Abstract

Cost effective machining of hybrid metal matrix composites (HMMC’s) with required surface integrity and without surface flaws is a challenging task for modern industries. This research explores the effect of end milling factors (spindle speed, feed rate, and depth of cut) and also weight percentage of reinforced materials on the surface integrity (surface roughness and microhardness) and material removal rate during machining of hybrid Al7075/SiC/Gr composites. Response surface methodology (RSM) is selected for experimental design and experimental results are analyzed using analysis of variance (ANOVA). Further, multi-objective optimization is carried out using composite desirability function. In addition, the morphology of the milled surfaces is examined for defining the flaws that affect quality of the milled surfaces. The experimental results reveal that apart from spindle speed and feed rate, the weight percentage of reinforced materials significantly affects the surface integrity of hybrid Al7075/SiC/Gr composites. The obtained optimum levels of the factors are spindle speed at 1000 rpm, feed rate at 0.0677 mm/rev, depth of cut at 1.1869 mm, and weight percentage of reinforced materials at 12.6970% that produce optimal values of the considered responses i.e. material removal rate up to 2043 mm3/min, roughness up to 1.29 μm and microhardness up to 142.36 μH.

Similar content being viewed by others

References

Gajadhur M (2015) Characterization of mechanical properties of prints. Printing on Polymers: Fundamentals and Applications, pp 347–352

Alaneme KK, Fajemisin AV, Maledi NB (2019) Development of aluminium-based composites reinforced with steel and graphite particles: structural, mechanical and wear characterization. J Mater Res Technol 8(1):670–682

Savina JP, Raghavendra BV (2018) Effect of fabrication methods on mechanical properties and machining parameters of aluminium matrix composites-a review. Mater Today Proc 5(10):22576–22580

Lalmuan SK, Das S, Chandrasekaran M, Tamang SK (2017) Machining investigation on hybrid metal matrix composites- a review. Mater Today Proc 4(8):8167–8175

K.Balamurugan, , M.Uthayakumar, , S.Sankar, , U.S. Hareesh, and K.G.K.Warrier, K.G.K., "Mathematical modelling on multiple variables in machining LaPO4/Y2O3 composite by abrasive waterjet," Int J Mach Mach Mater, vol.19, no.5, pp.426–439, 2017

K.Balamurugan, , M.Uthayakumar, , S.Sankar, , U.S. Hareesh, and K.G.K.Warrier, , "Modeling and surface texturing on surface roughness in machining LaPO4–Y2O3 composite," Mater Manuf Process, vol.33, no.4 pp.405–413, 2018.

Reddy NSK, Kwang-Sup S, Yang M (2008) Experimental study of surface integrity during end milling of Al/SiC particulate metal-matrix composites. J Mater Process Technol 201(1–3):574–579

**ong Y, Wang W, Jiang R, Lin K, Song G (2016) Surface integrity of milling in-situ TiB2 particle reinforced Al matrix composites. Int J Refract Met Hard Mater 54:407–416

Parashar V, Purohit R (2017) Analysis of machining behavior of Al/A206-Al2O3 metal matrix composite using end milling process. Mater Today Proc 4(2):2687–2692

Sridhar R, PerumalSubramaniyan S, Ramesh S (2019) Optimization of machining and geometrical parameters to reduce vibration while milling metal matrix composite. Trans Indian Inst Met

Yadav RS, Yadava V (2017) Experimental investigations on electrical discharge diamond peripheral surface grinding (EDDPSG) of hybrid metal matrix composite. J Manuf Process 27:241–251

Singh J, Chauhan A (2016) Characterization of hybrid aluminum matrix composites for advanced applications - a review. J Mater Res Technol 5(2):159–169

Johny James S, Venkatesan K, Kuppan P, Ramanujam R (2014) Hybrid aluminium metal matrix composite reinforced with SiC and TiB2. Proc Eng 97:1018–1026

Shetty N, Shahabaz SM, Sharma SS, DivakaraShetty S (2017) A review on finite element method for machining of composite materials. Compos Struct 176:790–802

Pang JS, Ansari MNM, Zaroog OS, Ali MH, Sapuan SM (2014) Taguchi design optimization of machining parameters on the CNC end milling process of halloysite nanotube with aluminium reinforced epoxy matrix (HNT/Al/Ep) hybrid composite. HBRC J 10(2):138–144

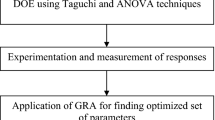

Rajeswari B, Amirthagadeswaran KS (2017) Experimental investigation of machinability characteristics and multi-response optimization of end milling in aluminium composites using RSM based grey relational analysis. Measurement 105:78–86

Daniel SAA, Pugazhenthi R, Kumar R, Vijayananth S (2019) Multi objective prediction and optimization of control parameters in the milling of aluminium hybrid metal matrix composites using ANN and Taguchi -grey relational analysis. Def Technol 15(4):545–556

Shinge AR, Dabade UA (2018) The effect of process parameters on material removal rate and dimensional variation of channel width in micro-milling of aluminium alloy 6063 T6. Proc Manuf 20:168–173

S. Karabulut, U. Gökmen and, H. Çinici,. Optimization of machining conditions for surface quality in milling AA7039-based metal matrix composites. Arab J Sci Eng, vol.43, no.3, pp.1071–1082, 2018

Rajeswari B, Amirthagadeswaran KS (2018) Study of machinability and parametric optimization of end milling on aluminium hybrid composites using multi-objective genetic algorithm. J Braz Soc Mech Sci Eng 40(8):377

Rotella G (2019) Effect of surface integrity induced by machining on high cycle fatigue life of 7075-T6 aluminum alloy. J Manuf Process 41:83–91

Liao Z, Abdelhafeez A, Li H, Yang Y, Diaz OG, Axinte D (2019) State-of-the-art of surface integrity in machining of metal matrix composites. Int J Mach Tools Manuf 143:63–91

Kumar H, Manna A, Kumar R (2018) Modeling of process parameters for surface roughness and analysis of machined surface in WEDM of Al/SiC-MMC. Trans Indian Inst Metals 71(1):231–244

Bai W, Roy A, Sun R, Silberschmidt VV (2019) Enhanced machinability of SiC-reinforced metal-matrix composite with hybrid turning. J Mater Process Technol 268:149–161

Sadagopan P, Mouliprasanth B (2017) Investigation on the influence of different types of dielectrics in electrical discharge machining. Int J Adv Manuf Technol 92(1–4):277–291

Mohammed BS, Achara BE, Liew MS, Alaloul WS, Khed VC (2019) Effects of elevated temperature on the tensile properties of NS-modified self-consolidating engineered cementitious composites and property optimization using response surface methodology (RSM). Constr Build Mater 206:449–469

ArunPremnath A (2015) Studies on machining parameters while milling particle reinforced hybrid (Al6061/Al2O3/Gr) MMC. Part Sci Technol 33(6):682–692

Deaquino-Lara R, Estrada-Guel I, Hinojosa-Ruiz G, Flores-Campos R, Herrera-Ramírez JM, Martínez-Sánchez R (2011) Synthesis of aluminum alloy 7075-graphite composites by milling processes and hot extrusion. J Alloys Compd 509(SUPPL. 1):S284–S289

Sharma A, Sharma VM, Mewar S, Pal SK, Paul J (2018) Friction stir processing of Al6061-SiC-graphite hybrid surface composites. Mater Manuf Process 33(7):795–804

Shihab SK (2018) Optimization of WEDM process parameters for machining of friction-stir-welded 5754 aluminum alloy using Box–Behnken design of RSM. Arab J Sci Eng 43(9):5017–5027

Jumare AI, Abou-El-Hossein K, Abdulkadir LN, Liman MM (2019) Predictive modeling and multiobjective optimization of diamond turning process of single-crystal silicon using RSM and desirability function approach. Int J Adv Manuf Technol 103(9–12):4205–4220

Saidi R, Ben Fathallah B, Mabrouki T, Belhadi S, Yallese MA (2019) Modeling and optimization of the turning parameters of cobalt alloy (Stellite 6) based on RSM and desirability function. Int J Adv Manuf Technol 100(9–12):2945–2968

Jones R (2002) Design and analysis of experiments (fifth edition), Douglas Montgomery, John Wiley and Sons, 2001, 684 pages, £33.95. Qual Reliab Eng Int 18(2):163

S. Qu, , J. Zhao, and T. Wang,. Experimental study and machining parameter optimization in milling thin-walled plates based on NSGA-II. Int J Adv Manuf Technol, vol. 89, no. 5–8, pp. 2399–2409. 2017

Bhushan RK, Kumar S, Das S (2010) Effect of machining parameters on surface roughness and tool wear for 7075 Al alloy SiC composite. Int J Adv Manuf Technol 50(5–8):459–469

Baradeswaran A, Perumal AE (2014) Wear and mechanical characteristics of Al 7075/graphite composites. Compos Part B Eng 56:472–476

Sozhamannan CG, Naveenkumar K, Mathiarasu A, Velmurugan K, Venkatachalapathy VSK (2018) Machining characteristics of Al/Ticp/Gr hybrid composites. Mater Today Proc 5(2):5940–5946

Shihab SK, Khan ZA, Siddiquee AN (2015) RSM based investigations on the effects of cutting parameters on surface integrity during cryogenic hard turning of AISI 52100. J Manuf Sci Prod 15(3)

Thakur RK, Sharma D, Singh KK (2019) Optimization of surface roughness and delamination factor in end milling of graphene modified GFRP using response surface methodology. Mater Today Proc 19:133–139

Song H, Dan J, Du J, Ren G, **ao J, Xu J (2019) Multiresponse optimization for laser-assisted machining of fused silica using response surface methodology. Silicon

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shihab, S.K., Gattmah, J. & Kadhim, H.M. Experimental Investigation of Surface Integrity and Multi-Objective Optimization of End Milling for Hybrid Al7075 Matrix Composites. Silicon 13, 1403–1419 (2021). https://doi.org/10.1007/s12633-020-00530-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00530-1