Abstract

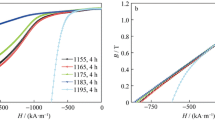

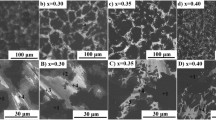

It is confirmed that the solid solution temperature range to obtain optimal magnetic properties is different for the magnets with different Fe contents, and the correlation between magnetic properties and microstructures influenced by solid solution temperature (Ts) has been systematically studied. The optimal solid solution temperature range is 1413–1463 K for the Sm(CobalFe0.213 Cu0.073Zr0.024)7.6 magnet, which is higher than that of the Sm(CobalFe0.262Cu0.073Zr0.024)7.6 magnet (1403–1453 K), and the optimal Ts range is about 50 K for both of the magnets. The solid solution temperature range shifting toward relatively high temperature is due to the increase in a phase transition temperature. The magnet solution-treated at proper temperature exhibits 1:7H single phase, and intact cell structure and high Cu concentration (23.12 at%) in the cell boundary are found after aging process, which makes the magnet shows high intrinsic coercivity (Hcj) and magnetic field at knee-point (Hknee). At a lower solid solution temperature, the 2:17H, 1:5H and Zr-rich precipitation phases appear, which affects the cell structure, density of lamellar phase and Cu concentration in the cell boundary, leading to the reduced magnetic properties. However, at a higher solid solution temperature, there exist obviously light gray and dark regions with different Sm, Cu and Fe contents in scanning electron microscopy observation, and the magnet shows low pinning field in the two regions and incomplete cell structure, resulting in an inferior Hcj and Hknee.

Graphic Abstract

Similar content being viewed by others

References

Gutfleisch O, Willard MA, Brück E, Chen CH, Sankar SG, Liu JP. Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Adv Mater. 2011;23(7):821.

Jiang CB, An SZ. Recent progress in high temperature permanent magnetic materials. Rare Met. 2013;32(5):431.

Ojima T, Tomizawa S, Yoneyama T, Hori T. Magnetic properties of a new type of rare-earth cobalt magnets. IEEE Trans Magn. 1977;13(5):1317.

Song KK, Sun W, Fang YK, Wang S, Yu NJ, Zhang ML, Zhu MG, Li W. Optimization of microstructures and magnetic properties of Sm(CobalFe0.227Cu0.07Zr0.023)7.6 magnets by sintering treatment. J Rare Earths. 2019;37(2):171.

Fang YK, Chang HW, Guo ZH, Liu T, Li XM, Li W, Chang WC, Han BS. Magnetic microstructures of phase-separated Sm–Co 2:17-type sintered magnets. J Alloys Compd. 2008;462(1–2):376.

**ong XY, Ohkubo T, Koyama T, Ohashi K, Tawara Y, Hono K. The microstructure of sintered Sm(Co0.72Fe0.20Cu0.055Zr0.025)7.5 permanent magnet studied by atom probe. Acta Mater. 2004;52(3):737.

Wang YQ, Yue M, Wu D, Zhang DT, Liu WQ, Zhang HG, Du YH. Effect of Cu redistribution in grain boundary on magnetic properties of Sm(Co0.665Fe0.25Cu0.06Zr0.025)7 permanent magnets. J Alloys Compd. 2018;741:495.

Xue ZQ, Liu L, Liu Z, Li M, Lee D, Chen RJ, Guo YQ, Yan AR. Mechanism of phase transformation in 2:17 type SmCo magnets investigated by phase stabilization. Scr Mater. 2016;113:226.

Yu NJ, Zhu MG, Fang YK, Song LW, Sun W, Song KK, Wang Q, Li W. The microstructure and magnetic characteristics of Sm(CobalFe0.1Cu0.09Zr0.03)7.24 high temperature permanent magnets. Scr Mater. 2017;132:44.

Zhang TL, Song Q, Wang H, Wang JM, Liu JH, Jiang CB. Effects of solution temperature and Cu content on the properties and microstructure of 2:17-type SmCo magnets. J Alloys Compd. 2018;735:1971.

Xu C, Wang H, Zhang TL, Popov A, Gopalan R, Jang CB. Correlation of microstructure and magnetic properties in Sm(CobalFe0.1Cu0.1Zr0.033)6.93 magnets solution-treated at different temperatures. Rare Met. 2019;38(1):20.

Goll D, Stadelmaier HH, Kronmüller H. Samarium–cobalt 2:17 magnets: analysis of the coercive field of Sm2(CoFeCuZr)17 high-temperature permanent magnets. Scr Mater. 2010;63(2):243.

Gopalan R, Hono K, Yan A, Gutfleisch O. Direct evidence for Cu concentration variation and its correlation to coercivity in Sm(Co0.74Fe0.1Cu0.12Zr0.04)7.4 ribbons. Scr Mater. 2009;60(9):764.

Sepehri-Amin H, Thielsch J, Fischbacher J, Ohkubo T, Schrefl T, Gutfleisch O, Hono K. Correlation of microchemistry of cell boundary phase and interface structure to the coercivity of Sm(Co0.784Fe0.100Cu0.088Zr0.028)7.19 sintered magnets. Acta Mater. 2017;126:1.

Yu NJ, Gao WY, Pan MX, Yang HF, Wu Q, Zhang PY, Ge HL. Influence mechanism of Fe content on the magnetic properties of Sm2Co17-type sintered magnets: microstructure and microchemistry. J Alloys Compd. 2019. https://doi.org/10.1016/j.jallcom.2019.152908.

Wang YQ, Shang ZF, Yue M, Wu D, Zhang DT, Zhang HG, Liu WQ. Correlation between Fe content and z value in Sm(CobalFexCu0.06Zr0.025)z permanent magnets. J Magn Magn Mater. 2019;474:417.

Zhang CY, Liu Z, Li M, Liu L, Li TY, Chen RJ, Lee D, Yan AR. The evolution of phase constitution and microstructure in iron-rich 2:17-type Sm-Co magnets with high magnetic performance. Sci Rep. 2018;8:9103.

Tang W, Zhang Y, Hadjipanayis GC. Microstructure and magnetic properties of Sm(CobalFexCu0.128Zr0.02)7.0 magnets with Fe substitution. J Magn Magn Mater. 2020;221(3):268.

Horiuchi Y, Hagiwara M, Endo M, Sanada N, Sakurada S. Influence of intermediate-heat treatment on the structure and magnetic properties of iron-rich Sm(CoFeCuZr)Z sintered magnets. J Appl Phys. 2015;117:17C704.

Sun W, Zhu MG, Fang YK, Liu ZY, Chen HS, Guo ZH, Li W. Magnetic properties and microstructures of high-performance Sm2Co17 based alloy. J Magn Magn Mater. 2015;378:214.

Ray AE. Metallurgical behavior of Sm(Co, Fe, Cu, Zr)z alloys. J Appl Phys. 1984;55(6):2094.

Shang ZF, Yue M, Li YQ, Zhang DT, **e ZH, Wang YQ. The effect of multi-scale Cu distribution regulation on magnetic properties of Sm(CoFeCuZr)z magnets. J Magn Magn Mater. 2020. https://doi.org/10.1016/j.jmmm.2020.166484.

Wang S, Fang YK, Song KK, Zhu XY, Wang L, Sun W, Pan W, Zhu MG, Li W. Optimization of both coercivity and knee-point magnetic field of Sm2Co17-type magnets via solid solution process. J Rare Earths. 2020. https://doi.org/10.1016/j.jre.2019.11.009.

Rabenberg L, Mishra RK, Thomas G. Microstructures of precipitation-hardened SmCo permanent magnets. J Appl Phys. 1982;53(3):2389.

Tang W, Zhang Y, Hadjipanayis GC. High-temperature magnetic properties of Sm(CobalFe0.1Cu0.088Zrx)8.5 magnets. J Magn Magn Mater. 2000;212(1–2):138.

Liafs TY, Liu Z, Feng YP, Liu L, Zhang CY, Yan GH, Feng ZX, Lee D, Yan AR. Effect of Zr on magnetic properties and electrical resistivity of Sm(CobalFe0.09Cu0.09Zrx)7.68 magnets. J Alloys Compd. 2018;753:162.

Lectard E, Allibert CH, Ballou R. Saturation magnetization and anisotropy fields in the Sm(Co1-xCux)5 phases. J Appl Phys. 1994;75(10):6277.

Liu JF, Zhang Y, Dimitrov D, Hadjipanayis GC. Microstructure and high temperature magnetic properties of Sm(Co, Cu, Fe, Zr)z (z = 6.7-9.1) permanent magnets. J Appl Phys. 1999;85(5):2800.

Wang S, Fang YK, Wang C, Wang L, Zhu MG, Li W, Hadjipanayis GC. Dependence of macromagnetic properties on the microstructure in high-performance Sm2Co17-type permanent magnets. J Magn Magn Mater. 2020;510(5):166942.

Wang C, Yu NJ, Zhu MG, Fang YK, Wang S, Li W. High temperature properties improvement and microstructure regulation of Sm2Co17-based permanent magnet. AIP Adv. 2019;9:125237.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2016YFB0700903) and the National Natural Science Foundation of China (Nos. 51871063 and 51590882).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, S., Chen, HS., Fang, YK. et al. Identification of optimal solid solution temperature for Sm2Co17-type permanent magnets with different Fe contents. Rare Met. 40, 3567–3574 (2021). https://doi.org/10.1007/s12598-020-01701-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01701-0