Abstract

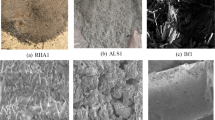

In modern days, one or the way, development of infrastructure plays a major role that decides upon the matrix of our lifestyle. The development of geopolymer concrete (GPC) is an important step towards the production of eco-friendly concrete. The effective usage of fiber content can reduce environmental pollution issues. An attempt was made to study the effect of the blend of metakaolin (MK) and ground granulated blast furnace slag (GGBFS) with Gujcon CFR fiber as secondary reinforcement was added as source material on the performance of GPC to prevent the effects of thermal variation. Fine aggregate, coarse aggregate, sodium hydroxide, nano-silicon dioxide (nano-SiO2), and cement have been used in the present work to make geopolymer mortar (GPM). GGBFS and Gujcon CFR fiber have been replaced with metakaolin an interval of 25%. The ratio of liquid to solid is 0.45 to 0.55, with a rise of 0.05. The samples are tested for split tensile and compression. To identify the surface morphology and phases SEM, XRD and EDAX have been analyzed. It is evident from the result that an equal proportion of source material with liquid to binder ratio 0.5 has yielded the highest mechanical properties.

Similar content being viewed by others

References

Diffo BK, Elimbi A, Cyr M, Manga JD, Kouamo HT (2015) Effect of the rate of calcination of kaolin on the properties of metakaolin-based geopolymers. J Asian Ceramic Soc 3:130–138

Kamseu E, Rizzuti A, Leonelli C, Perera D (2010) Enhanced thermal stability in K2O-metakaolin-based geopolymer concretes by Al2O3 and SiO2 fillers addition. J Mater Sci 45:1715–1724

Ravikumar D, Peethamparan S, Neithalath N (2010) Structure and strength of NaOH activated concretes containing fly ash or GGBFS as the sole binder. Cement Concrete Comp 32:399–410

Karakoc MB, Türkmen İ, Maraş MM, Kantarci F, Demirboğa R (2016) Sulfate resistance of ferrochrome slag based geopolymer concrete. Ceram Int 42:1254–1260

Qureshi MN, Ghosh S (2013) Effect of curing conditions on the compressive strength and microstructure of alkali-activated GGBS paste. Inter J Eng Sci Inven 2:24–31

Atea RS (2019) A case study on concrete column strength improvement with different steel fibers and polypropylene fibers. J Mater Res Tech 8:6106–6114

Hawileh RA, Abdalla JA, Fardmanesh F, Shahsana P, Khalili A (2017) Performance of reinforced concrete beams cast with different percentages of GGBS replacement to cement. Archives Civil Mech Eng 17:511–519

Song PS, Hwang S, Sheu BC (2005) Strength properties of nylon-and polypropylene-fiber-reinforced concretes. Cement Concrete Res 35:1546–1550

Rashad AM (2013) Metakaolin as cementitious material: history, scours, production and composition–a comprehensive overview. Constr Building Mater 41:303–318

Duxson P, Provis JL, Lukey GC, Mallicoat SW, Kriven WM, Van Deventer JS (2005) Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Sur A: Physicochem Eng Aspects 269:47–58

Al-Thairy H (2018) Effect of using river sand on the strength of Normal and high strength concrete. Inter J Eng Tech 7:222–228

Thakkar SP, Bhorwani DJ, Ambaliya R (2014) Geopolymer concrete using different source materials. Inter J Emer Tech Adv Eng 4:10–16

Ramani PV, Chinnaraj PK (2015) Geopolymer concrete with ground granulated blast furnace slag and black rice husk ash. Građevinar 67:741–748

Wardhono A, Law DW, Molyneaux TC (2015) Long term performance of alkali activated slag concrete. J Adva Concrete Tech 13:187–192

Rovnaník P (2010) Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr Building Mater 24:1176–1183

Duxson P, Provis JL, Lukey GC, Mallicoat SW, Kriven WM, Van Deventer JS (2005) Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Sur A: Physicochem Eng Aspects 269:47–58

Van Jaarsveld JG, Van Deventer JS, Lukey GC (2002) The effect of composition and temperature on the properties of fly ash-and kaolinite-based geopolymers. Chemical Eng J 89:63–73

Hatungimana D, Taşköprü C, İçhedef M, Saç MM, Yazıcı Ş (2019) Compressive strength, water absorption, water sorptivity and surface radon exhalation rate of silica fume and fly ash based mortar. J Building Eng 23:369–376

Zhang Y, Chen D, Liang Y, Qu K, Lu K, Chen S, Kong M (2020) Study on engineering properties of foam concrete containing waste seashell. Constr Building Mater 260:119896

Leon Raj J, Chockalingam T (2019) Strength and abrasion characteristics of pervious concrete. Road Mater Pavement Des 2:1–8

Sahdeo SK, Ransinchung GD, Rahul KL, Debbarma S (2020) Effect of mix proportion on the structural and functional properties of pervious concrete paving mixtures. Constr Building Mater 255:119260

Sun Z, Vollpracht A (2019) One year geopolymerisation of sodium silicate activated fly ash and metakaolin geopolymers. Cement Concrete Comp 95:98–110

Lv W, Sun Z, Su Z (2020) Study of seawater mixed one-part alkali activated GGBFS-fly ash. Cement Concrete Comp 106:103484

Cai J, Li X, Tan J, Vandevyvere B (2020) Thermal and compressive behaviors of fly ash and metakaolin-based geopolymer. J Building Eng 25:101307

Acknowledgments

I wish to thank the Department of Civil Engineering, Siddharth Institute of Engineering & Technology, Puttur, India, to provide facilities and necessary support in conducting experiments for providing facilities in the research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declare that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chandrasekhar Reddy, K. Investigation of Mechanical and Microstructural Properties of Fiber-Reinforced Geopolymer Concrete with GGBFS and Metakaolin: Novel Raw Material for Geopolymerisation. Silicon 13, 4565–4573 (2021). https://doi.org/10.1007/s12633-020-00780-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00780-z