Abstract

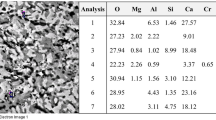

Possibility of utilizing bagasse ash (BA) as a filler for natural rubber (NR) and styrene–butadiene rubber (SBR) was investigated. Detailed measurement by several techniques was used to characterize. Various loadings of BA (0–30 phr) were then incorporated into NR and SBR. Morphology and properties of the BA filled rubbers were finally investigated. It was found that BA contained SiO\(_{2}\) as the major constituent with other metal oxides, such as CaO, Al\(_{2}\)O\(_{3}\) and K\(_{2}\)O, as the minor constituents. The average size of the particles and specific surface area of the BA were 48.8 \(\upmu \)m and 36.3 m\(^{2}\) g\(^{-1}\), respectively. When incorporated into the rubbers, both scorch and cure times decreased, whereas tensile modulus (\(M_{100})\) and hardness slightly increased with greater loadings of BA. Interestingly, tensile strength and tear strength did not significantly change with the addition of BA up to 30 phr. The results indicate the potential of using BA as a filler in the rubber industry for cost reduction and raising the environmental credentials of the product.

Similar content being viewed by others

References

Sae-oui, P.; Sirisinha, C.; Thepsuwan, U.; Hatthapanit, K.: Roles of silane coupling agents on properties of silica filled polychloroprene. Eur. Polym. J. 42, 479–486 (2006)

Siriwong, C.; Sae-oui, P.; Sirisinha, C.: Comparison of coupling effectiveness among amino-, chloro-, and mercapto silanes in chloroprene rubber. Polym. Test. 38, 64–72 (2014)

Prasertsri, S.; Rattanasom, N.: Fumed and precipitated silica reinforced natural rubber composites prepared from latex system: mechanical and dynamic properties. Polym. Test. 31, 593–605 (2012)

Feng, W.; Tang, Z.; Weng, P.; Gao, B.: Correlation of filler networking with reinforcement and dynamics properties of SSBR/carbon black/silica composites. Rubber Chem. Technol. 88, 676–689 (2015)

Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R.: Pozzolanic activity and filler effect of sugar cane bagasse ash in Portland cement and lime mortars. Cem. Concr. Compos. 30, 410–418 (2008)

Sae-oui, P.; Rakdee, C.; Thanmathorn, P.: Use of rice husk ash as filler in natural rubber vulcanizates: in comparison with other commercial fillers. J. Appl. Polym. Sci. 83(11), 2485–2493 (2002)

Sombatsompop, N.; Wimolmala, E.; Markpin, T.: Fly ash particles and precipitated silica as fillers in rubbers. I. Untreated filler in Natural rubber and styrene–butadiene rubber compounds. J. Appl. Polym. Sci. 93, 2119–2130 (2004)

Duchesne, J.; Reardon, E.J.: Lime treatment of fly ash: characterization of leachate composition and solid/water reaction. Waste Manag. 19, 221–231 (1999)

Janos, P.; Wildnerova, M.; Loucka, T.: Leaching of metal from fly ashes in the presence of complexing agents. Waste Manag. 22, 783–789 (2002)

Office of Cane and Sugar Board: Total cane crushing and sugar production 2006/2007 in Thailand. Report, Ministry of Industry, Thailand (2007)

Ganesan, K.; Rajagopal, K.; Thangavel, K.: Evaluation of bagasse ash as supplementary cementitious material. Cem. Concr. Compos. 29(6), 515–524 (2007)

Chusilp, N.; Jaturapitakkul, C.; Kiattikomol, K.: Utilization of bagasse ash as a pozzolanic material in concrete. Constr. Build. Mater. 23, 3352–3358 (2009)

Martirena, J.F.; Middendorf, B.; Gehrke, M.; Budelmann, H.: Use of wastes of sugar industry as pozzolana in lime–pozzolana binders: study of the reaction. Cem. Concr. Res. 28, 1525–1536 (1998)

Singh, N.B.; Singh, V.D.; Rai, S.: Hydration of bagasse ash-blended portland cement. Cem. Concr. Res. 30, 1485–1488 (2000)

Chindaprasirt, P.; Rukzon, S.: Utilization of bagasse ash in high-strength concrete. Mater. Des. 34, 45–50 (2012)

Payne, A.R.: Dynamic mechanical properties of filler loaded vulcanisates. Rubber Plast. Age 42, 963–967 (1691)

Siriwong, C.; Sae-Oui, P.; Sirisinha, C.: Performance comparison of various surface modifying agents on properties of silica-filled neoprene rubber. Rubber Chem. Technol. 90(1), 146–158 (2017)

Sumanda, B.; De, P.P.; Tripathy, D.K.; De, S.K.: Interaction between carboxylated nitrile rubber and precipitated silica: role of (3-aminopropyl) triethoxysilane. Rubber Chem. Technol. 69, 637–647 (1996)

Wolff, S.; Wang, M.J.; Tan, E.H.: Filler–elastomer interactions. Part VII. Study on bound rubber. Rubber Chem. Technol. 66, 163–177 (1993)

Lee, S.; Pawlowski, H.; Coran, A.Y.: Method for estimating the chemical crosslink densities of cured natural rubber and styrene–butadiene rubber. Rubber Chem. Technol. 67(5), 854–864 (1994)

Zhan, Y.; Wu, J.; **a, H.; Yan, N.; Fei, G.; Yuan, G.: Dispersion and exfoliation of graphene in rubber by an ultrasonically-assisted latex mixing and in situ reduction process. Macromol. Mater. Eng. 296(7), 590–602 (2011)

Abd-El-Messieh, S.L.; Abd-El-Nour, K.N.: Effect of curing time and sulfur content on the dielectric relaxation of styrene–butadiene rubber. J. Appl. Polym. Sci. 88, 1613–1621 (2003)

Sae-oui, P.; Sirisinha, C.; Thepsuwan, U.; Hatthapanit, K.: Dependence of mechanical and ageing properties of chloroprene rubber on silica and ethylene thiourea loadings. Eur. Polym. J. 43, 185–193 (2007)

Premalal, H.G.B.; Ismail, H.; Baharin, A.: Comparison of the mechanical properties of rice husk powder filled polypropylene composites with talc filled polypropylene composites. Polym. Test. 21(7), 833–839 (2002)

Boonstra, B.B.: Rubber Technology and Manufacture. In: Blow CM. (ed). Chapter 7. Butterworth, London (1971)

Morton, M.: Rubber technology. In: Van Nostrand Reinhold, 3rd ed, p. 90. New York (1987)

Ismail, H.; Shaari, S.; Othman, N.: The effect of chitosan loading on the curing characteristics, mechanical and morphological properties of chitosanfilled natural rubber (NR), epoxidised natural rubber (ENR) and styrenebutadiene rubber (SBR) compounds. Polym. Test. 30, 784–790 (2011)

Chough, S.H.; Chang, D.H.: Kinetics of sulfur vulcanization of NR, BR, SBR, and their blends using a rheometer and DSC. J. Appl. Polym. Sci. 61, 449–454 (1996)

Intiya, W.; Thepsuwan, U.; Sirisinha, C.; Sae-oui, P.: Possible use of sludge ash as filler in natural rubber. J. Mater. Cycles Waste Manag. 19(2), 774–781 (2017)

Acknowledgements

Financial and instrumental supports from Research Center for Environmental and Hazardous substance management, Faculty of Engineering Khon Kaen University and Polymer Research and Development Co., Ltd are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pangamol, P., Malee, W., Yujaroen, R. et al. Utilization of Bagasse Ash as a Filler in Natural Rubber and Styrene–Butadiene Rubber Composites. Arab J Sci Eng 43, 221–227 (2018). https://doi.org/10.1007/s13369-017-2859-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-017-2859-6