Abstract

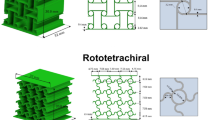

A classical re-entrant cell is a type of metamaterial known as auxetic. While the most unusual and advantageous feature of auxetic materials is that they have negative Poisson’s ratios, having low stiffness—as seen in the classical re-entrant cell—may be a drawback. A study was conducted to increase the stiffness of the classical re-entrant cell while maintaining the negative Poisson's ratio. This paper reports the nonlinear experimental and numerical works of three re-entrant cells one of which is a well-known classical re-entrant cell, and the latter two were modified based on classical re-entrant cell. In the work, the cellular structure specimens were fabricated with a 3D printer using polylactic acid (PLA) material and crushing tests were conducted until the full crush phase. The specimens were also modelled using solid finite elements considering wall-to-wall frictional contacts and analysed. The linear mechanical properties of the cells were also determined by employing analytical expressions that were developed for modified cells. Thus, both the theoretical and the nonlinear numerical results were validated using experiments. In conclusion, the modified cells exhibited an increase in stiffness, energy absorption capacity, and plasticity, compared to the classical re-entrant cell. All benefits and drawbacks of the modifications to achieve stiff cells are reported in this paper.

Similar content being viewed by others

Data availability

All the data used in this manuscript can be obtained on request from the corresponding author.

Code availability

There is no special code generated for this research.

References

Saxena KK, Das R, Calius EP (2016) Three decades of auxetics research—materials with negative Poisson’s ratio: a review. Adv Eng Mater 18:1847–1870. https://doi.org/10.1002/adem.201600053

Gibson LJ, Ashby MF (1997) Cellular solids structure and properties. Cambridge Solid State Science Series, Cambridge

Fung Y-C (1965) Foundations of solid mechanics. Prentice- Hall, New Jersey

Greaves GN, Greer AL, Lakes RS, Rouxel T (2011) Poisson’s ratio and modern materials. Nature Materials, UK

Ting TCT, Chen T (2005) Poisson’s ratio for anisotropic elastic materials can have no bounds. Quarterly J Mech Appl Math 58:73–82. https://doi.org/10.1093/qjmamj/hbh021

Williams JL, Lewis JL (1982) Properties and an anisotropic model of cancellous bone from the proximal Tibial epiphysis. J Biomech Eng 104:50–56. https://doi.org/10.1115/1.3138303

Lees C, Vincent JFV, Hillerton JE (1991) Poisson’s ratio in skin. Bio-Med Mater Eng 1:19–23. https://doi.org/10.3233/BME-1991-1104

Frolich LM, LaBarbera M, Stevens WP (1994) Poisson’s ratio of a crossed fibre sheath: the skin of aquatic salamanders. J Zool 232:231–252. https://doi.org/10.1111/j.1469-7998.1994.tb01571.x

Milstein F, Huang K (1979) Existence of a negative Poisson ratio in fcc crystals. Phys Rev B 19:2030–2033. https://doi.org/10.1103/PhysRevB.19.2030

Evans KE (1991) The design of doubly curved sandwich panels with honeycomb cores. Compos Struct. https://doi.org/10.1016/0263-8223(91)90064-6

Lakes RS (1979) (1987) Foam structures with a negative Poisson ’ s ratio. Science 235:1038–1040. https://doi.org/10.1126/science.235.4792.1038

Gibson LJ, Ashby MF, Schajer GS, Robertson CI (1982) The mechanics of two-dimensional cellular materials. Proc R Soc Lond A382:25–42

Masters IG, Evans KE (1996) Models for the elastic deformation of honeycombs. Compos Struct 35:403–422. https://doi.org/10.1016/S0263-8223(96)00054-2

Larsen UD, Sigmund O, Bouwstra S (1996) Design and fabrication of compliant micromechanisms and structures with negative Poisson’s ratio. In: Proceedings of the IEEE Micro Electro Mechanical Systems (MEMS)

Larsen UD, Signund O, Bouwsta S (1997) Design and fabrication of compliant micromechanisms and structures with negative Poisson’s ratio. J Microelectromech Syst 6:99–106. https://doi.org/10.1109/84.585787

Grima JN, Gatt R, Alderson A, Evans KE (2005) On the potential of connected stars as auxetic systems. Mol Simul. https://doi.org/10.1080/08927020500401139

Smith CW, Grima JN, Evans KE (2000) Novel mechanism for generating auxetic behaviour in reticulated foams: missing rib foam model. Acta Mater 48:4349–4356. https://doi.org/10.1016/S1359-6454(00)00269-X

Lim T-C (2015) Auxetic materials and structures. Springer, Singapore

Alderson KL, Evans KE (2000) Auxetic materials: the positive side of being negative. Eng Sci Educ J 9:148–154. https://doi.org/10.1049/esej:20000402

Alderson A, Alderson KL (2007) Auxetic materials. Proc Inst Mech Eng, Part G: J Aero Eng 221:565–575. https://doi.org/10.1243/09544100JAERO185

Evans KE, Alderson A (2000) Auxetic materials: functional materials and structures from lateral thinking. Adv Mater 12:617–628. https://doi.org/10.1002/(SICI)1521-4095(200005)12:9%3c617::AID-ADMA617%3e3.0.CO;2-3

Lakes RS, Elms K (1993) Indentability of Conventional and Negative Poisson’s ratio foams. J Compos Mater. https://doi.org/10.1177/002199839302701203

Dirrenberger J, Forest S, Jeulin D (2013) Effective elastic properties of auxetic microstructures: anisotropy and structural applications. Int J Mech Mater Des 9:21–33. https://doi.org/10.1007/s10999-012-9192-8

Evans KE (1991) Auxetic polymers: a new range of materials. Endeavour 15:170–174. https://doi.org/10.1016/0160-9327(91)90123-S

Ju J, Summers JD, Ziegert J, Fadel G (2009) Design of honeycomb meta-materials for high shear flexure. In: 35th Design automation conference, Parts A and B. ASMEDC

Lira C, Innocenti P, Scarpa F (2009) Transverse elastic shear of auxetic multi re-entrant honeycombs. Compos Struct 90:314–322. https://doi.org/10.1016/j.compstruct.2009.03.009

Schultz J, Griese D, Ju J et al (2012) Design of honeycomb mesostructures for crushing energy absorption. J Mech Des 134:071004. https://doi.org/10.1115/1.4006739

Shankar P, Ju J, Summers JD, Ziegert JC (2010) Design of sinusoidal auxetic structures for high shear flexure. In: 30th Computers and information in engineering conference, Parts A and B

Shankar P, Fazelpour M, Summers JD (2013) An energy-based design approach for a meso-structure with high shear flexure. In: 39th Design automation conference. American Society of Mechanical Engineers

Spadoni A (2011) An isotropic auxetic structural network with limited shear stiffness. In: Mechanics of solids, structures and fluids; vibration, acoustics and wave propagation. ASMEDC

Choi JB, Lakes RS (1996) Fracture toughness of re-entrant foam materials with a negative Poisson’s ratio: experiment and analysis. Int J Fract 80:73–83. https://doi.org/10.1007/BF00036481

Scarpa F, Giacomin JA, Bezazi A, Bullough WA (2006) Dynamic behavior and dam** capacity of auxetic foam pads. In: Smart structures and materials 2006: Dam** and Isolation

Ruzzene M, Scarpa F, Soranna F (2003) Wave beaming effects in two-dimensional cellular structures. Smart Mater Struct 12:363–372. https://doi.org/10.1088/0964-1726/12/3/307

Phani AS, Woodhouse J, Fleck NA (2006) Wave propagation in two-dimensional periodic lattices. J Acoust Soc Am 119:1995–2005. https://doi.org/10.1121/1.2179748

Shiyin X, **uchang H, Hongxing H (2015) A study on the isolation performance of trichiral lattices with gradient geometry. J Vib Control 21:3465–3475. https://doi.org/10.1177/1077546314524261

Spadoni A, Ruzzene M, Gonella S, Scarpa F (2009) Phononic properties of hexagonal chiral lattices. Wave Motion. https://doi.org/10.1016/j.wavemoti.2009.04.002

Zhu R, Liu XN, Hu GK et al (2014) A chiral elastic metamaterial beam for broadband vibration suppression. J Sound Vib 333:2759–2773. https://doi.org/10.1016/j.jsv.2014.01.009

Bacigalupo A, Gambarotta L (2014) Homogenization of periodic hexa- and tetrachiral cellular solids. Compos Struct. https://doi.org/10.1016/j.compstruct.2014.05.033

Liebold-Ribeiro Y, Körner C (2014) Phononic band gaps in periodic cellular materials. Adv Eng Mater 16:328–334. https://doi.org/10.1002/adem.201300064

Bacigalupo A, De Bellis ML (2015) Auxetic anti-tetrachiral materials: equivalent elastic properties and frequency band-gaps. Compos Struct. https://doi.org/10.1016/j.compstruct.2015.05.039

Choi JB, Lakes RS (1995) Analysis of elastic modulus of conventional foams and of re-entrant foam materials with a negative Poisson’s ratio. Int J Mech Sci. https://doi.org/10.1016/0020-7403(94)00047-N

Huang J, Zhang Q, Scarpa F et al (2017) In-plane elasticity of a novel auxetic honeycomb design. Compos B Eng 110:72–82. https://doi.org/10.1016/j.compositesb.2016.11.011

Korner C, Liebold-Ribeiro Y (2015) A systematic approach to identify cellular auxetic materials. Smart Mater Struct. https://doi.org/10.1088/0964-1726/24/2/025013

Lakes R (1991) Experimental micro mechanics methods for conventional and negative poisson’s ratio cellular solids as cosserat continua. J Eng Mater Technol, Trans ASME. https://doi.org/10.1115/1.2903371

Spadoni A, Ruzzene M (2012) Elasto-static micropolar behavior of a chiral auxetic lattice. J Mech Phys Solids. https://doi.org/10.1016/j.jmps.2011.09.012

Auffray N, Dirrenberger J, Rosi G (2015) A complete description of bi-dimensional anisotropic strain-gradient elasticity. Int J Solids Struct. https://doi.org/10.1016/j.ijsolstr.2015.04.036

Dirrenberger J, Forest S, Jeulin D, Colin C (2011) Homogenization of periodic auxetic materials. Procedia Eng 10:1847–1852. https://doi.org/10.1016/j.proeng.2011.04.307

Doyoyo M, Wan HuJ (2006) Plastic failure analysis of an auxetic foam or inverted strut lattice under longitudinal and shear loads. J Mech Phys Solids 54:1479–1492. https://doi.org/10.1016/j.jmps.2005.12.007

Shokri Rad M, Prawoto Y, Ahmad Z (2014) Analytical solution and finite element approach to the 3D re-entrant structures of auxetic materials. Mech Mater 74:76–87. https://doi.org/10.1016/j.mechmat.2014.03.012

Shokri Rad M, Ahmad Z, Alias A (2015) Computational approach in formulating mechanical characteristics of 3D star honeycomb auxetic structure. Adv Mater Sci Eng 2015:650769. https://doi.org/10.1155/2015/650769

Imbalzano G, Tran P, Ngo TD, Lee PVS (2016) A numerical study of auxetic composite panels under blast loadings. Compos Struct. https://doi.org/10.1016/j.compstruct.2015.09.038

Imbalzano G, Linforth S, Ngo TD et al (2018) Blast resistance of auxetic and honeycomb sandwich panels: comparisons and parametric designs. Compos Struct. https://doi.org/10.1016/j.compstruct.2017.03.018

Qiao J, Chen CQ (2015) Analyses on the in-plane impact resistance of auxetic double arrowhead honeycombs. J Appl Mech, Trans ASME. https://doi.org/10.1115/1.4030007

Clausen A, Wang F, Jensen JS et al (2015) Topology optimized architectures with programmable Poisson’s ratio over large deformations. Adv Mater. https://doi.org/10.1002/adma.201502485

Wang XT, Li XW, Ma L (2016) Interlocking assembled 3D auxetic cellular structures. Mater Des 99:467–476. https://doi.org/10.1016/j.matdes.2016.03.088

Zhang G, Khandelwal K (2019) Computational design of finite strain auxetic metamaterials via topology optimization and nonlinear homogenization. Comput Methods Appl Mech Eng. https://doi.org/10.1016/j.cma.2019.07.027

Schwerdtfeger J, Wein F, Leugering G et al (2011) Design of auxetic structures via mathematical optimization. Adv Mater. https://doi.org/10.1002/adma.201004090

Zied K, Osman M, Elmahdy T (2015) Enhancement of the in-plane stiffness of the hexagonal re-entrant auxetic honeycomb cores. Phys Status Solidi (B) Basic Res 252:2685–2692. https://doi.org/10.1002/pssb.201552164

Dong Z, Li Y, Zhao T et al (2020) Experimental and numerical research on foam filled re-entrant cellular structure with negative Poisson’s ratio. Mater Des 160:106679. https://doi.org/10.1080/17452759.2019.1644184

Hanssen AG, Girard Y, Olovsson L et al (2006) A numerical model for bird strike of aluminium foam-based sandwich panels. Int J Impact Eng 32:1127–1144. https://doi.org/10.1016/j.ijimpeng.2004.09.004

Hou X, Deng Z, Zhang K (2016) Dynamic crushing strength analysis of auxetic honeycombs. Acta Mech Solida Sin 29:490–501. https://doi.org/10.1016/S0894-9166(16)30267-1

Novak N, Hokamoto K, Vesenjak M, Ren Z (2018) Mechanical behaviour of auxetic cellular structures built from inverted tetrapods at high strain rates. Int J Impact Eng 122:83–90. https://doi.org/10.1016/j.ijimpeng.2018.08.001

Dirrenberger J, Forest S, Jeulin D (2012) Elastoplasticity of auxetic materials. In: Computational materials science

Mizzi L, Grima JN, Gatt R, Attard D (2019) Analysis of the Deformation Behavior and Mechanical Properties of Slit-Perforated Auxetic Metamaterials. Phys Status Solidi (B) Basic Res 256:1–15. https://doi.org/10.1002/pssb.201800153

Mizzi L, Attard D, Gatt R et al (2020) Implementation of periodic boundary conditions for loading of mechanical metamaterials and other complex geometric microstructures using finite element analysis. Eng Comput. https://doi.org/10.1007/s00366-019-00910-1

Mizzi L, Salvati E, Spaggiari A et al (2020) Highly stretchable two-dimensional auxetic metamaterial sheets fabricated via direct-laser cutting. Int J Mech Sci. https://doi.org/10.1016/j.ijmecsci.2019.105242

Evans KE, Nkansah MA, Hutchinson IJ (1994) Auxetic foams: modelling negative Poisson’s ratios. Acta Metall Mater 42:1289–1294. https://doi.org/10.1016/0956-7151(94)90145-7

**a Z, Zhang Y, Ellyin F (2003) A unified periodical boundary conditions for representative volume elements of composites and applications. Int J Solids Struct 40:1907–1921. https://doi.org/10.1016/S0020-7683(03)00024-6

Huang J, Gong X, Zhang Q et al (2016) In-plane mechanics of a novel zero Poisson’s ratio honeycomb core. Compos B Eng. https://doi.org/10.1016/j.compositesb.2015.11.032

Fu M, Chen Y, Zhang W, Zheng B (2016) Experimental and numerical analysis of a novel three-dimensional auxetic metamaterial. Phys Status Solidi (B) 253:1565–1575. https://doi.org/10.1002/pssb.201552769

Li D, Yin J, Dong L, Lakes RS (2018) Strong re-entrant cellular structures with negative Poisson’s ratio. J Mater Sci 53:3493–3499. https://doi.org/10.1007/s10853-017-1809-8

Chen Y, Fu M-H (2017) A novel three-dimensional auxetic lattice meta-material with enhanced stiffness. Smart Mater Struct 26:105029. https://doi.org/10.1088/1361-665X/aa819e

Chen Y, Fu M-H (2018) Design and modeling of a combined embedded enhanced honeycomb with tunable mechanical properties. Appl Compos Mater 25:1041–1055. https://doi.org/10.1007/s10443-017-9650-4

Ingrole A, Hao A, Liang R (2017) Design and modeling of auxetic and hybrid honeycomb structures for in-plane property enhancement. Mater Des 117:72–83. https://doi.org/10.1016/j.matdes.2016.12.067

Bezazi A, Scarpa F, Remillat C (2005) A novel centresymmetric honeycomb composite structure. Compos Struct 71:356–364. https://doi.org/10.1016/j.compstruct.2005.09.035

Rayneau-Kirkhope D (2018) Stiff auxetics: Hierarchy as a route to stiff, strong lattice based auxetic meta-materials. Sci Rep 8:12437. https://doi.org/10.1038/s41598-018-30822-x

Baran T, Öztürk M (2020) In-plane elasticity of a strengthened re-entrant honeycomb cell. Eur J Mech, A/Solids. https://doi.org/10.1016/j.euromechsol.2020.104037

Tatlıer MS, Öztürk M, Baran T (2021) Linear and non-linear in-plane behaviour of a modified re-entrant core cell. Eng Struct 234:111984. https://doi.org/10.1016/j.engstruct.2021.111984

Ratner BD, Hoffman AS, Schoen FJ, Lemons JE (2013) Biomaterials science an introduction to materials in medicine, 3rd edn. Elsevier, Amsterdam

ASTM-D638–14 (2014) Standard Test Method for Tensile Properties of Plastics. ASTM Standards

Morel S, Lespine C, Coureau JL et al (2010) Bilinear softening parameters and equivalent LEFM R-curve in quasibrittle failure. Int J Solids Struct. https://doi.org/10.1016/j.ijsolstr.2009.11.022

Eutionnat-Diffo PA, Chen Y, Guan J et al (2019) Stress, strain and deformation of poly-lactic acid filament deposited onto polyethylene terephthalate woven fabric through 3D printing process. Sci Rep. https://doi.org/10.1038/s41598-019-50832-7

Ansys® (2018), Academic Research Mechanical, Release 18.1, Help System, ANSYS, Inc.

Meena K, Singamneni S (2021) Novel hybrid auxetic structures for improved in- plane mechanical properties via additive manufacturing. Mech Mater. https://doi.org/10.1016/j.mechmat.2021.103890

Dong Z, Li Y, Zhao T et al (2019) Experimental and numerical studies on the compressive mechanical properties of the metallic auxetic reentrant honeycomb. Mater Des. https://doi.org/10.1016/j.matdes.2019.108036

Alomarah A, Masood SH, Sbarski I et al (2020) Compressive properties of 3D printed auxetic structures: experimental and numerical studies. Virtual Phys Prototyp 15:1–21. https://doi.org/10.1080/17452759.2019.1644184

Novak N, Vesenjak M, Krstulović-Opara L, Ren Z (2018) Mechanical characterisation of auxetic cellular structures built from inverted tetrapods. Compos Struct 196:96–107. https://doi.org/10.1016/j.compstruct.2018.05.024

Qi C, Jiang F, Remennikov A et al (2020) Quasi-static crushing behavior of novel re-entrant circular auxetic honeycombs. Compos B Eng 197:108117. https://doi.org/10.1016/j.compositesb.2020.108117

Acknowledgements

This work was partially supported by The Scientific and Technological Research Council of Turkey (TUBITAK, Project No: 119M180)

Author information

Authors and Affiliations

Contributions

MÖ helped in formal analysis, resources, visualization, writing—original draft, investigation, data curation, experimental work. TB contributed to conceptualization, methodology, validation, resources, writing—original draft, writing—review and editing, project administration, experimental work. MST was involved in conceptualization, validation, resources, supervision, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Disclaimer: The authors declare to accept the disclaimer.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 23705 KB)

Supplementary file2 (MP4 47201 KB)

Supplementary file3 (MP4 31062 KB)

Supplementary file4 (MP4 56900 KB)

Supplementary file5 (MP4 27364 KB)

Supplementary file6 (MP4 57044 KB)

Supplementary file7 (MP4 36879 KB)

Appendix

Appendix

Note that while calculating the classical re-entrant cell's mechanical properties it should be employed with very low stiffness and low cross-sectional parameters for the strengthening walls of the modified cells in the following equations.

-

(a)

Type-I cell equations:

All equations of the Type-I cell may be derived from the deformation of the inclined walls. Employing inclined inner and outer walls on the quarter cell, the equations may be derived employed in this paper (for further information please refer to Baran and Ozturk [77]). Poisson’s ratio and elasticity modulus of the Type-I cell may be expressed as:

Appearing terms in equations may be given as:

where \({\nu }_{12}\) is Poisson’s ratio, \({E}_{1}\) is the elasticity modulus of the re-entrant cell, \({A}_{1}\) and \({A}_{2}\) are the cross-sectional areas of the inclined outer walls and inner wall, respectively, \({E}_{s1}\) and \({E}_{s2}\) are the elasticity moduli of the inclined outer walls’ and inner wall’s materials, respectively, \({\theta }_{1}\) and \({\theta }_{2}\) are the angles of the inclined outer walls and inner wall, respectively, \({I}_{1}\) and \({I}_{2}\) are the second moment of inertias of the inclined outer walls and inner wall, respectively, \({l}_{2}\) is the length of the inclined inner wall, \({t}_{2}\) is the thickness of the inclined inner wall, \(h\) is the height of the re-entrant cell (length of the horizontal wall), \({b}_{2}\) is the width of the inclined wall, \({K}_{1}\), \({K}_{2}\), and \({K}_{3}\) are the stiffness terms that governs cell deformation, \({\alpha }_{1}\) and \({\alpha }_{2}\) are the shear deflection coefficients of the inclined outer walls and inner wall, respectively, \({k}_{1}\) and \({k}_{2}\) are the cross-section shear coefficients of the inclined outer walls and inner wall, respectively, \({l}_{1}\) is the length of the inclined outer walls, \({G}_{s1}\) and \({G}_{s2}\) are the shear moduli of the inclined outer walls’ and inner wall’s materials, respectively, \({\nu }_{s1}\) and \({\nu }_{s2}\) are Poisson’s ratios of the inclined outer walls’ and inner wall’s materials, respectively.

-

(b)

Type-II cell equations:

All equations of the Type-II cell may be derived from the deformation of the inclined and circular walls. Employing inclined and circular walls of the quarter cell, the equations may be derived employed in this paper (for further information please refer to Tatlıer et al. [78]). Poisson’s ratio and elasticity modulus of the Type-II cell may be expressed as:

Appearing terms in equations may be given as:

\({G}_{si}\), \({\alpha }_{i}\), R, and D that appear in equations above may be expressed as (where i is 1 for the circular wall and 2 for the inclined wall, respectively):

where \(\nu_{12}\) is Poisson’s ratio, \(E_{1}\) is the elasticity modulus of the re-entrant cell, \(\delta_{11}\) and \(\delta_{21}\) are the axial and the transverse displacement of cell, \(L\) is the length of inclined wall, \(t_{2}\) is the thickness of the inclined wall, \(\theta\) is the angle of the inclined wall, \(h\) is the height of the re-entrant cell (length of the horizontal wall), \(b_{2}\) is the width of the inclined wall, \(K_{ij}\) terms are the stiffness terms that govern cell deformation (where i and j indicate the cell’s degrees of freedoms: 1 and 3 are along with 1 axis and 2 is along with 2 axis), \(A_{1}\) and \(A_{2}\) are the cross-sectional areas of the circular and inclined walls, respectively, \(E_{s1}\) and \(E_{s2}\) are the elasticity moduli of the circular and inclined walls’ materials, respectively, \(I_{1}\) and \(I_{2}\) are the second moment of inertias of the circular and inclined walls, respectively, \(h\) is the height of the re-entrant cell (length of the horizontal wall), \(b_{2}\) is the width of the inclined wall, \(\alpha_{i}\) terms are the shear deflection coefficients of the circular and inclined walls, \(k_{i}\) terms are the cross-sectional shear coefficients of the circular and inclined walls, \(G_{si}\) terms are the shear moduli of the circular and inclined walls, \(\nu_{{{\text{si}}}}\) terms are Poisson’s ratios of the circular and inclined walls’ materials, \(R\) is the radius of the circular wall, and \(D\) is the determinant of the structural matrix of the cell.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Öztürk, M., Baran, T. & Tatlıer, M.S. Experimental and numerical investigation of conventional and stiffened re-entrant cell structures under compression. J Braz. Soc. Mech. Sci. Eng. 44, 593 (2022). https://doi.org/10.1007/s40430-022-03889-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03889-x