Abstract

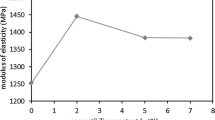

This innovative study explores the enhanced compatibility and miscibility of recycled polyethylene terephthalate and polyamide 11 (RPET/PA-11), particularly when modified with Joncryl®, a compatibilizer. This investigation marks the first venture into the detailed thermal and thermo-mechanical properties of the blends. Remarkably, the addition of 20% (by weight) PA-11 to RPET significantly boosts tensile strength from 18.5 ± 2.64 to 32.20 ± 4.95 MPa, flexural strength from 27.90 ± 3.17 to 46.75 ± 0.78 MPa, and impact strength from 110.53 to 147.12 J/m. Furthermore, introducing 2 phr Joncryl® further fortifies these strengths to 46.24 ± 0.87 MPa, 63.12 ± 4.75 MPa, and 667.68 ± 130.74 J/m, respectively. The study revealed a rise in the storage modulus of RPET from 1128 to 1298.5 MPa with 20% (by weight) of PA-11. Compatibility and miscibility assessments through Fourier transformation infrared (FTIR), dynamic mechanical analysis (DMA), differential scanning calorimetry (DSC), thermal gravimetric analysis (TGA), and scanning electron microscopy (SEM) validate the blend's uniformity. DSC reveals that the melting temperatures for RPET/PA-11 blends with varying PA-11 concentrations closely match the melting temperature of pure RPET, signifying stable thermal properties. DSC results confirmed that the Tm1 temperature for cold crystallization drops with the addition of Joncryl® content, suggesting improved interaction and miscibility between RPET and PA-11. TGA results disclosed that Joncryl® compatibilizer, especially at 2 phr, boosts the thermal stability of RPET/PA-11 blends by improving miscibility. The 2 phr Joncryl® blend was identified as the most robust in properties. This ground-breaking research highlights the potential of RPET in automotive and future advancements in polymer science.

Graphical abstract

Similar content being viewed by others

Data Availability

This data is part of an ongoing PhD project; therefore, we are sorry to say that it cannot be shared at this stage.

References

Priyanka P, Mali HS, Dixit A (2023) Carbon-Kevlar intraply hybrid fabric polymer composites: mechanical performance. Iran Polym J 32:633–645

Karaoui M, Hsissou R, Alami M, Assouag M (2023) Thermal, flow, and mechanical properties of composites based on polystyrene (PS) and snail shell powder (SSP) biofiller (PS/SSP). Iran Polym J 32:621–631

Tay CH, Norkhairunnisa M (2021) Mechanical strength of graphene reinforced geopolymer nanocomposites: a review. Front Mater 8:1–20

Khan ZI, Habib U, Mohamad ZB, Khan I (2024) Mechanical and thermal properties of a newly developed sepiolite filler-filled rPET/PA11 thermoplastic nanocomposites. Results Eng 21:101731

Khan ZI, Habib U, Mohamad ZB, Rehmat ARB, Abdullah NASB (2022) Mechanical and thermal properties of sepiolite strengthened thermoplastic polymer nanocomposites: a comprehensive review. Alexandria Eng J 61:975–990

Scariot MA, Fenner BR, Beltrami M, Beltrami LVR, Zattera AJ (2023) Conductive nanocomposites based on polymer with high concentrations of graphene nanoplatelets. Iran Polym J 32:59–69

Chowreddy RR, Nord-Varhaug K, Rapp F (2019) Recycled poly(ethylene terephthalate)/clay nanocomposites: rheology, thermal and mechanical properties. J Polym Environ 27:37–49

Abdullah NAS, Mohamad Z, Khan ZI et al (2021) Alginate based sustainable films and composites for packaging: a review. Chem Eng Trans 83:271–276

Andrew JJ, Dhakal HN (2022) Sustainable biobased composites for advanced applications: recent trends and future opportunities: a critical review. Compos Part C 7:100220

Jagdeva G, Lal S, Arora S, Kumar P (2023) Gamma-irradiated recycled polyethylene filled with Tectona grandis (teak) leaf powder: a method for upcycling of polyethylene. Iran Polym J 32:1075–1087

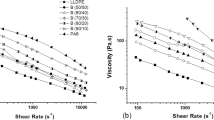

Othman N, Mohamad Z, Khan ZI, Abdullah LC (2023) Rheological behavior of recycled poly(ethylene terephthalate)/poly(amide) 11 blends with chain extender. Mater Today Proc (in press)

Shahrajabian H, Sadeghian F (2019) The investigation of alumina nanoparticles’ effects on the mechanical and thermal properties of HDPE/rPET/MAPE blends. Int Nano Lett 9:213–219

Ávila AF, Duarte MV (2003) A mechanical analysis on recycled PET/HDPE composites. Polym Degrad Stab 80:373–382

Wang D, Luo F, Luo C (2019) A novel blend material to improve the crystallization and mechanical properties of poly (ethylene terephthalate). J Polym Res 26:1–11

Rehman SU, Javaid S, Shahid M, Gul IH, Rashid B, Szczepanski CR, Naveed M, Curley SJ (2022) Polystyrene-sepiolite clay nanocomposites with enhanced mechanical and thermal properties. Polymers 14:3576

Lago ED, Boaretti C, Piovesan F, Roso M, Lorenzetti A, Modesti M (2018) The effect of different compatibilizers on the properties of a post-industrial PC/PET blend. Materials 12:1–14

Mishra RK, Mishra P, Verma K, Joseph K (2018) Manipulation of thermo-mechanical, morphological and electrical properties of PP/PET polymer blend using MWCNT as nano compatibilizer: a comprehensive study of hybrid nanocomposites. Vacuum 157:433–441

Louzi VC, Campos JSDC (2019) Corona treatment applied to synthetic polymeric monofilaments (PP, PET, and PA-6). Surf Interface 14:98–107

Li CQ, Zha JW, Li ZJ, Zhang DL, Wang SJ, Dang ZM (2018) Towards balanced mechanical and electrical properties of thermoplastic vulcanizates composites via unique synergistic effects of single-walled carbon nanotubes and graphene. Compos Sci Technol 157:134–143

Lu C, Gao X-P, Yao DH, Cao CL, Luo YJ (2018) Improving flame retardancy of linear low-density polyethylene/nylon 6 blends via controlling localization of clay and intumescent flame-retardant. Polym Degrad Stab 153:75–87

Khan ZI, Mohamad ZB, Rahmat ARB, Habib U, Abdullah NA (2021) A novel recycled polyethylene terephthalate/polyamide 11 (rPET/PA11) thermoplastic blend. Prog Rubber Plast Recycl Technol 37:233–244

Hynes A, Scott DA, Man A, Singer DL, Sowa MG, Liu KZ (2005) Molecular map** of periodontal tissues using infrared microspectroscopy. BMC Med Imaging 5:1–10

Al-Itry R, Lamnawar K, Maazouz A (2012) Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym Degrad Stab 97:1898–1914

Rasselet D, Caro-Bretelle AS, Taguet A, Lopez-Cuesta JM (2019) Reactive compatibilization of PLA/PA11 blends and their application in additive manufacturing. Materials 12:485

Mohamed MA, Jaafar J, Ismail AF, Othman MH, Rahman MA (2017) Fourier transform infrared (FTIR) spectroscopy. Membr Charact 2017:3–29

Khan ZI, Habib U, Mohamad ZB, Raji AM (2021) Enhanced mechanical properties of a novel compatibilized recycled polyethylene terephthalate/polyamide 11 (rPET/PA11) blends. Express Polym Lett 15:1206–1215

Dong S, Gauvin R (1993) Application of dynamic mechanical analysis for the study of the interfacial region in carbon fiber/epoxy composite materials. Polym Compos 14:414–420

Nofar M, Oğuz H (2019) Development of PBT/recycled-PET blends and the influence of using chain extender. J Polym Environ 27:1404–1417

Backes EH, Passador FR, Leopold C, Fiedler B, Pessan LA (2018) Electrical, thermal and thermo-mechanical properties of epoxy/multi-wall carbon nanotubes/mineral fillers nanocomposites. J Compos Mater 52:3209–3217

Zare Y, Rhee KY (2019) Following the morphological and thermal properties of PLA/PEO blends containing carbon nanotubes (CNTs) during hydrolytic degradation. Compos B 175:107132

Tomić NZ (2019) Thermal studies of compatibilized polymer blends. Compatib Polym Blend 2020:489–510

Drobny JG (2014) Handbook of thermoplastic elastomers. Elsevier, Amsterdam

Wiese M, Thiede S, Herrmann C (2020) Rapid manufacturing of automotive polymer series parts: a systematic review of processes, materials and challenges. Addit Manuf 36:101582

Wong S, Lee JWS, Naguib HE, Park CB (2008) Effect of processing parameters on the mechanical properties of injection molded thermoplastic polyolefin (TPO) cellular foams. Macromol Mater Eng 293:605–613

Acknowledgements

The authors would like to acknowledge the financial support from the Ministry of Higher Education Malaysia under the Fundamental Research Grant Scheme (FRGS) (FRGS/1/2019/TK05/UTM/02/17) and Zahid Iqbal Khan, postdoctoral fellow of Universiti Teknologi Malaysia under Postdoctoral Fellowship Scheme for the Project "Novel recycled polyethylene terephthalate/polyamide 11 blends filled with nanofillers" Q.J130000.21A2.06E98 (06E98).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Habib, U., Khan, Z.I. & Mohamad, Z.B. Compatibility and miscibility of recycled polyethylene terephthalate/polyamide 11 blends with and without Joncryl® compatibilizer: a comprehensive study of mechanical, thermal, and thermomechanical properties. Iran Polym J (2024). https://doi.org/10.1007/s13726-024-01357-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13726-024-01357-y