Abstract

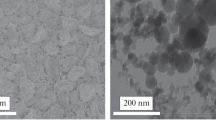

This work presents the results revealing the possibility of obtaining a cubic phase of silicon carbide with features of a biomorphic structure. Renewable plant raw materials were used as a source of carbon, in particular, pyrolyzed sawdust, which is a waste of a timber enterprise. Silicon dioxide powder was used as a source of silicon. The synthesis was realized using DC arc discharge plasma initiated in an open air. In this case, the oxidation of the synthesis products was prevented due to the effect of the reaction volume self-shielding from atmospheric oxygen. It was possible due to the generation of protective gaseous medium predominantly consisting of carbon dioxide and monoxide. The dependences of the product phase composition on the supplied energy and composition of initial components were established. The synthesis product was characterized by a significant excess of carbon, which was a caused by the erosion of the electrodes. After removal of chemically unbound carbon from synthesis product by annealing in an atmospheric furnace at 850 °C, obtained powder was sintered by the spark plasma sintering method. In the result, a bulk ceramic sample was obtained in which the only one crystalline phase of silicon carbide with a lattice parameter of 4.359 Å was identified.

Graphic Abstract

Similar content being viewed by others

Data Availability

Data available within the article or its supplementary materials.

References

Yu, M., Zhang, G.J., Saunders, T.: Wood-derived ultra-high temperature carbides and their composites: a review. Ceram. Int. 46, 5536–5547 (2020). https://doi.org/10.1016/j.ceramint.2019.11.104

Jayakumari, S., Vullum, P.E., van Helvoort, A.T.J., Tangstad, M.: SiC crystalline micro bullets on bio-carbon based charcoal substrate. J. Cryst. Growth. 545, 125740 (2020). https://doi.org/10.1016/j.jcrysgro.2020.125740

Kaarik, M., Arulepp, M., Kook, M., Kozlova, J., Ritslaid, P., Aruvali, J., Maeorg, U., Sammelselg, V., Leis, J.: High-performance microporous carbon from deciduous wood-origin metal carbide. Microporous Mesoporous Mater. 278, 14–22 (2019). https://doi.org/10.1016/j.micromeso.2018.11.010

Gomez-Martín, A., Orihuela, M.P., Becerra, J.A., Martinez-Fernandez, J., Ramirez-Rico, J.: Permeability and mechanical integrity of porous biomorphic SiC ceramics for application as hot-gas filters. Mater. Des. 107, 450–460 (2016). https://doi.org/10.1016/j.matdes.2016.06.060

Kormann, M., Gerhard, H., Popovska, N.: Comparative study of carbide-derived carbons obtained from biomorphic TiC and SiC structures. Carbon 47, 242–250 (2009). https://doi.org/10.1016/j.carbon.2008.10.002

Kim, J.W., Myoung, S.W., Kim, H.C., Lee, J.H., Jung, Y.G., Jo, C.Y.: Synthesis of SiC microtubes with radial morphology using biomorphic carbon template. Mater. Sci. Eng. A 434, 171–177 (2006). https://doi.org/10.1016/j.msea.2006.06.135

Qian, J., Wang, J., Hou, G., Qiao, G., **, Z.: Preparation and characterization of biomorphic SiC hollow fibers from wood by chemical vapor infiltration. Scr. Mater. 53, 1363–1368 (2005). https://doi.org/10.1016/j.scriptamat.2005.08.029

Lee, D.J., Jang, J.J., Park, H.S., Kim, Y.C., Lim, K.H., Park, S.B., Hong, S.H.: Fabrication of biomorphic SiC composites using wood preforms with different structures. Ceram. Int. 38, 3089–3095 (2012). https://doi.org/10.1016/j.ceramint.2011.12.008

Streitwieser, D.A., Popovska, N., Gerhard, H., Emig, G.: Application of the chemical vapor infiltration and reaction (CVI-R) technique for the preparation of highly porous biomorphic SiC ceramics derived from paper. J. Eur. Ceram. Soc. 25, 817–828 (2005). https://doi.org/10.1016/j.jeurceramsoc.2004.04.006

Pappacena, K.E., Gentry, S.P., Wilkes, T.E., Johnson, M.T., **e, S., Davis, A., Faber, K.T.: Effect of pyrolyzation temperature on wood-derived carbon and silicon carbide. J. Eur. Ceram. Soc. 29, 3069–3077 (2009). https://doi.org/10.1016/j.jeurceramsoc.2009.04.040

Qian, J., Wang, J., **, Z.: Preparation of biomorphic SiC ceramic by carbothermal reduction of oak wood charcoal. Mater. Sci. Eng. A 371, 229–235 (2004). https://doi.org/10.1016/j.msea.2003.11.051

Presas, M., Pastor, J.Y., Llorca, J., Arellano Lopez, A.R., Martınez Fernandez, J., Sepulveda, R.: Microstructure and fracture properties of biomorphic SiC. Int. J. Refract. Met. Hard Mater. 24, 49–54 (2006). https://doi.org/10.1016/j.ijrmhm.2005.07.003

Bautista, M.A., Quispe Cancapa, J., Martinez Fernandez, J., Rodriguez, M.A., Singh, M.: Microstructural and mechanical evaluation of porous biomorphic silicon carbide for high temperature filtering applications. J. Eur. Ceram. Soc. 31, 1325–1332 (2011). https://doi.org/10.1016/j.jeurceramsoc.2010.06.014

Li, J., Yu, S., Ge, M., Wei, X., Qian, Y., Zhou, Y., Zhang, W.: Fabrication and characterization of biomorphic cellular C/SiC–ZrC composite ceramics from wood. Ceram. Int. 41, 7853–7859 (2015). https://doi.org/10.1016/j.ceramint.2015.02.122

Borrajo, J.P., Serra, J., Liste, S., Gonzalez, P., Chiussi, S., Leon, B., Perez-Amor, M.: Pulsed laser deposition of hydroxylapatite thin films on biomorphic silicon carbide ceramics. Appl. Surf. Sci. 248, 355–359 (2005). https://doi.org/10.1016/j.apsusc.2005.03.051

Hou, G., **, Z., Qian, J.: Effect of starting Si contents on the properties and structure of biomorphic SiC ceramics. J. Mater. Process. Technol. 182, 34–38 (2007). https://doi.org/10.1016/j.jmatprotec.2006.07.003

Pavon, J.M.C., Alonso, E.V., Cordero, M.T.S., Torres, A.G.B., López-Cepero, J.M.: Use of spectroscopic techniques for the chemical analysis of biomorphic silicon carbide ceramics. Anal. Chim. Acta. 528, 129–134 (2005). https://doi.org/10.1016/j.aca.2004.09.090

Qian, J.M., Wang, J.P., Qiao, G.J., **, Z.H.: Preparation of porous SiC ceramic with a woodlike microstructure by sol-gel and carbothermal reduction processing. J. Eur. Ceram. Soc. 24, 3251–3259 (2004). https://doi.org/10.1016/j.jeurceramsoc.2003.10.042

Wu, H., Zhang, T., Li, Y.: Fabrication of biomorphic ZrC/C ceramics by sol–gel and carbothermal reduction processing. Ceram. Int. 41, 13034–13041 (2015). https://doi.org/10.1016/j.ceramint.2015.07.004

Li, Y., **e, S., Wei, B., Lian, G., Zhou, W., Tang, D., Zou, X., Liu, X., Wang, G.: Aligned small α-SiC nanorods on β-SiC particles grown in an arc-discharge. Solid State Commun. 119, 51–53 (2001). https://doi.org/10.1016/S0038-1098(01)00196-X

Li, Y.B., **e, S.S., Zou, X.P., Tang, D.S., Liu, Z.Q., Zhou, W.Y., Wang, G.: Large-scale synthesis of β-SiC nanorods in the arc-discharge. J. Cryst. Growth. 233, 125–128 (2001). https://doi.org/10.1016/S0022-0248(01)00597-8

Chiu, S.C., Huang, C.W., Li, Y.Y.: Synthesis of high-purity silicon carbide nanowires by a catalyst-free arc-discharge method. J. Phys. Chem. C 111, 10294–10297 (2007). https://doi.org/10.1021/jp0687192

Pak, A., Ivashutenko, A., Zakharova, A., Vassilyeva, Y.: Cubic SiC nanowire synthesis by DC arc discharge under ambient air conditions. Surf. Coat. Technol. 387, 125554 (2020). https://doi.org/10.1016/j.surfcoat.2020.125554

Pak, A., Shanenkov, I., Mamontov, G., Kokorina, A.: Vacuumless synthesis of tungsten carbide in a self-shielding atmospheric plasma of DC arc discharge. Int. J. Refract. Met. Hard Mater. 93, 105343 (2020). https://doi.org/10.1016/j.ijrmhm.2020.105343

Su, Y., Wei, H., Li, T., Geng, H., Zhang, Y.: Low-cost synthesis of single-walled carbon nanotubes by low-pressure air arc discharge. Mater. Res. Bull. 50, 23–25 (2014). https://doi.org/10.1016/j.materresbull.2013.10.013

Joseph Berkmans, A., Jagannatham, M., Rohit Reddy, D., Haridoss, P.: Synthesis of thin bundled single walled carbon nanotubes and nanohorn hybrids by arc discharge technique in open air atmosphere. Diamond Relat. Mater. 55, 12–15 (2015). https://doi.org/10.1016/j.diamond.2015.02.004

Zhao, J., Wei, L., Yang, Z., Zhang, Y.: Continuous and low-cost synthesis of high-quality multi-walled carbon nanotubes by arc discharge in air. Phys. E 44, 1639–1643 (2012). https://doi.org/10.1016/j.physe.2012.04.010

Arora, N., Sharma, N.N.: Arc discharge synthesis of carbon nanotubes: comprehensive review. Diamond Relat. Mater. 50, 135–150 (2014). https://doi.org/10.1016/j.diamond.2014.10.001

Chiu, S.C., Huang, C.W., Li, Y.Y.: SiC nanowires by a catalyst-free arc-discharge method. J. Phys. Chem. C 111, 10294–10297 (2007). https://doi.org/10.1021/jp0687192

Liang, C.H., Meng, G.W., Zhang, L.D., Wu, Y.C., Cui, Z.: Large-scale synthesis of b-SiC nanowires by using mesoporous silica embedded with Fe nanoparticles. Chem. Phys. Lett. 329, 323–328 (2000). https://doi.org/10.1016/S0009-2614(00)01023-X

Yang, W., Araki, H., Thaveethavorn, S.H., Suzuki, T.: Noda, in situ synthesis and characterization of pure SiC nanowires on silicon wafer. Appl. Surf. Sci. 241, 236–240 (2005). https://doi.org/10.1016/j.apsusc.2004.09.039

Hao, Y.J., **, G.Q., Han, X.D., Guo, X.Y.: Synthesis and characterization of bamboo-like SiC nanofibers. Mater. Lett. 60, 1334–1337 (2006). https://doi.org/10.1016/j.matlet.2005.10.115

Eom, J.H., Kim, Y.W., Song, I.H.: Effects of the initial-SiC content on the microstructure, mechanical properties, and permeability of macroporous silicon carbide ceramics. J. Eur. Ceram. Soc. 32, 1283–1290 (2012). https://doi.org/10.1016/j.jeurceramsoc.2011.11.040

Funding

Synthesis of the studied samples was carried out with the financial support of Tomsk Polytechnic University development program. The physicochemical characteristics of the studied samples was studied with the financial support of the Ministry of Science and Higher Education of the Russian Federation within the framework of the project No. 075-00268-20-02 (ID: 07180-2020-0040).

Author information

Authors and Affiliations

Contributions

AYP—direct current plasma arc processing of samples, writing—original draft. KBL—wood waste biochar samples acquisition and characterization. APK—XRD data acquisition and interpretation, plasma arc processing data analysis. TYY—SEM and EDS results acquisition and interpretation. SAY—DTA-TG data acquisition and interpretation. VEG—idea and design of article, general supervision. KVS—writing. AAG—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known conflict or competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Pak, A.Y., Larionov, K.B., Korchagina, A.P. et al. Advanced Arc Plasma Synthesis of Biomorphic Silicon Carbide Using Charcoal and Silicon Dioxide in Air. Waste Biomass Valor 13, 107–115 (2022). https://doi.org/10.1007/s12649-021-01517-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01517-8