Abstract

Silicon has been considered as one of the most promising anode materials due to its ultra-high specific capacity and moderate operating voltage. However, the huge volume variation and poor electronic conductivity that hindered its further practical applications. Preparing composite materials that combine multi-type advantages is an effective approach. Herein, a silicon/germanium/graphite@amorphous carbon (Si/Ge/G@C) composite anode material that combines the advantages of Si, Ge and carbon materials was prepared via a simple ball milling and high temperature annealing method, which exhibit a porous structure. The synergistic effect of Si, Ge, and carbon materials plays an important role in the composite, where Si and Ge both have high specific capacity, Ge improves the electronic conductivity, and carbon accelerates the electron transfer and effectively buffers the volume variation after lithiation and delithiation. As expected, the Si/Ge/G@C composite electrode exhibited excellent cycling stability with an initial discharge specific capacity of 1165.2 mAh g−1 and a high reversible capacity of 706.0 mAh g−1 after 100 cycles. At the same time, the good rate performance can be observed under different current densities from 100 to 600 mA g−1. The EIS results of the Si/Ge/G@C composite electrode suggest the formation of stable SEI layer on electrodes. This work demonstrates a facile and cost-effective approach to prepare high performance electrode with multi-type advantages for lithium ion batteries. The electrode with high specific capacity, good electronic conductivity and enhanced cycling stability was obtained by simple composite method. This research provides a new perspective for the mass production of high-performance LIB anodes for applications.

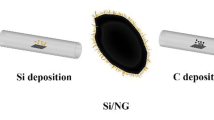

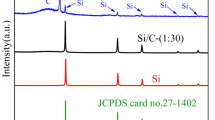

Graphical abstract

Similar content being viewed by others

Data Availability

All the data supporting the findings of this work are available in the manuscript.

References

Wan M, Kang S, Wang L, Lee HW, Zheng GW, Cui Y, Sun Y (2020) Mechanical rolling formation of interpenetrated lithium metal/lithium tin alloy foil for ultrahigh-rate battery anode. Nat Commun 11:829. https://doi.org/10.1038/s41467-020-14550-3

Geng L, Yang D, Gao S, Zhang Z, Sun F, Pan Y, Li S, Li X, Cao PF, Yang H (2019) Facile fabrication of porous Si microspheres from low-cost precursors for high-capacity electrode. Adv Mater Interfaces 7(3):1901726. https://doi.org/10.1002/admi.201901726

Yang W, Liu H, Ren Z, Jian N, Gao M, Wu Y, Liu Y, Pan H (2019) A novel multielement, multiphase, and B-containing SiOx composite as a stable anode material for Li-ion batteries. Adv Mater Interfaces 6(5):1801613. https://doi.org/10.1002/admi.201801631

Pandit B, Sankapal BR (2022) Cerium selenide Nanopebble/multiwalled carbon nanotube composite electrodes for solid-state symmetric supercapacitors. ACS Appl Nano Mat 5:3007–3017. https://doi.org/10.1021/acsanm.2c00374

Pandit B, Rondiya SR, Cross RW, Dzade NY, Sankapal BR (2022) Vanadium telluride nanoparticles on MWCNTs prepared by successive ionic layer adsorption and reaction for solid-state supercapacitor. Chem Eng J 429:132505. https://doi.org/10.1016/j.cej.2021.132505

Pandit B, Goda ES, Abu Elella MH, ur Rehman A, Eun Hong S, Rondiya SR, Barkataki P, Shaikh SF, Al-Enizi AM, El-Bahy SM, Ro Yoon K (2022) One-pot hydrothermal preparation of hierarchical manganese oxide nanorods for high-performance symmetric supercapacitors. J Energy Chem 65:116–126. https://doi.org/10.1016/j.jechem.2021.05.028

Pandit B, Agarwal A, Patel P, Sankapal BR (2021) The electrochemical kinetics of cerium selenide nano-pebbles: the design of a device-grade symmetric configured wide-potential flexible solid-state supercapacitor. Nanoscale Adv 3:1057–1066. https://doi.org/10.1039/d0na00893a

Jamil MA, Ali G, Khan KI, Jan Iftikhar F, Zaman S, Shaikh SF, Pandit B, Wali Q, Patil SA (2022) Highly efficient tin fluoride nanocomposite with conductive carbon as a high performance anode for Li-ion batteries. J Alloys Compd 900:163447. https://doi.org/10.1016/j.jallcom.2021.163447

Bashir T, Ismail SA, Song Y, Irfan RM, Yang S, Zhou S, Zhao J, Gao L (2021) A review of the energy storage aspects of chemical elements for lithium-ion based batteries. Energy Mat 1:100019. https://doi.org/10.20517/energymater.2021.20

Pandit B, Fraisse B, Stievano L, Monconduit L, Sougrati MT (2022) Carbon-coated FePO4 nanoparticles as stable cathode for Na-ion batteries: a promising full cell with a Na15Pb4 anode. Electrochim Acta 409(20):139997. https://doi.org/10.1016/j.electacta.2022.139997

Martínez-Cisneros CS, Pandit B, Antonelli C, Sanchez JY, Levenfeld B, Varez A (2021) Development of sodium hybrid quasi-solid electrolytes based on porous NASICON and ionic liquids. J Eur Ceram Soc 41:7723–7733. https://doi.org/10.1016/j.jeurceramsoc.2021.08.001

Pandit B, Sougrati MT, Fraisse B, Monconduit L (2022) Exploration of a Na3V2(PO4)3/C –Pb full cell Na-ion prototype. Nano Energy 95:107010. https://doi.org/10.1016/j.nanoen.2022.107010

Pandit B, Rondiya SR, Dzade NY, Shaikh SF, Kumar N, Goda ES, Al-Kahtani AA, Mane RS, Mathur S, Salunkhe RR (2021) High stability and long cycle life of rechargeable sodium-ion battery using manganese oxide cathode: a combined density functional theory (DFT) and experimental study. ACS Appl Mat Interf 13:11433–11441. https://doi.org/10.1021/acsami.0c21081

Pandit B, Goda E S, Ubaidullah M, Shaikh S F, Nakate U T, Khedulkar A P, Rana AUHS, Kumar D, and Doong R-A (2022) Hexagonal δ-MnO2 nanoplates as efficient cathode material for potassium-ion batteries. Ceram Int 48:28856–28863. https://doi.org/10.1016/j.ceramint.2022.03.279

Wang J, **a Y, Liu Y, Li W, Zhao D (2019) Mass production of large-pore phosphorus-doped mesoporous carbon for fast-rechargeable lithium-ion batteries. Energy Storage Mat 22:147–153. https://doi.org/10.1016/j.ensm.2019.01.008

Wagner NP, Tron A, Tolchard JR, Noia G, Bellmann MP (2019) Silicon anodes for lithium-ion batteries produced from recovered kerf powders. J Power Sources 414:486–494. https://doi.org/10.1016/j.jpowsour.2019.01.035

Xu ZL, Liu X, Luo Y, Zhou L, Kim JK (2017) Nanosilicon anodes for high performance rechargeable batteries. Prog Mater Sci 90:1–44. https://doi.org/10.1016/j.pmatsci.2017.07.003

Pan Y, Gao S, Sun F, Yang H, Cao P (2019) Polymer binders constructed via dynamic non-covalent bonds for high-capacity silicon-based anodes. Chem Eur J 25:10976–10994. https://doi.org/10.1002/chem.201900988

Zhou Z, Pan L, Liu Y, Zhu X, **e X (2019) From sand to fast and stable silicon anode: synthesis of hollow Si@void@C yolk-shell microspheres by aluminothermic reduction for lithium storage. Chin Chem Lett 30:610–617. https://doi.org/10.1016/j.cclet.2018.08.018

Zhu B, Wang X, Yao P, Li J, Zhu J (2019) Towards high energy density lithium battery anodes: silicon and lithium. Chem Sci 10:7132–7148. https://doi.org/10.1039/c9sc01201j

Ai Q, Li D, Guo J, Hou G, Sun Q, Sun Q, Xu X, Zhai W, Zhang L, Feng J et al (2019) Artificial solid electrolyte interphase coating to reduce Lithium trap** in silicon anode for high performance Lithium-ion batteries. Adv Mater Interfaces 6(21):1901187. https://doi.org/10.1002/admi.201901187

Guo Z, Zhao Y, Cai Y, Hou P, Zhao L, Wang B, Liu B, Wei Y (2019) A low-cost and energy-saving preparation method for silicon derived from rice husks and lithium ion battery applications. Mater Res Express 6:045505. https://doi.org/10.1088/2053-1591/aafa59

Liu T, Tong CJ, Wang B, Liu LM, Zhang S, Lin Z, Wang D, Lu J (2019) Trifunctional electrode additive for high active material content and volumetric Lithium-ion electrode densities. Adv Energy Mater 9(10):1803390. https://doi.org/10.1002/aenm.201803390

Jia H, Zheng J, Song J, Luo L, Yi R, Estevez L, Zhao W, Patel R, Li X, Zhang JG (2018) A novel approach to synthesize micrometer-sized porous silicon as a high performance anode for lithium-ion batteries. Nano Energy 50:589–597. https://doi.org/10.1016/j.nanoen.2018.05.048

Lang J, Ding B, Zhu T, Su H, Luo H, Qi L, Liu K, Wang K, Hussain N, Zhao C et al (2016) Cycling of a Lithium-ion battery with a silicon anode drives large mechanical actuation. Adv Mater 28:10236–10243. https://doi.org/10.1002/adma.201603061

Han Y, Lin N, Qian Y, Zhou J, Tian J, Zhu Y, Qian Y (2016) A scalable synthesis of N-doped Si nanoparticles for high-performance Li-ion batteries. Chem Commun (Camb) 52:3813–3816. https://doi.org/10.1039/c6cc00253f

Gao S, Sun F, Brady A, Pan Y, Erwin A, Yang D, Tsukruk V, Stack AG, Saito T, Yang H, Cao PF (2020) Ultra-efficient polymer binder for silicon anode in high-capacity lithium-ion batteries. Nano Energy 73:1044804. https://doi.org/10.1016/j.nanoen.2020.104804

Chen H, Ling M, Hencz L, Ling HY, Li G, Lin Z, Liu G, Zhang S (2018) Exploring chemical, mechanical, and electrical functionalities of binders for advanced energy-storage devices. Chem Rev 118:8936–8982. https://doi.org/10.1021/acs.chemrev.8b00241

Ling M, Qiu J, Li S, Yan C, Kiefel MJ, Liu G, Zhang S (2015) Multifunctional SA-PProDOT binder for Lithium ion batteries. Nano Lett 15:4440–4447. https://doi.org/10.1021/acs.nanolett.5b00795

Cao PF, Yang G, Li B, Zhang Y, Zhao S, Zhang S, Erwin A, Zhang Z, Sokolov AP, Nanda J, Saito T (2019) Rational Design of a Multifunctional Binder for high-capacity silicon-based anodes. ACS Energy Lett 4:1171–1180. https://doi.org/10.1021/acsenergylett.9b00815

Zeng L, Liu R, Han L, Luo F, Chen X, Wang J, Qian Q, Chen Q, Wei M (2018) Preparation of a Si/SiO2 -ordered-mesoporous-carbon nanocomposite as an anode for high-performance Lithium-ion and sodium-ion batteries. Chem Eur J 24:4841–4848. https://doi.org/10.1002/chem.201704780

Zhang H, Zong P, Chen M, ** H, Bai Y, Li S, Ma F, Xu H, Lian K (2019) (2019) in-situ synthesis of multilayer carbon matrix decorated with copper particles: enhancing the performance of Si as anode for Li-ion batteries. ACS Nano 13:3054–3306. https://doi.org/10.1021/acsnano.8b08088

Yang X, Ma H, Zhang G, Li X (2019) Silica/carbon composites with controllable nanostructure from a facile one-step method for Lithium-ion batteries application. Adv Mater Interfaces 6(6):1801809. https://doi.org/10.1002/admi.201801809

Xu K, Zhang Z, Su W, Wei Z, Zhong G, Wang C, Huang X (2017) Alumina coated nano silicon synthesized by aluminothermic reduction as anodes for lithium ion batteries. Funct Mater Lett 10:1650073. https://doi.org/10.1142/S1793604716500739

Mishra K, Zheng J, Patel R, Estevez L, Jia H, Luo L, El-Khoury PZ, Li X, Zhou XD, Zhang JG (2018) High performance porous Si@C anodes synthesized by low temperature aluminothermic reaction. Electrochim Acta 269:509–516. https://doi.org/10.1016/j.electacta.2018.02.166

Du FH, Li B, Fu W, **ong Y, Wang KX, Chen JS (2014) Surface binding of polypyrrole on porous silicon hollow nanospheres for Li-ion battery anodes with high structure stability. Adv Mater 26:6145–6150. https://doi.org/10.1002/adma.201401937

Wang B, Ryu J, Choi S, Zhang X, Pribat D, Li X, Zhi L, Park S, Ruoff RS (2019) Ultrafast-charging silicon-based coral-like network anodes for Lithium-ion batteries with high energy and power densities. ACS Nano 13:2307–2315. https://doi.org/10.1021/acsnano.8b09034

Wang MS, Wang GL, Wang S, Zhang J, Wang J, Zhong W, Tang F, Yang ZL, Zheng J, Li X (2019) In situ catalytic growth 3D multi-layers graphene sheets coated nano-silicon anode for high performance lithium-ion batteries. Chem Eng J 356:895–903. https://doi.org/10.1016/j.cej.2018.09.110

Nzabahimana J, Chang P, Hu X (2019) Porous carbon-coated ball-milled silicon as high-performance anodes for lithium-ion batteries. J Mater Sci 54:4798–4810. https://doi.org/10.1007/s10853-018-3164-9

Li P, Hwang JY, Sun YK (2019) Nano/microstructured silicon-graphite composite anode for high-energy-density Li-ion battery. ACS Nano 13:2624–2633. https://doi.org/10.1021/acsnano.9b00169

Ma T, Xu H, Yu X, Li H, Zhang W, Cheng X, Zhu W, Qiu X (2019) Lithiation behavior of coaxial hollow Nanocables of carbon-silicon composite. ACS Nano 13:2274–2280. https://doi.org/10.1021/acsnano.8b08962

Du FH, Wang KX, Chen JS (2016) Strategies to succeed in improving the lithium-ion storage properties of silicon nanomaterials. J Mater Chem A 4:32–50. https://doi.org/10.1039/c5ta06962a

Wang X, Ma L, Ji Q, Meng JQ, Liang S, Xu Z, Wang M, Zuo X, **ao Y, Zhu J et al (2019) MnO/metal/carbon Nanohybrid Lithium-ion battery anode with enhanced electrochemical performance: universal facile scalable synthesis and fundamental understanding. Adv Mater Interfaces 6(12):1900335. https://doi.org/10.1002/admi.201900335

Yang D, Shi J, Shi J, Yang H (2018) Simple synthesis of Si/Sn@C-G anodes with enhanced electrochemical properties for Li-ion batteries. Electrochim Acta 259:1081–1088. https://doi.org/10.1016/j.electacta.2017.10.117

Zhang T, Gao J, Fu LJ, Yang LC, Wu YP, Wu HQ (2007) Natural graphite coated by Si nanoparticles as anode materials for lithium ion batteries. J Mater Chem 17:1321–1325. https://doi.org/10.1039/b612967f

Yang LC, Gao QS, Li L, Tang Y, Wu YP (2010) Mesoporous germanium as anode material of high capacity and good cycling prepared by a mechanochemical reaction. Electrochem Commun 12:418–421. https://doi.org/10.1016/j.elecom.2010.01.008

Yin S, Zhao D, Ji Q, **a Y, **a S, Wang X, Wang M, Ban J, Zhang Y, Metwalli E et al (2018) Si/ag/C Nanohybrids with in situ incorporation of super-small silver nanoparticles: tiny amount, huge impact. ACS Nano 12:861–875. https://doi.org/10.1021/acsnano.7b08560

Yang Y, Liu S, Bian X, Feng J, An Y, Yuan C (2018) Morphology- and porosity-tunable synthesis of 3D Nanoporous SiGe alloy as a high-performance Lithium-ion battery anode. ACS Nano 12:2900–2908. https://doi.org/10.1021/acsnano.8b00426

Yu Z, Tian B, Li Y, Fan D, Yang D, Zhu G, Cai M, Yan DL (2019) Lithium Titanate matrix-supported Nanocrystalline silicon film as an anode for Lithium-ion batteries. ACS Appl Mater Interfaces 11:534–540. https://doi.org/10.1021/acsami.8b13878

Sun F, Feng H, Gao S, Yang D, Yang H (2020) Facile fabrication of Si/Sb/Sb2O3/G@C composite electrodes for high-performance Li-ion batteries. New J Chem 44:4122–4128. https://doi.org/10.1039/c9nj05852d

Tseng KW, Huang SB, Chang WC, Tuan HY (2018) Synthesis of mesoporous germanium phosphide microspheres for high-performance Lithium-ion and sodium-ion battery anodes. Chem Mater 30:4440–4447. https://doi.org/10.1021/acs.chemmater.8b01922

Bogart TD, Chockla AM, Korgel BA (2013) High capacity lithium ion battery anodes of silicon and germanium. Curr Opin Chem Eng 2:286–293. https://doi.org/10.1016/j.coche.2013.07.001

Mishraa K, Georgea K, Zhou XD Submicron silicon anode stabilized by single-step carbon and germanium coatings for high capacity lithium-ion batteries. Carbon 138:419–426. https://doi.org/10.1016/j.carbon.2018.07.065

Shao Y, ** Z, Li J, Meng Y, and Huang X (2022) Evaluation of the electrochemical and expansion performances of the Sn-Si/graphite composite electrode for the industrial use. Energy Mat 184(2):481-484. https://doi.org/10.20517/energymater.2021.27

Liu B, Chen A, Wang R, Sun T, Zhang J, Shu Y, Yang J, Wang C, Yang Y (2019) Sputtered Ge/Si nanocomposite films as high performance anode materials for Lithium-ion battery. J Inorg Organomet Polym Mater 30:427–437. https://doi.org/10.1007/s10904-019-01201-4

Meng F, Wang F, Yu H, Zhao Z, Lv Y, Ma C, Zhang D, Liu X (2021) Liquid metal-modified Nanoporous SiGe alloy as an anode for Li-ion batteries and its self-healing performance. ACS Appl Energy Mat 4:14575–14581. https://doi.org/10.1021/acsaem.1c03204

Kim C, Song G, Luo L, Cheong JY, Cho SH, Kwon D, Choi S, Jung JW, Wang CM, Kim ID, Park S (2018) Stress-tolerant Nanoporous germanium nanofibers for long cycle life Lithium storage with high structural stability. ACS Nano 12:8169–8176. https://doi.org/10.1021/acsnano.8b03278

Wu W, Liang Y, Ma H, Peng Y, Yang H (2016) Insights into the conversion behavior of SiO-C hybrid with pre-treated graphite as anodes for Li-ion batteries. Electrochim Acta 187:473–479. https://doi.org/10.1016/j.electacta.2015.11.008

Gao S, Yang D, Pan Y, Geng L, Li S, Li X, Cao PF, Yang H (2019) From natural material to high-performance silicon based anode: towards cost-efficient silicon based electrodes in high-performance Li-ion batteries. Electrochim Acta 327:135058. https://doi.org/10.1016/j.electacta.2019.135058

Yi Y, Lee GH, Kim JC, Shim HW, Kim DW (2017) Tailored silicon hollow spheres with Micrococcus for Li ion battery electrodes. Chem Eng J 327:297–306. https://doi.org/10.1016/j.cej.2017.06.103

Zhou X, Han K, Jiang H, Liu Z, Zhang Z, Ye H, Liu Y (2017) High-rate and long-cycle silicon/porous nitrogen-doped carbon anode via a low-cost facile pre-template-coating approach for Li-ion batteries. Electrochim Acta 245:14–24. https://doi.org/10.1016/j.electacta.2017.05.126

Nachimuthu S, Kannan K, Thangavel S, Gurushankar K (2022) Electrochemical and magnetic properties of 3D porous NiS/CuS nanocomposites. Appl Surf Sci Adv 7:100209. https://doi.org/10.1016/j.apsadv.2022.100209

Ma K, Lin N (2019) The controllable synthesis of Si/Ge composites with a synergistic effect for enhanced Li storage performance. Inorganic Chem Front 6:1897–1903. https://doi.org/10.1039/c9qi00526a

Stokes K, Flynn G, Geaney H, Bree G, Ryan KM (2018) Axial Si-Ge Heterostructure nanowires as Lithium-ion battery anodes. Nano Lett 18:5569–5575. https://doi.org/10.1021/acs.nanolett.8b01988

Hatchard TD, Dahn JR (2004) In situ XRD and electrochemical study of the reaction of lithium with amorphous silicon. J Electrochem Soc 151:A838–A842. https://doi.org/10.1149/1.1739217

Obrovac MN, Krause LJ (2007) Reversible cycling of crystalline silicon powder. J Electrochem Soc 154:A103–A108. https://doi.org/10.1149/1.2402112

Zhang Y, Du N, **ao C, Wu S, Chen Y, Lin Y, Jiang J, He Y, Yang D (2017) Simple synthesis of SiGe@C porous microparticles as high-rate anode materials for lithium-ion batteries. RSC Adv 7:33837–33842. https://doi.org/10.1039/c7ra04364c

Zhang M, Shen L, Liu Y (2019) Nanoshell Si/cu composites as anode materials for lithium ion battery. Int J Mod Physics B 34:240008. https://doi.org/10.1142/s0217979220400081

Qian L, Lan J-L, Xue M, Yu Y, Yang X (2017) Two-step ball-milling synthesis of a Si/SiOx/C composite electrode for lithium ion batteries with excellent long-term cycling stability. RSC Adv 7:36697–36704. https://doi.org/10.1039/c7ra06671f

Chinnaiah K, Kannan K, Sivaganesh D, Gurushankar K (2022) Electrochemical performance and charge density distribution analysis of ag/NiO nanocomposite synthesized from Withania somnifera leaf extract. Inorg Chem Commun 141:109580. https://doi.org/10.1016/j.inoche.2022.109580

Nagaraj G, K. Chinnaiah, Kannan K, and Gurushankar K (2022) Nano-sized neem plant particles as an electrode for electrochemical storage applications. Ionics 28:3787–3797. https://doi.org/10.1007/s11581-022-04618-z

Acknowledgements

This work was supported by Natural Science Foundation of China (21421001), Natural Science Foundation of Tian**, China (18JCZDJC31400) and the MOE Innovation Team (IRT13022) and Project funded by China Postdoctoral Science Foundation (2021 M701769).

Funding

This work was supported by Natural Science Foundation of China (21421001), Natural Science Foundation of Tian**, China (18JCZDJC31400) and the MOE Innovation Team (IRT13022) and Project funded by China Postdoctoral Science Foundation (2021 M701769).

Author information

Authors and Affiliations

Contributions

Z.L. and K.Z. contributed equally to this work. All authors contributed to the study conception and design. Kaikai Zhang: Conceptualization, Investigation, Methodology, Writing - Original Draft. Zhenxi Li: Editing and Proofreading of Final Manuscripts. Shilun Gao: Supervision, Validation, Writing-Review & Editing. Huabin Yang: Supervision. Youjia Zhang: Characterization of materials. Hao Feng: Characterization of materials. Peng-Fei Cao: Visualization, Formal analysis. The first draft of the manuscript was written by Kaikai Zhang and all authors commented on previous versions of the manuscript.

Corresponding authors

Ethics declarations

This manuscript has not been published and is not under consideration for publication elsewhere. The authors declare that there are no conflicts of interest to disclose. The authors declare that no funds, grants, or other support were received during the preparation of this manuscript. The authors have no relevant financial or non-financial interests to disclose.

Inform Consent

All the authors have informed consent.

Consent for Publication and Consent to Participate

All authors read and approved the final manuscript for publication in Silicon.

Ethics Approval

Not applicable.

Conflict of Interest

This manuscript has no potential conflicts of interest (financial or non-financial).

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 4645 kb)

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Z., Zhang, K., Ma, M. et al. Facile Fabrication of Si/Ge/G@C Composite Electrodes for High Performance Lithium-ion Batteries. Silicon 15, 1859–1869 (2023). https://doi.org/10.1007/s12633-022-02143-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02143-2