Abstract

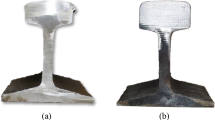

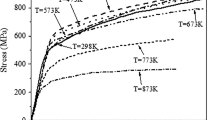

Little attention has been paid to the microstructure evolution of rail steel adding rare earth (RE) during hot deformation, so U75V-RE (RE = La, Ce) rail is compared with the traditional U75V rail. Thermal simulation test, mathematical regression analysis, finite element numerical simulation, cellular automata, OM, EBSD, and hardness tester were used to study the dynamic recrystallization evolution of U75V-RE rail and U75V rail at strain rates of 0.01–0.5 s−1 and hot deformation temperatures of 900–1150 °C. The results show that the simulation is quite close to that of the experimental measurements, and the dynamic recrystallization of U75V-RE rail and U75V rail easily occurs with a low strain rate and high temperature. U75V-RE rail has a much higher recrystallization critical strain than U75V rail during hot deformation. The recrystallization percentage and average grain size of U75V-RE rail are lower than those of U75V rail under the same hot deformation conditions, but the hardness of U75V-RE rail is higher. This can be attributed to the RE inhibit the dynamic recrystallization of U75V-RE rail, and RE elements play the main role in grain refinement of U75V-RE rail, which is the key reason for the excellent mechanical properties of U75V-RE rail.

Similar content being viewed by others

References

R.M. Wang, J.H. Zhou, M. Zhu et al., Analysis of reasons for sawing fracture of U75V rail. China Railw. Sci. 39(4), 50–55 (2018)

J. **nyu, L. Guoqing, L. **ubo, Y. Fei, Factors influencing fatigue crack initiation of rail for heavy haul railway. China Railw. Sci. 41(4), 40–47 (2020)

Y.H. Zhang, Q.Y. Zhou, Z.Y. Chen et al., Quality status and analysis of the rail for high-speed railway in China. Iron Steel. 46(12), 1–9 (2011)

X.S. **, X. Li, W. Li, Review of rail corrugation progress. J. Southwest Jiaotong Univ. 51(2), 264–273 (2016)

J.W. Ji, N. Yu, Z.Y. Sun et al., Effect of rare earth on the internal friction spectrum of the tread area of the BNb rail steel. Acta Metallrugica Sinica. 39(11), 1219–1222 (2003)

C.L. Li, Y.S. Wang, J.J. Chen et al., Effects of rare earth on structure and mechanical properties of clean BNbRE steel. J. Rare Earths. 23(4), 470–473 (2005)

X.R. Bao, L. Chen, Y.P. Guo, Mathematical model of dynamic recrystallization of U75V, RE-II heavy rails, in Kunming, 2011, International Conference on Advanced Engineering Materials and Technology, vol 287, pp. 352–356.

Y. Huang, G.G. Cheng, Y. **e, Modification mechanism of cerium on the inclusions in drill steel. Acta Metall. Sin. 54(9), 1253–1261 (2018)

N. Yu, Z.Y. Sun, J.W. Ji et al., Mechanisms of improving service properties of hot-rolled rail of pearlite steels with addition of rare earth. Chin. Rare Earths. 32(5), 49–55 (2011)

N. Yu, Z.Y. Sun, J.W. Ji et al., Mechanisms of improving service properties of hot-rolled rail of pearlite steels with addition of rare earth. Chin. Rare Earths. 32(6), 41–44 (2011)

L.M. Wang, Q. Lin, J.W. Ji et al., New study concerning development of application of rare earth metals in steels. J. Alloys Compd. 13(5), 384–386 (2006)

C.J. Liu, Y.H. Huang, M.F. Jiang, Effects of rare earths on structural transformation of heavy rail steel. Adv. Mater. Res. 194, 237–242 (2011)

X. Li, Q.B. Yang, X.Z. Fan, Influence of deformation parameters on dynamic recrystallization of 2195 Al–Li alloy. Acta Metallrugica Sinica. 6(55), 709–717 (2019)

B. Ma, Y. Peng, B. Jia et al., Static recrystallization kinetics model after hot deformation of low-alloy steel Q345B. J. Iron Steel Res. Int. 17(8), 61–66 (2010)

M. **, B. Lu, X.G. Liu et al., Static recrystallization behavior of 316LN austenitic stainless steel. J. Iron Steel Res. Int. 11(20), 67–72 (2013)

X. Liu, L.X. Li, F.Y. He, Simulation on dynamic recrystallization behavior of AZ31 magnesium alloy using cellular automaton method coupling Laasraoui–Jonas model. Trans. Nonferrous Met. Soc. China. 23(9), 2692–2699 (2013)

X.R. Bao, J.A. Wang, X.D. Wang, Effects of lanthanum on hot deformation behaviour of Mn–Cr–Mo bainitic rail steel. J. Rare Earths. 36(7), 772–780 (2018)

X.M. Chen, Y.C. Lin, D.X. Wen et al., Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation. Mater. Des. 57, 568–577 (2014)

T. Zhang, S.H. Lu, Y.X. Wu et al., Optimization of deformation parameters of dynamic recrystallization for 7055 aluminum alloy by cellular automaton. Trans. Nonferrous Met. Soc. China. 27(6), 1327–1337 (2017)

Y.X. Liu, Y.C. Lin, Y. Zhou, 2D cellular automaton simulation of hot deformation behavior in a Ni-based superalloy under varying thermal-mechanical conditions. Mater. Sci. Eng. A. 691, 88–99 (2017)

Y.X. Liu, Y.C. Lin, H.B. Li et al., Study of dynamic recrystallization in a Ni-based superalloy by experiments and cellular automaton model. Mater. Sci. Eng., A. 626, 432–440 (2015)

C. Zhang, L.W. Zhang, Q.H. Xu et al., The kinetics and cellular automaton modeling of dynamic recrystallization behavior of a medium carbon Cr−Ni−Mo alloyed steel in hot working process. Mater. Sci. Eng. A. 678, 33–43 (2016)

Z.Y. **, Z.S. Cui, Investigation on dynamic recrystallization using a modified cellular automation. Comput. Mater. Sci. 63, 249–255 (2012)

Acknowledgements

This work was supported by Natural Science Foundation of Inner Mongolia Autonomous Region of China (Grant Nos. 2019LH05016), and Research Program of Science and Technology at Universities of Inner Mongolia Autonomous Region of China (Grant Nos. NJZY20089), and Innovation fund of Inner Mongolia University of Science and Technology (Grant Nos. 2019QDL-B06 and 2019QDL-B07) and Inner Mongolia Science and Technology major special project Foundation (Grant Nos. ZDZX2018024). The authors gratefully acknowledge Science and Technology Innovation Guidance Project of Inner Mongolia Autonomous Region “Research and Application of Key Technology of the third Generation High Strength Heavy Load Wear Resistant Heat Treatment Rail”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cen, Y., Ji, C., Chen, L. et al. Microstructure Evolution of RE Rail Steel During Hot Deformation. Metallogr. Microstruct. Anal. 12, 545–556 (2023). https://doi.org/10.1007/s13632-023-00926-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-023-00926-6