Abstract

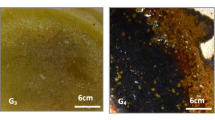

This study presents a new method for the production of nanomaterials from office paper waste. For this purpose, two types of office paper wastes were selected to extract kaolin and then metakaolin was produced after calcination at five different temperatures in the range of 500 to 1000 °C. The synthesized materials were investigated by differential thermal analysis/thermo-gravimetric analysis (DTA/TGA), X-ray diffraction (XRD), and Fourier transform infrared (FTIR) spectroscopy. Planetary ball mill was used for mechanical treatment of nanomaterials, followed by analyzing using scanning electron microscopy (SEM), dynamic light scattering (DLS), and transmission electron microscopy (TEM) techniques. The changes in the crystalline structure of the nanoparticles were also investigated. The synthesized nanominerals were also used in a nanobiocomposite, i.e., soy protein isolate (SPI) biofilm, to improve its barrier properties.

Graphical abstract

Similar content being viewed by others

Data availability

The data used to support the findings of this study are included within the article.

References

Fauberta P, Bélislea CL, Bertrandb N, Boucharda S, Martin H, Chantigny B, Maxime C, Paréa C, Rochetteb P, Ziadib N, Villeneuvea C (2019) Land application of pulp and paper mill sludge may reduce greenhouse gasemissions compared to landfilling. Resour Conserv Recycl 150(104415):33–53

Bajpai P (2015) Management of pulp and paper mill waste. Springer Int Publishing, Switzerland 208:45–78

Azevedo ARG, Alexandre J, Xavier GC, Pedroti LG (2018) Recycling paper industry effluent sludge for use in mortars: a sustainability perspective. J Clean Prod 192:335–346

Rashad AlaaM (2013) Metakaolin as cementitious material: history, scours, production and composition. A comprehensive overview Constr Build Mater 41:303–318

Mgbemena CO, Ibekwe BNO, RugminiSukumar CR, Ravindranatha Menon AR (2013) Characterization of kaolin intercalates of oleochemicals derived from rubber seed Hevea brasiliensis and tea seed Camellia Sinensi oils. J King Saud University Sci 25:149–155

RajikacemQaiss MAEK, Bouhfid R (2020) Effects of bleaching and functionalization of kaolinite on the mechanical and thermal properties of polyamide 6 nanocomposites. RSC Adv 10:4916–4926

Bundy WM, Ishley JN (1991) Kaolin in paper filling and coating. Appl Clay Sci 5:397–420

Hubbe MA, Gill RA (2016) Fillers for papermaking: a review of their properties, usage practices, and their mechanistic role. BioResources 11:2886–2963

Raghavan P, Chandrasekhar V, Vogt E, Gock S, Suresh S (2008) Additional investigations on the separation of titanoferrous impurities from kaolin by high shear pretreatment and froth flotation — Part II. Appl Clay Sci 42:50–56

Sarbatly R, Yee CP, Fong TS, Krishnaiah D (2009) Particle size distribution and purification of red clay for industrial use. J Appl Sci 9:2344–2347

Haydn M, Kogel J (2005) Engineered clay products for the paper industry. Appl Clay Sci 29:199–206

Byadgi SA, Kalburgib PB (2016) Production of bioethanol from waste newspaper. Procedia Environ Sci 35:555–562

Gottumukkala LD, Haigh K, Collard FX, Rensburg EV, Görgens J (2016) Opportunities and prospects of biorefinery-based valorization of pulp and paper sludge. Bioresour Technol 215:37–49

Zanoni PRS, Magalhaes WLE, Helm CV, de Lima EA, Tavares LBB, Kestur SG (2017) Review of ethanol production based on paper sludge: processes and prospects. ENVIRON ENG MANAG J 16:1227–1248

Al-Azkawi A, Elliston A, Al-Bahry S, Sivakumar N (2019) Review; waste paper to bioethanol: current and future prospective. Biotechnol Appl Microbiol 3(41):1106–1118

Gurram RN, Al-Shannag M, Lecher NJ, Duncan SM, Singsaas EL, Alkasrawi MC (2015) Bioconversion of paper mill sludge to bioethanol in the presence of accelerants or hydrogen peroxide pretreatment. Biores Technol 192:529–539

Branco RHR, Serafim LS, Xavier AMRB (2018) Second generation bioethanol production: on the use of pulp and paper industry wastes as feedstock. Fermentation 5(4):2–30

Sarfraz J, Gulin-Sarfraz T, Nilsen-Nygaard J, Pettersen M (2021) Nanocomposites for food packaging applications: an overview. Nanomaterials 11:10

Bumbudsanpharoke N, Seonghyuk JK (2019) Nano-food packaging: an overview of market, migration research, and safety regulations. Nanomaterials 8927167:1–14

Arora A, Padua GWJ (2010) Review: nanocomposites in food packaging. FOOD SCIENCE 75:43–49

Gao J, Yang Q, Ren F, Ma G, Lei Z (2016) Preparation and properties of novel eco-friendly superabsorbent composites based on raw wheat bran and clays. Appl Clay Sci 132:739–747

Dewi R, Agusnar H, Alfian ZT (2018) Characterization of technical kaolin using XRF, SEM, XRD, FTIR and its potentials as industrial raw materials. J Phys Conf Ser 1116:042010

Post JL, Crawford SM (2014) Uses of near-infared spectra for the identification of clay minerals. Appl Clay Sci 95:383–387

Asadi M, Nemati A, Naghizadeh R, Arzani K, Fahim J (2013) Effect of temperature and activator molar of Na2O to SiO2 in the process of synthesis and microstructure of cement geopolymer. J.A. Mater Process 1:3–10

Khan MI, Khan HU, Azizli K, Sufian S, Man Z, Siyal AA, Muhammad N (2017) The pyrolysis kinetics of the conversion of Malaysian kaolin to metakaolin. Appl Clay Sci 146:152–161

Cheng H, Liua Q, Yang J, Mac S, Frost RL (2012) The thermal behaviour of kaolinite intercalation complexes-a review. Thermochim Acta 545:1–13

Castelein O, Soulestin B, Bonnet JP, Blanchart P (2001) The influence of heating rate on the thermal behaviour and mullite formation from a kaolin raw material. Ceram Int 27:517–522

Valles MG, Alfonso P, Martínez S, Roca N (2020) Mineralogical and thermal characterization of kaolinitic clays from Terra Alta (Catalonia, Spain). Minerals 10:142

Tchakoute Kouamo H, Rüscher CH, Kong S, Kamseu E, Leonelli C (2020) Microstructural and mechanical properties of poly(sialate-siloxo) networks obtained using metakaolins from kaolin and halloysite as aluminosilicate sources: a comparative study. Appl Clay Sci 186:105448

Yu M, Huang Y, **a W, Zhu Z, Fan C, Liu C, Dong L, XuLiu L, Zha J, Wang (2020) XPbCl2 capture by kaolin and metakaolin under different influencing factors of thermal treatment. Energy Fuels 34(2):2284–2292

Vaculikova L, Plevova E, Vallova S, Koutnik I (2011) Characterization and differentiation of kaolinites from selected Czech deposits using infrared spectroscopy and differential thermal analysis. Acta Geodyn Geomater 8:59–67

Mortazavi Moghadam FA, Resalati H, Rasouli S, Asadpour G (2021) Fabrication of high mechanical properties papers coated with CMC-based nanocomposites containing nanominerals synthesized from paper waste. Cellulose 28:11153–11164. https://doi.org/10.1007/s10570-021-04241-7

Funding

There were three major sources of funding: individual donor (Dr. Faegheh Alsadat Mortazavi Moghadam), Sari Agriculture and Natural Science University, and Institute For Color Science and Technology.

Author information

Authors and Affiliations

Contributions

Dr. Faeghe Alsadat Mortazavi Moghadam conceived of the presented idea, carried out the synthesize nano material studies, designed of the study, the statistical analysis in the sequence alignment, and drafted the manuscript.

Prof. Hossein Resalati participated in the sequence alignment, writing—review and editing, and funding acquisition.

Dr. Susan Rasoli participated in writing—review and editing and funding acquisition.

Dr.Ghasem Asadpour participated in writing—review and editing and funding acquisition.

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

This manuscript has not been submitted to, nor is under review at, another journal or another publishing venue.

The authors have no affiliation with any organization with a direct or indirect financial interest in the subject matter discussed in the manuscript

The following authors have affiliations with organizations with direct or indirect financial interest in the subject matter discussed in the manuscript:

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• New method for producing nanominerals from office paper waste.

• Producing new products from these nanominerals for various applications (e.g., nanobiocomposites).

• Analytical calculations based on XRD and Scherrer equation in addition to microscopic and chemical analyses.

Rights and permissions

About this article

Cite this article

Mortazavi Moghadam, F.A., Resalati, H., Rasouli, S. et al. New method of producing nanominerals from office paper waste and investigating their microstructural properties. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-02782-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-02782-w