Abstract

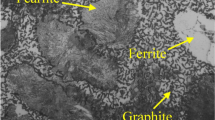

Cast iron is relatively cheap and highly machinable and is thus used for various mechanical parts. However, cast iron (H2 grade) is a high-carbon steel that shows cracks or craters owing to the martensitic transformation during conventional surface heat treatments. In this study, we investigated electron-beam (e-beam)-based direct preheating for preventing the formation of craters and cracks during the heat treatment of cast iron using a plasma diode e-beam. Scanning electron microscopy, X-ray diffraction analysis, energy-dispersive X-ray spectroscopy, and hardness measurements were performed to elucidate the crater and crack formation mechanism. Craters were formed within the graphite phase, owing to the low-melting-point elements and compounds. It was also observed that crack and crater formation was correlated to the distortion of the primary gamma phase, based on a significant decrease in the d-spacings. The direct preheating process resulted in a lower degree of distortion of the gamma phase. As a result, we could achieve a hardness as high as 800 HV without cracks or craters in cast iron, which is a cheap material. Moreover, the results of potentiodynamic polarization tests showed that the corrosion resistance increased after the surface treatment, owing to the removal of the low-melting-point impurities and grain refinement.

Similar content being viewed by others

References

Ming-der, J. and Yih-fong, T., “Optimisation of Electron-Beam Surface Hardening of Cast Iron for High Wear Resistance Using the Taguchi Method,” The International Journal of Advanced Manufacturing Technology, Vol. 24, Nos. 3-4, pp.190–198, 2004.

Kim, J., Lee, W. J., and Park, H. W., “The State of the Art in the Electron Beam Manufacturing Processes,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 11, pp. 1575–1585, 2016.

Tatarkina, N. V., Ziganshin, A. I., Dampilon, B. V., Durakov, V. G., and Tolstokulakov, A. M., “Formation of Wear-Resistant Chromium-Vanadium Cast Iron Coating Using a Continuous and Pulsed Electron Beam,” IOP Conference Series: Materials Science and Engineering, Vol. 66, No. 1, Paper No. 012022, 2014.

Zenker, R., Buchwalder, A., Rüthrich, K., Griesbach, W., and Nagel, K., “First Results of a New Duplex Surface Treatment for Cast Iron: Electron Beam Remelting and Plasma Nitriding,” Surface and Coatings Technology, Vol. 236, pp. 58–62, 2013.

Benyounis, K. Y., Fakron, O. M. A., Abboud, J. H., Olabi, A. G., and Hashmi, M. J. S., “Surface Melting of Nodular Cast Iron by Nd-YAG Laser and TIG,” Journal of Materials Processing Technology, Vol. 170, Nos. 1-2, pp.127–132, 2005.

Alabeedi, K. F., Abboud, J. H., and Benyounis, K. Y., “Microstructure and Erosion Resistance Enhancement of Nodular Cast Iron by Laser Melting,” Wear, Vol. 266, Nos. 9-10, pp. 925–933, 2009.

Gadag, S. P. and Srinivasan, M. N., “Dry Sliding Wear and Friction: Laser-Treated Ductile Iron,” Wear, Vol. 173, Nos. 1-2, pp. 21–29, 1994.

Jung, W., Lee, H.-J., and Park, K., “Investigation of Localized Heating Characteristics in Selective Ultrasonic Imprinting,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 9, pp. 1999–2004, 2015.

Lee, C.-M., Woo, W.-S., Kim, D.-H., Oh, W.-J., and Oh, N.-S., “Laser-Assisted Hybrid Processes: A Review,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 2, pp. 257–267, 2016.

Pagano, N., Angelini, V., Ceschini, L., and Campana, G., “Laser Remelting for Enhancing Tribological Performances of a Ductile Iron,” Procedia CIRP, Vol. 41, pp. 987–991, 2016.

Zhang, K. M., Zou, J. X., and Grosdidier, T., “Nanostructure Formations and Improvement in Corrosion Resistance of Steels by Means of Pulsed Electron Beam Surface Treatment,” Journal of Nanomaterials, Vol. 2013, Article ID: 978568, 2013.

Sekiguchi, S. and Shibata, F., “Mechanical Properties of Electron Beam Welded Spheroidal Graphite Cast Iron and Mild Steel Welded Joints,” Materials Transactions, Vol. 52, No. 10, pp. 1920–1925, 2011.

Sarafan, S., Wanjara, P., Champliaud, H., and Thibault, D., “Characteristics of an Autogenous Single Pass Electron Beam Weld in Thick Gage CA6NM Steel,” The International Journal of Advanced Manufacturing Technology, Vol. 78, No. 9, pp. 1523–1535, 2015.

Chen, F. R., Huo, L. X., Zhang, Y. F., Zhang, L., Liu, F. J., and Chen, G., “Effects of Electron Beam Local Post-Weld Heat-Treatment on the Microstructure and Properties of 30CrMnSiNi2A Steel Welded Joints,” Journal of Materials Processing Technology, Vol. 129, Nos. 1-3, pp. 412–417, 2002.

Kang, E.-G., Kim, J.-S., Lee, S.-W., Min, B.-K., and Lee, S.-J., “Emission Characteristics of High-Voltage Plasma Diode Cathode for Metal Surface Modification,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 1, pp. 13–19, 2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, E.G., Choi, H.Z., Min, BK. et al. Plasma diode electron beam heat treatment of cast iron: Effect of direct preheating. Int. J. Precis. Eng. Manuf. 18, 1339–1345 (2017). https://doi.org/10.1007/s12541-017-0159-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0159-4