Abstract

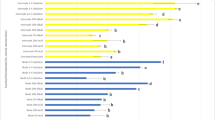

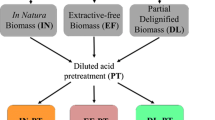

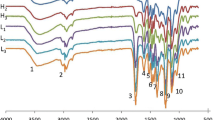

Biomass conversion is challenged by the heterogeneity and lignin, a component that acts as a barrier to the enzymatic hydrolysis of polysaccharides. This study evaluated the effect of pretreatments on different fractions of sugarcane biomass lignin and cellulose exposure. Two different methods were used: dilute sulfuric acid (5%, 10%, and 20% w/w at 121 °C/30 min) and partial delignification with sodium chlorite (30% m/m at 70 °C/1 h) to reduce the exposed surface of lignin. The surface area of lignin was obtained through the cationic dye Azure B, and cellulose access by enzymatic hydrolysis (15 FPU/g for 24 h—Cellic Cetec 2—Novozymes) was employed. Acid pretreatment was efficient in hemicellulose removal, and delignification removed lignin from all the biomasses fractions. Azure B dyes determined the surface area filled with lignin after dilute sulfuric acid pretreatment and partial delignification. The sample with the largest total surface area of lignin (52 m2/g of material) was the leaf pretreated with 5% sulfuric acid. The external fraction presented the largest specific surface area (240 m2/g) after partial delignification. These results indicate that reducing the lignin surface area enhances the glucose yield of enzymatic hydrolysis.

Similar content being viewed by others

References

Kumar AK, Sharma S (2017) Recent updates on different methods of pretreatment of lignocellulosic feedstocks: a review. Bioresour Bioprocess 4:1–19. https://doi.org/10.1186/S40643-017-0137-9

Melati RB, Shimizu FL, Oliveira G et al (2019) Key factors affecting the recalcitrance and conversion process of biomass. Bioenergy Res 12:1–20. https://doi.org/10.1007/s12155-018-9941-0

Brienzo M, Tyhoda L, Benjamin Y, Görgens J (2015) Relationship between physicochemical properties and enzymatic hydrolysis of sugarcane bagasse varieties for bioethanol production. New Biotechnol 32:253–262

Schmatz AA, Tyhoda L, Brienzo M (2020) Sugarcane biomass conversion influenced by lignin. Biofuels Bioprod Biorefin 14:469–480. https://doi.org/10.1002/bbb.2070

Candido JP, Claro EMT, de Paula CBC et al (2020) Detoxification of sugarcane bagasse hydrolysate with different adsorbents to improve the fermentative process. World J Microbiol Biotechnol 36(3):1–12. https://doi.org/10.1007/S11274-020-02820-7

Forsan CF, de Freitas C, Masarin F, Brienzo M (2021) Xylooligosaccharide production from sugarcane bagasse and leaf using Aspergillus versicolor endoxylanase and diluted acid. Biomass Convers Biorefin 2021:1–16. https://doi.org/10.1007/S13399-021-01403-2

Alves RC, Melati RB, Casagrande GM et al (2021) Sieving process selects sugarcane bagasse with lower recalcitrance to xylan solubilization. J Chem Technol Biotechnol 96:327–334. https://doi.org/10.1002/JCTB.6541

Schmatz AA, Salazar-Bryam AM, Contiero J et al (2020) Pseudo-lignin content decreased with hemicellulose and lignin removal, improving cellulose accessibility, and enzymatic digestibility. BioEnergy Research 1(14):106–121. https://doi.org/10.1007/S12155-020-10187-8

Shimizu FL, Monteiro PQ, Ghiraldi PHC et al (2018) Acid, alkali and peroxide pretreatments increase the cellulose accessibility and glucose yield of banana pseudostem. Ind Crops Prod 115:62–68. https://doi.org/10.1016/j.indcrop.2018.02.024

Wallace J, Brienzo M, García-Aparicio MP, Görgens JF (2016) Lignin enrichment and enzyme deactivation as the root cause of enzymatic hydrolysis slowdown of steam pretreated sugarcane bagasse. New Biotechnol 33:361–371

Fernandes ÉS, Bueno D, Pagnocca FC, Brienzo M (2020) Minor biomass particle size for an efficient cellulose accessibility and enzymatic hydrolysis. Chem Select 5:7627–7631. https://doi.org/10.1002/SLCT.202001008

Freitas C, Carmona E, Brienzo M (2019) Xylooligosaccharides production process from lignocellulosic biomass and bioactive effects. Bioact Carbohydr Diet Fibre 18:352–363. https://doi.org/10.1016/J.BCDF.2019.100184

Brienzo M, Fikizolo S, Benjamin Y et al (2017) Influence of pretreatment severity on structural changes, lignin content and enzymatic hydrolysis of sugarcane bagasse samples. Renew Energy 104:271–280. https://doi.org/10.1016/j.renene.2016.12.037

Brienzo M, Ferreira S, Vicentim MP et al (2014) Comparison study on the biomass recalcitrance of different tissue fractions of sugarcane culm. Bioenergy Res 7:1454–1465

Madadi M, Bakr MMA, Abdulkhani A et al (2022) Alleviating lignin repolymerization by carbocation scavenger for effective production of fermentable sugars from combined liquid hot water and green-liquor pretreated softwood biomass. Energy Convers Manage 251:114956. https://doi.org/10.1016/J.ENCONMAN.2021.114956

Shimizu FL, de Azevedo GO, Coelho LF et al (2020) Minimum lignin and xylan removal to improve cellulose accessibility. Bioenerg Research 3(13):775–785. https://doi.org/10.1007/S12155-020-10120-Z

Sipponen MH, Pihlajaniemi V, Pastinen O, Laakso S (2014) Reduction of surface area of lignin improves enzymatic hydrolysis of cellulose from hydrothermally pretreated wheat straw. RSC Adv 1:3. https://doi.org/10.1039/C4RA06926A

Sipponen MH, Pihlajaniemi V, Littunen K et al (2014) Determination of surface-accessible acidic hydroxyls and surface area of lignin by cationic dye adsorption. Biores Technol 169:80–87. https://doi.org/10.1016/J.BIORTECH.2014.06.073

Sant’Anna C, de Souza W, Brienzo M (2014) The influence of the heterogeneity, physicochemical and structural properties on the recalcitrance and conversion of sugarcane bagasse

Siqueira G, Milagres AM, Carvalho W et al (2011) Topochemical distribution of lignin and hydroxycinnamic acids in sugar-cane cell walls and its correlation with the enzymatic hydrolysis of polysaccharides. Biotechnol Biofuels 1(4):1–9. https://doi.org/10.1186/1754-6834-4-7

ABNT NBR 16550:2018 Sugarcane bagasse - chemical characterization. Brazilian National Standards Organization (2018) ABNT. https://www.abntcatalogo.com.br/norma.aspx?ID=395361. https://www.abntcatalogo.com.br/norma.aspx?ID=395361. Accessed 5 Oct 2021

Brienzo M, Carvalho AFA, Figueiredo FC, Oliva Neto, P (2016) Sugarcane bagasse hemicellulose properties, extraction technologies and xylooligosaccharides production. In: Riley GL (Ed.). Food Waste. 978–1–63485–025–4.

Santos C, Bueno D, Sant’Anna C, Brienzo M, (2020) High xylose yield from stem and external fraction of sugarcane biomass by diluted acid pretreatment. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-020-01088-z

Santos CC, de Souza W, Sant Anna C, Brienzo M (2018) Elephant grass leaves have lower recalcitrance to acid pretreatment than stems, with higher potential for ethanol production. Ind Crops Prod 111:193–200. https://doi.org/10.1016/j.indcrop.2017.10.013

Mesa L, Martínez Y, Barrio E, González E (2017) Desirability function for optimization of dilute acid pretreatment of sugarcane straw for ethanol production and preliminary economic analysis based in three fermentation configurations. Appl Energy 198:299–311. https://doi.org/10.1016/J.APENERGY.2017.03.018

Evert RF (2006) Esau’s plant anatomy: meristems, cells, and tissues of the plant body: their structure, function, and development, 3rd edn. Jonh Wiley and Son, New Jersey, p 601 http://dx.doi.org/10.1002/0470047380 624

Brienzo M, Abud Y, Ferreira S et al (2016) Characterization of anatomy, lignin distribution, and response to pretreatments of sugarcane culm node and internode. Ind Crops Prod 84:305–313. https://doi.org/10.1016/j.indcrop.2016.01.039

Moodley P, Kana EBG (2015) Optimization of xylose and glucose production from sugarcane leaves (Saccharum officinarum) using hybrid pretreatment techniques and assessment for hydrogen generation at semi-pilot scale. Int J Hydrogen Energy 40:3859–3867. https://doi.org/10.1016/J.IJHYDENE.2015.01.087

Junior CS, Milagres AMF, Ferraz A, Carvalho W (2013) The effects of lignin removal and drying on the porosity and enzymatic hydrolysis of sugarcane bagasse. Cellulose 6(20):3165–3177. https://doi.org/10.1007/S10570-013-0032-2

Li H, Pu Y, Kumar R et al (2014) Investigation of lignin deposition on cellulose during hydrothermal pretreatment, its effect on cellulose hydrolysis, and underlying mechanisms. Biotechnol Bioeng 111:485–492. https://doi.org/10.1002/BIT.25108

Hansen MAT, Jørgensen H, Laursen KH et al (2013) Structural and chemical analysis of process residue from biochemical conversion of wheat straw (Triticum aestivum L.) to ethanol. Biomass Bioenerg 56:572–581. https://doi.org/10.1016/J.BIOMBIOE.2013.06.007

Sun Q, Foston M, Meng X et al (2014) Effect of lignin content on changes occurring in poplar cellulose ultrastructure during dilute acid pretreatment. Biotechnol Biofuels 1(7):1–14. https://doi.org/10.1186/S13068-014-0150-6

Hatakeyama H, Hatakeyama T (2009) Lignin structure, properties, and applications. Adv Polym Sci 232:1–63. https://doi.org/10.1007/12_2009_12

Hashmi M, Sun Q, Tao J et al (2017) Comparison of autohydrolysis and ionic liquid 1-butyl-3-methylimidazolium acetate pretreatment to enhance enzymatic hydrolysis of sugarcane bagasse. Biores Technol 224:714–720. https://doi.org/10.1016/J.BIORTECH.2016.10.089

Yue Y, Han J, Han G et al (2015) Cellulose fibers isolated from energycane bagasse using alkaline and sodium chlorite treatments: structural, chemical and thermal properties. Ind Crops Prod 76:355–363. https://doi.org/10.1016/J.INDCROP.2015.07.006

Pandeirada CO, Merkx DWH, Janssen HG et al (2021) TEMPO/NaClO2/NaOCl oxidation of arabinoxylans. Carbohyd Polym 259:117781. https://doi.org/10.1016/J.CARBPOL.2021.117781

Funding

This study was supported by the Brazilian Council for Research and Development (CNPq, process 401900/2016–9) and São Paulo Research Foundation (Fapesp, process 2017/22401–8).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Azevedo, G.O., Shimizu, F.L., Fontes, L.C. et al. Lignin surface area influenced by biomass heterogeneity and pretreatment process. Biomass Conv. Bioref. 14, 477–488 (2024). https://doi.org/10.1007/s13399-021-02264-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02264-5