Abstract

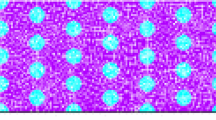

An EN31 steel-based metal matrix composite material has been developed with different reinforcements weight percentages by using ultrasonic vibration effect. In the present investigation, three material powders, namely primary reinforced element zirconia-toughened alumina (ZTA), secondary reinforced element chromite (FeCr2O4) and dissolving reinforcement element nickel (Ni), have been utilized as the reinforcement particles. Further, the weight percentage of primary reinforced element zirconia-toughened alumina (ZTA) was varied between 1.25 and 10wt.% during the development of composite material. Further, 2.5wt.% of secondary reinforced particle (chromite (FeCr2O4)) and dissolving reinforced particle nickel (Ni) was kept constant. The dissolving reinforced particle nickel (Ni) improved the wettability of ZTA and FeCr2O4 particles. The microstructural observation revealed that the ultrasonic vibration effect has fairly distributed the reinforcement particles in the matrix material. Further, the heat treatment process has also been performed on the developed composite material samples. The higher tensile strength has been observed for the composite composition of EN31/6.25 wt. % ZTA/2.5 wt. %FeCr2O4/2.5 wt. % Ni (for heat-treated (890.34 MPa) and without heat-treated (804.78 MPa)). Further, the heat treatment enhanced the EN31 matrix material tensile strength by about 44.06%. In addition, a representative volume element (RVE)-based finite element analysis (FEA) model has been developed for the heat-treated EN31/6.25 wt. % ZTA/2.5 wt. % FeCr2O4 metal matrix composite sample to analyze its tensile deformation behavior. Further, the results revealed that the matrix–reinforcement interfaces exhibited more stress (904.48 MPa) than only matrix material.

Similar content being viewed by others

References

Y. Sui, M. Zhou, Y. Jiang, Characterization of interfacial layer of ZTA ceramic particles reinforced iron matrix composites, J. Alloy. Comp. 741 (2018) 1169e1174.

N. Mandal, B. Doloi, B. Mondal, Force prediction model of Zirconia Toughened Alumina (ZTA) inserts in hard turning of AISI 4340 steel using response surface methodology, Int. J. Precis. Eng. Manuf. 13 (2012) 1589e1599.

J. P. Meng, Z.Q. Fu, X. P Liu, W. Yue and C. B. Wang, Influence of ion/atom arrival ratio on structure and optical properties of AlN films by ion beam assisted deposition Appl. Surf. Sci. 31 (2014) 7760-764.

J. Ru, H. He, Y.H. Jiang, R. Zhou and Y.X. Hua, Ionic Liquid-Assisted Preparation of Ni–Cr Dual Wrapped ZTA Particles for Reinforced Iron-Based Composites, Adv. Eng. Mater. 21 (2019) 1801120.

J. Rajaparthiban, M. Ravichandran, B. Stalin, P. Ramesh Kumar, V. Mohanavel, Machining of EN31 Steel Using Carbide Insert – A Statistical Approach, Mater. Today:. Proc. 22 (2020) 2559-2564.

R.K. Gunda, S. K. R. Narala, V.K.V. Kolipakula, S.R. Goda, Experimental investigation to study the performance of solid lubricant during turning EN31 steel and Ti-6Al-4V alloy, Mater. Today: Proc.28 (2020) 1227-1230.

Y.H. Lee, N. Kim, S.B. Lee, Y. Kim, S. Choa, S.K. Lee, I. Jo, Microstructure and mechanical properties of lightweight TiC-steel composite prepared by liquid pressing infiltration process, Mater. Charact.162 (2020) 110202.

Q. Hu, Y. Gao, X. Meng, Y. Diao, Axial compression of steel–timber composite column consisting of H-shaped steel and glulam, Eng. Struct. 216 (2020) 110561.

W. Liu, L. Zhang, Y. Ma, Q. Cai, W. Zhu, R. Wang, Z. Wen, Low temperature co–sintering of tungsten alloy/steel composite structure, nt. J. Refract. Met. Hard Mater. 90 (2020) 105224.

L. Fan, Q. Wang, P. Yang, H.H. Chen, H.P. Hong, W.T. Zhang, J. Ren, Preparation of nickel coating on ZTA particles by electroless plating, Ceram. Int.44 (2018)11013–11021.

S.P. Dwivedi, Effect of ball-milled MgO and Si3N4 addition on the physical, mechanical and thermal behaviour of aluminium based composite developed by hybrid casting technique. Int. J. Cast Met. Res. 33 (2020) 35-49.

S.P. Dwivedi, A. Saxena, Extraction of collagen powder from chrome containing leather waste and its composites with alumina employing different casting techniques, Mater. Chem. Phys. 253 (2020) 123274.

N. Lotfian, A. Nourbakhsh, S.N. Mirsattari, A. Saberi, K.D. Mackenzie, A comparison of the effect of nanostructured MgCr2O4 and FeCr2O4 additions on the microstructure and mechanical properties of direct-bonded magnesia-chrome refractories. Ceram. Int., 46 (2020) 747-754.

Miletich, Ronald, ed. Mineral behaviour at extreme conditions. Vol. 7. The Mineralogical Society of Great Britain and Ireland, 2005.

A. Saxena, S. P. Dwivedi, N. K. Maurya, and A. K. Srivastava. Proc. Inst. Mech. Eng. L P I Mech Eng L-J Mat. (2021): 14644207211009254.

R. Riedel, Handbook of Ceramic Hard Materials, Wiley, Germany, 2000, p. 649.

A. Saxena, A. Kumaraswamy, G. M. Reddy, V. Madhu. "Influence of welding consumables on tensile and impact properties of multi-pass SMAW Armox 500T steel joints vis-a-vis base metal." DEF. TECHNOL.14(2018)188-195.

A. Saxena, A. Kumaraswamy, S.P. Dwivedi, A.K. Srivastava, N.K. Maurya. Experimental and computational investigation on dynamic fracture toughness (J1d) behavior of multi-pass SMA armor steel weldments. Theor. Appl. Fract. Mech.106 (2020)102502.

T Mori, K. Tanaka. “Average stress in matrix and average elastic energy of materials with misfitting inclusions”. Acta. Metall., 21 (1973) 571-574.

A. Saxena, A. Kumaraswamy, S.P. Dwivedi, A.K. Srivastava, N.K. Maurya, M. Pandey. “Experimental and Numerical Investigation of Quasi-Static (10−3 s− 1) Fracture Behavior of Armor Steel”. ARAB. J. SCI. ENG.45 (2020) 5623–5629.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Saxena, A., Dwivedi, S.P., Srivastava, A.K. et al. Micro-Mechanical Finite Element Analysis on Mechanical Behavior of EN31 Steel-Based Metal Matrix Composite. Trans Indian Inst Met 76, 685–694 (2023). https://doi.org/10.1007/s12666-022-02691-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02691-6