Abstract

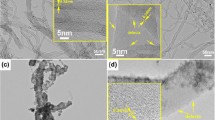

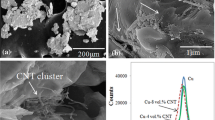

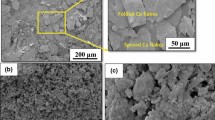

In this paper, the effects of Cu coating of carbon nanotube (CNTs) as reinforcement on structural, microstructural, physical and mechanical properties of Cu–3 wt%CNT nanocomposite were investigated. CNTs were coated by Cu using the electroless technique for 1 and 2 h. Bulk nanocomposite samples were produced by spark plasma sintering of a mechanically milled powder mixture of Cu and CNT. Kinetic study showed a nucleation and growth mechanism for the Cu coating process. Microstructural characterization showed that the coated CNTs dispersed more homogeneously in the powder mixture. Results also revealed that 1 h coating of CNTs led to the higher relative density and thermal properties. The coating process increased 62 Brinell hardness (BHN) in hardness, 14% IACS in electrical conductivity for Cu–CNT nanocomposite. Transmission electron microscopy analysis showed a strong bonding between CNT and Cu matrix within the distinguishable interface. About 20 MPa increase in shear strength of nanocomposite was observed by 1 h coating of CNTs. Also, the fracture surfaces exhibit changes in the mode of fracture by well-bonded CNTs with the Cu matrix. The coefficient of thermal expansion and thermal distortion parameter revealed 12.7 ppm/k and 0.037 ppm.m/w for the sample including 1 h coated CNT, respectively.

Graphic Abstract

Similar content being viewed by others

References

A. Mortensen, J.L. Llorca, Metal matrix composites. J. Annu. Rev. Mater. Res. 40, 243–270 (2010)

V.M. Kumar, C.V. Venkatesh, A comprehensive review on material selection, processing, characterization and applications of aluminium metal matrix composites. Mater. Res. Express 6, 072001 (2019)

A.D. Moghadam, E. Omrani, P. Menezes, Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—a review. Compos. Part B 77, 402–420 (2015)

Z. An, M. Toda, D. Ono, Comparative investigation into surface charged multi-walled carbon nanotubes reinforced Cu nanocomposites for interconnect applications. Compos. Part B 95, 137–143 (2016)

R. Miller, D. Liu, M. Horsinka, T. Nguyen, K. Kuppuswamy, T. Towe, H. Li, M. Berube, J. Harrison, E. Wolak, Composite-copper, low-thermal-resistance heat sinks for laser-diode bars, mini-bars and single-emitter devices. Int. Soc. Opt. Photonics 6878, 687607 (2008)

S. Sheibani, S. Heshmati-Manesh, A. Ataie, Influence of Al2O3 nanoparticles on solubility extension of Cr in Cu by mechanical alloying. Acta Mater. 58, 6828–6834 (2010)

Y. **, K. Adachi, T. Takeuchi, H.G. Suzuki, Ageing characteristics of Cu–Cr in situ composite. J. Mater. Sci. 33, 1333–1341 (1998)

E.Y. Yoon, D.J. Lee, B. Park, M.R. Akbarpour, M. Farvizi, H.S. Kim, Grain refinement and tensile strength of carbon nanotube-reinforced Cu matrix nanocomposites processed by high-pressure torsion. Met. Mater. Int. 19, 927–932 (2013)

M. Masroor, S. Sheibani, A. Ataie, Effect of milling energy on preparation of Cu–Cr/CNT hybrid nano-composite by mechanical alloying. Trans. Nonferrous Met. Soc. China 26, 1359–1366 (2016)

P.C. Tsai, Y.R. Jeng, J.T. Lee, I. Stachiv, P. Sittner, Effects of carbon nanotube reinforcement and grain size refinement mechanical properties and wear behaviors of carbon nanotube/copper composites. Diam. Relat. Mater. 74, 197–204 (2017)

A. Bor, B. Ichinkhorloo, B. Uyanga, J. Lee, H. Choi, Cu/CNT nanocomposite fabrication with different raw material properties using a planetary ball milling process. Powder Technol. 323, 563–573 (2018)

A. Ghorbani, S. Sheibani, A. Ataie, Microstructure and mechanical properties of consolidated Cu–Cr–CNT nanocomposite prepared via powder metallurgy. J. Alloys Compd. 732, 818–827 (2018)

S. Shakibhamedan, M. Abdi, S. Sheibani, Comparative study on hot rolling of Cu–Cr and Cu–Cr–CNT nanocomposites. Trans. Nonferrous Metals Soc. China 28, 2044–2052 (2018)

W.M. Daoush, Processing and characterization of CNT/Cu nanocomposites by powder technology. Powder Metall. Met. Ceram. 47, 531–537 (2008)

Z.A. Munir, U. Anselmi-Tamburini, M. Ohyanagi, The effect of electric field and pressure on the synthesis and consolidation of materials. A review of the spark plasma sintering method. J. Mater. Sci. 41, 763–777 (2006)

K. Chu, C. Jia, L. Jiang, W. Li, Improvement of interface and mechanical properties in carbon nanotube reinforced Cu–Cr matrix composites. Mater. Des. 45, 407–411 (2013)

W.M. Daoush, B.K. Lim, C.B. Mo, D.H. Nam, S.H. Hong, Electrical and mechanical properties of carbon nanotube reinforced copper nanocomposites fabricated by electroless deposition process. Mater. Sci. Eng. 513, 247–253 (2009)

J.L. Song, W.G. Chen, L.L. Dong, J.J. Wang, N. Deng, An electroless plating and planetary ball milling process for mechanical properties enhancement of bulk CNTs/Cu composites. J. Alloys Compd. 720, 54–62 (2017)

X. Chen, J. **a, J. Peng, W. Li, S. **e, Carbon-nanotube metal-matrix composites prepared by electroless plating. Compos. Sci. Technol. 60, 301–306 (2000)

M. Zhou, Y. Mai, H. Ling, F. Chen, W. Lian, X. Jie, Electrodeposition of CNTs/copper composite coatings with enhanced tribological performance from a low concentration CNTs colloidal solution. Mater. Res. Bull. 44, 537–543 (2008)

A.R. Boccaccini, J. Cho, J.A. Roether, B.J.C. Thomas, E. Minay, M. Shaffer, Electrophoretic deposition of carbon nanotubes. Carbon 44, 3149–3160 (2006)

Q. Li, S. Fan, W. Han, C. Sun, W. Liang, Coating of carbon nanotube with nickel by electroless plating method. J. Appl. Phys. 36, 501–503 (1997)

V.M. Dubin, Y. Shacham-Diamand, B. Zhao, P. Vasudev, C.H. Ting, Selective and blanket electroless copper deposition for ultralarge scale integration. J. Electrochem. Soc. 144, 898–908 (1997)

S.F. Moustafa, S.A. El-Badry, A.M. Sanad, Effect of graphite with and without copper coating on consolidation behavior and sintering of copper–graphite composite. Powder Metal. 40, 201–206 (1997)

C. Xu, G. Wu, Z. Liu, D. Wu, T.T. Meek, Q. Han, Preparation of copper nanoparticles on carbon nanotubes by electroless plating. Mater. Res. Bull. 39, 1499–1505 (2004)

S. Armyanov, J. Georgieve, D. Tachev, E. Valova, N. Nyagolova, S. Mehta, D. Leibman, A. Ruffini, Electroless deposition of Ni–Cu–P alloys in acidic solutions. Electrochem. Solid State Lett. 2, 323 (1999)

J. Ru, H. He, S. Wei, Preparation and characterization of Ni–Cu dual coated ZTA particles by ionic liquid-assisted electroless plating as reinforcement of metal-based composites. Surf. Coat. Technol. 387, 125476 (2020)

G. Williamson, W.H. Hall, X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1, 22–31 (1953)

ASTM, Standard test method for shear strength of plastics by punch tool (2010)

A. Maqbool, F. Ahmad Khalid, M. Asif Hussain, N. Baksh, Synthesis of copper coated carbon nanotubes for aluminium matrix composites. IOP Conf. Ser. 60(1), 012040 (2014)

A. Maqbool, M. Asif Hussain, F. Ahmad Khalod, N. Bakhsh, A. Hussain, M. Ho Kim, Mechanical characterization of copper coated carbon nanotubes reinforced aluminium matrix composites. Mater. Charact. 86, 39–48 (2013)

J.P. Braganti, O. Held, F.A. Kuhnast, E. Lllekova, Kinetic study of isothermal crystallization in amorphous Al33Ni16Zr51 produced by mechanical alloying. Thermochem. Acta 362, 71–78 (2000)

M.A. Bab, L. Mendoza-Zelis, L.C. Damonte, Nanocrystalline HfN produced by mechanical milling: kinetic aspects. Acta Mater. 49, 4205–4213 (2001)

J.W. Christian, The Theory of Phase Transformation in Metals and Alloys, 2nd edn. (Pergamon, Oxford, 2002)

L. Li, Y. Bao, J. Yi, L. Liu, S. Mao, Preparation of CNT/Cu nano composite powder with uniform dispersion and strong interface bonding by SP method. Powder Technol. 325, 107–112 (2018)

M. Rahimian, N. Ehsani, N. Parvin, H.R. Baharvandi, The effect of particle size, sintering temperature and sintering time on the properties of Al–Al2O3 composites, made by powder metallurgy. J. Mater. Process. Technol. 209, 5387–5393 (2009)

R.W. Siegel, G.E. Fougere, Mechanical properties of nanophase metals. Nanostruct. Mater. 6, 205–216 (1995)

J.M. Tao, X.F. Chen, P. Hong, J.H. Yi, Microstructure and electrical conductivity of laminated Cu/CNT/Cu composites prepared by electrodeposition. J. Alloys Compd. 717, 232–239 (2017)

Y. Yu, W. Zhang, H. Yu, Effect of Cu content and heat treatment on the properties and microstructure of W–Cu composites produced by hot extrusion with steel cup. Adv. Powder Technol. 26, 1047–1052 (2015)

D.K. Lim, T. Shibayanagi, A.P. Gerlich, Synthesis of multi-walled CNT reinforced aluminium alloy composite via friction stir processing. Mater. Sci. Eng. A 507, 194–199 (2009)

R. Ghosh, D. Basak, S. Fuijhara, Effect of substrate-induced strain on the structural, electrical, and optical properties of polycrystalline ZnO thin films. J. Appl. Phys. 96, 2689–2692 (2004)

G.E. Lucas, G.R. Odette, J.W. Sheckherd, Shear punch and microhardness tests for strength and ductility measurements, in The Use of Small-Scale Specimens for Testing Irradiated Material (ASTM International, 1986)

S.R. Bakshi, D. Lahiri, A. Agarwal, Carbon nanotube reinforced metal matrix composites—a review. Int. Mater. Rev. 55, 41–64 (2010)

G. Chai, Y. Sun, Q. Chen, Mechanical properties of carbon nanotube–copper nanocomposites. J. Micromech. Microeng. 18, 035013 (2008)

Y. Sun, Q. Chen, Diameter dependent strength of carbon nanotube reinforced composite. Appl. Phys. Lett. 95, 021901 (2009)

Y.S. Suh, S.P. Joshi, K.T. Ramesh, An enhanced continuum model for size-dependent strengthening and failure of particle-reinforced composites. Acta Mater. 57, 5848–5861 (2009)

Z. Zhang, D.L. Chen, Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites. Mater. Sci. Eng. A 483, 148–152 (2008)

X. Long, Y. Bai, M. Algarni, Study on the strengthening mechanisms of Cu/CNT nano-composites. Mater. Sci. Eng. A 645, 347–356 (2015)

Z. Zhang, D.L. Chen, Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: a model for predicting their yield strength. Scr. Mater. 54, 1321–1326 (2006)

B.R. You, S.B. Lee, A critical review on multiaxial fatigue assessments of metals. Int. J. Fatigue 18, 235–244 (1996)

K. Kumar, V. Kripesh, A. Tay, Single-wall carbon nanotuve (SWCNT) functionalized Sn–Ag–Cu lead-free composite solders. J. Alloys Compd. 450, 229–237 (2008)

X. Chen, J. Tao, J. Yi, Y. Liu, C. Li, R. Bao, Strengthening behavior of carbon nanotube-graphene hybrids in copper matrix composites. Mater. Sci. Eng. 718, 427–436 (2018)

B. Cheng, R. Bao, J. Yi, C. Li, J. Tao, Y. Liu, S. Tan, X. You, Interface optimization of CNT/Cu composite by forming TiC nanoprecipitation and low interface energy structure via spark plasma sintering. J. Alloys Compd. 722, 852–858 (2017)

B. Guo, B. Chen, X. Zhang, X. Cen, X. Wang, M. Song, S. Ni, J. Yi, T.D. Yong, Exploring the size effects of Al4C3 on the mechanical properties and thermal behaviors of Al-based composites reinforced by SiC and carbon nanotubes. Carbon 135, 224–235 (2018)

P.A. Carvalho, I. Fonseca, M.T. Marques, J.B. Correia, A. Almeida, R. Vilar, Characterization of copper-cementite nanocomposite produced by mechanical alloying. Acta Mater. 53, 967–976 (2005)

M.J. Biercuk, M.C. Llaguno, M. Radosavljevic, J.K. Hyun, T. Johnson, Carbon nanotube composites for thermal management. Appl. Phys. Lett. 80, 2676–2769 (2002)

V. Koti, R. George, P.G. Koppad, K.V. Murthy, A. Shakiba, Friction and wear characteristics of copper nanocomposites reinforced with uncoated and nickel coated carbon nanotubes. Mater. Res. Express 5, 095607 (2018)

K. Chu, Q. Wu, C. Jia, X. Liang, J. Nie, W. Tian, G. Gai, H. Guo, Fabrication and effective thermal conductivity of multi-walled carbon nanotubes reinforced Cu matrix composites for heat sink applications. Compos. Sci. Technol. 70, 298–304 (2010)

H.L. Zhang, J.F. Li, K.F. Yao, L.D. Chen, Spark plasma sintering and thermal conductivity of carbon nanotube bulk materials. J. Appl. Phys. 97, 114310 (2005)

N. Ferrer-Anglada, V. Gomis, Z. El-Hachemi, U. Dettlaff-Weglikovska, M. Kaempgen, S. Roth, Carbon nanotube based composites for electronic applications: cNT-conducting polymers, CNT–Cu. Phys. Status Solidi 203, 1082–1087 (2006)

T. Schubert, B. Trindade, T. Weibgarber, B. Kieback, interfacial design of Cu-based composites prepared by powder metallurgy for heat sink applications. Mater. Sci. Eng. A 475, 39–44 (2008)

S. Gao, N. Zhao, Q. Liu, Y. Li, G. Xu, X. Cheng, J. Yang, Sc2W3O12/Cu composites with low thermal expansion coefficient and high thermal conductivity for efficient cooling of electronics. J. Alloys Compd. 779, 108–114 (2019)

L. Guo, Z. Zhang, R. Kang, Y. Chen, X. Hou, Y. Wu, M. Wang, B. Wang, J. Cui, N. Jiang, C.T. Lin, J. Yu, Enhanced thermal conductivity of epoxy composites filled with tetrapod-shaped ZnO. RSC Adv. 8, 12337–12343 (2018)

I. Firkowska, A. Boden, A.M. Vogt, S. Reich, Effect of carbon nanotube surface modification on thermal properties of copper–CNT composites. J. Mater. Chem. 21, 17541–17546 (2011)

K. Chu, H. Guo, C. Jia, F. Yin, X. Zhang, X. Liang, H. Chen, Thermal properties of carbon nanotube–copper composites for thermal management applications. Nano. Express 5, 868–874 (2010)

Acknowledgements

The authors would like to acknowledge the supports of the University of Tehran and the Iran Nanotechnology Initiative Council for this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shakibhamedan, S., Sheibani, S. & Ataie, A. High Performance Cu Matrix Nanocomposite Fabricated Through Spark Plasma Sintering of Cu and Cu-Coated CNT. Met. Mater. Int. 27, 4271–4285 (2021). https://doi.org/10.1007/s12540-020-00816-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00816-4