Abstract

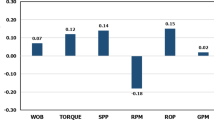

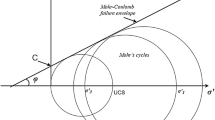

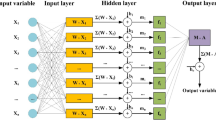

The study of the geomechanical parameters is necessary for field planning and development. Two of the most critical parameters used to describe the rock strength are the tensile (Ts) and the uniaxial compressive strength (UCS). Measuring these two parameters in the lab is time-consuming. Consequently, non-destructive methods have been developed to predict these parameters fast and reliable. Field drilling data can be reliable, continuous, and rapid technology in predicting UCS and Ts. Herein, an artificial neural intelligence network (ANN) predicts Ts and UCS from actual drilling data collected from two fields in the Middle East. The data include rate of penetration (ROP), weight on bit (WOB), torque (T), drilling fluid injection rate (Q), and the standpipe pressure (SPP). Several sensitivity analyses were conducted to optimize the models’ parameters and inputs, followed by extracting the weights and biases for develo** ANN-based relations for Ts and UCS. The results showed that the ANN was highly accurate during the training phase in predicting UCS with an AAPE of 0.28%, and Ts with an AAPE of 0.28%. The developed correlation effectively predicted Ts and UCS for an average AAPE of 0.59 % during the testing phase and only 0.65 % for the validation data set for both parameters. This method provides a real-time effective tool for predicting the strength parameters in continuous, fast, and reliable measurements from the drilling field data.

Similar content being viewed by others

Abbreviations

- AI :

-

artificial intelligence

- ANN :

-

artificial neural network

- ANFIS :

-

adaptive neuro-fuzzy inference system

- ML :

-

machine learning

- FIS :

-

fuzzy inference system

- SFS :

-

Stochastic Fractal Search

- R :

-

correlation coefficient

- AAPE :

-

absolute average percentage error

- IWO :

-

invasive weed optimization

- PSO :

-

particle swarm optimization

- Rn :

-

Schmidt hammer rebound number

- Vp :

-

p-wave velocity

- Is50 :

-

point load strength index

- BTS :

-

Brazilian tensile strength

- BPI :

-

block punch index

- RL :

-

lithology type

- W :

-

weathering grade

- CPI :

-

cylinder punch index

- UCS :

-

unconfined compressive strength

- Ts :

-

tensile strength

- y i :

-

dependent parameter

- x i :

-

independent parameter

- σ x :

-

standard deviation of independent parameter

- σ y :

-

standard deviation of independent parameter

- μ x :

-

mean of independent parameter

- μ y :

-

mean of dependent parameter

- WOB :

-

weight on bit

- ROP :

-

rate of penetration

- Q :

-

drilling fluid injection rate

- T :

-

torque

- SPP :

-

standpipe pressure

- SDI :

-

four cycle slake durability index

- Id4 :

-

four-cycle SDI (%)

- μ:

-

Poisson’s ratio

- b:

-

dry unit weight kN/m3

References

Aboutaleb S, Bagherpour R, Behnia M et al (2017) Combination of the physical and ultrasonic tests in estimating the uniaxial compressive strength and Young’s modulus of intact limestone rocks. Geotech Geol Eng 35:3015–3023. https://doi.org/10.1007/s10706-017-0281-1

Agatonovic-Kustrin S, Beresford R (2000) Basic concepts of artificial neural network (ANN) modeling and its application in pharmaceutical research. J Pharm Biomed Anal 22(5):717–727

Ahmed A, Ali A, Elkatatny S, Abdulraheem A (2019) New artificial neural networks model for predicting rate of penetration in deep shale formation. Sustainability 11(22):6527

Al-Abduljabbar A, Gamal H, Elkatatny S (2020) Application of artificial neural network to predict the rate of penetration for S-shape well profile, Arabian J. Geosci., 13(16)

Altındağ R, Güney A (2010) Predicting the relationships between brittleness and mechanical properties (UCS, TS and SH) of rocks. https://hdl.handle.net/20.500.12809/4536. Accessed 20 Aug 2022

Armaghani DJ, Tonnizam Mohamad E, Momeni E, Monjezi M, Sundaram Narayanasamy M (2016) Prediction of the strength and elasticity modulus of granite through an expert artificial neural network. Arab J Geosci 9(1):1–16

Ashtari M, Mousavi SE, Cheshomi A, Khamechian M (2019) Evaluation of the single compressive strength test in estimating uniaxial compressive and Brazilian tensile strengths and elastic modulus of marlstone. Eng Geol 248:256–266. https://doi.org/10.1016/j.enggeo.2018.12.005

Azimian A, Ajalloeian R, Fatehi L (2014) An empirical correlation of uniaxial compressive strength with P-wave velocity and point load strength index on marly rocks using statistical method. Geotech Geol Eng 32:205–214. https://doi.org/10.1007/s10706-013-9703-x

Boutt DF, Cook BK, Williams JR (2011) A coupled fluid–solid model for problems in geomechanics: application to sand production. Int J Numer Anal Methods Geomech 35(9):997–1018. https://doi.org/10.1002/nag.938

Çelik SB (2019) Prediction of uniaxial compressive strength of carbonate rocks from nondestructive tests using multivariate regression and LS-SVM methods. Arab J Geosci 12(6):1–17. https://doi.org/10.1007/s12517-019-4307-2

Comakli R, Cayirli S (2019a) A correlative study on textural properties and crushability of rocks. Bull Eng Geol Environ 78:3541–3557. https://doi.org/10.1007/s10064-018-1357-8

Comakli R, Cayirli S (2019b) A correlative study on textural properties and crushability of rocks. Bull Eng Geol Environ 78:3541–3557. https://doi.org/10.1007/s10064-018-1357-8

Diamantis K, Moussas VC (2021) Estimating uniaxial compressive strength of peridotites from simple tests using neural networks. Arab J Geosci 14(23):1–13

Ebdali M, Khorasani E, Salehin S (2020) A comparative study of various hybrid neural networks and regression analysis to predict unconfined compressive strength of travertine. Innovative Infrastructure Solutions 5(3):1–14. https://doi.org/10.1007/s41062-020-00346-3

Elmo D, Donati D, Stead D (2018) Challenges in the characterisation of intact rock bridges in rock slopes. Eng Geol 245:81–96. https://doi.org/10.1016/j.enggeo.2018.06.014

Farah R (2011) Correlations between index properties and unconfined compressive strength of weathered Ocala limestone. Master’s Thesis. The University of North Florida, College of Computing, Engineering & Construction, Florida

Ferentinou M, Fakir M (2017) An ANN approach for the prediction of uniaxial compressive strength, of some sedimentary and igneous rocks in eastern KwaZulu-Natal. In ISRM European Rock Mechanics Symposium - EUROCK 2017, Ostrava, Czech Republic, June 2017. Paper Number: ISRM-EUROCK-2017-141

Fjaer E, Holt RM, Horsrud P, Raaen AM, Risne A (2008) Petroleum related rock mechanics, 2nd edn. The Netherlands, Oxford, UK, Elsevier

Germay C, Lhomme T, Richard T (2017, June) Using high resolution, continuous profiles of core properties for the upscaling of Rock Mechanical Tests results and the accurate calibration of geomechanical models. Presented at the 51st U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, California, USA, June 2017. Paper Number: ARMA-2017-0691.

Ghasemi E, Kalhori H, Bagherpour R, Yagiz S (2018) Model tree approach for predicting uniaxial compressive strength and Young’s modulus of carbonate rocks. Bull Eng Geol Environ 77(1):331–343. https://doi.org/10.1007/s10064-016-0931-1

Harandizadeh H, Armaghani DJ, Mohamad ET (2020) Development of fuzzy-GMDH model optimized by GSA to predict rock tensile strength based on experimental datasets. Neural Comput & Applic 32(17):14047–14067. https://doi.org/10.1007/s00521-020-04803-z

Hassanvand M, Moradi S, Fattahi M, Zargar G, Kamari M (2018) Estimation of rock uniaxial compressive strength for an Iranian carbonate oil reservoir: modeling vs. artificial neural network application. Petrol Res 3(4):336–345. https://doi.org/10.1016/j.ptlrs.2018.08.004

He M, Zhang Z, Ren J, Huan J, Li G, Chen Y, Li N (2019) Deep convolutional neural network for fast determination of the rock strength parameters using drilling data. Int J Rock Mech Min Sci 123:104084

He M, Li N, Zhu J, Chen Y (2020) Advanced prediction for field strength parameters of rock using drilling operational data from impregnated diamond bit. J Petrol Sci Eng 187(December 2019): 106847. https://doi.org/10.1016/j.petrol.2019.106847

Heidari M, Khanlari GR, Kaveh MT, Kargarian S (2012) Predicting the uniaxial compressive and tensile strengths of gypsum rock by point load testing. Rock Mech Rock Eng 45(2):265–273. https://doi.org/10.1007/s00603-011-0196-8

Heidari M, Mohseni H, Jalali SH (2018) Prediction of uniaxial compressive strength of some sedimentary rocks by fuzzy and regression models. Geotech Geol Eng 36:401–412. https://doi.org/10.1007/s10706-017-0334-5

Huang L, Asteris PG, Koopialipoor M, Armaghani DJ, Tahir MM (2019) Invasive weed optimization technique-based ANN to the prediction of rock tensile strength. Appl Sci 9(24):5372. https://doi.org/10.3390/app9245372

Hussain M, Amao AO, Al-Ramadan K, Negara A, Saleh TA (2020) Non-destructive techniques for linking methodology of geochemical and mechanical properties of rock samples. J Pet Sci Eng 195:107804. https://doi.org/10.1016/j.petrol.2020.107804

**g H, Nikafshan Rad H, Hasanipanah M, Jahed Armaghani D, Qasem SN (2021) Design and implementation of a new tuned hybrid intelligent model to predict the uniaxial compressive strength of the rock using SFS-ANFIS. Engineering with Computers 37(4):2717–2734. https://doi.org/10.1007/s00366-020-00977-1

Kahraman SAİR (2014) The determination of uniaxial compressive strength from point load strength for pyroclastic rocks. Eng Geol 170:33–42. https://doi.org/10.1016/j.enggeo.2013.12.009

Kahraman S, Fener M, Gunaydin O (2017) Estimating the uniaxial compressive strength of pyroclastic rocks from the slake durability index. Bull Eng Geol Environ 76:1107–1115. https://doi.org/10.1007/s10064-016-0893-3

Kalantari S, Hashemolhosseini H, Baghbanan A (2018) Estimating rock strength parameters using drilling data. Int J Rock Mech Min 104:45–52. https://doi.org/10.1016/j.ijrmms.2018.02.013

Khosravanian R, Aadnoy BS (2016) Optimization of casing string placement in the presence of geological uncertainty in oil wells: offshore oilfield case studies. J Pet Sci Eng 142:141–151. https://doi.org/10.1016/j.petrol.2016.01.033

Klimentos T (2005) Optimizing drilling performance by wellbore stability and pore-pressure evaluation in deepwater exploration. In International Petroleum Technology Conference. OnePetro

Lashkaripour GR (2002) Predicting mechanical properties of mudrock from index parameters. Bull Eng Geol Environ 61(1):73–77. https://doi.org/10.1007/s100640100116

Luo Y (2020) Influence of water on mechanical behavior of surrounding rock in hard-rock tunnels: an experimental simulation. Eng Geol 277:105816. https://doi.org/10.1016/j.enggeo.2020.105816

Madhubabu N, Singh PK, Kainthola A, Mahanta B, Tripathy A, Singh TN (2016) Prediction of compressive strength and elastic modulus of carbonate rocks. Measurement 88:202–213. https://doi.org/10.1016/j.measurement.2016.03.050

Mahdiabadi N, Khanlari G (2019) Prediction of uniaxial compressive strength and modulus of elasticity in calcareous mudstones using neural networks, fuzzy systems, and regression analysis. Periodica Polytechnica Civil Engineering 63(1):104–114. https://doi.org/10.3311/PPci.13035

Mahdiyar A, Armaghani DJ, Marto A, Nilashi M, Ismail S (2019) Rock tensile strength prediction using empirical and soft computing approaches. Bull Eng Geol Environ 78(6):4519–4531. https://doi.org/10.1007/s10064-018-1405-4

Mahmoodzadeh A, Mohammadi M, Daraei A, Faraj RH, Omer RMD, Sherwani AFH (2020) Decision-making in tunneling using artificial intelligence tools. Tunn Undergr Space Technol 103:103514. https://doi.org/10.1016/j.tust.2020.103514

Mahmoodzadeh A, Mohammadi M, Hashim Ibrahim H, Nariman Abdulhamid S, Ghafoor Salim S, Farid Hama Ali H, Kamal Majeed M (2021) Artificial intelligence forecasting models of uniaxial compressive strength. Transport Geotech 27(December 2020):100499. https://doi.org/10.1016/j.trgeo.2020.100499

Mohamad ET, Armaghani DJ, Momeni E, Abad SVANK (2015) Prediction of the unconfined compressive strength of soft rocks: a PSO-based ANN approach. Bull Eng Geol Environ 74(3):745–757. https://doi.org/10.1007/s10064-014-0638-0

Moos D, Peska P, Finkbeiner T, Zoback M (2003) Comprehensive wellbore stability analysis utilizing quantitative risk assessment. J Pet Sci Eng 38(3-4):97–109. https://doi.org/10.1016/S0920-4105(03)00024-X

Moussas VC, Diamantis K (2021) Predicting uniaxial compressive strength of serpentinites through physical, dynamic and mechanical properties using neural networks. J Rock Mech Geotech Eng 13(1):167–175

Mozumder RA, Laskar AI (2015) Prediction of unconfined compressive strength of geopolymer stabilized clayey soil using artificial neural network. Comput Geotech 69:291–300

Najibi AR, Ghafoori M, Lashkaripour GR, Asef MR (2017) Reservoir Geomechanical Modeling: In-Situ Stress, Pore Pressure, and Mud Design. J Pet Sci Eng 151(January):31–39. https://doi.org/10.1016/j.petrol.2017.01.045

Nazir R, Momeni E, Armaghani DJ, Amin MM (2013) Correlation between unconfined compressive strength and indirect tensile strength of limestone rock samples. Electron J Geotech Eng 18(1):1737–1746

Nefeslioglu HA (2013) Evaluation of geo-mechanical properties of very weak and weak rock materials by using non-destructive techniques: ultrasonic pulse velocity measurements and reflectance spectroscopy. Eng Geol 160:8–20. https://doi.org/10.1016/j.enggeo.2013.03.023

Palassi M, Emami V (2014) A new nail penetration test for estimation of rock strength. Int J Rock Mech Min Sci 66:124–127. https://doi.org/10.1016/j.ijrmms.2013.12.016

Palchik V (1999) Influence of porosity and elastic modulus on uniaxial compressive strength in soft brittle porous sandstones. Rock Mech Rock Eng 32(4):303–309. https://doi.org/10.1007/s006030050050

Parsajoo M, Armaghani DJ, Mohammed AS, Khari M, Jahandari S (2021) Tensile strength prediction of rock material using non-destructive tests: a comparative intelligent study. Transport Geotech 31:100652. https://doi.org/10.1016/j.trgeo.2021.100652

Perras MA, Diederichs MS (2014) A review of the tensile strength of rock: concepts and testing. Geotech Geol Eng 32(2):525–546. https://doi.org/10.1007/s10706-014-9732-0

Rabbani E, Sharif F, Koolivand Salooki M, Moradzadeh A (2012) Application of neural network technique for prediction of uniaxial compressive strength using reservoir formation properties. Int J Rock Mech Min Sci 1997(56):100–111. https://doi.org/10.1016/j.ijrmms.2012.07.033

Settari A, Walters DA (2001) Advances in coupled geomechanical and reservoir modeling with applications to reservoir compaction. SPE J 6(03):334–342. https://doi.org/10.2118/74142-PA

Sharma LK, Vishal V, Singh TN (2017) Develo** novel models using neural networks and fuzzy systems for the prediction of strength of rocks from key geomechanical properties. Measure J Intl Measure Conf 102:158–169. https://doi.org/10.1016/j.measurement.2017.01.043

Singh VK, Singh D, Singh TN (2001) Prediction of strength properties of some schistose rocks from petrographic properties using artificial neural networks. Int J Rock Mech Min Sci 38(2):269–284. https://doi.org/10.1016/S1365-1609(00)00078-2

Torabi-Kaveh M, Naseri F, Saneie S, Sarshari B (2015) Application of artificial neural networks and multivariate statistics to predict UCS and E using physical properties of Asmari limestones. Arab J Geosci 8(5):2889–2897. https://doi.org/10.1007/s12517-014-1331-0

Tsiambaos G, Sabatakakis N (2004) Considerations on strength of intact sedimentary rocks. Eng Geol 72(3-4):261–273. https://doi.org/10.1016/j.enggeo.2003.10.001

Tuğrul A, Zarif IH (1999) Correlation of mineralogical and textural characteristics with engineering properties of selected granitic rocks from Turkey. Eng Geol 51(4):303–317. https://doi.org/10.1016/S0013-7952(98)00071-4

Ulusay R, Hudson JA (2007) The blue book–the complete ISRM suggested methods for rock characterization, Testing and Monitoring: 1974–2006. ISRM and Turkish National Group of ISRM, Ankara

Wu YC, Feng JW (2018) Development and application of artificial neural network. Wirel Pers Commun 102(2):1645–1656

Yagiz S (2009) Predicting uniaxial compressive strength, modulus of elasticity and index properties of rocks using the Schmidt hammer. Bull Eng Geol Environ 68:55–63. https://doi.org/10.1007/s10064-008-0172-z

Yasar E, Erdogan Y (2004) Correlating sound velocity with the density, compressive strength and Young’s modulus of carbonate rocks. Int J Rock Mech Min Sci 41(5):871–875. https://doi.org/10.1016/j.ijrmms.2004.01.012

Yılmaz I, Sendır H (2002) Correlation of Schmidt hardness with unconfined compressive strength and Young’s modulus in gypsum from Sivas (Turkey). Eng Geol 66(3-4):211–219. https://doi.org/10.1016/S0013-7952(02)00041-8

Ying J, Han Z, Shen L, Li W (2020) Influence of parent concrete properties on compressive strength and chloride diffusion coefficient of concrete with strengthened recycled aggregates. Materials 13(20):4631. https://doi.org/10.3390/ma13204631

Zhang L, Cao P, Radha KC (2010) Evaluation of rock strength criteria for wellbore stability analysis. Int J Rock Mech Min Sci 47(8):1304–1316. https://doi.org/10.1016/j.ijrmms.2010.09.001

Zoback MD (2010) Reservoir geomechanics. Cambridge university press

Acknowledgements

The authors would like to thank King Fahd University of Petroleum & Minerals (KFUPM) for employing its resources in conducting this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that that they have no competing interests.

Additional information

Responsible Editor: Santanu Banerjee

Appendix

Appendix

Unit conversion table

SI metric conversion factors | |

|---|---|

cP × 1* | E-03 = Pa s |

(°F-32) × 5/9 + 273.15 | E+00 = K |

in. × 2.54* | E-02 = m |

psi × 145.038 | MPa |

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hiba, M., Ibrahim, A.F. & Elkatatny, S. Real-time prediction of tensile and uniaxial compressive strength from artificial intelligence-based correlations. Arab J Geosci 15, 1546 (2022). https://doi.org/10.1007/s12517-022-10785-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-022-10785-0