Abstract

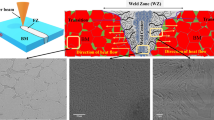

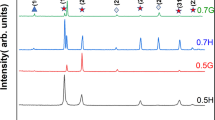

The weld solidification behavior, segregation tendency, phase formation, and cracking susceptibility of Al0.5CoCrCu0.1FeNi high-entropy alloy (HEA) were investigated. The AlCoCrCuFeNi alloy system has received wide attention due to its high temperature stability and strength retention. Characterization of the as-melted, heat-treated, and hot-rolled and heat-treated alloy conditions was performed and compared to thermodynamic CALPHAD-based calculations. Autogenous gas tungsten arc (GTA) and laser beam welding was done on the different alloy conditions. Microstructural changes in the fusion zone and heat-affected zone (HAZ) were investigated by optical microscopy and micro-hardness. Hot cracking susceptibility was evaluated using the cast pin tear test (CPTT). The fusion zone solidification microstructure of Al0.5CoCrCu0.1FeNi alloy consists of primary face centered cubic dendrites and interdendritic body centered cubic phase that forms at the end of solidification. GTA welding results in the partial dissolution of the interdendritic phase in the high-temperature HAZ, adjacent to the fusion boundary. Welding on the heat-treated alloy leads to HAZ softening due to the dissolution of strengthening nano-sized precipitates. No solidification cracking or HAZ liquation cracking was observed. Laser welding did not result in a drop in hardness or significant microstructural changes in the HAZ. The CPTT results correspond well with the predicted solidification temperature range (141 K) for Al0.5CoCrCu0.1FeNi alloy and its overall good weldability that was observed in the present work.

Similar content being viewed by others

References

Yeh J-W, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY (2004) Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater 6(5):299–303

Cantor B, Chang ITH, Knight P, Vincent AJB (2004) Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A 375–377:213–218

Hsu C-Y, Yeh J-W, Chen S-K, Shun T-T (2004) Wear resistance and high-temperature compression strength of Fcc CuCoNiCrAl0.5Fe alloy with boron addition. Metall Mater Trans A 35(5):1465–1469

Miracle DB, Senkov ON (2017) A critical review of high entropy alloys and related concepts. Acta Mater 122:448–511

Chen H-L, Mao H, Chen Q (2018) Database development and Calphad calculations for high entropy alloys: challenges, strategies, and tips. Mater Chem Phys 210:279–290

Ye YF, Wang Q, Lu J, Liu CT, Yang Y (2016) High-entropy alloy: challenges and prospects. Mater Today 19(6):349–362

Tsai M-H, Yeh J-W (2014) High-entropy alloys: a critical review. Materials Research Letters 2(3):107–123. https://doi.org/10.1080/21663831.2014.912690

Martin AC, Oliveira JP, Fink C (2018) Elemental effects on weld cracking susceptibility in AlxCoCrCuyFeNi high entropy alloy. Not yet published

Wang W-R, Wang W-L, Yeh J-W (2014) Phases, microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloys at elevated temperatures. J Alloys Compd 589:143–152

Tong C-J, Chen MR, Yeh JW, Lin SJ, Chen SK, Shun TT, Chang SY (2005) Mechanical performance of the Al x CoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall Mater Trans A 36(5):1263–1271

Niu S, Kou H, Guo T, Zhang Y, Wang J, Li J (2016) Strengthening of nanoprecipitations in an annealed Al0.5CoCrFeNi high entropy alloy. Mater Sci Eng A 671:82–86

Alexandrov BT, Lippold JC (2013) Use of the cast pin tear test to study solidification cracking. Welding in the World 57(5):635–648

Vander Voort G, Manilova E (2004) Metallographic techniques for superalloys. Microsc Microanal 10(S02):690–691

Wang W-R, Wang W-L, Wang S-C, Tsai Y-C, Lai C-H, Yeh J-W (2012) Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 26:44–51

Singh S, Wanderka N, Murty BS, Glatzel U, Banhart J (2011) Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy. Acta Mater 59(1):182–190

Jantzen CMF, Herman H (1978) Spinodal decomposition–phase diagram representation and occurence, In: Phase diagrams: materials science and technology, pp 127–184. https://www.sciencedirect.com/science/article/pii/B9780120532056500115?via%3Dihub. Accessed 28 Jan 2019

Hu B, Richardson IM (2006) Mechanism and possible solution for transverse solidification cracking in laser welding of high strength aluminium alloys. Mater Sci Eng A 429(1–2):287–294

Bergmann JP, Bielenin M, Herzog RA, Hildebrand J, Riedel I, Schricker K, Trunk C, Worthmann K (2017) Prevention of solidification cracking during pulsed laser beam welding. PAMM 17(1):405–406

Loginova I, Khalil A, Pozdniakov A, Solonin A, Zolotorevskiy V (2017) Effect of pulse laser welding parameters and filler metal on microstructure and mechanical properties of Al-4.7Mg-0.32Mn-0.21Sc-0.1Zr alloy. Metals 7(12):564

Funding

The authors gratefully acknowledge the partial financial support for this research by the Institute of Materials Research at Ohio State University under an Exploratory Materials Research Grant and by the American Welding Society under an AWS Graduate Research Fellowship Grant.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Martin, A.C., Fink, C. Initial weldability study on Al0.5CrCoCu0.1FeNi high-entropy alloy. Weld World 63, 739–750 (2019). https://doi.org/10.1007/s40194-019-00702-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00702-7