Abstract

Nanocellulose emerges as a highly promising material with versatile applications, offering solutions to environmental and sustainability challenges. This study delves into the extraction of cellulose nanofibers (CNFs) from Wodyetia bifurcata fruit pulp through mild oxalic acid hydrolysis assisted by steam explosion. To ensure environmental compatibility, chlorine-free pre-treatments were applied to eliminate non-cellulosic components. Chemical composition analysis verified the effective removal of non-cellulosic elements, validated by Fourier transform infrared spectroscopy (FTIR). Solid-state 13C nuclear magnetic resonance (13C NMR) spectroscopy confirmed the presence of type I cellulose α-polymorph in the CNF, while a crystallinity index of 60% was determined by X-ray diffraction analysis (XRD). The transmission electron microscopy (TEM) images revealed a fibrous morphology with a fiber diameter ranging from 9 to 36 nm. Dynamic light scattering (DLS) was employed to corroborate the observed fiber diameter. Mild acid hydrolysis elevated the maximum degradation temperature (Tmax) of CNF to 39 °C compared to the pristine sample. Furthermore, this research explores the application of CNFs in nanopaper development using a casting method. The resulting nanopapers exhibited a tensile strength of ~ 17 MPa and a transmittance of 25%. These nanopapers present a viable pathway toward eco-friendly products in various industries, promising to revolutionize upcoming sustainable packaging technologies.

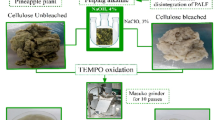

Graphical Abstract

Similar content being viewed by others

Data availability

All of the data sets that were included and/or examined in the present study can be obtained from the corresponding author upon request.

References

Ewnetu Sahlie M, Zeleke TS, Aklog Yihun F (2022) Water hyacinth: a sustainable cellulose source for cellulose nanofiber production and application as recycled paper reinforcement. J Polym Res 29:230. https://doi.org/10.1007/s10965-022-03089-0

Ra**ipriya M, Nagalakshmaiah M, Robert M, Elkoun S (2018) Importance of agricultural and industrial waste in the field of nanocellulose and recent industrial developments of wood based nanocellulose: a review. ACS Sustain Chem Eng 6:2807–2828. https://doi.org/10.1021/acssuschemeng.7b03437

Ilyas RA, Sapuan SM, Ibrahim R et al (2020) Production, processes and modification of nanocrystalline cellulose from agro-waste: a review. Nanocrystalline Materials. IntechOpen. https://doi.org/10.5772/intechopen.87001

Palm F, Perez K, Kobayashi K et al (2009) Foxtail palm, pp 8–11. https://api.semanticscholar.org/CorpusID:130246365

**e H, Du H, Yang X, Si C (2018) Recent strategies in preparation of cellulose nanocrystals and cellulose nanofibrils derived from raw cellulose materials. Int J Polym Sci 2018:. https://doi.org/10.1155/2018/7923068

Pakutsah K, Aht-Ong D (2020) Facile isolation of cellulose nanofibers from water hyacinth using water-based mechanical defibrillation: insights into morphological, physical, and rheological properties. Int J Biol Macromol 145:64–76. https://doi.org/10.1016/j.ijbiomac.2019.12.172

Oliva C, Huang W, El Badri S et al (2020) Concentrated sulfuric acid aqueous solution enables rapid recycling of cellulose from waste paper into antimicrobial packaging. Carbohydr Polym 241:116256. https://doi.org/10.1016/j.carbpol.2020.116256

Almashhadani AQ, Leh CP, Chan SY et al (2022) Nanocrystalline cellulose isolation via acid hydrolysis from non-woody biomass: importance of hydrolysis parameters. Carbohydr Polym 286:119285. https://doi.org/10.1016/j.carbpol.2022.119285

Perumal AB, Nambiar RB, Sellamuthu PS et al (2022) Extraction of cellulose nanocrystals from areca waste and its application in eco-friendly biocomposite film. Chemosphere 287:132084. https://doi.org/10.1016/j.chemosphere.2021.132084

Velázquez ME, Ferreiro OB, Menezes DB, et al. (2022) Nanocellulose extracted from Paraguayan residual agro-industrial biomass: extraction process, physicochemical and morphological characterization. Sustain 14:. https://doi.org/10.3390/su141811386

Ravindran L, Sreekala MS, Thomas S (2019) Novel processing parameters for the extraction of cellulose nanofibres (CNF) from environmentally benign pineapple leaf fibres (PALF): structure-property relationships. Int J Biol Macromol 131:858–870. https://doi.org/10.1016/j.ijbiomac.2019.03.134

Thomas MG, Abraham E, Jyotishkumar P et al (2015) Nanocelluloses from jute fibers and their nanocomposites with natural rubber: preparation and characterization. Int J Biol Macromol 81:768–777. https://doi.org/10.1016/j.ijbiomac.2015.08.053

Neenu KV, Midhun Dominic CD, Begum PMS et al (2022) Effect of oxalic acid and sulphuric acid hydrolysis on the preparation and properties of pineapple pomace derived cellulose nanofibers and nanopapers. Int J Biol Macromol 209:1745–1759. https://doi.org/10.1016/j.ijbiomac.2022.04.138

Midhun Dominic CD, Raj V, Neenu KV et al (2022) Chlorine-free extraction and structural characterization of cellulose nanofibers from waste husk of millet (Pennisetum glaucum). Int J Biol Macromol 206:92–104. https://doi.org/10.1016/j.ijbiomac.2022.02.078

Midhun Dominic CD, Maheswary S, Neenu KV et al (2022) Colocasia esculenta stems for the isolation of cellulose nanofibers: a chlorine-free method for the biomass conversion. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-022-03171-z

Faradilla RHF, Lee G, Arns J et al (2017) Characteristics of a free-standing film from banana pseudostem nanocellulose generated from TEMPO-mediated oxidation. Carbohydr Polym 174:1156–1163. https://doi.org/10.1016/j.carbpol.2017.07.025

Ra**ipriya M, Nagalakshmaiah M, Robert M, Elkoun S (2018) Homogenous and transparent nanocellulosic films from carrot. Ind Crops Prod 118:53–64. https://doi.org/10.1016/j.indcrop.2018.02.076

Lay M, Méndez JA, Delgado-Aguilar M et al (2016) Strong and electrically conductive nanopaper from cellulose nanofibers and polypyrrole. Carbohydr Polym 152:361–369. https://doi.org/10.1016/j.carbpol.2016.06.102

Chávez-Guerrero L, Toxqui-Terán A, Pérez-Camacho O (2022) One-pot isolation of nanocellulose using pelagic Sargassum spp. from the Caribbean coastline. J Appl Phycol 34:637–645. https://doi.org/10.1007/s10811-021-02643-5

Juárez-Luna GN, Favela-Torres E, Quevedo IR, Batina N (2019) Enzymatically assisted isolation of high-quality cellulose nanoparticles from water hyacinth stems. Carbohydr Polym 220:110–117. https://doi.org/10.1016/j.carbpol.2019.05.058

Ilyas RA, Sapuan SM, Atikah MSN et al (2021) Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb.) Merr). Text Res J 91:152–167. https://doi.org/10.1177/0040517520932393

Nagarajan KJ, Balaji AN, Ramanujam NR (2019) Extraction of cellulose nanofibers from Cocos nucifera var aurantiaca peduncle by ball milling combined with chemical treatment. Carbohydr Polym 212:312–322. https://doi.org/10.1016/j.carbpol.2019.02.063

Debiagi F, Faria-Tischer PCS, Mali S (2020) Nanofibrillated cellulose obtained from soybean hull using simple and eco-friendly processes based on reactive extrusion. Cellulose 27:1975–1988. https://doi.org/10.1007/s10570-019-02893-0

Syafri E, Jamaluddin SNH et al (2022) Isolation and characterization of cellulose nanofibers from Agave gigantea by chemical-mechanical treatment. Int J Biol Macromol 200:25–33. https://doi.org/10.1016/j.ijbiomac.2021.12.111

Yuan JC, Huang R, Jiang LY et al (2023) Facile production of cellulose nanofibers from raw elephant grass by an aluminum chloride-enhanced acidic deep eutectic solvent. Int J Biol Macromol 246:125687. https://doi.org/10.1016/j.ijbiomac.2023.125687

Mantovan J, Giraldo GAG, Marim BM et al (2020) Valorization of orange bagasse through one-step physical and chemical combined processes to obtain a cellulose-rich material. J Sci Food Agric. https://doi.org/10.1002/jsfa.10859

Shen P, Tang Q, Chen X, Li Z (2022) Nanocrystalline cellulose extracted from bast fibers : preparation, characterization, and application. Carbohydr Polym 290:119462. https://doi.org/10.1016/j.carbpol.2022.119462

Kalita E, Nath BK, Deb P et al (2015) High quality fluorescent cellulose nanofibers from endemic rice husk: isolation and characterization. Carbohydr Polym 122:308–313. https://doi.org/10.1016/j.carbpol.2014.12.075

Chirayil CJ, Joy J, Mathew L et al (2014) Isolation and characterization of cellulose nanofibrils from Helicteres isora plant. Ind Crops Prod 59:27–34. https://doi.org/10.1016/j.indcrop.2014.04.020

Lima AR, Cristofoli NL, Rosa da Costa AM et al (2023) Comparative study of the production of cellulose nanofibers from agro-industrial waste streams of Salicornia ramosissima by acid and enzymatic treatment. Food Bioprod Process 137:214–225. https://doi.org/10.1016/j.fbp.2022.11.012

Zaki FA, Abdullah I, Ahmad I (2014) The physical and chemical natures of cellulose extracted from torch ginger stems. Int J Mater Eng Innov 5:48–60. https://doi.org/10.1504/IJMATEI.2014.059484

Wang J, Xu J, Zhu S et al (2021) Preparation of nanocellulose in high yield via chemi-mechanical synergy. Carbohydr Polym 251:117094. https://doi.org/10.1016/j.carbpol.2020.117094

Julie Chandra CS, George N, Narayanankutty SK (2016) Isolation and characterization of cellulose nanofibrils from arecanut husk fibre. Carbohydr Polym 142:158–166. https://doi.org/10.1016/j.carbpol.2016.01.015

Fu T-K, Li J-H, Wei X-Y, et al (2016) Preparation and characterization of pineapple leaf nanocellulose by high pressure homogenization. In: Proceedings of the 2nd annual international conference on advanced material engineering (AME 2016). Atlantis Press, Paris, France, pp 713–720. https://doi.org/10.2991/ame-16.2016.119

Chen YW, Hasanulbasori MA, Chiat PF, Lee HV (2019) Pyrus pyrifolia fruit peel as sustainable source for spherical and porous network based nanocellulose synthesis via one-pot hydrolysis system. Int J Biol Macromol 123:1305–1319. https://doi.org/10.1016/j.ijbiomac.2018.10.013

Szymańska-Chargot M, Chylińska M, Pieczywek PM, Zdunek A (2019) Tailored nanocellulose structure depending on the origin. Example of apple parenchyma and carrot root celluloses. Carbohydr Polym 210:186–195. https://doi.org/10.1016/j.carbpol.2019.01.070

Nasution H, Yahya EB, Abdul Khalil HPS et al (2022) Extraction and isolation of cellulose nanofibers from carpet wastes using supercritical carbon dioxide approach. Polymers (Basel) 14:1–14. https://doi.org/10.3390/polym14020326

Bano S, Negi YS (2017) Studies on cellulose nanocrystals isolated from groundnut shells. Carbohydr Polym 157:1041–1049. https://doi.org/10.1016/j.carbpol.2016.10.069

Raza M, Abu-Jdayil B, Banat F, Al-Marzouqi AH (2022) Isolation and characterization of cellulose nanocrystals from date palm waste. ACS Omega 7:25366–25379. https://doi.org/10.1021/acsomega.2c02333

Mariño MA, Rezende CA, Tasic L (2018) A multistep mild process for preparation of nanocellulose from orange bagasse. Cellulose 25:5739–5750. https://doi.org/10.1007/s10570-018-1977-y

Chen Q, **ong J, Chen G, Tan T (2020) Preparation and characterization of highly transparent hydrophobic nanocellulose film using corn husks as main material. Int J Biol Macromol 158:781–789. https://doi.org/10.1016/j.ijbiomac.2020.04.250

Love R, Whiteside WS, Doh H, et al. (2022) Physicochemical characterizations of nanocellulose isolated from kudzu (Pueraria montana var. lobata) for potential packaging applications. SSRN Electron J 1–27. https://doi.org/10.2139/ssrn.4076935

Pereira PHF, Ornaghi Júnior HL, Coutinho LV et al (2020) Obtaining cellulose nanocrystals from pineapple crown fibers by free-chlorite hydrolysis with sulfuric acid: physical, chemical and structural characterization. Cellulose 27:5745–5756. https://doi.org/10.1007/s10570-020-03179-6

Sai Prasanna N, Mitra J (2020) Isolation and characterization of cellulose nanocrystals from Cucumis sativus peels. Carbohydr Polym 247:116706. https://doi.org/10.1016/j.carbpol.2020.116706

Al-Dulaimi AA, Wanrosli WD (2017) Isolation and characterization of nanocrystalline cellulose from totally chlorine free oil palm empty fruit bunch pulp. J Polym Environ 25:192–202. https://doi.org/10.1007/s10924-016-0798-z

Kéri M, Palcsu L, Túri M et al (2015) 13C NMR analysis of cellulose samples from different preparation methods. Cellulose 22:2211–2220. https://doi.org/10.1007/s10570-015-0642-y

Trilokesh C, Uppuluri KB (2019) Isolation and characterization of cellulose nanocrystals from jackfruit peel. Sci Rep 9:1–9. https://doi.org/10.1038/s41598-019-53412-x

Foster EJ, Moon RJ, Agarwal UP et al (2018) Current characterization methods for cellulose nanomaterials. Chem Soc Rev 47:2609–2679. https://doi.org/10.1039/C6CS00895J

Wang Y, Wei X, Li J et al (2015) Study on nanocellulose by high pressure homogenization in homogeneous isolation. Fibers Polym 16:572–578. https://doi.org/10.1007/s12221-015-0572-1

Duan L, Yu W, Li Z (2017) Analysis of structural changes in jute fibers after peracetic acid treatment. J Eng Fiber Fabr 12:155892501701200. https://doi.org/10.1177/155892501701200104

Reddy KO, Maheswari CU, Dhlamini MS et al (2018) Extraction and characterization of cellulose single fibers from native African Napier grass. Carbohydr Polym 188:85–91. https://doi.org/10.1016/j.carbpol.2018.01.110

Hassan SH, Velayutham TS, Chen YW, Lee HV (2021) TEMPO-oxidized nanocellulose films derived from coconut residues: physicochemical, mechanical and electrical properties. Int J Biol Macromol 180:392–402. https://doi.org/10.1016/j.ijbiomac.2021.03.066

Orasugh JT, Saha NR, Sarkar G et al (2018) A facile comparative approach towards utilization of waste cotton lint for the synthesis of nano-crystalline cellulose crystals along with acid recovery. Int J Biol Macromol 109:1246–1252. https://doi.org/10.1016/j.ijbiomac.2017.11.123

Gupta V, Ramakanth D, Verma C et al (2021) Isolation and characterization of cellulose nanocrystals from amla (Phyllanthus emblica) pomace. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-01852-9

An VN, Thuc H, Nhan C et al (2020) Extraction of high crystalline nanocellulose from biorenewable sources of Vietnamese agricultural wastes. J Polym Environ 28:1465–1474. https://doi.org/10.1007/s10924-020-01695-x

Mandal A, Chakrabarty D (2011) Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydr Polym 86:1291–1299. https://doi.org/10.1016/j.carbpol.2011.06.030

Karina M, Satoto R, Dawam Abdullah AH, Yudianti R (2020) Properties of nanocellulose: obtained from sugar palm (Arenga pinnata) fiber by acid hydrolysis in combination with high-pressure homogenization. Cellul Chem Technol 54:33–38. https://doi.org/10.35812/CelluloseChemTechnol.2020.54.04

Chen Y, Wu Q, Huang B et al (2014) Isolation and characteristics of cellulose and nanocellulose from lotus leaf stalk agro-wastes. BioResources 10:684–696. https://doi.org/10.15376/biores.10.1.684-696

Souza AG, Santos DF, Ferreira RR et al (2020) Innovative process for obtaining modified nanocellulose from soybean straw. Int J Biol Macromol 165:1803–1812. https://doi.org/10.1016/j.ijbiomac.2020.10.036

Gond RK, Gupta MK, Jawaid M (2021) Extraction of nanocellulose from sugarcane bagasse and its characterization for potential applications. Polym Compos 42:5400–5412. https://doi.org/10.1002/pc.26232

Shrestha P, Bilal M, Kumar A (2021) Development of antibacterial biocomposites reinforced with cellulose nanocrystals derived from banana pseudostem development of antibacterial biocomposites reinforced with cellulose nanocrystals derived from banana pseudostem. Carbohydr Polym Technol Appl 2:100112. https://doi.org/10.1016/j.carpta.2021.100112

Camacho M, Ureña YRC, Lopretti M et al (2017) Synthesis and characterization of nanocrystalline cellulose derived from pineapple peel residues. J Renew Mater 5:271–279. https://doi.org/10.7569/JRM.2017.634117

Onkarappa HS, Prakash GK, Pujar GH et al (2020) Facile synthesis and characterization of nanocellulose from Zea mays husk. Polym Compos 41:3153–3159. https://doi.org/10.1002/pc.25606

Flauzino Neto WP, Silvério HA, Dantas NO, Pasquini D (2013) Extraction and characterization of cellulose nanocrystals from agro-industrial residue – soy hulls. Ind Crops Prod 42:480–488. https://doi.org/10.1016/j.indcrop.2012.06.041

Debiagi F, Faria-Tischer PCS, Mali S (2021) A green approach based on reactive extrusion to produce nanofibrillated cellulose from oat hull. Waste and Biomass Valorization 12:1051–1060. https://doi.org/10.1007/s12649-020-01025-1

Melikoğlu AY, Bilek SE, Cesur S (2019) Optimum alkaline treatment parameters for the extraction of cellulose and production of cellulose nanocrystals from apple pomace. Carbohydr Polym 215:330–337. https://doi.org/10.1016/j.carbpol.2019.03.103

Hafemann E, Battisti R, Bresolin D et al (2020) Enhancing chlorine-free purification routes of rice husk biomass waste to obtain cellulose nanocrystals. Waste and Biomass Valorization 11:6595–6611. https://doi.org/10.1007/s12649-020-00937-2

Prado KS, Gonzales D, Spinacé MAS (2019) Recycling of viscose yarn waste through one-step extraction of nanocellulose. Int J Biol Macromol 136:729–737. https://doi.org/10.1016/j.ijbiomac.2019.06.124

Mahardika M, Abral H, Kasim A et al (2018) Production of nanocellulose from pineapple leaf fibers via high-shear homogenization and ultrasonication. Fibers 6:1–12. https://doi.org/10.3390/fib6020028

Maciel MMÁD, de Benini KCC, Voorwald HJC, Cioffi MOH (2019) Obtainment and characterization of nanocellulose from an unwoven industrial textile cotton waste: effect of acid hydrolysis conditions. Int J Biol Macromol 126:496–506. https://doi.org/10.1016/j.ijbiomac.2018.12.202

Liu C, Li M, Mei C et al (2020) Cellulose nanofibers from rapidly microwave-delignified energy cane bagasse and their application in drilling fluids as rheology and filtration modifiers. Ind Crops Prod 150:112378. https://doi.org/10.1016/j.indcrop.2020.112378

Rashid S, Dutta H (2020) Characterization of nanocellulose extracted from short, medium and long grain rice husks. Ind Crops Prod 154:112627. https://doi.org/10.1016/j.indcrop.2020.112627

Gabriel T, Belete A, Hause G et al (2021) Isolation and characterization of cellulose nanocrystals from different lignocellulosic residues: a comparative study. J Polym Environ 29:2964–2977. https://doi.org/10.1007/s10924-021-02089-3

Khan MN, Rehman N, Sharif A et al (2020) Environmentally benign extraction of cellulose from dunchi fiber for nanocellulose fabrication. Int J Biol Macromol 153:72–78. https://doi.org/10.1016/j.ijbiomac.2020.02.333

Yadav C, Saini A, Maji PK (2017) Energy efficient facile extraction process of cellulose nanofibres and their dimensional characterization using light scattering techniques. Carbohydr Polym 165:276–284. https://doi.org/10.1016/j.carbpol.2017.02.049

Kalita E, Nath BK, Agan F et al (2015) Isolation and characterization of crystalline, autofluorescent, cellulose nanocrystals from saw dust wastes. Ind Crops Prod 65:550–555. https://doi.org/10.1016/j.indcrop.2014.10.004

Tan VY, Chou PM (2020) Effectiveness of using different mechanical methods for extraction of nanocellulose from kapok husk. AIP conference proceedings, p 020027. https://doi.org/10.1063/5.0001967

Song Y, Jiang W, Zhang Y et al (2018) A novel process of nanocellulose extraction from kenaf bast. Mater Res Express 5:085032. https://doi.org/10.1088/2053-1591/aac80d

Naduparambath S, **itha TV, Shaniba V et al (2018) Isolation and characterisation of cellulose nanocrystals from sago seed shells. Carbohydr Polym 180:13–20. https://doi.org/10.1016/j.carbpol.2017.09.088

Salimi F, Moradi M, Tajik H, Molaei R (2020) Optimization and characterization of eco-friendly antimicrobial nanocellulose sheet prepared using carbon dots of white mulberry (Morus alba L.). J Sci Food Agric. https://doi.org/10.1002/jsfa.10974

Shao H, He L, **ang L et al (2021) Transparent and UV-absorbing nanocellulose films prepared by directly dissolving microwave liquefied bamboo in TBAA/DMSO co-solvent system. Ind Crops Prod 171:113899. https://doi.org/10.1016/j.indcrop.2021.113899

Sun X, Wu Q, Ren S, Lei T (2015) Comparison of highly transparent all-cellulose nanopaper prepared using sulfuric acid and TEMPO-mediated oxidation methods. Cellulose 22:1123–1133. https://doi.org/10.1007/s10570-015-0574-6

Wakabayashi M, Fujisawa S, Saito T, Isogai A (2020) Nanocellulose film properties tunable by controlling degree of fibrillation of TEMPO-oxidized cellulose. Front Chem 8:1–9. https://doi.org/10.3389/fchem.2020.00037

Khawas P, Das AJ, Deka SC (2016) Production of renewable cellulose nanopaper from culinary banana (Musa ABB) peel and its characterization. Ind Crops Prod 86:102–112. https://doi.org/10.1016/j.indcrop.2016.03.028

Llanos JHR, Tadini CC (2018) Preparation and characterization of bio-nanocomposite films based on cassava starch or chitosan, reinforced with montmorillonite or bamboo nanofibers. Int J Biol Macromol 107:371–382. https://doi.org/10.1016/j.ijbiomac.2017.09.001

Sehaqui H, Zhou Q, Ikkala O, Berglund LA (2011) Strong and tough cellulose nanopaper with high specific surface area and porosity. Biomacromol 12:3638–3644. https://doi.org/10.1021/bm2008907

Zhu H, Zhu S, Jia Z et al (2015) Anomalous scaling law of strength and toughness of cellulose nanopaper. Proc Natl Acad Sci U S A 112:8971–8976. https://doi.org/10.1073/pnas.1502870112

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–85. https://doi.org/10.1007/s10570-008-9244-2

Nurul Atiqah MS, Gopakumar DA, Owolabi FAT et al (2019) Extraction of cellulose nanofibers via eco-friendly supercritical carbon dioxide treatment followed by mild acid hydrolysis and the fabrication of cellulose nanopapers. Polymers (Basel) 11:1813. https://doi.org/10.3390/polym11111813

Shahi N, Min B, Sapkota B, Rangari VK (2020) Eco-friendly cellulose nanofiber extraction from sugarcane bagasse and film fabrication. Sustain 12:1–15. https://doi.org/10.3390/su12156015

Mtibe A, Linganiso LZ, Mathew AP et al (2015) A comparative study on properties of micro and nanopapers produced from cellulose and cellulose nanofibres. Carbohydr Polym 118:1–8. https://doi.org/10.1016/j.carbpol.2014.10.007

Lizundia E, Delgado-Aguilar M, Mutjé P et al (2016) Cu-coated cellulose nanopaper for green and low-cost electronics. Cellulose 23:1997–2010. https://doi.org/10.1007/s10570-016-0920-3

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically transparent nanofiber paper. Adv Mater 21:1595–1598. https://doi.org/10.1002/adma.200803174

Salajkova M, Valentini L, Zhou Q, Berglund LA (2013) Tough nanopaper structures based on cellulose nanofibers and carbon nanotubes. Compos Sci Technol 87:103–110. https://doi.org/10.1016/j.compscitech.2013.06.014

Poiini P, Subramanian KS, Janavi GJ, Subramanian J (2020) Synthesis of nano-film from nanofibrillated cellulose of banana pseudostem (Musa spp.) to extend the shelf life of tomato. BioResources 15:2882–2905. https://doi.org/10.15376/biores.15.2.2882-2905

Ra**ipriya M, Nagalakshmaiah M, Robert M, Elkoun S (2018) Industrial crops & products homogenous and transparent nanocellulosic fi lms from carrot. Ind Crop Prod 118:53–64. https://doi.org/10.1016/j.indcrop.2018.02.076

Sakare P, Bharimalla AK, Dhakane-Lad J, Patil PG (2021) Development of greaseproof paper from banana pseudostem fiber for packaging of butter. J Nat Fibers 18:1974–1982. https://doi.org/10.1080/15440478.2019.1710652

Chang H, Yao S, Kang X et al (2020) Flexible, transparent, and hazy cellulose nanopaper with efficient near-infrared luminescence fabricated by 2D lanthanide (Ln = Nd, Yb, or Er) metal-organic-framework-grafted oxidized cellulose nanofibrils. Inorg Chem 59:16611–16621. https://doi.org/10.1021/acs.inorgchem.0c02518

de Coelho CC, S, Silva RBS, Carvalho CWP, et al (2020) Cellulose nanocrystals from grape pomace and their use for the development of starch-based nanocomposite films. Int J Biol Macromol 159:1048–1061. https://doi.org/10.1016/j.ijbiomac.2020.05.046

Acknowledgements

We express our gratitude to SAIF STIC, CUSAT, for the chemical analysis. Dr. Midhun Dominic C.D would like to thank Sacred Heart College (Autonomous), Thevara, for the Sacred Heart Research Initiative (SHRI) seed money (SHC/IQAC/SHRI/2022-23/03).

Author information

Authors and Affiliations

Contributions

Sameera Sankar: investigation, Neenu K. V.: writing—original draft, Jyotishkumar Parameswaranpillai: writing, reviewing and editing, T. G. Ajithkumar: formal analysis, Ankita Shelke: data curation, P. M. Sabura Begum: supervision, Bipinbal Parambath Kanoth: formal analysis, Tresa Sunitha George: data curation, Michael Badawi: resources, supervision, project administration, writing, reviewing and editing, Midhun Dominic C. D.: conceptualization, methodology, visualization, supervision, project administration, writing, reviewing and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Declaration of generative AI and AI-assisted technologies in the writing process

During the preparation of this work, the corresponding author (Midhun Dominic C D) used ChatGpt in order to improve the language and readability. After using this tool/service, the author reviewed and edited the content as needed and takes full responsibility for the content of the publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sankar, S., K. V., N., Parameswaranpillai, J. et al. Green engineering of cellulose nanofibers and nanopapers from Wodyetia bifurcata fruits: a sustainable approach with emphasis on process optimization and tensile property assessment. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05751-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05751-7