Abstract

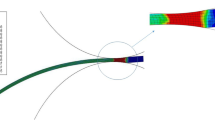

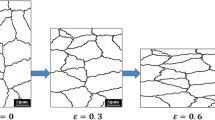

Static recrystallization and microstructural changes in austenitic stainless steel 304L were studied. The rolling experiments at 200 °C were carried out, and then, annealing treatment was made at temperatures ranging between 500 and 830 °C. A model was also developed to simulate the kinetics of non-isothermal recrystallization within the rolled steel. The distribution of plastic strains during rolling was predicted utilizing an elastic–plastic finite element formulation performed in ABAQUS/Explicit, while the predicted results were used to generate the as-rolled microstructure and to estimate the stored energy. Finally, microstructural–thermal model based on cellular automata was developed to evaluate the rate of static recrystallization within the rolled steel. The comparison between experimental and simulations showed a good consistency. The predictions illustrated that inhomogeneous distribution of plastic strain was produced during multi-pass rolling leading to different rates of recrystallization in the center and the surface regions of the rolled plate. The onset temperature of recrystallization was found about 700 °C, and the activation energies for nucleation and growth for recrystallization were determined as 180 kJ/mol and 240 kJ/mol, respectively. It was found that homogenous nucleation mechanism can be operative in recrystallization of multi-pass rolled steel, i.e., for reduction of 40% or higher.

Similar content being viewed by others

References

I. Shakhova, V. Dudko, A. Belyakov, K. Tsuzaki, R. Kaibyshev, Effect of large strain cold rolling and subsequent annealing on microstructure and mechanical properties of an austenitic stainless steel. Mater. Sci. Eng. A 545, 176–186 (2012)

N. Solomon, I. Solomon, Deformation induced martensite in AISI 316 stainless steel. Rev. Metal. Madrid 46, 121–128 (2010)

F. Stachowicz, T. Trzepiecinski, Warm forming of stainless steel sheet. Arch. Civ. Mech. Eng. 10, 85–94 (2010)

P. Pourabdollah, S. Serajzadeh, A study on deformation behavior of 304 l stainless steel during and after plate rolling at elevated temperatures. J. Mater. Eng. Perform. 26, 885–893 (2017)

M. Odnobokovaa, A. Belyakova, N. Enikeevb, D.A. Molodovc, R. Kaibyshev, Annealing behavior of a 304L stainless steel processed by large strain cold and warm rolling. Mater. Sci. Eng. A 689, 370–383 (2017)

Z. Yanushkevich, S.V. Dobatkin, A. Belyakov, R. Kaibyshev, Hall–Petch relationship for austenitic stainless steels processed by large strain warm rolling. Acta Mater. 136, 39–48 (2017)

C. Zheng, N. **ao, D. Li, Y. Li, Mesoscopic modeling of austenite static recrystallization in a low carbon steel using a coupled simulation method. Comput. Mater. Sci. 45, 568–575 (2009)

L. Madej, M. Sitko, A. Legwand, K. Perzynski, K. Michalik, Development and evaluation of data transfer protocols in the fully coupled random cellular automata finite element model of dynamic recrystallization. J. Comput. Sci. 26, 66–77 (2018)

Y.C. Lin, Y. Liu, M. Chen, M. Huang, X. Ma, Z. Long, Study of static recrystallization behavior in hot deformed Ni-based superalloy using cellular automaton model. Mater. Des. 99, 107–114 (2016)

Y. Liu, Y.C. Lin, H. Li, D. Wen, X. Chen, M. Chen, Study of dynamic recrystallization in a Ni-based superalloy by experiments and cellular automaton model. Mater. Sci. Eng. A 626, 432–440 (2015)

F. Han, T. Hongchao, K. **shan, L.Y. Feng, Cellular automata modeling of static recrystallization based on the curvature driven subgrain growth mechanism. J. Mater. Sci. 48, 7142–7152 (2013)

F. Chen, K. Qi, Z. Cui, X. Lai, Modeling the dynamic recrystallization in austenitic stainless steel using cellular automaton method. Comput. Mater. Sci. 83, 331–340 (2014)

Y. Zhi, X. Liu, H. Yu, Cellular automaton simulation of hot deformation of TRIP steel. Comput. Mater. Sci. 81, 104–112 (2014)

C. Zheng, N. **ao, D. Li, Y. Li, Microstructure prediction of the austenite recrystallization during multi-pass steel strip hot rolling: a cellular automaton modeling. Comput. Mater. Sci. 44, 507–514 (2008)

M. Seyed Salehi, S. Serajzadeh, Simulation of static recrystallization in non-isothermal annealing using a coupled cellular automata and finite element model. Comput. Mater. Sci. 53, 145–152 (2012)

R.J. Contieri, M. Zanotello, R. Caram, Simulation of CP-Ti recrystallization and grain growth by a cellular automata algorithm: simulated versus experimental results. Mater. Res. 20, 688–701 (2017)

S. Kobayashi, Metal Forming and the Finite Element Method (Oxford University Press, Oxford, 1989)

T. Belytschko, W.K. Liu, B. Moran, Nonlinear Finite Elements for Continua and Structures (Wiley, Hoboken, 2000)

M.M. Farag, Selection of Materials and Manufacturing Processes for Engineering Design (Prentice Hall, Upper Saddle River, 1989)

S.L. Semiatin, J.H. Holbrook, Plastic flow phenomenology of 304 l stainless steel. Metall. Trans. A 14A, 1681–1695 (1983)

R.-B. Mei, C.-S. Li, X.-H. Liu, H. Bin, Analysis of strip temperature in hot rolling process by finite element method. J. Iron. Steel Res. Int. 17, 17–21 (2010)

K.G.F. Janssens, D. Raabe, Computational Materials Science (Elsevier, London, 2007)

N. **ao, C. Zheng, D. Li, Y. Li, A simulation of dynamic recrystallization by coupling a cellular automaton method with a topology deformation technique. Comput. Mater. Sci. 41, 366–374 (2008)

H. Monshat, S. Serajzadeh, Simulation of austenite decomposition in continuous cooling conditions: a cellular automata-finite element modeling. Ironmak. Steelmak. 1, 1 (2019). https://doi.org/10.1080/03019233.2017.1405178

D.J. Srolovitz, G.S. Grest, M.P. Anderson, Computer simulation of recrystallization—II. Heterogeneous nucleation and growth. Acta Metall. 36(8), 2115–2128 (1988)

P.J. Hurley, F.J. Humphreys, Modeling the recrystallization of single-phase aluminum. Acta Mater. 51, 3779–3793 (2003)

X. Song, M. Rettenmayr, C. Müller, H.E. Exner, Modeling of recrystallization after inhomogeneous deformation. Metall. Mater. Trans. 32A, 2199–2206 (2001)

S.N.S. Mortazavi, S. Serajzadeh, Simulation of non-isothermal recrystallization kinetics in cold-rolled steel. Multiscale Multidiscip. Model. Exp. Des. 2, 23–33 (2019)

K. Kremeyer, Cellular automata investigations of binary solidification. J. Comput. Phys. 142, 243–262 (1998)

F.L. Stasa, Applied Finite Element Analysis for Engineers (CBS Publishing, Tokyo, 1985)

S. Shabaniverki, S. Serajzadeh, Simulation of softening kinetics and microstructural events in aluminum alloy subjected to single and multi-pass rolling operations. Appl. Math. Model. 40, 7571–7582 (2016)

J. Gopal, C. Pandey, M. Mohan, R.S. Mulik, An assessment for mechanical and microstructure behavior of dissimilar material welded joint between nuclear grade martensitic P91 and austenitic SS304 L steel. J. Manuf. Process. 48C, 249–259 (2019)

K. Nohara, O. Yutaka, N. Ohashi, Composition and grain size dependencies of strain-induced martensitic transformation in metastable austenitic stainless steels. Tetsu-to-Hagané 63, 772–782 (1977)

R.E. Schramm, R.P. Reed, Stacking fault energies of seven commercial austenitic stainless steels. Metall. Trans. A 6, 1345–1351 (1975)

J. Humphreys, M. Hartherly, Recrystallization and Related Annealing Phenomena (Pergamon Press, Oxford, 2004)

N. Hirota, F. Yin, T. Inoue, T. Azuma, Recrystallization and grain growth behavior in severe cold-rolling deformed SUS316L steel under anisothermal. ISIJ Int. 48(4), 475–482 (2008)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alavi, P., Serajzadeh, S. Microstructural Changes During Static Recrystallization of Austenitic Stainless Steel 304L: Cellular Automata Simulation. Metallogr. Microstruct. Anal. 9, 223–238 (2020). https://doi.org/10.1007/s13632-020-00623-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-020-00623-8