Abstract

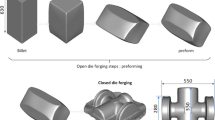

In this paper, a new method of simultaneous die and preform optimization is proposed for closed die forging of nearly plane-strain components with complex geometry along their axes. In this method, using two-dimensional finite element simulations and the response surface method, optimal values for the width and thickness of the flash land and the amount of additional material in each of the main sections are obtained. Accordingly, using the variable gutter technique, the preform and dies are designed based on the optimization goal. To investigate the usefulness of the method in three optimization approaches, including the minimum forging force, the minimum excess material, and a balance between the forging force and the excess material, the values of forging load, waste material, die stress, deformation, heat distribution, material flow, and die wear were determined numerically and compared to the conventional method. The results showed that the presented method can save up to 60% in forging force and up to 51.5% in excess material compared to the conventional method. It can also minimize die wear by up to 74% and die stress by up to 50%. Finally, the numerical results showed that a balanced mode between the minimum forging load and the minimum excessive materials can be chosen as the most appropriate selection for practical purposes.

Graphic Abstract

Similar content being viewed by others

Data availability

All the data is presented in the manuscript.

References

Gronostajski, Z., Pater, Z., Madej, L., Gontarz, A., Lisiecki, L., Łukaszek-Sołek, A., Ziółkiewicz, S.: Recent development trends in metal forming. Arch. Civil Mech. Eng. 19(3), 898–941 (2019). https://doi.org/10.1016/j.acme.2019.04.005

Hosseini-Ara, R., Yavari, P.: A new criterion for preform design of H-shaped hot die forging based on shape complexity factor. Int.J. Mater. Form. 11(2), 233–238 (2018). https://doi.org/10.1007/s12289-017-1345-8

Knust, J., Podszus, F., Stonis, M., Behrens, B.A., Overmeyer, L., Ullmann, G.: Preform optimization for hot forging processes using genetic algorithms. Int. J. Adv. Manuf. Technol. 89, 1623–1634 (2017). https://doi.org/10.1007/s00170-016-9209-9

Knust, J., Stonis, M., Behrens, B.A.: Preform optimization for hot forging processes using an adaptive amount of flash based on the cross section shape complexity. Prod. Eng. Res. Devel. 10, 587–598 (2016). https://doi.org/10.1007/s11740-016-0702-7

Kampen, D., Richter, J., Blohm, T., Knust, J., Langner, J., Stonis, M., Behrens, B.A.: Design of a genetic algorithm to preform optimization for hot forging processes. Int. J. Mater. Form. 13, 77–89 (2020). https://doi.org/10.1007/s12289-019-01469-4

Meng, F.X., Cai, Z.Y., Chen, Q.M.: Multi-objective optimization of preforming operation in near-net shape forming of complex forging. Int. J. Adv. Manuf. Technol. 105, 4359–4371 (2019). https://doi.org/10.1007/s00170-019-04539-8

Guan, Y., Bai, X., Liu, M., Song, L., Zhao, G.: Preform design in forging process of complex parts by using quasi-equipotential field and response surface methods. Int. J. Adv. Manuf. Technol. 79, 21–29 (2015). https://doi.org/10.1007/s00170-014-6775-6

Ke, W.E.I., Mei, Z.H.A.N., **aoguang, F.A.N., He, Y.A.N.G., Pengfei, G.A.O., Miao, M.E.N.G.: Unequal-thickness billet optimization in transitional region during isothermal local loading forming of Ti-alloy rib-web component using response surface method. Chin. J. Aeronaut. 31(4), 845–859 (2018). https://doi.org/10.1016/j.cja.2017.07.005

Mirahmadi, S.J., Hamedi, M.: Flash gap optimization in precision blade forging. Int. J. Mech. Eng. Robot. Res. 6(3), 200–205 (2017). https://doi.org/10.18178/ijmerr.6.3.200-205

Pandya, V.A., George, P.M.: Preform optimization for the anchor shackle during closed die forging process on one ton hammer. Mater. Today 47, 3256–3262 (2021). https://doi.org/10.1016/j.matpr.2021.06.450

Ding, T., Wei, K., Yang, C., Tang, H.: Robust optimization of consistency in filling of rib-grooves for titanium alloy multi-rib eigenstructure. Int. J. Adv. Manuf. Technol. (2023). https://doi.org/10.1007/s00170-023-11379-0

Sedighi, M., Pourbashiri, M.: Variable gutter technique as a novel method to reduce waste material in closed die-forging process. J. Mech. Sci. Technol. 28, 5129–5134 (2014). https://doi.org/10.1007/s12206-014-1135-x

Hu, C., Zeng, F., Zhao, Z., Guo, Z.: Process optimization for design of duplex universal joint fork using unequal thickness flash. Int. J. Precis. Eng. Manuf. 16, 2517–2527 (2015). https://doi.org/10.1007/s12541-015-0323-7

Pourbashiri, M., Sedighi, M.: Investigating the effect of variable gutter technique as a novel method on vertical flow of material in closed die forging processes. J. Mech. Sci. Technol. 30, 1851–1857 (2016). https://doi.org/10.1007/s12206-016-0342-z

Langner, J., Stonis, M., Behrens, B.A.: Investigation of a moveable flash gap in hot forging. J. Mater. Process. Technol. 231, 199–208 (2016). https://doi.org/10.1016/j.jmatprotec.2015.12.019

Liu, Y., Wang, J., Wang, D.: Numerical optimization on hot forging process of connecting rods based on RSA with experimental verification. Int. J. Adv. Manuf. Technol. 90, 3129–3135 (2017). https://doi.org/10.1007/s00170-016-9635-8

Kabataş, B., Livatyali, H., Temiztaş, B.A.: Process optimization for hot forging of difficult parts by computer experiments and response surface analysis. J. Adv. Manuf. Eng. 3(2), 33–45 (2023)

Zhang, Y., Cao, S., Huang, M., Yan, Y., Deng, Q., Li, S., **a, J., Deng, L., **, J., Chen, T., Yang, J.: Research and application of precision forging forming process for flat thin flash of automobile disc steering knuckle. Procedia Manuf. 50, 32–36 (2020). https://doi.org/10.1016/j.promfg.2020.08.007

Altan, T., Ngaile, G., Shen, G. (Eds.): Cold and hot forging: fundamentals and applications (Vol. 1). ASM international (2004)

DIN 15401: Lifting hooks for lifting appliances, single hooks, unmachined parts (1982)

Sleeckx, E., Kruth, J.P.: Review of flash design rules for closed-die forgings. J. Mater. Process. Technol. 31(1–2), 119–134 (1992). https://doi.org/10.1016/0924-0136(92)90013-I

Shahriari, D., Sadeghi, M. H., Cheraghzadeh, M., & Taghipour, M.: Flash design optimization in blade forging using FEM method. In: AIP Conference Proceedings (Vol. 908, No. 1, pp. 1035–1040). American Institute of Physics (2007) https://doi.org/10.1063/1.2740947

Samolyk, G., Pater, Z.: Application of the slip-line field method to the analysis of die cavity filling. J. Mater. Process. Technol. 153, 729–735 (2004). https://doi.org/10.1016/j.jmatprotec.2004.04.092

Lin, Y.C., Chen, M.S., Zhang, J.: Modeling of flow stress of 42CrMo steel under hot compression. Mater. Sci. Eng. A 499(1–2), 88–92 (2009). https://doi.org/10.1016/j.msea.2007.11.119

Luo, S., Yao, J., Zou, G., Li, J., Jiang, J., Yu, F.: Influence of forging velocity on temperature and phase transformation characteristics of forged Ti-6Al-4V aeroengine drum. Int. J. Adv. Manuf. Technol. 110, 3101–3111 (2020). https://doi.org/10.1007/s00170-020-06084-1

Luo, S., Zhu, D., Hua, L., Qian, D., Yan, S.: Numerical analysis of die wear characteristics in hot forging of titanium alloy turbine blade. Int. J. Mech. Sci. 123, 260–270 (2017). https://doi.org/10.1016/j.ijmecsci.2017.02.013

Simufact forming 13. 0 manual: (2016)

Myers, R.H., Montgomery, D.C., Anderson-Cook, C.M.: Response surface methodology: Process and product optimization using designed experiments. Wiley, Nashville (2016)

Politis, D.J., Politis, N.J., Lin, J., Dean, T.A.: A review of force reduction methods in precision forging axisymmetric shapes. Int. J. Adv. Manuf. Technol. 97, 2809–2833 (2018). https://doi.org/10.1007/s00170-018-2151-2

Chen, F., Cui, Z., Chen, J.: Prediction of microstructural evolution during hot forging. Manuf. Rev. 1, 6 (2014). https://doi.org/10.1051/mfreview/2014006

Łukaszek-Sołek, A., Krawczyk, J., Śleboda, T., Grelowski, J.: Optimization of the hot forging parameters for 4340 steel by processing maps. J. Market. Res. 8(3), 3281–3290 (2019). https://doi.org/10.1016/j.jmrt.2019.05.018

Buchmayr, B., Elser, J.: High temperature friction and wear testing for closed-die steel and aluminium forgings. Key Eng. Mater. 767, 204–211 (2018). https://doi.org/10.4028/www.scientific.net/KEM.767.204

Yu, Y., Zottis, J., Wolfgarten, M., Hirt, G.: Investigation of applying protective sheet metal die covers for hot forging dies on a cross-forging geometry. Int. J. Adv. Manuf. Technol. 102, 999–1007 (2019). https://doi.org/10.1007/s00170-018-03250-4

Buchmayr, B.: Damage, lifetime, and repair of forging dies. Berg Huettenmaenn Monatsh 162, 88–93 (2017). https://doi.org/10.1007/s00501-016-0566-3

Chander, S., Chawla, V.: Failure of hot forging dies–an updated perspective. Mater. Today Proceed. 4(2), 1147–1157 (2017). https://doi.org/10.1016/j.matpr.2017.01.131

Funding

The preparation of this manuscript was not supported by any grant or funding.

Author information

Authors and Affiliations

Contributions

Hamed Sheikhbahaee designed the research strategy and performed computer modeling and simulation. S. Javid Mirahmadi conducted data analysis and manuscript editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest that are relevant to the content of this article.

Ethical approval

The authors declare that there are no ethical issues involved in this research.

Consent to participate

The authors declare that they all consent to participate in this research.

Consent to publish

The authors declare that they all consent to publish the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sheikhbahaee, H., Mirahmadi, S.J. 2D-based optimization of closed die forging using the variable gutter technique and response surface methodology. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01842-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01842-x