Abstract

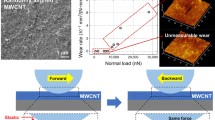

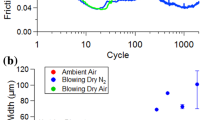

Silicon has been irreplaceable for a long time due to its well-estiblished design and fabrication in the field of Micro-Electro-Mechanical System (MEMS). However, it has poor tribological properties, which limits the further application of actuators (with relative motion) based MEMS. First, the amorphous silicon (a-Si) coatings were prepared on silicon substrates and high-speed steel (HSS) substrates by plasma enhanced chemical vapor deposition, and the relationships between mechanical properties and tribological performance were also systematically discussed. The wear rate of a-Si film on HSS has decreased significantly (decreased by 81.55%) compared with a-Si coating on silicon, which can be attributed to the larger elastic modulus and hardness of a-Si on the HSS matrix. Then, tungsten disulfide (WS2) nanoflake coatings with low interlayer shear stress were successfully prepared on the amorphous silicon (a-Si) coatings by the drop-casting method, forming a WS2 + a-Si coating to enhance the tribological properties. Combined with first-principles simulations and the characterization of the wear scar morphology, the macro-scale sliding friction of this composite coating against the Al2O3 ceramic ball was investigated in ambient air. The results indicated that the introduction of WS2 nanoflakes reduces the coefficient of friction (CoF) from 0.5 to 0.08. The reduction in CoF could be attributed to the in-situ formation of WS2 lubricating transfer film on the wear scar of the ball and the WS2 heterogeneous interface on a-Si film, leading to asymmetric contact between the friction pairs, which in turn triggers low and stable friction.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Zheng XH, Gao L, Yao QZ, Li QY, Zhang M, **e XM, Qiao S, Wang G, Ma TB, Di ZF, Luo JB, Wang X (2016) Robust ultra-low-friction state of graphene via moire superlattice confinement. Nat Commun 7:13204

Davim JP (2011) Tribology for engineers: a practical guide. Woodhead/Elsevier, Cambridge/Oxford

Davim JP (2013) Tribology of nanocomposites. Springer, Heidelberg

Holmberg K, Erdemir A (2017) Influence of tribology on global energy consumption, costs and emissions. Friction 5:263–284

Yi S, Li JJ, Liu YF, Ge XY, Zhang J, Luo JB (2021) In-situ formation of tribofilm with Ti3C2Tx MXene nanoflakes triggers macroscale superlubricity. Tribol Int 154:106695

Zhang RH, Chen Q, He ZY, **ong LP (2020) In situ friction-induced amorphous carbon or graphene at sliding interfaces: Effect of loads. Appl Surf Sci 534:146990

Aldana PU, Dassenoy F, Vacher B, Mogne TL, Thiebaut B (2016) WS2 nanoparticles anti-wear and friction reducing properties on rough surfaces in the presence of. ZDDP additive Tribol Int 102:213–221

Liu EY, Wang WZ, Gao YM, Jia JH (2013) Tribological properties of Ni-based self-lubricating composites with addition of silver and molybdenum disulfide. Tribol Int 57:235–241

Zeng QF, Erdemir A, Erylimaz O (2017) Ultralow friction of ZrO2 ball sliding against DLC films under various environments. Appl Sci-Basel 7(9):938

Guo CQ, Lin SS, Gao D, Shi Q, Wei CB, Dai MJ, Su YF, Xu W, Tang P, Li H, Wang W, Zhu XG (2020) Modulation of Si on microstructure and tribo-mechanical properties of hydrogen-free DLC films prepared by magnetron sputtering. Appl Surf Sci 509:145381

He DQ, He C, Li WS, Shang LL, Wang LP, Zhang GG (2020) Tribological behaviors of in-situ textured DLC films under dry and lubricated conditions. Appl Surf Sci 525:146581

Zhu JN, Zeng QF, Yan C, He WJ (2019) WS2 nanopowders as high-temperature lubricants: an experimental and theoretical study. ACS Appl Nano Mater 2:5604–5613

Yu GM, Gong ZB, Jiang BZ, Wang DL, Bai CN, Zhang JY (2020) Superlubricity for hydrogenated diamond like carbon induced by thin MoS2 and DLC layer in moist air. Diam Relat Mater 102:107668

Kumar KM, Shanmuganathan PV, Sethuramiah A (2018) Tribology of silicon surfaces: a review. Mater Today-Proc 5:24809–24819

Sriraman S, Agarwal S, Aydil ES, Maroudas D (2002) Mechanism of hydrogen-induced crystallization of amorphous silicon. Nature 418:62–65

Kang ZX, Liu Q, Liu YH (2013) Preparation and micro-tribological property of hydrophilic self-assembled monolayer on single crystal silicon surface. Wear 303:297–301

Katiyar JK, Mohammed AS (2022) Physical, tribological and mechanical properties of polymer composite coating on silicon wafer. Tribol Int 165:107307

Pan SH, ** KY, Wang TL, Zhang ZN, Zheng L, Umehara N (2022) Metal matrix nanocomposites in tribology: manufacturing, performance, and mechanisms. Friction (Early Access). https://doi.org/10.1007/s40544-021-0572-7

He WJ, Zeng QF (2021) Enhanced micro/nano-tribological performance in partially crystallized 60NiTi film. Friction 9:1635–1647

Gustavsson F, Jacobson S (2016) Diverse mechanisms of friction induced self-organisation into a low-friction material – An overview of WS2 tribofilm formation. Tribol Int 101:340–347

Rapuc A, Wang H, Polcar T (2021) Nanotribology of transition metal dichalcogenide flakes deposited by chemical vapour deposition: The influence of chemical composition and sliding speed on nanoscale friction of monolayers. Appl Surf Sci 556:149762

Polcar T, Cavaleiro A (2011) Self-adaptive low friction coatings based on transition metal dichalcogenides. Thin Solid Films 519:4037–4044

Kohlhauser B, Vladu CI, Gachot C, Mayrhofer PH, Ripoll MR (2021) Reactive in-situ formation and self-assembly of MoS2 nanoflakes in carbon tribofilms for low friction. Mater Des 199:109427

Berman D, Narayanan B, Cherukara MJ, Sankaranarayanan SKRS, Erdemir A, Zinovev A, Sumant AV (2018) Operando tribochemical formation of onion-like-carbon leads to macroscale superlubricity. Nat Commun 9:1164

Song HJ, Wang BA, Zhou QA, **ao JX, Jia XH (2017) Preparation and tribological properties of MoS2/graphene oxide composites. Appl Surf Sci 419:24–34

Liu YF, Chen XC, Li JJ, Luo JB (2019) Enhancement of friction performance enabled by a synergetic effect between graphene oxide and molybdenum disulfide. Carbon 154:266–276

Li Y, Zhou YJ, Wang YL, Liu M, Yuan JY, Men XH (2021) Facile synthesis of WS2@GO nanohybrids for significant improvement in mechanical and tribological performance of EP composites. Tribol Int 163:107148

Li X, Deng J, Liu L, Duan R, Ge D (2021) Fabrication of WS2/C composite coatings via electro hydro dynamic atomization and their tribology behaviours. Appl Surf Sci 538:148128

Li XM, Deng JX, Zhang LL, Liu YY, Yue HZ, Duan R, Ge DL (2019) Effect of surface textures and electro hydro dynamically atomized WS2 films on the friction and wear properties of ZrO2 coatings. Ceram Int 45:1020–1030

Xu Z, Lou WJ, Zhao G, Zheng DD, Hao JY, Wang XB (2019) Cu nanoparticles decorated WS2 nanosheets as a lubricant additive for enhanced tribological performance. RSC Adv 9:7786–7794

**ao JK, Zhang W, Zhang C (2018) Microstructure evolution and tribological performance of Cu-WS2 self-lubricating composites. Wear 412:109–119

Tyagi R, Das AK, Mandal A (2018) Electrical discharge coating using WS2 and Cu powder mixture for solid lubrication and enhanced tribological performance. Tribol Int 120:80–92

Zhu JN, Zeng QF, Wang YF, Yan C, He WJ (2020) Nano-crystallization-driven high temperature self-lubricating properties of magnetron-sputtered WS2 coatings. Tribol Lett 68(1):50

Shi J, **a T, Wang C, Yuan K, Zhang J (2018) Ultra-low friction mechanism of highly sp(3)-hybridized amorphous carbon controlled by interfacial molecule adsorption. Phys Chem Chem Phys 20:22445–22454

Aouadi SM, Gao H, Martini M, Scharf TW, Muratore C (2014) Lubricious oxide coatings for extreme temperature applications: A review. Surf Coat Tech 257:266–277

Yan C, Zeng QF, He WJ, Zhu JN (2020) First-principles investigation on the adsorption and dissociation of O2 and H2O molecules on the Ni-rich TiNi alloy surface. Appl Surf Sci 534:147570

Lopez T, Mangolini L (2014) Low activation energy for the crystallization of amorphous silicon nanoparticles. Nanoscale 6:1286–1294

Gajovic A, Gracin D, Juraic K, Sancho-Parramon J, Ceh M (2009) Correlating Raman-spectroscopy and high-resolution transmission-electron-microscopy studies of amorphous/nanocrystalline multilayered silicon thin films. Thin Solid Films 517:5453–5458

Smit C, Swaaij R, Donker H, Petit A, Kessels W, van de Sanden M (2003) Determining the material structure of microcrystalline silicon from Raman spectra. J Appl Phys 94:3582–3588

Hotovy I, Spiess L, Sojkova M, Kostic I, Mikolasek M, Predanocy M, Romanus H, Hulman M, Rehacek V (2018) Structural and optical properties of WS2 prepared using sulfurization of different thick sputtered tungsten films. Appl Surf Sci 461:133–138

Sinha S, Sathe V, Arora SK (2019) Temperature dependent Raman investigations of few-layered WS2 nanosheets. Solid State Commun 298:113626

Rigney DA (2000) Transfer, mixing and associated chemical and mechanical processes during the sliding of ductile materials. Wear 245:1–9

Davim JP (2012) Wear of advanced materials. Wiley, Hoboken

Davim JP (2018) Wear of composite materials. DE Gruyter, Berlin

Zhu SY, Cheng J, Qiao ZH, Yang J (2019) High temperature solid-lubricating materials: A review. Tribol Int 133:206–223

Wan SH, Tieu AK, **a TN, Zhu HT, Tran BH, Cui SG (2016) An overview of inorganic polymer as potential lubricant additive for high temperature tribology. Tribol Int 102:620–635

Berman D, Deshmukh SA, Sankaranarayanan SKRS, Erdemir A, Sumant AV (2015) Macroscale superlubricity enabled by graphene nanoscroll formation. Science 348:1118–1122

Rehman U, Jacob J, Mahmood K, Ali A, Ashfaq A, Basit M, Amin N, Ikram S, Hussain S, Noor H, Ahmad A, Rehman NU (2020) Improving the thermoelectric performance of hydrothermally synthesized FeS2 nanoparticles by post sulfurization. Ceram Int 46:20496–20499

Zeng QF, Zhu JN, Long Y, Bouchet MID, Martin JM (2019) Transformation-induced high temperature low friction behaviors of ZrO2-steel system at temperatures up to 900 oC. Mater Res Express 6(8):0865f5

Setyawan W, Curtarolo S (2010) High-throughput electronic band structure calculations: challenges and tools. Comp Mater Sci 49:299–312

Zhao S, Song G, Chen J, Yao M, Liu L (2022) Adsorption behavior and mechanism of multiple Mg atoms on the surface of AlNi compound at Mg alloy/steel interface. Curr Appl Phys 33:51–58

Song G, Zhao S, Khan MS, Chen J, Yao M (2021) Microscale bonding mechanism of Mg alloy and steel welded joint with nanoscale Al-based intermetallic compound interface layers. Mater Today Commun 26:101924

Li PP, Ju PF, Ji L, Li HX, Liu XH, Chen L, Zhou HD, Chen JM (2020) Toward robust macroscale superlubricity on engineering steel substrate. Adv Mater 32(36):2002039

Acknowledgements

We are grateful to the financial support from Project of National Natural Science Foundation of China (51675409), the National Science and Technology Major Project (j2019-IV-0004-0071), the Natural Science Foundation of Chongqing, China (cstc2019jcyj-msxmX0577), and Natural Science Basic Research Plan in Shaanxi Province of China (2022JM-251).

Funding

This work was financially supported by the National Natural Science Foundation of China (51675409), the National Science and Technology Major Project (j2019-IV-0004-0071), the Natural Science Foundation of Chongqing, China (cstc2019jcyj-msxmX0577), and Natural Science Basic Research Plan in Shaanxi Province of China (2022JM-251).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Qunfeng Zeng: Methodology, Visualization, Writing-review. Zekun Ning: Methodology, Analyzed data, Writing-original draft. Jianing Zhu: Simualtion, Investigation. Zhao Wang: Investigation, Visualization. Zeming Pang: Investigation, Visualization. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

All authors are agreed.

Consent for Publication

We agree to the terms and policies for the publication of the articles.

Conflict of Interest

The authors declare that there is no conflict of interest regarding the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

ESM 1

The initial morphology of the friction pair material; The primative unit cell (WS2, Fe and a-Si); EDS spectrum of a-Si film. (DOCX 1.19 MB )

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zeng, Q., Ning, Z., Zhu, J. et al. A Comparative Study on the Anti-Friction Performance of Amorphous Silicon Films Enhanced by WS2 Nanoflakes. Silicon 15, 1291–1302 (2023). https://doi.org/10.1007/s12633-022-02110-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02110-x