-speed spindle. Int J Adv Manuf Technol 71:1669–1675. https://doi.org/10.1007/s00170-014-5606-0

Ma C, Zhao L, Mei X, Shi H, Yang J (2017) Thermal error compensation of high-speed spindle system based on a modified BP neural network. Int J Adv Manuf Technol 89:3071–3085. https://doi.org/10.1007/s00170-016-9254-4Q2

Miao E, Niu P, Fei Y, Yan Y (2011) Selecting temperature-sensitive points and modeling thermal errors of machine tools. J Chin Soc Mech Eng Trans Chin Inst Eng Ser C 32(6):559–565

** L, Liu N, Chen Y, Liu Q (2017) The selection of key temperature measuring points for the compensation of thermal errors of CNC machining tools. Int J Manuf Res 12(3):338–350. https://doi.org/10.1504/IJMR.2017.086177

Gholami R, Fakhari N (2017) Chapter 27—Support vector machine: principles, parameters, and applications. Handbook of neural computation. Academic Press, pp 515–535

ISO230-3 (2020) Test code for machine tools—part 3: determination of thermal effects. ISO copyright office, Switzerland

ISO230-2 (2014) Test code for machine tools—part 2: determination of accuracy and repeatability of positioning numerically controlled axes. ISO copyright office, Switzerland

Funding

This work is supported by the National Natural Science Foundation of China (No. 51775432) and Shaanxi Province Major Science and Technology Project (No. 2018ZDZX01-02-01).

Author information

Authors and Affiliations

Contributions

YL contributed to conceptualization, methodology, supervision, and writing—original draft. QC contributed to methodology, software, formal analysis, and experiment. FG contributed to writing—review and editing, project administration, and funding acquisition. XK contributed to experiment, formal analysis, and investigation. YL contributed to data curation. XW contributed to visualization.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Consent for publication

The manuscript has not been published before and is not being considered for publication elsewhere. All authors have contributed to the creation of this manuscript for important intellectual content and approved the final manuscript.

Additional information

Technical Editor: Rogério Sales Gonçalves.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Chen, Q., Gao, F. et al. Synthetic positioning error modeling for a linear feed system based on GA-SVR algorithm. J Braz. Soc. Mech. Sci. Eng. 45, 85 (2023). https://doi.org/10.1007/s40430-023-04019-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04019-x