Abstract

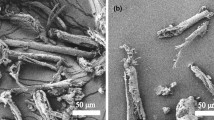

The removal of crude oil in saline water from microemulsion by cotton linter fiber was investigated by batch sorption. The experimental sorption data were collected without changing the water pH, biosorbent dosage (0.5 g/L), or medium rotation (140 rpm). The contact time varied from 10 min to 4.0 h and the initial crude oil concentration from 23 to 107 mg/L. The kinetics study was performed at 310 K and the sorption isotherms at 300, 310, and 320 K. Before oil sorption, the cotton linter fiber was characterized by scanning electron microscopy, energy-dispersive X-ray spectroscopy, and Fourier transform infrared spectroscopy. A pseudo-second-order kinetic model best described the sorption process. The Freundlich isothermal model fit the batch equilibrium data well. For initial crude oil concentration at around 100 mg/L, removal efficiency of 82, 76, and 56% was observed for sorption at temperatures of 300, 310, and 320 K, respectively. The thermodynamic parameter values demonstrate that the sorption of crude oil in saline water is spontaneous and exothermic. The results suggest that the sorption of crude oil in saline water emulsion by cotton linter fiber occurs through the surface of the rough fraction of the fiber and capillary suction due to the hollow lumens present in the fiber. The use of cotton linter fiber as a cleaning medium before discarding the produced water may cause a further decrease in the crude oil concentration flowing into the seawater bodies, below the values defined by the present legislation.

Similar content being viewed by others

References

Abdelwahab O, Nasr SM, Thabet WM (2017) Palm fibers and modified palm fibers adsorbents for different oils. Alex Eng J 56:749–755. https://doi.org/10.1016/j.aej.2016.11.020

Abidi N, Cabrales L, Haigler CH (2014) Changes in the cell wall and cellulose content of develo** cotton fibers investigated by FTIR spectroscopy. Carbohydr Polym 100:9–16. https://doi.org/10.1016/j.carbpol.2013.01.074

Abidin MAZ, Jalil AA, Triwahyono S, Adam SH, Kamarudin NHN (2011) Recovery of gold (III) from an aqueous solution onto a durio zibethinus husk. Biochem Eng J 54(2):124–131. https://doi.org/10.1016/j.bej.2011.02.010

Abou-State MA (1979) Non-wood plant fibre pul**: part 1—cotton linters and cotton waste fibres. Fibre Sci Technol 12(2):139–148. https://doi.org/10.1016/0015-0568(79)90026-5

Ahmad AL, Sumathi SE, Hameed BH (2006) Coagulation of residue oil and suspended solid in palm oil mill effluent by chitosan, alum and PAC. Chem Eng J 118(1–2):99–105. https://doi.org/10.1016/j.cej.2006.02.001

Alvarez VA, Vasquez A (2006) Influence of fiber chemical modification procedure on the mechanical properties and water absorption of MaterBi-Y/sisal fiber composites. Compos Part A Appl Sci Manuf 37(10):1672–1680. https://doi.org/10.1016/j.compositesa.2005.10.005

Angelova D, Uzunovb I, Uzunovaa S, Gigovac A, Minchevd L (2011) Kinetics of oil and oil products adsorption by carbonized rice husks. Chem Eng J 172(1):306–311. https://doi.org/10.1016/j.cej.2011.05.114

Ansari IA, East GC, Johnson DJ (2009) Structure–property relationships in natural cellulosic fibers. Part III: Flax—an oil sorbent. J Text Inst 94(1–2):1–15. https://doi.org/10.1080/00405000308630590

Ardanuy M, Claramunt J, García-Hortal JA, Barra M (2011) Fiber-matrix interactions in cement mortar composites reinforced with cellulosic fibers. Cellulose 18(2):281–289. https://doi.org/10.1007/s10570-011-9493-3

Arellano IH, Pendleton P (2016) Phenomenological analyses of carbon dioxide adsorption kinetics on supported zinc-functionalized ionic liquid hybrid sorbents. Chem Eng J 288(15):255–263. https://doi.org/10.1016/j.cej.2015.11.054

Bhattacharyya KG, Gupta SS (2006) Pb(II) uptake by kaolinite and montmorillonite in aqueous medium: influence of acid activation of the clays. Colloids Surf A Physicochem Eng Asp 277(1–3):191–200. https://doi.org/10.1016/j.colsurfa.2005.11.060

Brandão PC, Souza TC, Ferreira CA, Hori CE, Romanielo IL (2010) Removal of petroleum hydrocarbons from aqueous solution using sugarcane bagasse as adsorbent. J Hazard Mater 175(1–3):1106–1112. https://doi.org/10.1016/j.jhazmat.2009.10.060

Cerqueira DA, Filho GR, Meireles CS (2007) Optimization of sugarcane bagasse cellulose acetylation. Carbohydr Polym 69(3):579–582. https://doi.org/10.1016/j.carbpol.2007.01.010

Chen X (2015) Modeling of experimental adsorption isotherm data. Information 6(1):14–22. https://doi.org/10.3390/info6010014

Cheu SC, Kong H, Song ST, Johari K, Saman N, Yunus MAC, Mat H (2016) Separation of dissolved oil from aqueous solution by sorption onto acetylated lignocellulosic biomass-equilibrium, kinetics and mechanism studies. Environ Chem Eng 4:864–881. https://doi.org/10.1016/j.jece.2015.12.028

Choi H-J (2019) Agricultural bio-waste for adsorptive removal of crude oil in aqueous solution. J Mater Cycles Waste Manag 21(2):356–364. https://doi.org/10.1007/s10163-018-0797-3

Choi H-M, Cloud RM (1992) Natural sorbents in oil spill cleanup. Environ Sci Technol 26(4):772–776. https://doi.org/10.1021/es00028a016

Choi HM, Kwon HJ, Moreau JP (1993) Cotton nonwovens as oil spill cleanup sorbents. Text Res J 63(4):211–218. https://doi.org/10.1177/004051759306300404

Cocero MJ, Cabeza Á, Abad N, Adamovic T, Vaquerizo L, Martínez CM, Pazo-Cepeda MV (2018) Understanding biomass fractionation in subcritical & supercritical water. J Supercrit Fluids 133(2):550–565. https://doi.org/10.1016/j.supflu.2017.08.012

CONAMA (2007) Resolução CONAMA Nº 393/2007. Data da legislação: 08/08/2007 http://conama.mma.gov.br/?option=com_sisconama&task=arquivo.download&id=530. Accessed May 25 2020

Costa AS, Romão LPC, Araújo BR, Lucas SCO, Maciel STA, Wisniewski A, Alexandre MR (2012) Environmental strategies to remove volatile aromatic fractions (BTEX) from petroleum industry wastewater using biomass. Bioresour Technol 105:31–39. https://doi.org/10.1016/j.biortech.2011.11.096

Dai Y, Sun Q, Wang W, Lu L, Liu M, Li J, Zheng W (2018) Utilizations of agricultural waste as adsorbent for the removal of contaminants: a review. Chemosphere 211:235–253. https://doi.org/10.1016/j.chemosphere.2018.06.179

De Smedt C, Spanoghe P, Biswas S, Leus K, Van Der Voort P (2015) Comparison of different solid adsorbents for the removal of mobile pesticides from aqueous solutions. Adsorption 21:243–254. https://doi.org/10.1007/s10450-015-9666-8

Dong T, Wang F, Xu G (2015) Sorption kinetics and mechanism of various oils into kapok assembly. Mar Pollut Bull 91:230–237. https://doi.org/10.1016/j.marpolbul.2014.11.044

Elanchezhiyan SSD, Meenakshi S (2017) Synthesis and characterization of chitosan/Mg-Al layered double hydroxide composite for the removal of oil particles from oil-in-water emulsion. Int J Biol Macromol 104:1586–1595. https://doi.org/10.1016/j.ijbiomac.2017.01.095

Fakhru’l-Razi A, Pendashteh A, Abdullah LC, Biak DRA, Madaeni SS, Abidin ZZ (2009) Review of technologies for oil and gas produced water treatment. J Hazard Mater 170(2–3):530–551. https://doi.org/10.1016/j.jhazmat.2009.05.044

Fang JM, Sun RC, Tomkinson J (2000) Isolation and characterization of hemicelluloses and cellulose from rye straw by alkaline peroxide extraction. Cellulose 7:87–107. https://doi.org/10.1023/A:1009245100275

FAOSTAT Agricultural data (2021) production—crops and livestock products. Food and agriculture organization of the United Nations. http://faostat.fao.org/default.aspx/. Accessed Jan 06 2021

Foo KY, Hameed BH (2010) Insights into the modeling of adsorption isotherm systems. Chem Eng J 156(1):2–10. https://doi.org/10.1016/j.cej.2009.09.013

Gargouri B, Karray F, Mhiri N, Aloui F, Sayadi S (2014) Bioremediation of petroleum hydrocarbons-contaminated soil by bacterial consortium isolated from an industrial wastewater treatment plant. J Chem Technol Biotechnol 89(2):978–987. https://doi.org/10.1002/jctb.4188

Garside P, Wyeth P (2003) Identification of cellulosic fibers by FTIR spectroscopy—thread and single fiber analysis by attenuated total reflectance. Stud Conserv 48(4):269–275. https://doi.org/10.1179/sic.2003.48.4.269

Grem ICS, Lima BNB, Carneiro WF, Queirós YGC, Mansur CRE (2013) Chitosan microspheres applied for removal of oil from produced water in the oil industry. Polímeros Ciência e Tecnologia 23(6):705–711. https://doi.org/10.4322/polimeros.2014.008

Gusmão KAG, Gurgel LVA, Melo TMS, Gil LF (2012) Application of succinylated sugarcane bagasse as adsorbent to remove methylene blue and gentian violet from aqueous solutions e Kinetic and equilibrium studies. Dyes Pigments 92(3):967–974. https://doi.org/10.1016/j.dyepig.2011.09.005

Ibrahim S, Ang H-M, Wang S (2009) Removal of emulsified food and mineral oils from wastewater using surfactant modified barley straw. Bioresour Technol 100(23):5744–5749. https://doi.org/10.1016/j.biortech.2009.06.070

Ibrahim S, Wang S, Ang H-M (2010) Removal of emulsified oil from oily wastewater using agricultural waste barley straw. Biochem Eng J 49(1):78–83. https://doi.org/10.1016/j.bej.2009.11.013

Jalil AA, Triwahyono S, Adam SH, Rahim ND, Aziz MAA, Hairom NHH, Razali NAM, Abidin MAZ, Mohamadiah MKA (2010) Adsorption of methyl orange from aqueous solution onto calcined Lapindo volcanic mud. J Hazard Mater 181(1–3):755–762. https://doi.org/10.1016/j.jhazmat.2010.05.078

Jia Z, Li Z, Ni T, Li S (2017) Adsorption of low-cost absorption materials based on biomass (Cortaderia selloana flower spikes) for dye removal: kinetics, isotherms and thermodynamic studies. J Mol Liq 229:285–292. https://doi.org/10.1016/j.molliq.2016.12.059

Jiang Y, Wang D, Zhao T (2007) Preparation, characterization, and prominent thermal stability of phase-change microcapsules with phenolic resin shell and n-hexadecane core. J Appl Polym Sci 104(5):2799–2806. https://doi.org/10.1002/app.25962

Koh A, Gillies G, Gore J, Saunders BR (2000) Flocculation and coalescence of oil-in-water poly(dimethylsiloxane) emulsions. J Colloid Interface Sci 227:390–397. https://doi.org/10.1006/jcis.2000.6909

Kose B, Ozgun H, Ersahin ME, Dizge N, Koseoglu-Imer DY, Atay B, Koyuncu I (2012) Performance evaluation of a submerged membrane bioreactor for the treatment of brackish oil and natural gas field produced water. Desalination 285:295–300. https://doi.org/10.1016/j.desal.2011.10.016

Kumar A, Negi YS, Choudhary V, Bhardwaj NK (2014) Characterization of cellulose nanocrystals produced by acid-hydrolysis from sugarcane bagasse as agro-waste. J Mater Phys Chem 2(1):1–8. https://doi.org/10.12691/jmpc-2-1-1

Langevin D, Poteau S, Hénaut I, Argillier JF (2004) Crude oil emulsion properties and their application to heavy oil transportation. Oil Gas Sci Technol 59(5):511–521. https://doi.org/10.2516/ogst:2004036

Lee RF (1999) Agents which promote and stabilize water-in-oil emulsions. Spill Sci Technol Bull 5(2):117–126. https://doi.org/10.1016/s1353-2561(98)00028-0

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15(1):25–33. https://doi.org/10.1007/s10924-006-0042-3

Liew FK, Hamdan S, Rahman MdR, Rusop M, Lai JCH, Hossen MdF, Rahman MdM (2015) Synthesis and characterization of cellulose from green bamboo by chemical treatment with mechanical. J Chem. https://doi.org/10.1155/2015/212158

Likon M, Remskar M, Ducman V, Svegl F (2013) Populus seed fibers as a natural source for production of oil super absorbents. J Environ Manag 114:158–167. https://doi.org/10.1016/j.jenvman.2012.03.047

Lira Junior CA, Silva DSA, Costa Filho AP, Lucas EF, Santana SSA (2017) Smectic clay modified with quaternary ammonium as oil remover. J Braz Chem Soc 28(2):208–216. https://doi.org/10.5935/0103-5053.20160165

Liu Q-S, Zheng T, Wang P, Jiang J-P, Li N (2010) Adsorption isotherm, kinetic and mechanism studies of some substituted phenols on activated carbon fibers. Chem Eng J 157(2–3):348–356. https://doi.org/10.1016/j.cej.2009.11.013

Liu X, Ge L, Li W, Wang X, Li F (2015) Layered double hydroxide functionalized textile for effective oil/water separation and selective oil adsorption. ACS Appl Mater Inter 7(1):791–800. https://doi.org/10.1021/am507238y

Lopez-Ramon MV, Stoeckli F, Moreno-Castilla C, Carrasco-Marin F (1999) On the characterization of acidic and basic surface sites on carbons by various techniques. Carbon 37(8):1215–1221. https://doi.org/10.1016/s0008-6223(98)00317-0

Lv N, Wang X, Peng S, Zhang H, Luo L (2018) Study of the kinetics and equilibrium of the adsorption of oils onto hydrophobic jute fiber modified via the sol-gel method. Int J Env Res Pub He 15(5):969–982. https://doi.org/10.3390/ijerph15050969

Mall ID, Srivastava VC, Kumar GVA, Mishra IM (2006) Characterization and utilization of mesoporous fertilizer plant waste carbon for adsorptive removal of dyes from aqueous solution. Colloid Surf A Physicochem Eng Asp 278(1–3):175–187. https://doi.org/10.1016/j.colsurfa.2005.12.017

Meléndez LV, Lache A, Orrego-Ruiz JA, Pachón Z, Mejía-Ospino E (2012) Prediction of the SARA analysis of Colombian crude oil using ATR–FTIR spectroscopy and chemometric methods. J Petrol Sci and Eng 90–91:56–60. https://doi.org/10.1016/j.petrol.2012.04.016

Morais JPS, Rosa MF, Souza Filho M, Sá M, Nascimento LD, Nascimento DM, Cassales AR (2013) Extraction and characterization of nanocellulose structures from raw cotton linter. Carbohydr Polym 91:229–235. https://doi.org/10.1016/j.carbpol.2012.08.010

Nwadiogbu JO, Okoye PAC, Ajiwe VI, Nnaji NJN (2014) Hydrophobic treatment of corn cob by acetylation: kinetics and thermodynamics studies. J Environ Chem Eng 2(3):1699–1704. https://doi.org/10.1016/j.jece.2014.06.003

Nwadiogbu JO, Ajiwe VIE, Okoye PAC (2016) Removal of crude oil from aqueous medium by sorption on hydrophobic corncobs: equilibrium and kinetic studies. J Taibah Univ Sci 10(1):56–63. https://doi.org/10.1016/j.jtusci.2015.03.014

Okiel K, El-Sayed M, El-Kady MY (2011) Treatment of oil–water emulsions by adsorption onto activated carbon, bentonite and deposited carbon. Egypt J Pet 20(2):9–15. https://doi.org/10.1016/j.ejpe.2011.06.002

Oksman K, Mathew AP, Långström R, Nyström B, Joseph K (2009) The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene. Compos Sci Technol 69(11–12):1847–1853. https://doi.org/10.1016/j.compscitech.2009.03.020

Paiva MC, Ammar I, Campos AR, Cheikh RB, Cunha AM (2007) Alfa fibres: mechanical, morphological and interfacial characterization. Compos Sci Technol 67(6):1132–1138. https://doi.org/10.1016/j.compscitech.2006.05.019

Rajak VK, Kumar S, Thombre NV, Mandal A (2018) Synthesis of activated charcoal from saw-dust and characterization for adsorptive separation of oil from oil-in-water emulsion. Chem Eng Commun 205(7):897–913. https://doi.org/10.1080/00986445.2017.1423288

Reddi MRG, Gomathi T, Saranya M, Sudh PN (2017) Adsorption and kinetic studies on the removal of chromium and copper onto Chitosan-g-maliec anhydride-g-ethylene dimethacrylate. Int J Biol Macromol 104:1578–1585. https://doi.org/10.1016/j.ijbiomac.2017.01.142

Ribeiro TH, Rubio J, Smith RW (2003) A dried hydrophobic Aquaphyte as an oil filter for oil/water emulsions. Spill Sci Technol Bull 8(5–6):483–489. https://doi.org/10.1016/s1353-2561(03)00130-0

Rosa IM, Kenny JM, Puglia D, Santulli C, Sarasini F (2010) Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos Sci Technol 70(1):116–122. https://doi.org/10.1016/j.compscitech.2009.09.013

Rubio J, Souza M, Smith R (2002) Overview of flotation as a wastewater treatment technique. Miner Eng 15(3):139–155. https://doi.org/10.1016/s0892-6875(01)00216-3

Ruthven DM (1984) Principles of adsorption and adsorption processes. John Wiley & Sons

Said A, Ludwick A, Aglan H (2009) Usefulness of raw bagasse for oil absorption: a comparison of raw and acylated bagasse and their components. Bioresour Technol 100(7):2219–2222. https://doi.org/10.1016/j.biortech.2008.09.060

Santo CE, Vilar VJP, Botelho CMS, Bhatnagar A, Kumar E, Boaventura RAR (2012) Optimization of coagulation–flocculation and flotation parameters for the treatment of a petroleum refinery effluent from a Portuguese plant. Chem Eng J 183:117–123. https://doi.org/10.1016/j.cej.2011.12.041

Sathasivam K, Mas Haris MRH (2010) Adsorption kinetics and capacity of fatty acid-modified banana trunk fibers for oil in water. Water Air Soil Pollut 213(1):413–423. https://doi.org/10.1007/s11270-010-0395-z

Sczostak A (2009) Cotton Linters: An alternative cellulosic raw material. Macromol Symp 280(1):45–53. https://doi.org/10.1002/masy.200950606

Sidik SM, Jalil AA, Triwahyono S, Adam SH, Satar MAH, Hameed BH (2012) Modified oil palm leaves adsorbent with enhanced hydrophobicity for crude oil removal. Chem Eng J 203:9–18. https://doi.org/10.1016/j.cej.2012.06.132

Silva C, Rocha P, Aversa T, Lucas E (2019) Removal of petroleum from aqueous systems by poly (divinylbenzene) and poly (methyl methacrylate-divinylbenzene) resins: isothermal and kinetics studies. Chem Chem Technol 13(3):399–406. https://doi.org/10.23939/chcht13.03.399

Singh YD, Mahanta P, Bora U (2017) Comprehensive characterization of lignocellulosic biomass through proximate, ultimate and compositional analysis for bioenergy production. Renew Energy 103:490–500. https://doi.org/10.1016/j.renene.2016.11.039

Site AD (2001) Factors affecting sorption of organic compounds in natural sorbent/water systems and sorption coefficients for selected pollutants. A review. J Phys Chem Ref Data 30:187–439. https://doi.org/10.1063/1.1347984

Spinacé MAS, Lambert CS, Fermoselli KKG, De Paoli M-A (2009) Characterization of lignocellulosic curaua fibres. Carbohydr Polym 77(1):47–53. https://doi.org/10.1016/j.carbpol.2008.12.005

Tembhurkar AR, Deshpande R (2012) Powdered activated lemon peels as adsorbent for removal of cutting oil from wastewater. J Hazard Toxic Radioact Waste 16(4):311–315. https://doi.org/10.1061/(asce)hz.2153-5515.0000132

USEPA (2014) http://www.epa.gov. Accessed June 12 2014

Van Soest PJ (1963) Use of detergents in the analysis of fibrous feeds. II. A rapid method for the determination of fiber and lignin. J Assoc Off Agric Chem 46(5):829–835

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74(10):3583–3597. https://doi.org/10.3168/jds.s0022-0302(91)78551-2

Vidal RRL, Moraes JS (2019) Removal of organic pollutants from wastewater using chitosan: a literature review. Int J Environ Sci Technol 16:1741–1754. https://doi.org/10.1007/s13762-018-2061-8

Vidal RRL, Desbrières J, Borsali R, Guibal E (2019) Oil removal from crude oil-in-saline water emulsions using chitosan as biosorbent. Sep Sci Technol 55(5):835–847. https://doi.org/10.1080/01496395.2019.1575879

Vlaev L, Petkov P, Dimitrov A, Genieva S (2011) Cleanup of water polluted with crude oil or diesel fuel using rice husks ash. J Taiwan Inst Chem Eng 42(6):957–964. https://doi.org/10.1016/j.jtice.2011.04.004

Wang J, Zheng Y, Wang A (2012) Superhydrophobic kapok fiber oil absorbent: preparation and high oil absorbency. Chem Eng J 213:1–7. https://doi.org/10.1016/j.cej.2012.09.116

Wang J, Zheng Y, Wang A (2013a) Investigation of acetylated kapok fibers on the sorption of oil in water. J Environ Sci 25(2):246–253. https://doi.org/10.1016/S1001-0742(12)60031-X

Wang J, Zheng Y, Wang A (2013b) Coated kapok fiber for removal of spilled oil. Mar Pollut Bull 69(1–2):91–96. https://doi.org/10.1016/j.marpolbul.2013.01.007

Weschenfelder SE, Mello ACC, Borges CP, Campos JC (2015) Oilfield produced water treatment by ceramic membranes: preliminary process cost estimation. Desalination 360:81–86. https://doi.org/10.1016/j.desal.2015.01.015

Williams A, Jones JM, Ma L, Pourkashanian M (2012) Pollutants from the combustion of solid biomass fuels. Prog Energy Combust Sci 38(2):113–137. https://doi.org/10.1016/j.pecs.2011.10.001

Wisniewska SK, Nalaskowski J, Witka-Jezewska E, Hupka J, Miller JD (2003) Surface properties of barley straw. Colloids Surf B 29(2–3):131–142. https://doi.org/10.1016/S0927-7765(02)00178-9

Wu J, Wang N, Wang L, Dong H, Zhao Y, Jiang L (2012) Electrospun porous structure fibrous film with high oil adsorption capacity. ACS Appl Mater Interfaces 4(6):3207–3212. https://doi.org/10.1021/am300544d

Wu Y, Qi H, Li B, Zhanhua H, Li W, Liu S (2017) Novel hydrophobic cotton fibers adsorbent for the removal of nitrobenzene in aqueous solution. Carbohydr Polym 155:294–302. https://doi.org/10.1016/j.carbpol.2016.08.088

Xue Z, Cao Y, Liu N, Feng L, Jiang L (2014) Special wettable materials for oil/water separation. J Mater Chem A 2(8):2445–2460. https://doi.org/10.1039/c3ta13397d

Yang Y, Chun Y, Sheng G, Huang M (2004) pH-Dependence of pesticide adsorption by wheat-residue-derived black carbon. Langmuir 20(16):6736–6741. https://doi.org/10.1021/la049363t

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86(12–13):1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Zhang H, Long X, Sha R, Zhang G, Meng Q (2009) Biotreatment of oily wastewater by rhamnolipids in aerated active sludge system. J Zhejiang Univ Sci B 10(11):852–859. https://doi.org/10.1631/jzus.b0920122

Zulfiqar U, Thomas AG, Yearsley K, Bolton LW, Matthews A, Lewis DJ (2019) Renewable adsorbent for the separation of surfactant-stabilized oil in water emulsions based on nanostructured sawdust. ACS Sustain Chem Eng 7(23):18935–18942. https://doi.org/10.1021/acssuschemeng.9b04294

Acknowledgements

The authors thank the Institutional Scientific Initiation Scholarship (PIBIC-UFBA) and the National Council for Scientific and Technological Development (CNPq-BRAZIL) for the scholarship, the Medical Research Laboratory (LAPEMM) for the analysis of ATR-FTIR, the Animal Nutrition laboratory (LANA) for determining the chemical composition of cotton linter fiber by van Soest Method, the Electron Microscopy Multiuser Laboratory (LAMUME) for the analysis of Scanning Electron Microscopy, and LabCat for EDX analysis. All laboratories are located at Universidade Federal da Bahia (UFBA). The English text of this paper has been revised by Sidney Pratt, Canadian, MAT (The Johns Hopkins University), RSAdip—TESL (Cambridge University).

Funding

The authors have no financial or proprietary interests in any material discussed in this article.

Author information

Authors and Affiliations

Contributions

Material preparation, data collection, and primary analysis were performed by Maiara S. Santos. Rosangela R.L. Vidal and Roger Fréty contributed to the study conception and design and wrote the first draft of the manuscript. All authors commented on previous versions of the manuscript, read and approved the final text.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Editorial responsibility: S. Mirkia.

Rights and permissions

About this article

Cite this article

Silva, M.S., Fréty, R. & Vidal, R.R.L. Cotton linter as biosorbent: removal study of highly diluted crude oil-in-saline water emulsion. Int. J. Environ. Sci. Technol. 20, 2111–2126 (2023). https://doi.org/10.1007/s13762-022-04132-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-022-04132-9