Abstract

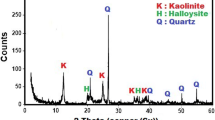

The addition of various quantities of raw materials could be used in order to improve the physical and pyroscopic performances of silica-alumina refractories manufacturing. Here we study the possibility of local kaolinitic clay (SB) valorization in low alumina fireclay refractory materials manufacturing. Alumina-rich commercial kaolin (AS) (33.4% alumina) was also used as an additive to (SB) clay (24% alumina), to improve the physical and pyroscopic performances of the manufactured samples. The thermal behavior of (SB) clay was studied to determine necessary parameters for the production of good chamotte. In order to elaborate the refractory samples, two mixtures were optimized; mixture M1 (80 wt.% of chamotte (SB) and 20 wt.% of (SB) clay as a binder in crude fine form) and mixture M2 (80 wt.% of chamotte (SB) and 20 wt.% of (AS) kaolin as a binder in crude fine form) and sintered at 1350 °C for 2 h after compaction and molding. The obtained samples were characterized by their bulk density, open porosity, shrinkage, cold crushing strength, microstructure by scanning electron microscope (SEM) micrographs, mineralogical composition, and their refractoriness under load. Our data suggest that the addition of the alumina-rich clay to the main mixture enhances the refractoriness from 1198 to 1213 °C (T0.5), the mechanical behavior of the manufactured pellets from 36 to 44 MPa, and the mullite amount from 25 to 29%, and decreases the open porosity from 19.6 to 18.6 %.

Similar content being viewed by others

References

Aladesuyi O, Pal M, Das SK, Ajanaku KO (2017) Phase and microstructural evolution during sintering of mixture of 75:25. Nigerian kaolin and calcined alumina powder compacts, JMES, 2017 8(8):2682–2838

Amrane B (2003) Élaboration et caractérisation d’un matériau réfractaire thermorésistant pour supports de cuisson rapide des produits céramiques. In: Mémoire de mastère. Université de Boumerdes, Faculté des Sciences de l’Ingénieur, p 117

Amrane B (2012) Thèse de doctorat en métallurgie, Modelisation du comportement thermomecanique des ceramiques par la mecanique de l’endommagement : cas des refractaires silico-alumineux façon, Ecole Nationale Polytechnique d’Alger. Algérie:187

Amrane B, Ouedraogo E, Mamen B, Djaknoun Mesrati N (2011) Experimental study of thermo-mechanical behaviour of alumina-silicat refractory materialsbased on mixture of Algerian kaolinitic clays. Ceram Int 37:3217–3227

Bennour A, Mahmoudi S, Srasra E, Boussen S, Htira N (2015) Composition, firing behavior and ceramic properties of the Sejnène clays (Northwest Tunisia). Appl Clay Sci 115:30–38

Bouzidi N (2012) Thèse de doctorat en Génie des procédés, Influence des impuretés des kaolins sur les propriétés des produits de cuisson. Université de Bjaia, Algériee, p 135

Chargui H, Hajjaji W, Wouters J, Yans J, Jamoussi F (2018) Direct orange34 dye fixation by modified Kaolin. Clay Miner 53:271–287

Chen L, Mlfiet A, TomJones P, Blanpin B, Guo M (2015) Degradation mechanisms of alumina–silica runner refractories by carbon steel during ingot casting process. Ceram Int 42:10209–10214

Delphine B (2004) Néogenèses silico-alumineuses en contexte cryptokarstique de l'halloysite de Beez (Namur, Belgique) et de Aïn Khamouda (Kasserine, Tunisie). PhD Thesis, University Paris- Sud XI, France. 231

Dermech M (1990) Le complexe de l'oued Bélif-Sidi Driss (Tunisie septentrionale) Hydrothermalisme et métallogénie, PhD Thesis, University Tunis El manar, Tunisia. 336

Djangang, C.N., Elimbi, A., Melo, U.C., Lecomte, G.L., Nkoumbou, C., Soro, N., Bonnet,J., Blanchart, P., Njopwouo, D., 2008. Sintering of clay-chamotte ceramic composites for refractory bricks, Ceram Int, 34, 1207–1213.

El-Kheshen A, Zawrah M (2003) Sinterability, microstructure and properties of glass/ceramic composites. Ceram Int 29:251–257

EN ISO (1893) 2007. Produits réfractaires -- Détermination de l'affaissement sous charge -- Méthode différentielle avec élévation de la température

Fayyad SM, Al Marahleh G, Abu-Ein S (2012) Improvement of the Refractoriness under Load of Fire-Clay Refractory Bricks Adv. Theor Appl Mech 5, 2012(4):161–172

Felhi M, Tlili A, Gaied ME, Montacer M (2008) Mineralogical study of kaolinitic clays from Sidi El Bader in the far north of Tunisia. Appl Clay Sci 39:208–217

Fildes C, Stow DAV, Riahi S, Soussi M, Patel U, Milton JA, Marsh S (2009) European Provenance of the Numidian Flysch in northern Tunisia. Terra Nova 22(2):94–102

Galdina N (1983) Improvement in the quality of refectory materials. Glas Ceram 7-8:439–442

Hachani M (2011) Thèse de doctorat. In: Valorisation céramique de quelques argiles du Crétacé inférieur: formation Bouhedma (Altlas centro-méridional) et Duiret (Plateforme saharienne). Université de Carthage, Faculté des Sciences de Bizerte, p 177

Hassan SB, Aigbodion VS (2014) Effect coal ash on some refractory properties of alumino-silicate (Kankara) clay for furnace lining. Sciences direct:1–8

Ilavsky J (1966) Les argiles de Tunisie. Service Géologique, Office Nationale des Mines, Tunisie, p 150

Jamoussi F (2001) Caractérisation minéralogique, géochimique, géotechnique et utilisation industrielle des argiles de Tunisie. Doc. Thesis, University Tunis, Tunisie.437

Jeridi K, Hachani M, Hajjaji W, Moussi B, Medhioub M, Lopez-Galindo A, Zargouni F, Labrincha J, Jamoussi F (2008) Technological behaviour of some Tunisian clays prepared by dry ceramic processing. Clay Miner 43(3):339–350

Jouenne CA (1990) Traite de Céramiques et Matériaux Minéraux, Editions Septima Paris, 1990

Khiari I (2017) Etudes de quelques argiles utilisées dans les domaines cosmétiques et pharmaceutiques en méditerrané occidentale. Thèse de doctorat en sciences géologique, Université de Sfax, Tunisie .208

Kirabira JB (2003) Properties of Ugandan minerals and fireclay refractories. Doctoral thesis, Stocholm, Swedenpp, pp 1–50

Kolli M 2008 Elaboration et caractérisation thermomécanique de réfractaires à base de kaolin DD3. Thèse de doctorat en optique et mécanique de précision, Université Ferhat Abbas-Setif UFAS (Algerie). 175

Kolli M, Hamidouche M, Fantozzi G, Chevalier J (2007) Elaboration and characterization of a refractory based on Algerian kaolin. Ceram Int 33:1435–1443

Mahmoudi S, Bennour A, Meguebli A, srasra, E., Zargouni, F. (2016) Characterization and traditional ceramic application of clays from the Douiret region in South Tunisia. Appl Clay Sci 127–128(2016):78–87

Mécif A (2010) Elaboration et Etude Des Réfractaires à Base de Mullite et du Zircon. Thèse de doctorat en physique, Université de Mentouri – Constantine, Algérie. 123

Minlheiro FAC, Freire MN, Silva AG, Holanda PJNF (2005) Densification behaviour of red firing Brazilian kaolinitic clay. Ceram Int 31:757–763

Moussi B (2012) Mode de genèse et valorisation de quelques argiles de la région de Nefza-Sejnane (Tunisie Septentrionale). Thèse de doctorat en sciences géologique, Université de Carthage, Tunisie. 157

Moussi B, Medhioub M, Hatira N, Yans J, Hajjaji W, Rocha F, Labrincha JA, Jamoussi F (2011) Identification and use of white clayey deposits from the area of Tamra (northern Tunisia) as ceramic raw materials. Clay Miner 46:165–175

Parize O, Beaudoin B, Burollet PF, Cojan G, Fries G, Pinault M (1986) La provenance du matériel gréseux numidien est septentrionale (Sicile et Tunisie). CR Acad Sci Paris 18:1671–1674

Poirier, J., 2011. Les céramiques réfractaires de l’élaboration aux propriétés d’emploi. Verres céramiques & composites, vol. 1, n°2 28-42

Rahman H, Tariqul Islam Md, Ibn Minhaj T, Azad MAK, Mehedi Hassan MD, Haque R, Md AA (2015) Study of thermal conductivity and mechanical property of insulating firebrick produced by local clay and petroleum coal dust as raw materials. Science Direct Procedia Engineering 105(2015):121–128

Routschka G (ed) (2004) Pocket manual—refractory materials: basics, structures and properties, 2nd edn. Essen, Vulkan-Verlag

Rouvier H (1967) Géologie de l'extrême Nord tunisien: tectoniques et paléogéographies superposées à l'extrémité orientale de la chaîne nord magrébine. Annale des Mines et de la Géologie. Office Nationale des Mines, Tunisie, p 29

Rouvier H (1994) Notice explicative de la carte géologique de la Tunisie à 1/50.000.Nefza, feuilleN° 10.OfficeNationale des Mines,Tunisie

Sadik C, Albizane A, El Amrani E (2013) Production of porous firebrick from mixtures of clay and recycled refractory waste with expanded perlite addition, 2002. J Mater Environ Sci 4:123–130

Sadik C, Albizane A, El Amrani E (2014) Recent advances in silica-alumina refractory: a review. Journal of Asian Ceramic Societies 2:83–96

Sadik C, Moudden O, El Bouari A, El Amrani I (2016) Review on the elaboration and characterization of ceramics refractories based on magnesite and dolomite. Journal of Asian Ceramic Societies 4(2016):219–233

Serna F, Lagneau J, Carpentier JM (2014) La diffraction des rayons X: une technique puissante pour résoudre certains problèmes industriels et technologiques. Chimie nouvelle n° 116

Serra MF, Conconie MS, Gaune MR, Suarez G, Aglietti EF, Randtorff NM (2015) Mullite (3Al2O3·2SiO2) ceramics obtained by reaction sintering of rice husk ash and alumina, phase evolution, sintering and microstructure. Journal of Asian ceramic societies:7

Seynou M, Flamen P, Swadogo M, Tirlocq J, Ouedraogo R (2013) Refractory bricks based on Tikaré (Burkina Faso) Kaolinitic clay material. Journal de la société Ouest-Africaine de chimie. 18 éme année, n°035.ISSN 0796-6687

Shaw K (1972) Refractories and their uses Applied Science Publishers Ltd, London

Talbi F (1998) Petrologie, géochimie, études des phases fluides et gîtologie liées au magmatisme néogène de la Tunisie septentrionale. Thèse de doctorat. Université Tunis II. 368

Wildi W (1983) La chaîne tello-rifaine (Algérie, Maroc, Tunisie): structure, stratigraphie et évolution du Trias au Miocène. Rev Géol Dyn Géogr Phys 24:201–297

Yaich C, Hooyberghs HJF, Durlet C, Renard M (2000) Corrélation stratigraphique entre les unités oligo-miocènes de Tunisie centrale et le Numidien. C.R. Acad. Sci. Paris 331:499–506

Zawrah M, Hamzawy E (2002) Effect of the cristobalite formation on sinterability microstructure and the properties of glass/ceramic composites. Ceramics international 28:123–130

Acknowledgements

Special thanks to all the staff and collaborators of the Ministry of Higher Education and Scientific Research of Tunisia, the University of Namur (UNamur), the Belgian Ceramic Research Center (Mons, Belgium), the Water Researches and Technologies Center Borj Cedria-Tunisia. Special thanks also to Pr Saidi Talha and Pr Bouneb Yahya who did the linguistic revision of this paper.

Funding

This work was supported by the Tunisian Belgium Wallonie-Bruxelles International WBI research project “Valorisation des argiles tunisiennes.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Rights and permissions

About this article

Cite this article

Grine, O., Moussi, B., Hajjaji, W. et al. Low-cost northern Tunisian kaolinitic clay-based refractory materials and effect of a rich alumina clay addition. Arab J Geosci 14, 1595 (2021). https://doi.org/10.1007/s12517-021-08099-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-08099-8