Abstract

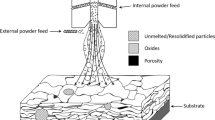

This review article specifically focuses on today’s cutting-edge technology i.e., the cold gas dynamic spray coating process, which is a relatively new technique in the field of orthopedics and antibacterial coatings. Cold gas dynamic spray coating (CGDS) has many advantages over conventional high-temperature processes, such as cost-effectiveness, suitability for oxygen-sensitive materials, and sustainable environmentally-friendly properties and functionality. Powdered form feedstock material is used in this process and accelerated supersonically onto the appropriate substrate without melting. The deposition of pure ceramic deposits, such as hydroxyapatite, remains a challenge. Therefore, the authors attempt to analyze more than 100 design, experimental, numerical, and statistical-based case studies which include the challenges and future perspective of the cold gas dynamic spray coating process for biomedical applications. Further, an inclusive evaluation is carried out related to bio-implants and the development and optimization of thermal spray coatings, with a focus on the emerging CGDS coating systems for orthopedics and antibacterial purposes. By analyzing the process parameters involved in CGDS, this review intends to provide insights into the critical factors affecting the quality and properties of the coatings produced, including substrate preparation, powder characteristics, spraying conditions, and post-treatment. The results of this review could help researchers optimize the CS technique to produce more reliable and efficient bio-implants, with improved biocompatibility and mechanical properties.

Similar content being viewed by others

References

Liao, T.Y., Biesiekierski, A., Berndt, C.C., et al.: Multifunctional cold spray coatings for biological and biomedical applications: A review. Prog. Surf. Sci. 97, 100654 (2022). https://doi.org/10.1016/J.PROGSURF.2022.100654

Kumar, S.: Influence of processing conditions on the mechanical, tribological and fatigue performance of cold spray coating: A review. 38:324–365. (2022). https://doi.org/10.1080/02670844.2022.2073424

Hench, L.L.: Biomaterials: A forecast for the future. Biomaterials. 19, 1419–1423 (1998). https://doi.org/10.1016/S0142-9612(98)00133-1

Ratner, B.D., Hoffman, A.S., Schoen, F.J., et al.: Introduction to Biomaterials Science: An Evolving, Multidisciplinary Endeavor. Academic Press Cambridge, MA, USA (2020)

Ramakrishna, S., Mayer, J., Wintermantel, E., Leong, K.W.: Biomedical applications of polymer-composite materials: A review. Compos. Sci. Technol. 61, 1189–1224 (2001). https://doi.org/10.1016/S0266-3538(00)00241-4

Katti, K.S.: Biomaterials in total joint replacement. Colloids Surf., B. 39, 133–142 (2004). https://doi.org/10.1016/J.COLSURFB.2003.12.002

Bauer, S., Schmuki, P., von der Mark, K., Park, J.: Engineering biocompatible implant surfaces: Part I: Materials and surfaces. Prog. Mater. Sci. 58, 261–326 (2013). https://doi.org/10.1016/J.PMATSCI.2012.09.001

Liao, Z., Li, J., Su, Y., et al.: Antibacterial hydroxyapatite coatings on titanium dental implants. Frontiers of Materials Science 2023 17:1 17:1–17. (2023). https://doi.org/10.1007/S11706-023-0628-X

Lv, Y., Chen, Y., Zheng, Y., et al.: Evaluation of the antibacterial properties and in-vitro cell compatibilities of doped copper oxide/hydroxyapatite composites. Colloids Surf., B. 209, 112194 (2022). https://doi.org/10.1016/J.COLSURFB.2021.112194

Shanmugam, K., Doosthosseini, H., Varanasi, S., et al.: Flexible spray coating process for smooth nanocellulose film production. Cellulose. 25, 1725–1741 (2018). https://doi.org/10.1007/S10570-018-1677-7/FIGURES/17

Singh, N., Batra, U., Kumar, K., et al.: Progress in bioactive surface coatings on biodegradable mg alloys: A critical review towards clinical translation. Bioactive Mater. 19, 717–757 (2023). https://doi.org/10.1016/J.BIOACTMAT.2022.05.009

Atiq Ur Rehman, M., Bastan, F.E., Haider, B., Boccaccini, A.R.: Electrophoretic deposition of PEEK/bioactive glass composite coatings for orthopedic implants: A design of experiments (DoE) study. Mater. Design. 130, 223–230 (2017). https://doi.org/10.1016/J.MATDES.2017.05.045

Cizek, J., Matejicek, J.: Medicine meets Thermal Spray Technology: A review of patents. J. Therm. Spray Technol. 27, 1251–1279 (2018). https://doi.org/10.1007/S11666-018-0798-8/FIGURES/20

Vardelle, A., Moreau, C., Akedo, J., et al.: The 2016 Thermal Spray Roadmap. J. Therm. Spray Technol. 2016. 25, 8 (2016). https://doi.org/10.1007/S11666-016-0473-X

Tejero-Martin, D., Rezvani Rad, M., McDonald, A., Hussain, T.: Beyond Traditional Coatings: A Review on Thermal-Sprayed Functional and Smart Coatings. J. Therm. Spray Technol. 2019. 28(4), 598–644 (2019). https://doi.org/10.1007/S11666-019-00857-1

Vilardell, A.M., Cinca, N., Concustell, A., et al.: Cold spray as an emerging technology for biocompatible and antibacterial coatings: State of art. J. Mater. Sci. 50, 4441–4462 (2015). https://doi.org/10.1007/S10853-015-9013-1/TABLES/7

Rokni, M.R., Nutt, S.R., Widener, C.A., et al.: Review of Relationship between particle deformation, Coating Microstructure, and Properties in high-pressure Cold Spray. J. Therm. Spray Technol. 2017. 26(6), 1308–1355 (2017). https://doi.org/10.1007/S11666-017-0575-0

Sun, W., Chu, X., Lan, H., et al.: Current implementation status of Cold Spray Technology: A short review. J. Therm. Spray Technol. 31, 848–865 (2022). https://doi.org/10.1007/S11666-022-01382-4/FIGURES/17

Govande, A.R., Chandak, A., Sunil, B.R., Dumpala, R.: Carbide-based thermal spray coatings: A review on performance characteristics and post-treatment. Int. J. Refract. Met. Hard Mater. 103, 105772 (2022). https://doi.org/10.1016/J.IJRMHM.2021.105772

Sharma, V., Kazi, S.: An investigation on D-gun sprayed Al2O3-SiC coatings. Surf. Coat. Technol. 375, 303–314 (2019). https://doi.org/10.1016/J.SURFCOAT.2019.07.021

Sharma, R.K., Das, R.K., Kumar, S.R.: Microstructure, mechanical and tribological properties of high velocity oxy fuel thermal spray coating: A review. Materialwiss. Werkstofftech. 54, 90–97 (2023). https://doi.org/10.1002/MAWE.202200101

Kuroda, S., Kawakita, J., Watanabe, M., Katanoda, H.: Warm spraying—a novel coating process based on high-velocity impact of solid particles. http://www.tandfonline.com/action/journalInformation?show=aimsScope&journalCode=tsta20#VmBmuzZFCUk 9:17. (2008). https://doi.org/10.1088/1468-6996/9/3/033002

Kawakita, J., Katanoda, H., Watanabe, M., et al.: Warm spraying: An improved spray process to deposit novel coatings. Surf. Coat. Technol. 202, 4369–4373 (2008). https://doi.org/10.1016/J.SURFCOAT.2008.04.011

Tikkanen, J., Gross, K.A., Berndt, C.C., et al.: Characteristics of the liquid flame spray process. Surf. Coat. Technol. 90, 210–216 (1997). https://doi.org/10.1016/S0257-8972(96)03153-2

Wagner, N.: Effect of process parameters on Twin Wire Arc Sprayed Steel Coatings. J. Mater. Eng. Perform. 30, 6650–6655 (2021). https://doi.org/10.1007/S11665-021-05941-8/FIGURES/9

Gedzevicius, I., Valiulis, A.V.: Analysis of wire arc spraying process variables on coatings properties. J. Mater. Process. Technol. 175, 206–211 (2006). https://doi.org/10.1016/J.JMATPROTEC.2005.04.019

Viscusi, A., Astarita, A., Gatta, R., Della, Rubino, F.: A perspective review on the bonding mechanisms in cold gas dynamic spray. 35:743–771. (2018). https://doi.org/10.1080/02670844.2018.1551768

Lupoi, R., O’Neill, W.: Powder stream characteristics in cold spray nozzles. Surf. Coat. Technol. 206, 1069–1076 (2011). https://doi.org/10.1016/J.SURFCOAT.2011.07.061

Irissou, E., Legoux, J.G., Ryabinin, A.N., et al.: Review on cold spray process and technology: Part I - intellectual property. J. Therm. Spray Technol. 17, 495–516 (2008). https://doi.org/10.1007/S11666-008-9203-3/FIGURES/23

Singh, H., Sidhu, T.S., Kalsi, S.B.S., Karthikeyan, J.: Development of cold spray from innovation to emerging future coating technology. J. Brazilian Soc. Mech. Sci. Eng. 35, 231–245 (2013). https://doi.org/10.1007/S40430-013-0030-1/FIGURES/15

Singh, S., Raman, R.K.S., Berndt, C.C., Singh, H.: Influence of Cold Spray Parameters on Bonding Mechanisms. Rev. Met. 2021. 11 (2021). Page 2016 11:2016 https://doi.org/10.3390/MET11122016

Jodoin, B.: Cold spray nozzle mach number limitation. J. Therm. Spray Technol. 11, 496–507 (2002). https://doi.org/10.1361/105996302770348628/METRICS

Góral, A., Żórawski, W., Makrenek, M.: The effect of the standoff distance on the microstructure and mechanical properties of cold sprayed Cr3C2-25(Ni20Cr) coatings. Surf. Coat. Technol. 361, 9–18 (2019). https://doi.org/10.1016/J.SURFCOAT.2019.01.006

Gabor, T., Akin, S., Tsai, J.T., et al.: Numerical Studies on Cold Spray Particle Deposition Using a Rectangular Nozzle. Proceedings of ASME 2022 17th International Manufacturing Science and Engineering Conference, MSEC 2022 1:. (2022). https://doi.org/10.1115/MSEC2022-85673

Li, S., Muddle, B., Jahedi, M., Soria, J.: A numerical investigation of the cold spray process using underexpanded and overexpanded jets. J. Therm. Spray Technol. 21, 108–120 (2012). https://doi.org/10.1007/S11666-011-9691-4/FIGURES/15

Yin, S., Suo, X., Liao, H., et al.: Significant influence of carrier gas temperature during the cold spray process. https://doi.org/101179/1743294414Y0000000276 30:443–450. (2014). https://doi.org/10.1179/1743294414Y.0000000276

Kamaraj, M., Radhakrishnan, V.M.: Cold Spray Coating Diagram: Bonding Properties and Construction Methodology. J. Therm. Spray Technol. 28, 756–768 (2019). https://doi.org/10.1007/S11666-019-00853-5/FIGURES/8

Raoelison, R.N., **e, Y., Sapanathan, T., et al.: Cold gas dynamic spray technology: A comprehensive review of processing conditions for various technological developments till to date. Additive Manuf. 19, 134–159 (2018). https://doi.org/10.1016/J.ADDMA.2017.07.001

Singh, S., Singh, H., Chaudhary, S., Buddu, R.K.: Effect of substrate surface roughness on properties of cold-sprayed copper coatings on SS316L steel. Surf. Coat. Technol. 389, 125619 (2020). https://doi.org/10.1016/J.SURFCOAT.2020.125619

Jodoin, B., Ajdelsztajn, L., Sansoucy, E., et al.: Effect of particle size, morphology, and hardness on cold gas dynamic sprayed aluminum alloy coatings. Surf. Coat. Technol. 201, 3422–3429 (2006). https://doi.org/10.1016/J.SURFCOAT.2006.07.232

Ziemian, C.W., Wright, W.J., Cipoletti, D.E.: Influence of Impact Conditions on Feedstock Deposition Behavior of Cold-Sprayed Fe-Based metallic glass. J. Therm. Spray Technol. 27, 843–856 (2018). https://doi.org/10.1007/S11666-018-0720-4/FIGURES/18

Bhattiprolu, V.S., Johnson, K.W., Ozdemir, O.C., Crawford, G.A.: Influence of feedstock powder and cold spray processing parameters on microstructure and mechanical properties of Ti-6Al-4V cold spray depositions. Surf. Coat. Technol. 335, 1–12 (2018). https://doi.org/10.1016/J.SURFCOAT.2017.12.014

Sandhu, H.S., Phull, G.S., Saini, M.S., et al.: A Review: Bio-compatible thermal spray coating on bio-implant. Lecture Notes in Mechanical Engineering. 71–77 (2021). https://doi.org/10.1007/978-981-16-1079-0_8/COVER

Adebiyi, D.I., Popoola, A.P.I., Botef, I.: Low pressure cold spray coating of Ti-6Al-4V with SiC-based cermet. Mater. Lett. 175, 63–67 (2016). https://doi.org/10.1016/J.MATLET.2016.03.142

MacDonald, D., Fernández, R., Delloro, F., Jodoin, B.: Cold Spraying of Armstrong process Titanium Powder for Additive Manufacturing. J. Therm. Spray Technol. 26, 598–609 (2017). https://doi.org/10.1007/S11666-016-0489-2/FIGURES/11

Raha, S., Mallick, R., Basak, S., Duttaroy, A.K.: Is copper beneficial for COVID-19 patients? Med. Hypotheses. 142, 109814 (2020). https://doi.org/10.1016/J.MEHY.2020.109814

Tang, J.R., Zhao, Z.P., Cui, X.Y., et al.: Microstructure and bioactivity of a cold sprayed rough/porous Ta coating on Ti6Al4V substrate. Sci. China Technological Sci. 63, 731–739 (2020). https://doi.org/10.1007/S11431-019-1446-0/METRICS

Zeng, G., Zahiri, S.H., Gulizia, S., et al.: A comparative study of cell growth on a cold sprayed Ti–Ta composite. J. Alloys Compd. 826, 154014 (2020). https://doi.org/10.1016/J.JALLCOM.2020.154014

Soro, N., Attar, H., Brodie, E., et al.: Evaluation of the mechanical compatibility of additively manufactured porous Ti–25Ta alloy for load-bearing implant applications. J. Mech. Behav. Biomed. Mater. 97, 149–158 (2019). https://doi.org/10.1016/J.JMBBM.2019.05.019

Tang, J., Zhao, Z., Li, N., et al.: Influence of feedstock powder on microstructure and mechanical properties of Ta cold spray depositions. Surf. Coat. Technol. 377, 124903 (2019). https://doi.org/10.1016/J.SURFCOAT.2019.124903

Al-Mangour, B., Mongrain, R., Irissou, E., Yue, S.: Improving the strength and corrosion resistance of 316L stainless steel for biomedical applications using cold spray. Surf. Coat. Technol. 216, 297–307 (2013). https://doi.org/10.1016/J.SURFCOAT.2012.11.061

Goyal, K., Goyal, R.: Improving hot corrosion resistance of Cr3C2–20NiCr coatings with CNT reinforcements. (2019). 36:1200–1209. https://doi.org/10.1080/02670844.2019.1662645

Sova, A., Papyrin, A., Smurov, I.: Influence of ceramic powder size on process of cermet coating formation by cold spray. J. Therm. Spray Technol. 18, 633–641 (2009). https://doi.org/10.1007/S11666-009-9359-5/TABLES/3

Guillem-Marti, J., Cinca, N., Punset, M., et al.: Porous titanium-hydroxyapatite composite coating obtained on titanium by cold gas spray with high bond strength for biomedical applications. Colloids Surf., B. 180, 245–253 (2019). https://doi.org/10.1016/J.COLSURFB.2019.04.048

Tang, J., Zhao, Z., Liu, H., et al.: A novel bioactive Ta/hydroxyapatite composite coating fabricated by cold spraying. Mater. Lett. 250, 197–201 (2019). https://doi.org/10.1016/J.MATLET.2019.04.123

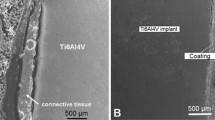

Lee, J.H., Jang, H.L., Lee, K.M., et al.: Cold-spray coating of hydroxyapatite on a three-dimensional polyetheretherketone implant and its biocompatibility evaluated by in vitro and in vivo minipig model. J. Biomedical Mater. Res. Part B: Appl. Biomaterials. 105, 647–657 (2017). https://doi.org/10.1002/JBM.B.33589

Hajipour, H., Abdollah-zadeh, A., Assadi, H., et al.: Effect of feedstock powder morphology on Cold-Sprayed Titanium Dioxide Coatings. J. Therm. Spray Technol. 27, 1542–1550 (2018). https://doi.org/10.1007/S11666-018-0782-3/FIGURES/10

Khalik, M.A., Zahiri, S.H., Palanisamy, S., et al.: Rapid elimination of porosity and brittleness in cold spray additive manufactured grade 2 titanium via in situ electro-plastic treatment. Int. J. Adv. Manuf. Technol. 119, 773–788 (2022). https://doi.org/10.1007/S00170-021-08309-3/FIGURES/17

Singh, G., Saini, A., Pabla, B.S.: Preparation and characterization of sr-doped hap biomedical coatings on polydopamine-treated ti6al4v substrates. 30:. (2022). https://doi.org/10.1142/S0218625X21410092

Vilardell, A.M., Cinca, N., Garcia-Giralt, N., et al.: Osteoblastic cell response on high-rough titanium coatings by cold spray. J. Mater. Science: Mater. Med. 29, 1–10 (2018). https://doi.org/10.1007/S10856-018-6026-8/FIGURES/9

Sun, J., Han, Y., Cui, K.: Innovative fabrication of porous titanium coating on titanium by cold spraying and vacuum sintering. Mater. Lett. 62, 3623–3625 (2008). https://doi.org/10.1016/J.MATLET.2008.04.011

Stenson, C., McDonnell, K.A., Yin, S., et al.: Cold spray deposition to prevent fouling of polymer surfaces. 34:193–204. (2016). https://doi.org/10.1080/02670844.2016.1229833

Koivuluoto, H., Näkki, J., Vuoristo, P.: Corrosion properties of cold-sprayed tantalum coatings. J. Therm. Spray Technol. 18, 75–82 (2009). https://doi.org/10.1007/S11666-008-9281-2/TABLES/3

Gardon, M., Melero, H., Garcia-Giralt, N., et al.: Enhancing the bioactivity of polymeric implants by means of cold gas spray coatings. J. Biomedical Mater. Res. Part B: Appl. Biomaterials. 102, 1537–1543 (2014). https://doi.org/10.1002/JBM.B.33134

Kusiński, J., Kac, S., Kowalski, K., et al.: Microstructure and Properties of TiC/Ti Coatings deposited by the Supersonic Cold gas spray technique. Archives of Metallurgy and Materials Vol. 63, 867–873 (2018). https://doi.org/10.24425/122416

Zander, Z.K., Becker, M.L.: Antimicrobial and antifouling strategies for Polymeric Medical Devices. ACS Macro Lett. 7, 16–25 (2018). https://doi.org/10.1021/ACSMACROLETT.7B00879/ASSET/IMAGES/LARGE/MZ-2017-008792_0005.JPEG

Aydin, H., Alomair, M., Wong, W., et al.: Cold sprayability of mixed commercial purity Ti Plus Ti6Al4V Metal powders. J. Therm. Spray Technol. 26, 360–370 (2017). https://doi.org/10.1007/S11666-017-0528-7/FIGURES/14

Gkomoza, P., Lampropoulos, G.S., Vardavoulias, M., et al.: Microstructural investigation of porous titanium coatings, produced by thermal spraying techniques, using plasma atomization and hydride-dehydride powders, for orthopedic implants. Surf. Coat. Technol. 357, 947–956 (2019). https://doi.org/10.1016/J.SURFCOAT.2018.10.072

Wang, Z., Chen, X., Gong, Y., et al.: Superhydrophobic nanocoatings prepared by a novel vacuum cold spray process. Surf. Coat. Technol. 325, 52–57 (2017). https://doi.org/10.1016/J.SURFCOAT.2017.06.044

Niinomi, M.: Recent progress in Research and Development of Metallic Structural Biomaterials with mainly focusing on mechanical biocompatibility. Mater. Trans. 59, 1–13 (2018). https://doi.org/10.2320/MATERTRANS.M2017180

Rui, D., Li, X., Jia, W., et al.: Releasing kinetics of dissolved copper and antifouling mechanism of cold sprayed copper composite coatings for submarine screen doors of ships. J. Alloys Compd. 763, 525–537 (2018). https://doi.org/10.1016/J.JALLCOM.2018.05.355

Apostu, D., Lucaciu, O., Berce, C., et al.: Current methods of preventing aseptic loosening and improving osseointegration of titanium implants in cementless total hip arthroplasty: A review. J. Int. Med. Res. 46, 2104–2119 (2018). https://doi.org/10.1177/0300060517732697

Li, S., Ni, J., Liu, X., et al.: Surface characteristics and biocompatibility of sandblasted and acid-etched titanium surface modified by ultraviolet irradiation: An in vitro study. J. Biomedical Mater. Res. Part B: Appl. Biomaterials. 100B, 1587–1598 (2012). https://doi.org/10.1002/JBM.B.32727

Hatamleh, M.M., Wu, X., Alnazzawi, A., et al.: Surface characteristics and biocompatibility of cranioplasty titanium implants following different surface treatments. Dent. Mater. 34, 676–683 (2018). https://doi.org/10.1016/J.DENTAL.2018.01.016

Diba, F.S., Reynolds, N., Thissen, H., et al.: Tunable chemical and topographic patterns based on Binary Colloidal crystals (BCCs) to modulate MG63 cell growth. Adv. Funct. Mater. 29, 1904262 (2019). https://doi.org/10.1002/ADFM.201904262

Yoon, B.J.V., Xavier, F., Walker, B.R., et al.: Optimizing surface characteristics for cell adhesion and proliferation on titanium plasma spray coatings on polyetheretherketone. Spine J. 16, 1238–1243 (2016). https://doi.org/10.1016/J.SPINEE.2016.05.017

Walsh, W.R., Bertollo, N., Christou, C., et al.: Plasma-sprayed titanium coating to polyetheretherketone improves the bone-implant interface. Spine J. 15, 1041–1049 (2015). https://doi.org/10.1016/J.SPINEE.2014.12.018

Vogel, D., Dempwolf, H., Baumann, A., Bader, R.: Characterization of thick titanium plasma spray coatings on PEEK materials used for medical implants and the influence on the mechanical properties. J. Mech. Behav. Biomed. Mater. 77, 600–608 (2018). https://doi.org/10.1016/J.JMBBM.2017.09.027

Ma, R., Tang, T.: Current Strategies to Improve the Bioactivity of PEEK. International Journal of Molecular Sciences 2014, 15, 5426–5445 15:5426–5445. (2014). https://doi.org/10.3390/IJMS15045426

Oliveira, W.F., Silva, P.M.S., Silva, R.C.S., et al.: Staphylococcus aureus and Staphylococcus epidermidis infections on implants. J. Hosp. Infect. 98, 111–117 (2018)

Arciola, C.R., Campoccia, D., Speziale, P., et al.: Biofilm formation in Staphylococcus implant infections. A review of molecular mechanisms and implications for biofilm-resistant materials. Biomaterials. 33, 5967–5982 (2012). https://doi.org/10.1016/J.BIOMATERIALS.2012.05.031

El-Eskandrany, M.S., Al-Azmi, A.: Potential applications of cold sprayed Cu50Ti20Ni30 metallic glassy alloy powders for antibacterial protective coating in medical and food sectors. J. Mech. Behav. Biomed. Mater. 56, 183–194 (2016). https://doi.org/10.1016/J.JMBBM.2015.11.030

Suo, X., Abdoli, L., Liu, Y., et al.: Colonization of Bacteria on the Surfaces of Cold-Sprayed copper Coatings alters their Electrochemical Behaviors. J. Therm. Spray Technol. 26, 687–694 (2017). https://doi.org/10.1007/S11666-017-0535-8/FIGURES/7

Zhao, Z., Meng, F., Tang, J., et al.: A novel method of fabricating an antibacterial aluminum-matrix composite coating doped graphene/silver-nanoparticles. Mater. Lett. 245, 211–214 (2019). https://doi.org/10.1016/J.MATLET.2019.02.121

Wang, K., Wang, S., **ong, T., et al.: Properties of Zn-Al-Mg-TiO2 coating prepared by cold spraying. Surf. Coat. Technol. 387, 125549 (2020). https://doi.org/10.1016/J.SURFCOAT.2020.125549

Costa, P., Polícia, R., Perinka, N., et al.: Multifunctional Touch Sensing and Antibacterial polymer-based Core-Shell Metallic Nanowire Composites for High Traffic Surfaces. Adv. Mater. Technol. 7, 2101575 (2022). https://doi.org/10.1002/ADMT.202101575

Mishchenko, O., Filatova, V., Vasylyev, M., et al.: Kinetically Deposited Copper Antimicrobial Surfaces. Coatings 2019, 9, 257 9:257. (2019). https://doi.org/10.3390/COATINGS9040257

Sundberg, K., Champagne, V., McNally, B., et al.: Effectiveness of nanomaterial copper cold spray surfaces on inactivation of influenza a virus. J. Biotechnol. Biomater. 5, 205 (2015)

Liu, Y., Dang, Z., Wang, Y., et al.: Hydroxyapatite/graphene-nanosheet composite coatings deposited by vacuum cold spraying for biomedical applications: Inherited nanostructures and enhanced properties. Carbon. 67, 250–259 (2014). https://doi.org/10.1016/J.CARBON.2013.09.088

Tamai, K., Kawate, K., Kawahara, I., et al.: Inorganic antimicrobial coating for titanium alloy and its effect on bacteria. J. Orthop. Sci. 14, 204–209 (2009). https://doi.org/10.1007/S00776-008-1306-7/METRICS

Sanpo, N., Tharajak, J.: Antimicrobial Property of Cold-Sprayed transition Metals-Substituted Hydroxyapatite/PEEK coating. Appl. Mech. Mater. 866, 77–80 (2017). https://doi.org/10.4028/WWW.SCIENTIFIC.NET/AMM.866.77

Hutasoit, N., Kennedy, B., Hamilton, S., et al.: Sars-CoV-2 (COVID-19) inactivation capability of copper-coated touch surface fabricated by cold-spray technology. Manuf. Lett. 25, 93–97 (2020). https://doi.org/10.1016/J.MFGLET.2020.08.007

Maan, A.M.C., Hofman, A.H., de Vos, W.M., Kamperman, M.: Recent developments and practical feasibility of polymer-based Antifouling Coatings. Adv. Funct. Mater. 30, 2000936 (2020). https://doi.org/10.1002/ADFM.202000936

Dumée, L.F., He, L., King, P.C., et al.: Towards integrated anti-microbial capabilities: Novel bio-fouling resistant membranes by high velocity embedment of silver particles. J. Membr. Sci. 475, 552–561 (2015). https://doi.org/10.1016/J.MEMSCI.2014.10.051

Khanmohammadi Chenab, K., Sohrabi, B., Rahmanzadeh, A.: Superhydrophobicity: Advanced biological and biomedical applications. Biomaterials Sci. 7, 3110–3137 (2019). https://doi.org/10.1039/C9BM00558G

Gibas, A., Baszczuk, A., Jasiorski, M., Winnicki, M.: Prospects of low-pressure Cold Spray for Superhydrophobic Coatings. Coat. 2019. 9, 829 (2019). https://doi.org/10.3390/COATINGS9120829

Moura, D., Souza, M.T., Liverani, L., et al.: Development of a bioactive glass-polymer composite for wound healing applications. Mater. Sci. Engineering: C. 76, 224–232 (2017). https://doi.org/10.1016/J.MSEC.2017.03.037

Civantos, A., Martínez-Campos, E., Ramos, V., et al.: Titanium Coatings and Surface modifications: Toward clinically useful bioactive implants. ACS Biomaterials Science and Engineering. 3, 1245–1261 (2017). https://doi.org/10.1021/ACSBIOMATERIALS.6B00604/ASSET/IMAGES/MEDIUM/AB-2016-00604X_0006.GIF

Moreau, D., Borit, F., Corté, L., Guipont, V.: Cold Spray Coating of Submicronic ceramic particles on poly(vinyl alcohol) in dry and Hydrogel States. J. Therm. Spray Technol. 26, 958–969 (2017). https://doi.org/10.1007/S11666-017-0551-8/FIGURES/12

Vilardell, A.M., Cinca, N., Garcia-Giralt, N., et al.: In-vitro study of hierarchical structures: Anodic oxidation and alkaline treatments onto highly rough titanium cold gas spray coatings for biomedical applications. Mater. Sci. Engineering: C. 91, 589–596 (2018). https://doi.org/10.1016/J.MSEC.2018.05.071

Manivasagam, G., Dhinasekaran, D., Rajamanickam, A.: Biomedical Implants: Corrosion and its Prevention - A Review. Recent Pat. Corros. Sci. 2, 40–54 (2010). https://doi.org/10.2174/1877610801002010040

Deshpande, P.P., Jadhav, N.G., Gelling, V.J., Sazou, D.: Conducting polymers for corrosion protection: A review. J. Coat. Technol. Res. 11, 473–494 (2014). https://doi.org/10.1007/S11998-014-9586-7/FIGURES/4

Arthur, D.E., Jonathan, A., Ameh, P.O., Anya, C.: A review on the assessment of polymeric materials used as corrosion inhibitor of metals and alloys. Int. J. Industrial Chem. 2013. 4(1 4), 1–9 (2013). https://doi.org/10.1186/2228-5547-4-2

Kumar, S., Vidyasagar, V., Jyothirmayi, A., Joshi, S.V.: Effect of Heat Treatment on Mechanical Properties and Corrosion Performance of Cold-Sprayed Tantalum Coatings. J. Therm. Spray Technol. 25, 745–756 (2016). https://doi.org/10.1007/S11666-016-0388-6/TABLES/2

Zhou, X., Mohanty, P.: Corrosion behaviour of cold sprayed titanium coatings in simulated body fluid. 47:145–154. (2013). https://doi.org/10.1179/1743278211Y.0000000037

Dikici, B., Topuz, M.: Production of Annealed Cold-Sprayed 316L Stainless Steel Coatings for Biomedical Applications and their in-vitro corrosion response. Prot. Met. Phys. Chem. Surf. 54, 333–339 (2018). https://doi.org/10.1134/S2070205118020168/METRICS

Cetiner, D., Paksoy, A.H., Tazegul, O., et al.: Thermal oxidation of Cold Sprayed Titanium-Based Coating deposited on Co-Cr Alloy. J. Therm. Spray Technol. 27, 1414–1427 (2018). https://doi.org/10.1007/S11666-018-0772-5/TABLES/2

Bitar, D., Parvizi, J.: Biological response to prosthetic debris. World J. Orthop. 6, 172 (2015). https://doi.org/10.5312/WJO.V6.I2.172

Radha, R., Sreekanth, D.: Insight of magnesium alloys and composites for orthopedic implant applications – a review. J. Magnesium Alloys. 5, 286–312 (2017). https://doi.org/10.1016/J.JMA.2017.08.003

Yildiz, F., Yetim, A.F., Alsaran, A., Efeoglu, I.: Wear and corrosion behaviour of various surface treated medical grade titanium alloy in bio-simulated environment. Wear. 267, 695–701 (2009). https://doi.org/10.1016/J.WEAR.2009.01.056

Ching, H.A., Choudhury, D., Nine, M.J., Abu Osman, N.A.: Effects of surface coating on reducing friction and wear of orthopaedic implants. Sci. Technol. Adv. Mater. 15, 014402 (2014). https://doi.org/10.1088/1468-6996/15/1/014402

Penkov, O.V., Khadem, M., Lee, J.S., et al.: Highly durable and biocompatible periodical Si/DLC nanocomposite coatings. Nanoscale. 10, 4852–4860 (2018). https://doi.org/10.1039/C7NR06762C

Kheradmandfard, M., Kashani-Bozorg, S.F., Lee, J.S., et al.: Significant improvement in cell adhesion and wear resistance of biomedical β-type titanium alloy through ultrasonic nanocrystal surface modification. J. Alloys Compd. 762, 941–949 (2018). https://doi.org/10.1016/J.JALLCOM.2018.05.088

Yin, S., Chen, C., Suo, X., Lupoi, R.: Cold-Sprayed Metal Coatings with nanostructure. Adv. Mater. Sci. Eng. 2018 (2018). https://doi.org/10.1155/2018/2804576

Spencer, K., Fabijanic, D.M., Zhang, M.X.: The influence of Al2O3 reinforcement on the properties of stainless steel cold spray coatings. Surf. Coat. Technol. 206, 3275–3282 (2012). https://doi.org/10.1016/J.SURFCOAT.2012.01.031

Melendez, N.M., McDonald, A.G.: Development of WC-based metal matrix composite coatings using low-pressure cold gas dynamic spraying. Surf. Coat. Technol. 214, 101–109 (2013). https://doi.org/10.1016/J.SURFCOAT.2012.11.010

Al-Hamdani, K.S., Murray, J.W., Hussain, T., et al.: Cold sprayed metal-ceramic coatings using satellited powders. Mater. Lett. 198, 184–187 (2017). https://doi.org/10.1016/J.MATLET.2017.03.175

Funding

The author(s) have received no funding.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Ethical concerns

Not Required.

Conflict of Interest

The author declares that no conflict of interest exists among all authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sandhu, H.S., Goyal, D., Sharma, A. et al. Sustainable development in cold gas dynamic spray coating process for biomedical applications: challenges and future perspective review. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01474-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01474-7