Abstract

The acceleration of cheese ripening is of major interest in the cheese industry because it is related to both product characteristics and production costs. In this study, different temperature-time combinations using elevated temperatures of 20 °C within the first month of maturation were applied during Reggianito cheese ripening. Data obtained from proteolysis, lipolysis, analysis of volatile compounds and sensory analysis were considered to establish optimal ripening conditions. Principal component analysis showed that the two first principal components explained 56.4% of data variability. Ripening at 20 °C during the first month followed by 12 °C resulted in 4-month-old cheeses with characteristics similar to Reggianito cheese traditionally ripened for 6 months at 12 °C.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cheese ripening acceleration is of major interest in the cheese industry, mainly due to the high costs associated with long storage periods. Shortened ripening times provide benefits, such as net savings in refrigeration, labour and inventory costs, as well as increased cheese production when storage facilities are limited (Azarnia et al. 2006). Achievements of this type are of special interest when low-moisture, slow-ripening hard cheese varieties are considered; accordingly, extensive work has been done in this area in the last decades (El Soda 1993; Fox et al. 2000). Increasing the temperature of ripening rooms is the cheapest and simplest of the proposed methods for acceleration of cheese ripening (Fox et al. 2000).

Two different approaches have been applied regarding how temperatures are elevated. One of them considers ripening temperatures being held elevated during the whole ripening period, whereas the other focuses on the use of different temperature-time combinations (i.e. the use of elevated storage temperatures during a limited period combined with low usual temperatures for the rest of the ripening period). Despite the economic benefits involved in the use of higher ripening temperatures, this technique has not been broadly used at commercial scale. Fear of microbial spoilage or unspecific increases in the reactions occurring during ripening, leading to unbalance or unpredictability in flavour formation, seem to be the principal reasons (Hannon et al. 2005).

The use of temperature-time combinations appears as a viable alternative for ripening acceleration that offers both a more controlled development of flavour and textural characteristics of cheese and a reduction in the risk of uncontrolled microbial growth, because the longest part of the ripening period occurs at the low traditional temperature and high temperatures are used only for a short period. In using temperature-time combinations for the purpose of both practicality (from the dairy industry point of view) (Aston et al. 1983; Fedrick et al. 1983) and effectiveness (Ferrazza et al. 2004; O’Mahony et al. 2006), it is convenient that elevated temperatures be applied at the beginning of the ripening period. Accordingly, a successful ripening acceleration has been achieved for Cheddar (Aston et al. 1983; Aston et al. 1985; Hannon et al. 2005; O’Mahony et al. 2006) and Zamorano (Ferrazza et al. 2004) cheeses.

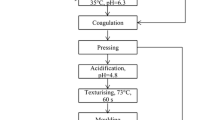

Reggianito is the major hard cheese variety produced in Argentina, in the central zone known as Pampa region. Its manufacture process is similar in many aspects to that of Parmigiano Reggiano and Grana Padano hard Italian cheeses, and its origins can be traced back to the arrival of Italian immigrants during the second half of the nineteenth century. Pasteurised bovine milk, natural whey as starter (mainly composed of thermophilic lactobacilli Lactobacillus helveticus and Lactobacillus delbrueckii subsp. lactis) and bovine chymosin are used, while a curd-cooking step up to 52 °C and brine salting are applied. Cheeses (6–7 kg blocks of cylindrical geometry) are usually ripened at 11–13 °C for 6 months (Sihufe et al. 2012). Ceruti et al. (2012, 2014) analysed the influence of initial elevated ripening temperatures on proteolysis and sensory characteristics of Reggianito cheese. In the present work, the effect of initial elevated ripening temperatures on lipolysis and volatile compounds of Reggianito cheese was investigated. Additionally, a multivariate analysis of the data corresponding to proteolysis, lipolysis, volatile compounds and sensory analysis was carried out to determine an optimal ripening time for the used conditions.

2 Materials and methods

Some of the data analysed in this study was obtained from our preceding publications on Reggianito cheese (Ceruti et al. 2012, 2014). For the sake of completeness, all the methods used to obtain the data are briefly summarised.

2.1 Cheese sampling and ripening conditions

Ripening conditions and sampling were presented by Ceruti et al. (2012). Briefly, 20 cheeses (7.8 ± 0.1 kg weight, 23.7 ± 0.2 cm diameter, 15.3 ± 0.2 cm height) were manufactured at a local factory, using pasteurised milk from the same cheese vat and following a standard cheese manufacture procedure. Cheeses were brought to our laboratory immediately after a 7-day brining. Two cheeses were used to determine their initial composition, and 18 cheeses were kept under three different temperature-time combinations for 6 months. Six cheeses were ripened at 12 °C and 85% relative humidity (cheeses C), whereas the other 12 cheeses were stored at two different temperature-time combinations (cheeses E1 and E2), also at 85% relative humidity (Table 1). Cheeses in duplicate were sampled at 61, 124 and 180 days of ripening.

2.2 Physicochemical and microbiological analysis

Samples of grated cheese were analysed for moisture and chloride contents (Zorrilla and Rubiolo 1994), pH (Ceruti et al. 2012), total nitrogen (TN) and water-soluble nitrogen at pH 4.6 (WSN) (Sihufe et al. 2003). Fat content was determined for initial composition (IDF 1969). Total counts in MRS agar media at 42 and 30 °C (Ceruti et al. 2014) were used to estimate thermophilic and mesophilic lactobacilli, respectively.

2.3 Proteolysis analysis

A maturation index (MI) was calculated as the percent ratio of WSN to TN to assess proteolysis during Reggianito cheese ripening. In addition, the following analyses were conducted: urea-polyacrylamide gel electrophoresis (urea-PAGE) analysis of the urea-soluble fraction, reversed phase HPLC (RP-HPLC) analysis of the water-soluble fraction at pH 4.6 (WSF) and RP-HPLC analysis of the 25 g.L−1 sulfosalicylic acid-soluble fraction (SSA-SF) for free amino acid (FAA) determination, as described by Ceruti et al. (2012).

2.4 Lipolysis analysis

Free fatty acids (FFA) were isolated from whole cheese fat by a column chromatographic separation step, using an alumina stationary phase and subsequent elution with solvents, according to Deeth et al. (1983). Odd-numbered-chain fatty acids C5:0, C13:0, C15:0 and C17:0 were used as internal standards. FFA from C4:0 to C18:1 were determined by GC analysis (1:80 split injection) using a Shimadzu CG-17A gas chromatograph equipped with a flame ionisation detector (Shimadzu Corporation, Kyoto, Japan) and with a Nukol column (Supelco, Inc., Bellefonte, PA, USA, 30 m × 0.25 mm ID × 0.25 μm film thickness). The carrier gas was N2 at 3 mL.min−1 flow rate, and the oven temperature programme was 100 °C (0 min), 16 °C.min−1, 210 °C (30 min).

2.5 Analysis of volatile compounds

Before chromatographic analysis, volatile compounds were both concentrated and isolated from a cheese matrix by a solid-phase microextraction (SPME) procedure. Five grammes of grated cheese were placed in a 30-mL vial and sealed with PTFE-silicone septa and an aluminium crimp seal. Then, a 1-cm long DVB/CAR/PDMS 50/30 μm SPME fibre (Supelco, Inc., Bellefonte, PA, USA) housed in its manual holder (Supelco, Inc., Bellefonte, PA, USA) was used to concentrate volatile compounds on the vial headspace. The vial was kept at 40 °C for 10 min and then the fibre was exposed to headspace during 30 min at 40 °C. Compounds loaded onto the fibre were then analysed with a gas chromatograph Hewlett-Packard HP 5890 series II (Hewlett-Packard, Palo Alto, CA, USA) equipped with a split/splitless injector and a flame ionization detector (FID) and using an Alltech EC-WAX column (Alltech, Deerfield, IL, USA, 30 m × 0.25 mm ID × 0.25 μm film thickness). Volatile compounds were desorbed from the fibre at the injection port of the chromatograph, splitless mode, during 5 min at 230 °C. The carrier gas was N2 at 1 mL.min−1 flow rate, oven temperature programme being 10 min at 40 °C, then 6 °C.min−1 to 150 °C, 10 °C.min−1 to 230 °C and 9 min at 230 °C. The injector temperature was 250 °C, and the detector temperature was 280 °C.

2.6 Sensory analysis

A sensory analysis of cheese samples was carried out according to quantitative descriptive analysis, performed by a panel of seven trained assessors. Panel members were used to working with Reggianito cheese samples and used previously developed lexicons (Candioti et al. 2002; Sihufe et al. 2010). The complete methodology is described in Ceruti et al. (2014).

2.7 Statistical analysis

ANOVA was performed considering ripening temperature and ripening time as main factors. When differences between treatment effects were significant (P < 0.05), the least significant differences (LSD) test was used for multiple comparison of means. Both statistical tests were performed using Statgraphics (Statgraphics Inc., Rockville, MD, USA). Principal component analysis (PCA) was performed taking into account information provided by the maturation index, proteolysis, lipolysis, volatile compounds and sensory analysis. PCA was applied to a correlation matrix, as the variables studied differed considerably in their measurement units (Coker et al. 2005), using Minitab (Minitab Inc., State college, PA, USA).

3 Results and discussion

3.1 Physicochemical and microbiological analysis

Values of physicochemical and microbiological parameters were thoroughly analysed by Ceruti et al. (2012, 2014). The main results are summarised for better understanding of the multivariate analysis. Only small changes occurred in pH values during ripening, final pH values being similar to those previously reported by other authors for the same type of cheese (Hynes et al. 2003; Sihufe et al. 2007; Wolf et al. 2010), and included in a range considered safe in relation to potential spoilage with unusual microorganisms.

Although the combined impact of temperature-time modified both salt and moisture distribution during the first months, the general trend in central zones of cheeses as an increase and decrease respectively was observed, as previously reported by Ceruti et al. (2012, 2014). This behaviour, explained by diffusion phenomena, is characteristic of cheeses salted by brine immersion and ripened without wrap** (Simal et al. 2001). Furthermore, moisture and chloride contents were similar for all cheeses at the end of the storage period, and levels observed (360 g.kg−1 cheese and 10 g.kg−1 cheese, respectively) were similar to previously reported values (Sihufe et al. 2007; Wolf et al. 2010).

Values of MI were significantly affected by temperature-time combination and ripening time (Ceruti et al. 2012). MI levels corresponding to cheeses stored at 12 °C were similar to those informed by other authors (Hynes et al. 2003; Sihufe et al. 2007; Wolf et al. 2010). A significant effect of time and temperature-time combination was also observed, with MI values increasing over ripening; values were significantly higher for experimental cheeses (E1 and E2) than for control cheeses ones all throughout ripening.

Initial (i.e. immediately after brining) microbial counts were 6.5 ± 2.0 × 106 colony-forming unit (CFU).g−1 cheese at 42 °C and 1.9 ± 0.4 × 107 CFU.g−1 cheese at 30 °C. From 61 days of ripening onwards, starter thermophilic counts (incubation at 42 °C on MRS agar) were nondetectable (<103 CFU.g−1 cheese) (Ceruti et al. 2014). Bacterial counts at 30 °C, aimed at estimating mesophilic nonstarter lactic acid bacteria (NSLAB) levels, were significantly affected by both ripening time and temperature-time combination; indeed, NSLAB cell number decreased over time for all treatments from 61 days onwards, and levels for experimental cheeses E1 and E2 were one log order below those corresponding to control cheeses during the last 2 months of ripening. Therefore, these results suggest that only controlled and limited changes occurred in mesophilic lactobacilli when initial storage temperature was increased during ripening.

3.2 Proteolysis

The study of proteolysis was focused on casein, peptide and amino acid analysis. Detailed description of these changes was given by Ceruti et al. (2012), and a brief, general description is included in this section.

Casein degradation was monitored by urea-PAGE analysis and five principal fractions, corresponding to αS1-, αS1-I, β- and γ-caseins and F3 fraction were identified. Principal casein fractions αS1- and β-casein were degraded during ripening, with this decrease being enhanced by elevated initial ripening temperatures applied to experimental cheeses. Degradation of αS1-casein originated αS1-I-casein and F3 fractions. The αS1-I-casein fraction levels increased during the first months of ripening, then decreasing due to further proteolytic degradation to shorter peptides; this phenomenon was more intense in experimental cheeses (especially E2).

Peptide formation was monitored by RP-HPLC, and 16 chromatographic peaks accounting for about 90% of chromatographic area were selected for statistical analysis. Most of the peak areas increased with ripening time, and the presence of significantly higher area values for experimental cheeses was observed. No changes were observed in the distribution of relative peak areas in the chromatogram, suggesting that changes assayed under ripening conditions affected the overall rate rather than the pathways of proteolysis.

Concentrations of 14 FAA (Asp, Glu, Asn, Gln, Gly, Ala, Tyr, Trp, Met, Val, Phe, Ile, Leu, Lys) were determined by RP-HPLC analysis of the SSA-SF. The amino acids Glu, Lys, Leu, Val and Ile were present at high concentrations, representing about 60% of total concentration in all samples. Ripening time and temperature-time concentration significantly affected the concentrations of the studied amino acids, except for Gln and Lys, which were not affected by temperature-time combination. Total FAA content for experimental cheeses at 2 and 4 months of ripening were similar to those corresponding to control cheeses at 4 and 6 months of ripening, respectively. Despite significantly affecting the concentration of most of the amino acids quantified, ripening conditions did not produce considerable differences in FAA profiles between control and experimental cheeses.

3.3 Lipolysis

The most abundant FFA in all samples analysed were C16:0, C18:1, C18:0 and C14:0 (Table 2); this predominance was consistent with triglyceride profile of bovine milk fat (Taylor and MacGibbon 2011) and previous findings in Reggianito cheese (Perotti et al. 2005; Sihufe et al. 2007). No significant effects of the ripening time and temperature-time combination were observed, with the exception of butyric acid (C4:0), which showed a late, increasing-with-time tendency. Similar FFA profiles were found for all cheeses at 180 days of ripening, regardless of the temperature-time combination. Individual relative contribution of FFA remained almost constant, and similar distribution patterns were observed for all determined FFA. Towards the end of the ripening period, a level of total FFA of 1100 mg.kg−1 cheese was observed, indicating a moderate degree of lipolysis (Collins et al. 2003). Previous studies on Reggianito cheese also reported moderate final levels of lipolysis (Perotti et al. 2005; Sihufe et al. 2007; Wolf et al. 2010). Therefore, the applied temperature-time combinations did not cause modifications in both levels and profile of lipolysis.

3.4 Volatile compounds

Based on the SPME-GC-FID technique, 62 peaks were detected on chromatograms, eluting during the first 32 min of chromatographic run. Of this total, 46 peaks present in all cheese samples from 61 days of ripening onwards, and accounting for more than 90% of total area, were selected for further analysis (Fig. 1). Half of these peak areas were not significantly affected by either temperature-time combination or ripening time factors. Of the other 23 peaks, 14 were significantly affected by temperature-time combination, 2 by ripening time only and the remaining 7 peaks were significantly affected by both factors. For the peaks with areas changing with time, two different behaviours were observed. Some of them increased with ripening time, whereas others showed the opposite behaviour. Regarding temperature-time combination, 14 peaks showed greater areas in control than in experimental cheeses, whereas 7 peaks showed the opposite tendency, and peaks corresponding to experimental cheeses had greater area values than that for control cheeses.

In the case of the areas of 7 peaks for which both factors were significant, a similar behaviour with ripening time (i.e. increasing or decreasing trends in the peak areas) was observed for control and experimental cheeses. These results agree with our previous findings for proteolysis, especially the production of FAA (Ceruti et al. 2012), and suggest that the increase of ripening temperature did not alter the chemical pathways for formation and disappearance of volatile compounds during ripening in Reggianito cheese, but it affected their concentrations.

From 61 days of ripening onwards, no appearance or disappearance of chromatographic peaks was observed. Moreover, taking into account that total area at the beginning of the ripening period (day 0) was considerably lower than that of the total area from 61 day of ripening onwards and that several compounds were not present at the beginning of ripening, it can be affirmed that most of changes that define the characteristic volatile profile of Reggianito cheese occur during the first 2 months.

From 2 months of ripening onwards, no significant differences were observed in total area values (total concentration of volatile compounds) for the different cheese samples with respect to ripening time or temperature-time combination. There were no differences between the different chromatograms obtained, indicating that the application of elevated initial ripening temperatures did not alter the characteristic volatile profile of Reggianito cheese.

3.5 Sensory analysis

For quantitative descriptive analysis, 10 sensory attributes including appearance, texture and flavour characteristics were evaluated, namely aroma, colour, visual texture, granular cut, fracturability, oral texture, genuine flavour, residual flavour, salty and bitter taste (Ceruti et al. 2014). Attribute scores for cheeses ripened for 6 months at 12 °C were similar to those obtained for cheeses under similar ripening conditions in previous studies (Candioti et al. 2002; Sihufe et al. 2010). Analysis of data for cheeses ripened at 12 °C showed that genuine flavour and salty taste were the attributes with the greatest changes from 61 to 180 days of ripening, therefore differentiating an immature 61-day cheese from a mature full-ripened one. For experimental cheeses, scores corresponding to 61 and 124 days of ripening were similar to those corresponding to mature control cheeses, and only aroma and bitter taste attributes showed significant, though limited, changes with temperature-time combination factor (Ceruti et al. 2014). Hence, the use of elevated initial ripening temperatures resulted in a mild acceleration in the development of sensory characteristics of Reggianito cheese.

3.6 Principal component analysis

Principal component analysis was performed taking into account information from the 101 variables, i.e. MI, 5 fractions from the casein analysis by urea-PAGE, 16 peak areas from RP-HPLC analysis of pH 4.6-WSF, concentration values corresponding to 14 amino acids determined by RP-HPLC analysis of SSA-SF, concentrations of 9 FAA determined by GC-FID, 46 peak areas corresponding to the analysis of volatile compounds by SPME-GC-FID and scores assigned by a panel to the 10 studied sensory attributes. Two factors at three levels each, ripening time (i.e. 61, 124 and 180 days) and temperature-time combination (i.e. cheeses C, E1 and E2), were considered for the analysis. As a result, the data set consisted of a matrix of 18 cheese samples and 101 parameters measured on those samples.

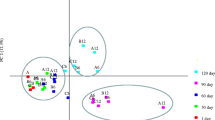

The biplot is shown considering separately the information of the main areas studied for a clear presentation of the PCA results (Fig. 2). Figure 2a–c shows the plot of both PCA scores and loadings (biplot) for the first two principal components, which together accounted for 56.4% of total observed variability. The first component (PC1, 38.6% variance (VAR)) was clearly related to ripening time, since information corresponding to samples (scores) were right-to-left spread with increasing ripening time along the PC1-axis, and the second component (PC2, 17.8% VAR) extended scores along the y-axis by the effect of cheese ripening conditions.

Biplot of scores and loadings of data obtained from proteolysis, lipolysis, volatile fraction and sensory analysis of Reggianito cheese samples. Selected variables shown separately: a sensory analysis data, b proteolysis data and c lipolysis and volatile fraction data. Numbers close to symbols indicate days of ripening. p1 to p16 peak areas from RP-HPLC analysis of pH 4.6-WSF, v1 to v46 peak areas from the analysis of volatile compounds by SPME-GC-FID

Focusing on sensory characteristics (Fig. 2a), it can be observed that sensory attributes related to texture (fracturability, granular cut, oral and visual texture) were strongly connected to the scores corresponding to young, early-ripened cheeses, which were both placed on the left side of the biplot. This behaviour suggests that during the early ripening period, cheeses undergo mainly textural changes. Similarly, loadings for sensory attributes describing flavour characteristics (genuine flavour, aroma, salty and bitter taste) were clearly related to samples at late ripening times.

Attributes related to cheese texture (fracturability, granular cut, oral and visual texture) are clearly in connection with the degradation of major casein fractions evaluated by urea-PAGE (αS1-, αS1-I and β-casein) occurring at early stages of ripening (Fig. 2a, b). This observation agrees with the fundamental role generally attributed to the degradation of caseins in cheese texture development (Lucey et al. 2003). The tendency to increase with ripening observed for F3 and γ-casein fractions, most of WSF peaks and FAA can be related to the location of loadings corresponding to those parameters on the right side of the biplot. Additionally, there is an association between parameters related to secondary proteolysis and the evolution of the genuine flavour attribute. An association between bitter taste and the hydrophobic part of RP-HPLC chromatograms of pH 4.6-WSF was detected. Hydrophobic peptides are associated with bitter taste development in cheeses (McSweeney and Sousa 2000).

The negligible or nil effect of ripening time and temperature-time combination factors on FFA (Fig. 2c) was reflected in the low values observed for most loadings, with the exception of that corresponding to C4:0 which increased moderately during ripening, in agreement with the positive value found for its PC1 loading. Regarding volatile compounds (Fig. 2c), a distribution of loadings in all directions was observed, which can be attributed to the different evolutions of the peaks evaluated. Those peaks with the highest statistical weight of the factor temperature-time combination had PC1 values close to 0. Those peaks with greater areas in experimental cheeses than in control cheeses had positive PC2 values, whereas those with greater areas in control cheeses had negative PC2 values. Peaks placed on the left (negative PC1 values) side of the graphic decreased with ripening time and represented compounds characterising cheeses at early ripening time.

Finally, the score distribution along PC1-axis showed interesting sample grou**s (Fig. 2), since cheeses E2 at 61 days were grouped with control cheeses at 124 days of ripening. Experimental cheeses (mainly E2) ripened for 124 days were grouped with control cheeses at 180 days of ripening. Considering control cheeses ripened for 6 months as the full-ripened cheeses, it can be assumed that ripening acceleration strategies using increase of the ripening temperature during initial storage periods allowed a reduction of about 2 months in the total ripening period of cheeses. In addition, the ripening conditions of cheeses E2 were the most effective one.

4 Conclusions

In this work, different temperature-time combinations were assayed to accelerate Reggianito cheese ripening using elevated initial ripening temperatures. Information from proteolysis, lipolysis, analysis of volatile compounds and sensory characteristics was thoroughly analysed together to establish optimal ripening conditions for accelerated-ripening cheeses. It can be concluded that an increase of the initial ripening temperature to 20 °C during the first 4 weeks followed by 12 °C allows obtaining after 4-month cheeses with characteristics similar to the Reggianito cheese ripened for 6 months at a conventional temperature (12 °C).

References

Aston JW, Fedrick IA, Durward IG, Dulley JR (1983) The effect of elevated ripening temperatures on proteolysis and flavour development in Cheddar cheese I: higher initial storage temperatures. N Z J Dairy Sci 18:143–151

Aston JW, Giles JE, Durward IG, Dulley JR (1985) Effect of elevated ripening temperatures on proteolysis and flavour development in Cheddar cheese. J Dairy Res 52:565–572

Azarnia S, Robert N, Lee B (2006) Biotechnological methods to accelerate Cheddar cheese ripening. Crit Rev Biotechnol 26:121–143

Candioti MC, Hynes E, Quiberoni A, Palma SB, Sabbag N, Zalazar CA (2002) Reggianito Argentino cheese: influence of Lactobacillus helveticus strains isolated from natural whey cultures on cheese making and ripening processes. Int Dairy J 12:923–931

Ceruti RJ, Zorrilla SE, Sihufe GA (2012) The influence of elevated initial ripening temperature on the proteolysis in Reggianito cheese. Food Res Int 48:34–40

Ceruti RJ, Zorrilla SE, Sabbag NG, Costa SC, Sihufe GA (2014) Effect of elevated initial ripening temperature on the sensory characteristics of Reggianito cheese. Int J Dairy Technol 67:539–546

Coker CJ, Crawford RA, Johnston KA, Singh H, Creamer LK (2005) Towards the classification of cheese variety and maturity on the basis of statistical analysis of proteolysis data—a review. Int Dairy J 15:631–643

Collins YF, McSweeney PLH, Wilkinson MG (2003) Lipolysis and free fatty acid catabolism in cheese: a review of current knowledge. Int Dairy J 13:841–866

Deeth HC, Fitzgerald CH, Snow AJ (1983) A gas chromatographic method for the quantitative determination of free fatty acids in milk and milk products. N Z J Dairy Sci 18:13–20

El Soda M (1993) Accelerated maturation of cheese. Int Dairy J 3:531–544

Fedrick IA, Aston JW, Durward IF, Dulley JR (1983) The effect of elevated ripening temperatures on proteolysis and flavour development in Cheddar cheese II: high temperature storage midway through ripening. N Z J Dairy Sci 18:253–260

Ferrazza RE, Fresno JM, Ribeiro JI, Tornadijo ME, Mansur Furtado M (2004) Changes in the microbial flora of Zamorano cheese (P.D.O.) by accelerated ripening process. Food Res Int 37:149–155

Fox PF, Guinee TP, Cogan TM, McSweeney PLH (2000) Acceleration of cheese ripening. In: Fundamentals of cheese science. Aspen publishers, Gaithersburg, pp 349–362

Hannon JA, Wilkinson MG, Delahunty CM, Wallace JM, Morrisey PA, Beresford TP (2005) Application of descriptive sensory analysis and key chemical indices to assess the impact of elevated ripening temperatures on the acceleration of Cheddar cheese ripening. Int Dairy J 15:263–273

Hynes ER, Bergamini CV, Suárez VB, Zalazar CA (2003) Proteolysis on Reggianito Argentino cheeses manufactured with natural whey cultures and selected strains of Lactobacillus helveticus. J Dairy Sci 86:3831–3840

IDF (1969) Determination of the fat content of cheese and of processed cheese products. (IDF Standard 5A) International Dairy Federation, Brussels

Lucey JA, Johnson ME, Horne DS (2003) Invited review: perspectives on the basis of the rheology and texture properties of cheese. J Food Sci 86:2725–2743

McSweeney PLH, Sousa MJ (2000) Biochemical pathways for the production of flavour compounds in cheeses during ripening: a review. Lait 80:293–324

O’Mahony JA, Sheehan EM, Delahunty CM, McSweeney PLH (2006) Lipolysis and sensory characteristics of Cheddar cheeses ripened using different temperature-time treatments. Lait 86:59–72

Perotti MC, Bernal SM, Meinardi CA, Zalazar CA (2005) Free fatty acid profiles of Reggianito Argentino cheese produced with different starters. Int Dairy J 15:1150–1155

Sihufe GA, Zorrilla SE, Rubiolo AC (2003) Casein degradation of Fynbo cheese salted with NaCl/KCl brine and ripened at various temperatures. J Food Sci 68:117–123

Sihufe GA, Zorrilla SE, Mercanti DJ, Perotti MC, Zalazar CA, Rubiolo AC (2007) The influence of ripening temperature and sampling site on the lipolysis in Reggianito Argentino cheese. Food Res Int 40:1220–1226

Sihufe GA, Zorrilla SE, Sabbag NG, Costa SC, Rubiolo AC (2010) The influence of ripening temperatures on the sensory characteristics of Reggianito Argentino cheese. J Sens Stud 25:94–107

Sihufe GA, Rubiolo AC, Zorrilla SE (2012) Reggianito cheese: hard cheese produced in Argentina. In: Hui YH (ed) Handbook of animal-based fermented food and beverage technology, 2nd edn. CRC press, Boca Raton, pp 377–386

Simal S, Sánchez ES, Bon J, Femenia A, Rosselló C (2001) Water and salt diffusion during cheese ripening: effect of the external and internal resistances to mass transfer. J Food Eng 48:269–275

Taylor MW, MacGibbon AKH (2011) Milk lipids: fatty acids. In: Fuquay JW, Fox PF, McSweeney PLH (eds) Encyclopedia of dairy sciences, vol 3, 2nd edn. Academic, London, pp 655–659

Wolf IV, Perotti MC, Bernal SM, Zalazar CA (2010) Study of the chemical composition, proteolysis, lipolysis and volatile compounds profile of commercial Reggianito Argentino cheese: characterization of Reggianito Argentino cheese. Food Res Int 43:1204–1211

Zorrilla SE, Rubiolo AC (1994) Fynbo cheese NaCl and KCl changes during ripening. J Food Sci 59:972–975 & 985

Acknowledgments

This research was partially supported by the Universidad Nacional del Litoral (Santa Fe, Argentina), Consejo Nacional de Investigaciones Científicas y Técnicas (Argentina) and Agencia Nacional de Promoción Científica y Tecnológica (Argentina). We thank Milkaut S.A. for the supply of cheeses.

Conflict of interest

Roberto J. Ceruti, Susana E. Zorrilla, Nora G. Sabbag, Silvia C. Costa and Guillermo A. Sihufe declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects performed by any of the authors.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Ceruti, R.J., Zorrilla, S.E., Sabbag, N.G. et al. Acceleration of Reggianito cheese ripening. Effect of increased initial ripening temperatures on biochemical and sensory characteristics. Dairy Sci. & Technol. 95, 231–243 (2015). https://doi.org/10.1007/s13594-014-0205-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13594-014-0205-2