Abstract

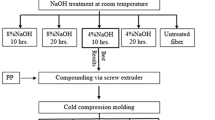

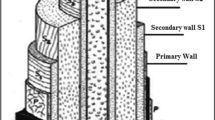

The present study examines the influence of successive treatments on the fiber surface (NaOH, hydrogen peroxide, and acetic anhydride). The palm petiole fibers were incorporated as reinforcement in linear low-density polyethylene (LLDPE) composites with a loading of 15 wt% and evaluated for mechanical, morphological, and dynamic mechanical properties. The effect of treatments on fiber surfaces has been confirmed using FTIR. The scanning electron microscopy (SEM) results showed that the enhanced interfacial adhesion between the fibers and the matrix makes treated composites more rigid and homogeneous, which means that the fibers are distributed uniformly. The tensile modulus and flexural strength were all enhanced by adding 15% of untreated palm petiole fibers recorded at 598 MPa and 15.56 MPa, respectively, while the tensile strength was decreased. Palm-petiole fiber composites’ storage modulus increased, and the acetylated-alkali fiber (FNA) reinforced LLDPE composite showed the highest storage modulus. Loss modulus increased when palm petiole fibers were strengthened. The Tan delta of composites made from palm petiole fibers was low initially but expanded with fiber addition. We concluded that successive treatments improve the performance of the palm petiole fiber residue and have the potential to create a new type of sustainable and eco-friendly material for various applications.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author (Jawaid, M.), upon reasonable request.

References

Yue R, An C, Ye Z, Owens E, Taylor E, Zhao S (2022) Green biomass-derived materials for oil spill response: recent advancements and future perspectives. Curr Opin Chem Eng 36:100767

George A, Sanjay M, Srisuk R, Parameswaranpillai J, Siengchin S (2020) A comprehensive review on chemical properties and applications of biopolymers and their composites. Int J Biol Macromol 154:329–338

Gurunathan T, Mohanty S, Nayak SK (2015) A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos A: Appl Sci Manuf 77:1–25

FM AL-O, Rababah M (2017) Challenges in design of nanocellulose and its composites for different applications. In: Cellulose-reinforced nanofibre composites. Elsevier, pp 113–127

Atitallah IB, Ntaikou I, Antonopoulou G, Bradai C, Mechichi T, Lyberatos G (2022) Effect of alkaline/hydrogen peroxide pretreatment on date palm fibers: induced chemical and structural changes and assessment of ethanol production capacity via Pichia anomala and Pichia stipitis. Biomass Convers 12:4473–4489

Neto J, Lima R, Cavalcanti D, Souza J, Aguiar R, Banea M (2019) Effect of chemical treatment on the thermal properties of hybrid natural fiber-reinforced composites. J Appl Polym Sci 136:47154

Khiari R, Belgacem MN (2020) Date palm nanofibres and composites. In: Date Palm Fiber Composites. Springer, pp 185–206

Lahouioui M, Ben Arfi R, Fois M, Ibos L, Ghorbal A (2020) Investigation of fiber surface treatment effect on thermal, mechanical and acoustical properties of date palm fiber-reinforced cementitious composites. Waste and Biomass Valorization 11:4441–4455

Eslami-Farsani R (2015) Effect of fiber treatment on the mechanical properties of date palm fiber reinforced PP/EPDM composites. Advanced Composite Materials 24:27–40

Filgueira D, Holmen S, Melbø JK, Moldes D, Echtermeyer AT, Chinga-Carrasco G (2017) Enzymatic-assisted modification of thermomechanical pulp fibers to improve the interfacial adhesion with poly (lactic acid) for 3D printing. ACS Sustain Chem Eng 5:9338–9346

Reixach R, Espinach FX, Franco-Marquès E, Ramirez de Cartagena F, Pellicer N, Tresserras J et al (2013) Modeling of the tensile moduli of mechanical, thermomechanical, and chemi-thermomechanical pulps from orange tree pruning. Polym Compos 34:1840–1846

Kalia S, Thakur K, Celli A, Kiechel MA, Schauer CL (2013) Surface modification of plant fibers using environment friendly methods for their application in polymer composites, textile industry and antimicrobial activities: a review. J Environ Chem Eng 1:97–112

Chihaoui B, Serra-Parareda F, Tarrés Q, Espinach FX, Boufi S, Delgado-Aguilar M (2020) Effect of the fiber treatment on the stiffness of date palm fiber reinforced PP composites: macro and micromechanical evaluation of the Young’s modulus. Polymers 12:1693

Mehanny S, Abu-El Magd EE, Ibrahim M, Farag M, Gil-San-Millan R, Navarro J et al (2021) Extraction and characterization of nanocellulose from three types of palm residues. J Mater Res Technol 10:526–537

Hussin FNNM, Attan N, Wahab RA (2020) Extraction and characterization of nanocellulose from raw oil palm leaves (Elaeis guineensis). Arab J Sci Eng 45:175–186

Ling PA, Ismail H, Bakar A (2018) Linear low density polyethylene/poly (vinyl alcohol)/kenaf composites: effect of natural weathering on functional group, weight loss characteristics, tensile, morphological and thermal properties. Sains Malays 47:571–580

Krupa I, Luyt A (2001) Thermal and mechanical properties of extruded LLDPE/wax blends. Polym Degrad Stab 73:157–161

Ventura-Cruz S, Flores-Alamo N, Tecante A (2020) Preparation of microcrystalline cellulose from residual Rose stems (Rosa spp.) by successive delignification with alkaline hydrogen peroxide. Int J Biol Macromol 155:324–329

Zaman HU, Khan RA (2021) Acetylation used for natural fiber/polymer composites. J Thermoplast Compos Mater 34:3–23

Joglekar JJ, Munde Y, Jadhav A, Bhutada D, Radhakrishnan S, Kulkarni M (2021) Mechanical and morphological properties of Citrus Maxima waste powder filled Low-density polyethylene composites. Mater Today: Proc 47:5640–5645

Shinoj S, Visvanathan R, Panigrahi S, Varadharaju N (2011) Dynamic mechanical properties of oil palm fibre (OPF)-linear low density polyethylene (LLDPE) biocomposites and study of fibre–matrix interactions. Biosystems Engineering 109:99–107

Bekele AE, Lemu HG, Jiru MG (2022) Experimental study of physical, chemical and mechanical properties of enset and sisal fibers. Polym Test 106:107453

Rajeshkumar G, Seshadri SA, Devnani G, Sanjay M, Siengchin S, Maran JP et al (2021) Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites—a comprehensive review. J Clean Prod 310:127483

Wang W, Xu M, Lou J, Dong A (2020) Changes in physicomechanical properties and structures of jute fibers after tetraacetylethylenediamine activated hydrogen peroxide treatment. J Mater Res Technol 9:15412–15420

Liu Y, Liu H, **ong J, Li A, Wang R, Wang L et al (2022) Bioinspired design of electrospun nanofiber based aerogel for efficient and cost-effective solar vapor generation. J Chem Eng 427:131539

Barczewski M, Matykiewicz D, Szostak M (2020) The effect of two-step surface treatment by hydrogen peroxide and silanization of flax/cotton fabrics on epoxy-based laminates thermomechanical properties and structure. J Mater Res Technol 9:13813–13824

Bartz J, Goebel JT, Giovanaz MA, da Rosa Zavareze E, Schirmer MA, Dias ARG (2015) Acetylation of barnyardgrass starch with acetic anhydride under iodine catalysis. Food Chem 178:236–242

Nampitch T (2021) Mechanical, thermal and morphological properties of polylactic acid/natural rubber/bagasse fiber composite foams. Results in Materials 12:100225

Maou S, Meghezzi A, Grohens Y, Meftah Y, Kervoelen A, Magueresse A (2021) Effect of various chemical modifications of date palm fibers (DPFs) on the thermo-physical properties of polyvinyl chloride (PVC)–high-density polyethylene (HDPE) composites. Crops Prod 171:113974

Verma D, Goh KL (2021) Effect of mercerization/alkali surface treatment of natural fibres and their utilization in polymer composites: mechanical and morphological studies. J Compos Sci 5:175

Chun KS, Yeng CM, Husseinsyah S, Pang MM, Ismail A (2017) Effect of eco-degradant on properties of low density polyethylene/corn stalk eco-composites. J Eng Sci Technol 12:1165–1177

AlMaadeed MA, Nógellová Z, Janigová I, Krupa I (2014) Improved mechanical properties of recycled linear low-density polyethylene composites filled with date palm wood powder. Materials & Design 58:209–216

Cao Y, Shibata S, Fukumoto I (2006) Mechanical properties of biodegradable composites reinforced with bagasse fibre before and after alkali treatments. Compos A: Appl Sci Manuf 37:423–429

Venkateshwaran N, Perumal AE, Arunsundaranayagam D (2013) Fiber surface treatment and its effect on mechanical and visco-elastic behaviour of banana/epoxy composite. Materials & Design 47:151–159

Li M, Pu Y, Thomas VM, Yoo CG, Ozcan S, Deng Y et al (2020) Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos Part B Eng 200:108254

Gulati K, Lal S, Kumar S, Arora S (2021) Effect of gamma irradiation on thermal, mechanical and water absorption behavior of LLDPE hybrid composites reinforced with date pit (Phoenix dactylifera) and glass fiber. Polymer Bulletin 78:7019–7038

Kabir M, Wang H, Lau K, Cardona F (2012) Chemical treatments on plant-based natural fibre reinforced polymer composites: an overview. Compos Part B Eng 43:2883–2892

Sahari J, Sapuan S, Zainudin E, Maleque MA (2013) Mechanical and thermal properties of environmentally friendly composites derived from sugar palm tree. Materials & Design 49:285–289

Bledzki A, Mamun A, Lucka-Gabor M, Gutowski V (2008) The effects of acetylation on properties of flax fibre and its polypropylene composites. Express Polymer Letters 2:413–422

Elappunkal TJ, Mathew R, Thomas P, Thomas S, Joseph K (2009) Dynamic mechanical properties of cotton/polypropylene commingled composite systems. J Appl Polym Sci 114:2624–2631

Faker M, Aghjeh MR, Ghaffari M, Seyyedi S (2008) Rheology, morphology and mechanical properties of polyethylene/ethylene vinyl acetate copolymer (PE/EVA) blends. Eur Polym J 44:1834–1842

Faria H, Cordeiro N, Belgacem MN, Dufresne A (2006) Dwarf cavendish as a source of natural fibers in poly (propylene)-based composites. Macromolecular Materials and Engineering 291:16–26

Khonakdar HA (2015) Dynamic mechanical analysis and thermal properties of LLDPE/EVA/modified silica nanocomposites. Compos Part B Eng 76:343–353

Asim M, Jawaid M, Fouad H, Alothman O (2021) Effect of surface modified date palm fibre loading on mechanical, thermal properties of date palm reinforced phenolic composites. Composite Structures 267:113913

Jacob M, Francis B, Thomas S, Varughese K (2006) Dynamical mechanical analysis of sisal/oil palm hybrid fiber-reinforced natural rubber composites. Polym Compos 27:671–680

Abhilash S, Lenin Singaravelu D (2022) A comparative study of mechanical, dynamic mechanical and morphological characterization of tampico and coir fibre-reinforced LLDPE processed by rotational moulding. Journal of Industrial Textiles 51:285S–310S

Singh T, Gangil B, Patnaik A, Kumar S, Rishiraj A, Fekete G (2018) Physico-mechanical, thermal and dynamic mechanical behaviour of natural-synthetic fiber reinforced vinylester based homogenous and functionally graded composites. Materials Research Express 6:025704

Shahroze RM, Ishak MR, Salit MS, Leman Z, Chandrasekar M, Munawar NS et al (2020) Sugar palm fiber/polyester nanocomposites: influence of adding nanoclay fillers on thermal, dynamic mechanical, and physical properties. J Vinyl Addit Technol 26:236–243

Saba N, Jawaid M, Alothman OY, Paridah M (2016) A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Construct Build Mater 106:149–159

Asim M, Jawaid M, Nasir M, Saba N (2018) Effect of fiber loadings and treatment on dynamic mechanical, thermal and flammability properties of pineapple leaf fiber and kenaf phenolic composites. Journal of Renewable Materials 6:383

Martínez-Hernández A, Velasco-Santos C, De-Icaza M, Castano VM (2007) Dynamical–mechanical and thermal analysis of polymeric composites reinforced with keratin biofibers from chicken feathers. Compos Part B Eng 38:405–410

Saba N, Paridah M, Abdan K, Ibrahim NA (2016) Dynamic mechanical properties of oil palm nano filler/kenaf/epoxy hybrid nanocomposites. Construct Build Mater 124:133–138

Aziz SH, Ansell MP (2004) The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: Part 1—polyester resin matrix. Composites Science and Technology 64:1219–1230

Acknowledgements

The authors would like to thank the Centre for Scientific and Technical Research on Arid Regions (CRSTRA) in Biskra, Algeria, and the Cable Company’s Plastic Analysis Laboratory in Biskra, Algeria for sponsoring this research. The authors would like to extend their gratitude to King Saud University (Riyadh, Saudi Arabia) for the funding of this Research through Researchers Supporting Project number (RSP2023R117).

Funding

The authors extend their gratitude to Researchers Supporting Project number

(RSP2023R117) King Saud University, Riyadh, Saudi Arabia for funding this work.

Author information

Authors and Affiliations

Contributions

Data curation, O.D. and O.K.; formal analysis, N.D. and H.B.; project administration and funding, M.J., N.D., and H.F.; writing—original draft, N.D., H.M., and M.J.; writing—review and editing, H.F, M.A.A., and M.J. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

No ethical clearance is required. We declare that there are no animal studies or human participant involvement in the study.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Debabeche, N., Kribaa, O., Boussehel, H. et al. Effect of fiber surface treatment on the mechanical, morphological, and dynamic mechanical properties of palm petiole fiber/LLDPE composites. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04197-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04197-7