Abstract

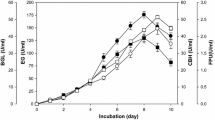

Fungal treatment of lignocellulose is an ecologically and economically acceptable method. However, it needs improvement to increase the hydrolysis rate. A novel combination of multiple response optimization of ligninolytic activity of Trametes hirsuta F13 and supplementation of the lignocellulosic substrate (beechwood sawdust) with sugar beet molasses stillage was employed to improve and manage the desired type of fungal ligninolytic activity leading to a significant enhancement of biomass saccharification. Obtained optimal cultivation conditions (molasses stillage concentration, 13%; substrate moisture, 63%; and temperature, 25 °C) provided the desired combination of laccase and manganese-dependent peroxidase activity, and maintained the activities longer and at higher values (51.5 ± 3.5 U/L and 91 ± 4.24 U/L, respectively) than the conditions without molasses stillage (21.5 ± 2.12 U/L and 31.5 ± 4.9 U/L, respectively). Enzyme hydrolysis of the substrate treated for 7 days in the presence of molasses stillage released 20.54 ± 0.80 mg/mL fermentable sugars, and 63.58 ± 1.47 mg/mL from 18-days treated substrate, while sugar concentrations released from the substrates pretreated without the supplementation were 16.84 ± 0.30 mg/mL and 53.63 ± 2.16 mg/mL, respectively. The proposed new approach of the lignocellulose supplementation with sugar beet molasses stillage and manipulation and improvement of fungal ligninolytic activity proved to be a promising solution for the enhancement of lignocellulose bioconversion.

Graphical abstract

Similar content being viewed by others

References

Cubas-Cano E, González-Fernández C, Ballesteros M, Tomás-Pejó E (2018) Biotechnological advances in lactic acid production by lactic acid bacteria: lignocellulose as novel substrate. Biofuels Bioprod Biorefin 12:290–303. https://doi.org/10.1002/bbb.1852

Jiang Y, Lv Y, Wu R, Sui Y, Chen C, **n F, Zhou J, Dong W, Jiang M (2019) Current status and perspectives on biobutanol production using lignocellulosic feedstocks. Bioresour Technol Rep 7:100245. https://doi.org/10.1016/j.biteb.2019.100245

Parsons S, McManus MC, Taylor CM (2018) Chapter 13 - Second-generation ethanol from lignocellulose. In: Thornley P, Adams P (eds) Greenhouse gas balances of bioenergy systems. Academic Press, pp 193–206

Jović JM, Pe** JD, Kocić-Tanackov SD, Mojović LV (2015) Application of lignocellulolytic fungi for bioethanol production from renewable biomass. Hem Ind 69:627–641. https://doi.org/10.2298/HEMIND140916086J

Zoghlami A, Paës G (2019) Lignocellulosic biomass: understanding recalcitrance and predicting hydrolysis. Front Chem 7. https://doi.org/10.3389/fchem.2019.00874

Xu N, Liu S, **n F, Zhou J, Jia H, Xu J, Jiang M, Dong W (2019) Biomethane production from lignocellulose: biomass recalcitrance and its impacts on anaerobic digestion. Front Bioeng Biotechnol 7. https://doi.org/10.3389/fbioe.2019.00191

Kucharska K, Rybarczyk P, Hołowacz I, Łukajtis R, Glinka M, Kamiński M (2018) Pretreatment of lignocellulosic materials as substrates for fermentation processes. Molecules. 23:2937. https://doi.org/10.3390/molecules23112937

Baruah J, Nath BK, Sharma R, Kumar S, Deka RC, Baruah DC, Kalita E (2018) Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front Energy Res 6. https://doi.org/10.3389/fenrg.2018.00141

Aftab MN, Iqbal I, Riaz F, Karadag A, Tabatabaei M (2019) Different pretreatment methods of lignocellulosic biomass for use in biofuel production. In: Abomohra AEF (ed) Biomass Bioenergy - Recent Trends Future Chall, IntechOpen Limited, London, UK. https://doi.org/10.5772/intechopen.84995

Bairoch A (2000) The ENZYME database in 2000. Nucleic Acids Res 28:304–305. https://doi.org/10.1093/nar/28.1.304

BRENDA, https://www.brenda-enzymes.org

Ferreira P, Hernandez-Ortega A, Herguedas B, Martínez ÁT, Medina M (2009) Aryl-alcohol oxidase involved in lignin degradation. J Biol Chem 284:24840–24847. https://doi.org/10.1074/jbc.M109.011593

Qin X, Sun X, Huang H, Bai Y, Wang Y, Luo H, Yao B, Zhang X, Su X (2017) Oxidation of a non-phenolic lignin model compound by two Irpex lacteus manganese peroxidases: evidence for implication of carboxylate and radicals. Biotechnol Biofuels 10:103. https://doi.org/10.1186/s13068-017-0787-z

Riley R, Salamov AA, Brown DW, Nagy LG, Floudas D, Held BW, Levasseur A, Lombard V, Morin E, Otillar R, Lindquist EA, Sun H, LaButti KM, Schmutz J, Jabbour D, Luo H, Baker SE, Pisabarro AG, Walton JD, Blanchette RA, Henrissat B, Martin F, Cullen D, Hibbett DS, Grigoriev IV (2014) Extensive sampling of basidiomycete genomes demonstrates inadequacy of the white-rot/brown-rot paradigm for wood decay fungi. Proc Natl Acad Sci 111:9923–9928. https://doi.org/10.1073/pnas.1400592111\

García-Torreiro M, López-Abelairas M, Lu-Chau TA, Lema JM (2016) Fungal pretreatment of agricultural residues for bioethanol production. Ind Crop Prod 89:486–492. https://doi.org/10.1016/j.indcrop.2016.05.036

Zhao J, Zheng Y, Li Y (2014) Fungal pretreatment of yard trimmings for enhancement of methane yield from solid-state anaerobic digestion. Bioresour Technol 156:176–181. https://doi.org/10.1016/j.biortech.2014.01.011

Saha BC, Qureshi N, Kennedy GJ, Cotta MA (2016) Biological pretreatment of corn stover with white-rot fungus for improved enzymatic hydrolysis. Int Biodeterior Biodegrad 109:29–35. https://doi.org/10.1016/j.ibiod.2015.12.020

Song L, Ma F, Zeng Y, Zhang X, Yu H (2013) The promoting effects of manganese on biological pretreatment with Irpex lacteus and enzymatic hydrolysis of corn stover. Bioresour Technol 135:89–92. https://doi.org/10.1016/j.biortech.2012.09.004

Mishra V, Jana AK (2017) Fungal pretreatment of sweet sorghum bagasse with combined CuSO4-gallic acid supplement for improvement in lignin degradation, selectivity, and enzymatic saccharification. Appl Biochem Biotechnol 183:200–217. https://doi.org/10.1007/s12010-017-2439-y

Ahmed PM, Pajot HF, de Figueroa LIC, Gusils CH (2018) Sustainable bioremediation of sugarcane vinasse using autochthonous macrofungi. J Environ Chem Eng 6:5177–5185. https://doi.org/10.1016/j.jece.2018.08.007

Ahmed PM, de Figueroa LIC, Pajot HF (2020) Dual purpose of ligninolytic-basidiomycetes: mycoremediation of bioethanol distillation vinasse coupled to sustainable bio-based compounds production. Fungal Biol Rev 34:25–40. https://doi.org/10.1016/j.fbr.2019.12.001

Christofoletti CA, Escher JP, Correia JE, Marinho JFU, Fontanetti CS (2013) Sugarcane vinasse: environmental implications of its use. Waste Manag 33:2752–2761. https://doi.org/10.1016/j.wasman.2013.09.005

Wilkie AC, Riedesel KJ, Owens JM (2000) Stillage characterization and anaerobic treatment of ethanol stillage from conventional and cellulosic feedstocks. Biomass Bioenergy 19:63–102. https://doi.org/10.1016/S0961-9534(00)00017-9

Satyawali Y, Balakrishnan M (2008) Wastewater treatment in molasses-based alcohol distilleries for COD and color removal: a review. J Environ Manag 86:481–497. https://doi.org/10.1016/j.jenvman.2006.12.024

Pant D, Adholeya A (2007) Biological approaches for treatment of distillery wastewater: a review. Bioresour Technol 98:2321–2334. https://doi.org/10.1016/j.biortech.2006.09.027

Sun W, Xu M, **a C, Li A, Sun G (2013) Enhanced production of laccase by Coriolus hirsutus using molasses distillery wastewater. Front Environ Sci Eng 7:200–210. https://doi.org/10.1007/s11783-012-0457-0

Decloux M, Bories A (2002) Stillage treatment in the French alcohol fermentation industry. Int Sugar J 104:509–517

Lutosławski K, Cibis E, Krzywonos M, Lutosławski K, Cibis E, Krzywonos M (2017) The effect of temperature on the efficiency of aerobic biodegradation of sugar beet distillery stillage: removal of pollution load and biogens. Braz J Chem Eng 34:985–996. https://doi.org/10.1590/0104-6632.20170344s20160417

Fuess LT, Garcia ML (2014) Implications of stillage land disposal: a critical review on the impacts of fertigation. J Environ Manag 145:210–229. https://doi.org/10.1016/j.jenvman.2014.07.003

Espinosa A, Rosas L, Ilangovan K, Noyola A (1995) Effect of trace metals on the anaerobic degradation of volatile fatty acids in molasses stillage. Water Sci Technol 32:121–129. https://doi.org/10.1016/0273-1223(96)00146-1

Bodirlau R, Teaca CA, Spiridon I (2008) Chemical modification of beech wood: effect on thermal stability. BioResources. 3:789–800

Jović J, Buntić A, Radovanović N, Petrović B, Mojović L (2018) Lignin-degrading abilities of novel autochthonous fungal isolates Trametes hirsuta F13 and Stereum gausapatum F28. Food Technol Biotechnol 56:354–365. https://doi.org/10.17113/ftb.56.03.18.5348

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Box G, Hunter S, Hunter W (2005) Statistics for experimenters. Wiley-Interscience

Mee R (2009) A comprehensive guide to factorial two - level experimentation. Springer, Dordrecht Heidelberg London New York

Šnajdr J, Baldrian P (2007) Temperature affects the production, activity and stability of ligninolytic enzymes in Pleurotus ostreatus and Trametes versicolor. Folia Microbiol (Praha) 52:498–502. https://doi.org/10.1007/BF02932110

Asgher M, Ahmed N, Iqbal HMN (2011) Hyperproductivity of extracellular enzymes from indigenous white rot fungi (Phanerochaete chrysosporium) by utilizing agro-wastes. BioResources. 6:4454–4467

Kuhn M (2016) desirability: function optimization and ranking via desirability functions. R package version 2.1., https://CRAN.R-project.org/package=desirability.

Derringer G, Suich R (1980) Simultaneous optimization of several response variables. J Qual Technol 12:214–219. https://doi.org/10.1080/00224065.1980.11980968

Scrucca L (2013) GA: a package for genetic algorithms in R. J Stat Softw 53(1):37

Sun X, Zhang D, Chen Y, Zhao Y (2008) GA-based multi-response desirability function optimization approach. In: 2008 IEEE International Conference on Service Operations and Logistics, and Informatics, pp 1771–1773

R Core Team (2018) R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna

Groem** U (2014) R Package FrF2 for creating and analyzing fractional factorial 2-level designs. J Stat Softw 56(1):56

Lenth RV (2010) Response-surface methods in R, using rsm. J Stat Softw 32(1):17

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268. https://doi.org/10.1351/pac198759020257

Waterborg JH (2002) The Lowry method for protein quantitation. In: Walker JM (ed) The protein protocols handbook. Humana Press, Totowa, pp 7–9

Anderson MJ, Whitcomb PJ, Whitcomb PJ (2016) RSM simplified: optimizing processes using response surface methods for design of experiments, second edition. Productivity Press

Fox J, Weisberg S (2010) An R companion to applied regression. SAGE Publications, Inc, Thousand Oaks

Zhang B, Zhou J, Li Q, Gan B, Peng W, Zhang X, Tan W, Jiang L, Li X (2019) Manganese affects the growth and metabolism of Ganoderma lucidum based on LC-MS analysis. PeerJ. 7:e6846. https://doi.org/10.7717/peerj.6846

Martani F, Beltrametti F, Porro D, Branduardi P, Lotti M (2017) The importance of fermentative conditions for the biotechnological production of lignin modifying enzymes from white-rot fungi. FEMS Microbiol Lett 364. https://doi.org/10.1093/femsle/fnx134

Wang F, Xu L, Zhao L, Ding Z, Ma H, Terry N (2019) Fungal laccase production from lignocellulosic agricultural wastes by solid-state fermentation: a review. Microorganisms. 7:665. https://doi.org/10.3390/microorganisms7120665

Kannaiyan R, Mahinpey N, Martinuzzi RJ, Kostenko V (2014) Induction and suppression of Dichomitus squalens and Ceriporiopsis subvermispora peroxidase activity by manganese sulphate in response to carbon and nitrogen sources. Can J Chem Eng 92:779–786. https://doi.org/10.1002/cjce.21935

Rosales E (2005) Rodrı́guez Couto, S., Ángeles Sanromán, M.: Reutilisation of food processing wastes for production of relevant metabolites: application to laccase production by Trametes hirsuta. J Food Eng 66:419–423. https://doi.org/10.1016/j.jfoodeng.2004.04.010

Yang J, Wang G, Ng TB, Lin J, Ye X (2016) Laccase production and differential transcription of laccase genes in Cerrena sp. in response to metal ions, aromatic compounds, and nutrients. Front Microbiol 6. https://doi.org/10.3389/fmicb.2015.01558

Fu SY, Yu H, Buswell JA (1997) Effect of nutrient nitrogen and manganese on manganese peroxidase and laccase production by Pleurotus sajor-caju. FEMS Microbiol Lett 147:133–137. https://doi.org/10.1111/j.1574-6968.1997.tb10232.x

Buswell JA, Cai Y, Chang S (1995) Effect of nutrient nitrogen and manganese on manganese peroxidase and laccase production by Lentinula (Lentinus) edodes. FEMS Microbiol Lett 128:81–87. https://doi.org/10.1111/j.1574-6968.1995.tb07504.x

Tsegaye B, Balomajumder C, Roy P (2019) Microbial delignification and hydrolysis of lignocellulosic biomass to enhance biofuel production: an overview and future prospect. Bull Natl Res Cent 43:51. https://doi.org/10.1186/s42269-019-0094-x

Sun F, Li J, Yuan Y, Yan Z, Liu X (2011) Effect of biological pretreatment with Trametes hirsuta yj9 on enzymatic hydrolysis of corn stover. Int Biodeterior Biodegrad 65:931–938. https://doi.org/10.1016/j.ibiod.2011.07.001

Yang J, Li W, Ng TB, Deng X, Lin J, Ye X (2017) Laccases: production, expression regulation, and applications in pharmaceutical iodegradation. Front Microbiol 8. https://doi.org/10.3389/fmicb.2017.00832

Vasina DV, Mustafaev ON, Moiseenko KV, Sadovskaya NS, Glazunova OA, Tyurin АА, Fedorova TV, Pavlov AR, Tyazhelova TV, Goldenkova-Pavlova IV, Koroleva OV (2015) The Trametes hirsuta 072 laccase multigene family: genes identification and transcriptional analysis under copper ions induction. Biochimie. 116:154–164. https://doi.org/10.1016/j.biochi.2015.07.015

Badon MM, Tekverk DG, Vishnosky NS, Woolridge EM (2019) Establishing the oxidative tolerance of Thermomyces lanuginosus xylanase. J Appl Microbiol 127:508–519. https://doi.org/10.1111/jam.14306

Yu H, Li X, **ng Y, Liu Z, Jiang J (2014) A sequential combination of laccase pretreatment and enzymatic hydrolysis for glucose production from furfural residues. BioResources. 9:4581–4595

Hofrichter M (2002) Review: lignin conversion by manganese peroxidase (MnP). Enzym Microb Technol 30:454–466. https://doi.org/10.1016/S0141-0229(01)00528-2

Patel H, Gupte A, Gupte S (2009) Effect of different culture conditions and inducers on production of laccase by a basidiomycete fungal isolate Pleurotus ostreatus hp-1 under solid state fermentation. BioResources. 4:268–284

Kostadinova N, Krumova E, Boeva R, Abrashev R, Miteva-Staleva J, Spassova B, Angelova M (2018) Effect of copper ions on the ligninolytic enzyme complex and the antioxidant enzyme activity in the white-rot fungus Trametes trogii 46. Plant Biosyst Int J Deal Asp Plant Biol 152:1128–1133. https://doi.org/10.1080/11263504.2017.1418450

Vrsanska M, Voberkova S, Langer V, Palovcikova D, Moulick A, Adam V, Kopel P (2016) Induction of laccase, lignin peroxidase and manganese peroxidase activities in white-rot fungi using copper complexes. Molecules. 21. https://doi.org/10.3390/molecules21111553

Şeker UÖŞ, Catal T, Taptık Y, Tamerler C, Bermek H (2008) Enhanced production of manganese-peroxidase by the white-rot fungus Bjerkandera adusta using media engineering. Biotechnol Biotechnol Equip 22:844–848. https://doi.org/10.1080/13102818.2008.10817565

Catal T, Liu H, Bermek H (2008) Selenium induces manganese-dependent peroxidase production by the white-rot fungus Bjerkandera adusta (Willdenow) P Karsten. Biol Trace Elem Res 123:211–217. https://doi.org/10.1007/s12011-007-8084-5

Kumar M, Singhal A, Thakur IS (2016) Comparison of submerged and solid state pretreatment of sugarcane bagasse by Pandoraea sp. ISTKB: enzymatic and structural analysis. Bioresour Technol 203:18–25. https://doi.org/10.1016/j.biortech.2015.12.034

Salvachúa D, Katahira R, Cleveland NS, Khanna P, Resch MG, Black BA, Purvine SO, Zink EM, Prieto A, Martínez MJ, Martínez AT, Simmons BA, Gladden JM, Beckham GT (2016) Lignin depolymerization by fungal secretomes and a microbial sink. Green Chem 18:6046–6062. https://doi.org/10.1039/C6GC01531J

Vrsanska M, Buresova A, Damborsky P, Adam V, Influence of different inducers on ligninolytic enzyme activities. J Met Nanotechnol 3:64–70.

Djukić-Vuković A, Lazović S, Mladenović D, Knežević-Jugović Z, Pe** J, Mojović L (2019) Non-thermal plasma and ultrasound-assisted open lactic acid fermentation of distillery stillage. Environ Sci Pollut Res 26:35543–35554. https://doi.org/10.1007/s11356-019-04894-9

España-Gamboa E, Vicent T, Font X, Dominguez-Maldonado J, Canto-Canché B, Alzate-Gaviria L (2017) Pretreatment of vinasse from the sugar refinery industry under non-sterile conditions by Trametes versicolor in a fluidized bed bioreactor and its effect when coupled to an UASB reactor. J Biol Eng 11:6. https://doi.org/10.1186/s13036-016-0042-3

Fungal biotechnology in agricultural, food, and environmental applications, https://www.routledge.com/Fungal-Biotechnology-in-Agricultural-Food-and-Environmental-Applications/Arora/p/book/9780824747701

Potumarthi R, Baadhe RR, Nayak P, Jetty A (2013) Simultaneous pretreatment and saccharification of rice husk by Phanerochaete chrysosporium for improved production of reducing sugars. Bioresour Technol 128:113–117. https://doi.org/10.1016/j.biortech.2012.10.030

Wilk M, Krzywonos M, Borowiak D, Seruga P (2018) Decolourization of sugar beet molasses vinasse by lactic acid bacteria – the effect of yeast extract dosage. Pol J Environ Stud 28:385–392. https://doi.org/10.15244/pjoes/84861

Availability of data and material

All analyzed data are provided in the manuscript.

Funding

Research presented in this paper was funded by the Ministry of Education, Science and Technological Development, Republic of Serbia [Project #I-1]. It is a part of Scientific and Technological Collaboration of Republic of Serbia and People’s Republic of China.

Author information

Authors and Affiliations

Contributions

Contributed the idea for the research (Jelena Jović and Ljiljana Mojović); created models, performed the model analysis, conducted a research and performed the experiments, wrote original draft, and performed editing (Jelena Jović); performed some experiments, wrote original draft (Jian Hao and Sunčica Kocić-Tanackov); supervised the experiments, wrote, revised, and edited the manuscript (Ljiljana Mojović). All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to participate

Not applicable

Consent for publication

Not applicable

Code availability

Not applicable

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 240 kb)

Rights and permissions

About this article

Cite this article

Jović, J., Hao, J., Kocić-Tanackov, S. et al. Improvement of lignocellulosic biomass conversion by optimization of fungal ligninolytic enzyme activity and molasses stillage supplementation. Biomass Conv. Bioref. 12, 2749–2765 (2022). https://doi.org/10.1007/s13399-020-00929-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00929-1