Abstract

This study investigated the impact of sprouted oats (SO) on dough properties and biscuit features. Unsprouted oats (USO) and SO (for 48 h and 72 h) were studied in wheat dough at 10, 20, and 30%, and gluten aggregation, mixing, and extensional properties were evaluated. USO caused a weakening in gluten aggregation capacity, an increase in water uptake, development time and dough rigidity, and a decrease in extensibility. Dough enriched in SO showed mixing profiles similar to wheat, but using SO strongly affected dough extensional properties, indicating gluten weakening. Changes in rheological properties suggested the use of SO at 20% level in biscuit production. Using oats did not affect either biscuit size or volume, but decreased both the hardness and the toughness of the product, with 72 h-SO having the greatest impact, especially on hardness. Further study will address consumer acceptability and nutritional features of the developed baked product.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Oats (Avena sativa L.) are known to present a balanced nutritional composition, serving as a good source of carbohydrates (up to 70 g/100 g), fiber (up to 15% g/100 g), and protein (up to 16%; Alemayehu et al., 2023) with a more complete amino acid profile than other cereals (Alemayehu et al., 2023). Additionally, oats contain bioactive compounds, including phenolics, carotenoids, phytic acid, and sterols, and a variety of micronutrients, including vitamins and minerals (e.g., Vitamin E, potassium, and phosphorus, as reviewed, among others, by Gangopadhyay et al. (2015). One of the major components of interest in oats is β-glucans, i.e. up to 6 g/100 g (Miller et al., 1993), the consumption of which is positively associated with several health benefits, including reduction in cholesterol and control of diabetes and weight (Wang & Ellis, 2014; Daou & Zhang, 2012). In this regard, the European Food Safety Authority (EFSA) has indicated that it will allow claiming “regular consumption of β-glucans contributes to the maintenance of normal blood cholesterol concentrations” (EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA), 2009). Specifically, in order to bear the claim, foods should provide at least 3 g/d of beta-glucans (EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA), 2009).

Given the nutritional characteristics, oats inclusion in food products is of great benefit to consumers. However, oats have long been utilized mainly for animal feed thanks to the high protein content, until being more recently replaced by soybean (Webster, 2016). This has led to a decline in world oat cultivation in recent years, with a decrease in the share relating to animal feed and an increase in the share relating to industrial and food uses (FAO, 2021). Specifically, the use of oats in the food sector has been mainly involved in the production of breakfast products, cereal bars, and plant-based drinks (Menon et al., 2016; Rasane et al., 2015; Yang et al., 2023). Currently, the oat ingredients frequently found in the literature are flakes (also called oatmeal or rolled oats), flour, bran, and purified β-glucan, and several reviews have been reported on this topic (Leszczyńska et al., 2023; Mao et al., 2022). More recently, interest is growing in the baked good sector although some issues still need to be solved: (i) the high lipid content (on average 8%; Biel et al., 2009) that makes oats susceptible to lipid oxidation, especially during product storage (Heiniö et al., 2002), thus negatively affecting the sensory profile of oats and related products; (ii) the absence of gluten-forming protein that makes the inclusion of oats in widely consumed baked goods difficult; (iii) the high fiber content, which interferes with gluten formation; (iv) the sensory profile which is generally characterized by bitterness and rancidity (Heiniö et al., 2001, 2002). All these aspects account for the limited consumer acceptability towards oat-based products. In this context, various processes have been proposed to enhance the sensory properties of oats. Thermal processing (including kilning and extrusion) is typically applied to oats to inactivate endogenous enzymes, especially lipase, to prevent rancidity and extend shelf life. Drawbacks of thermal treatments include an increase in the glycemic index to varied degrees and the decomposition of other active compounds, such as β-glucans (Zhang et al., 2021). More recently, bioprocessing techniques (including fermentation, sprouting, and enzymatic treatments) are drawing more and more interest to oat products, since they can enhance the nutritional value and functional characteristics of oats (Zhang et al., 2021). Among bioprocessing, sprouting (or germination) was effective in decreasing both the bitterness and rancidity of oats during storage (Heiniö et al., 2002). In addition to positively impact on sensory attributes and improving some nutritional traits (e.g., increase in minerals and phenolic compounds; decrease in antinutritional factors (Hübner & Arendt, 2013; Lemmens et al., 2019)), sprouting was effective in improving bread-making performance (e.g., increased volume and crumb softness also during storage) of formulations enriched in alternative crops, such as sorghum and quinoa (Marchini et al., 2023; Cardone et al., 2021; Suárez-Estrella et al., 2020). Such changes depend on the botanical origin of the raw material, the variety, the sprouting conditions, and the final formulation. As regards oats, sprouted oats have primarily been employed in applications such as bread (Cao et al., 2023; He et al., 2023), with a notable absence of literature examining the effects of incorporating sprouted oats into other baked products, such as biscuits. While numerous researchers have explored the impacts of sprouting on the chemical composition and on nutritional and sensory aspects of oats, as far as our knowledge extends, the relation between sprouting conditions and the characteristics of doughs and baked goods enriched with sprouted oats remains unexamined, with only limited instances of such investigations in the context of bread. Hence, the objectives of this study were to elucidate the modifications occurring in wheat doughs enriched in sprouted oat through various rheological approaches and to investigate the physical and textural attributes of cookies enriched in sprouted oat.

Materials and Methods

Materials and Sprouting Conditions

Commercial dehulled oats were sprouted in a climate chamber (Memmert GmbH Co. KG, Schwabach, Germany). Specifically, the seeds were sprouted in three batches of 1.5 kg for each sprouting time and after processing the batches were combined. The seeds were soaked in distilled water (1:2) for 8 h at 22 °C and then after draining the excess water, they were sprouted for 48 and 72 h. After sprouting, the seeds were dried at 50 °C for 16 h (Self Cooking Center, Rational International AG, Landsberg am Lech, Germany). Unsprouted oats were used as control. All samples were ground with a laboratory mill M20 Universal Mill (IKA, Werke Staufen, Germany) and sieved to obtain a flour with a particle size less than 250 µm. A commercial wheat flour (W = 155 × 10−4 J, protein content = 11 g /100 g of flour) was used as the base for oat substitution at 10, 20, and 30% levels.

Pasting Properties of Oat Flours

Pasting properties of oat flours were measured using a Micro-Visco-Amylograph device (MVAG, Brabender GmbH & Co. KG, Duisburg, Germany) as reported by Suarez et al. (2020). An aliquot of sample (12 g) was dispersed in 100 mL of distilled water or 1 mM silver nitrate solution and stirred at 250 rpm. The following temperature profile was applied: heating from 30 to 95 °C at a rate of 3 °C/min, holding at 95 °C for 20 min, cooling from 95 to 30 °C at a cooling rate of 3 °C/min, and holding at 30 °C for 1 min.

Gluten Aggregation Properties of Oat-Wheat Blends

Gluten aggregation properties of composite flours were measured using the GlutoPeak device (Brabender GmbH & Co. KG, Duisburg, Germany). The test was conducted by dispersing 8.5 g of sample in 9.5 g of a 0.4 M solution of CaCl2 using a speed of 1900 rpm.

Mixing Properties and Extensibility Properties of Oat-Wheat Blends

The mixing properties of composite flours were performed by means of the Farinograph-E (Brabender GmbH & Co. KG, Duisburg, Germany) equipped with a 50 g mixing bowl, following the ICC method n. 115/1. Three-dimensional extension properties of oat-wheat mixtures were measured using the Alveograph (Chopin Technologies, Villeneuve La Garenne Cedex, France) according to the ICC method n. 121.

Biscuit Production

Based on rheological properties, sprouted oats were used at a replacement level of 20% for the production of the biscuits. The recipe used was as follows: flour (200 g), distilled water (75 g), sugar (60 g), sunflower oil (30 g), leavening agent (4 g; Paneangeli, Cameo spa, Desenzano del Garda, BS, Italy), and salt (0.4 g).

The dough was prepared in an automatic mixer (KitchenAid 5KSM125EER, Whirlpool, St. Paul, USA) equipped with a dough hook. After the first minute of premixing all dry ingredients, water, and oil were added and mixed for 5 min. Thereafter, the dough was rolled for three times through the KitchenAid sheeter obtaining a sheet of 2 mm thickness. The cookie was formed with a metal template with the dimensions of 7 × 3 cm. Baking took place in a static oven at 180 °C for 13 min, turning them halfway through baking. Two batches were produced for each sample.

Biscuit Characterization

All analyses were conducted two hours after biscuit production. Using a ruler and a thickness gauge, the three dimensions (height, width, and thickness) were measured. The volume was measured in duplicate on five biscuits using the sesame seed displacement method (AACC 10–05.01, AACC, 2001).

Determination of biscuit texture was performed based on the study of Agrahar-Murugkar et al. (2015), by means of the Texture Analyzer TA.XTplus (Stable Micro Systems Ltd., Godalming, UK), equipped with a 100 N load cell and the probe HDP/3 PB. A three-point bending test was conducted using a 3-point bending rig (A/3 PB, Stable Micro Systems, UK). The following settings were used for the test: pre-test speed, 1.0 mm/s; test speed, 1 mm/s; post-test speed, 10.0 mm/s; distance, 10 mm to contact the biscuit. The downward movement continued until the biscuit broke. The maximum force was recorded as the “hardness” of the biscuit, whereas the area under the curve was expressed as “toughness.”

Statistical Analysis

Pasting and mixing properties were carried out in duplicate, whereas the gluten aggregation properties were evaluated in triplicate. From the Alveograph test, five subsamples were considered. For each batch of biscuits, geometric indices and texture analysis were performed on ten biscuits, whereas five biscuits were used for the analysis of volume.

All data underwent one-way analysis of variance (ANOVA) with a significance level of 0.05, conducted using Statgraphics Plus 5.1 (StatPoint Inc., Warrenton, VA, USA). Significantly different factors were further assessed using the Tukey HSD test.

Results and Discussion

Pasting Properties of Oat Flours

Changes in viscosity during heating and cooling of oats before and after sprouting were reported in Fig. 1. This approach allows to indirectly evaluate the effect of sprouting on starch gelatinization and retrogradation properties. Such properties are strategic in determining the product structure during its baking and cooling.

The test was performed both in distilled water (data not shown) and in AgNO3 (Fig. 1). The latter is known to inactivate α-amylases that otherwise would be able to hydrolyze starch granules during the test. Indeed, when the test was performed in water, no viscosity was registered (data not shown), likely due to the intense starch hydrolysis in free sugars that do not impair viscosity to the system. On the other hand, using AgNO3 provides information on starch modifications promoted by the sprouting process.

Sprouting caused a significant increase in pasting temperature and a decrease in peak viscosity, breakdown, final viscosity, and setback (Table 1). Such changes depend on the sprouting time: as the sprouting time increased from 48 to 72 h, all the parameters, but pasting temperature, decreased. Overall the observed changes in viscosity profile are expressions of a decrease in the ability of starch granules to gelatinize (i.e., pasting temperature decreased), swell (i.e., peak viscosity decreased), and retrograde (setback and final viscosity decreased) after sprouting, but a greater stability to thermal and mechanical stresses (i.e., breakdown decreased). According to the effect on viscosity, sprouted grains can be exploited in food formulations to contain/control the viscosity (for example in batter production) or in baked products to decrease staling.

Similar changes in pasting properties were observed for other grains, including quinoa (Suárez-Estrella et al., 2020), sorghum (Marchini et al., 2021), rice, corn, wheat, and oats (Kaur & Gill, 2020). It is generally recognized that the linkages of the starch molecules were destroyed by enzymes activated during sprouting, resulting in a lower gelatinization tendency (Olaerts et al., 2016; Simsek et al., 2014). As an effect of the decrease in gelatinization properties, the retrogradation tendency also decreased. However, the extent of such changes could be related to both botanical origin and degree of sprouting, which depends on the processing conditions (i.e., temperature, time, and relative humidity adopted during the sprouting phase).

Gluten Aggregation Properties of Oat-Wheat Blends

Gluten aggregation properties of wheat flour, alone or in combination with oats, are shown in Fig. 2. This approach would provide information on the impact of oats on gluten protein interactions and would predict gluten formation during mixing.

Gluten aggregation properties of wheat flour (WF) and oat blends. a Maximum torque. b Peak maximum time. c Energy. Blends were prepared replacing WF with 10, 20, and 30% of unsprouted oat (USO) and sprouted oat for 48 h (SO48) and 72 h (SO72). Different letters indicate significant differences among samples (one-way ANOVA; Tukey HSD test; p ≤ 0.05). GPU, GlutoPeak Units

The indices reported in Fig. 2 (i.e., maximum torque, peak maximum time, and energy) have been extrapolated by the curve that reports changes in torque upon mixing time. As the gluten is formed, the device registers an increase in torque, until a maximum which corresponds to the maximum gluten formation. After this point, the torque decreases due to the gluten breakage because of the effect of the high shear stress. A decrease in torque, peak maximum time, and/or energy (i.e., the area under the curve) suggests gluten weakening (Güçbilmez et al., 2019; Marti et al., 2015).

The presence of oats affected the gluten aggregation kinetics of wheat flour, especially in regard to maximum torque (Fig. 2a) and energy (Fig. 2c). These parameters decreased as the enrichment level increased, likely due to both a decrease in the amount of gluten (i.e., dilution effect) and an interference of oat proteins and fiber with the gluten network. Indeed, a positive correlation between gluten content and its strength/tenacity and maximum torque and energy has been observed by Rakita et al. (2018). Overall, a decrease in maximum torque and energy and an increase in peak maximum time are generally associated with gluten weakening (Güçbilmez et al., 2019; Rakita et al., 2018).

Although an increase in peak maximum time as the oat enrichment level increased is expected, no significant differences in such index were observed between wheat and unsprouted oat-wheat blends (Fig. 2b), suggesting an effect on the strength of the gluten but not on the time required for its aggregation.

The effect of sprouting and its duration on the increase in peak maximum time and on the decrease in both maximum torque and energy was significant only at the highest enrichment level (30_TQ > 30 48 h > 30_72), suggesting an overall gluten weakening. It is likely that sprouting promoted protein structural changes (e.g., increase in soluble proteins (Hübner et al., 2010); Klose & Arendt, 2012; Hübner & Arendt, 2010) or interactions (e.g., tannin-protein hydrophobic interactions (Rosa Perez-Gregorio & Simal-Gandara, 2017)) so that wheat-oat protein interaction could have been delayed/negatively affected. However, further studies on the effect of limited sprouting (up to 72 h) on protein structural characteristics are needed to confirm this phenomenon.

Mixing Properties of Oat-Wheat Blends

The mixing properties of wheat flour (WF) with the addition of unsprouted oats and sprouted oats at different replacement levels are shown in Fig. 3. In addition to the information provided by the GlutoPeak test (Fig. 2), it is important to investigate the impact of sprouted oats on the Farinograph profile, because this test is carried out on a dough system and aims to mimic the mixing stage of the process of a baked product.

Mixing properties of wheat flour (WF) and oat blends. a Water absorption. b Dough development time. c Dough stability. Blends were prepared replacing WF with 10, 20, and 30% of unsprouted oat (USO) and sprouted oat for 48 h (SO48) and 72 h (SO72). Different letters indicate significant differences among samples (one-way ANOVA; Tukey HSD test; p ≤ 0.05)

Wheat dough showed a short dough development time (about 1.5 min) and short stability (less than 3 min) with an absorption of about 55.4%, which is a common characteristic for medium-weak flours, suitable for chemical-leavened products.

Replacement of wheat with 10% unsprouted oats did not significantly affect the water absorption of the dough (Fig. 3a). On the other hand, at higher replacement levels (20% and 30%), the water uptake significantly increased, reaching the highest value (i.e., 57.3%) at the highest replacement level. Dough development time significantly increased three- to fourfold from 10 to 30% enrichment level, while dough stability upon mixing increased about twofold regardless of replacement level.

The increase in water absorption upon the addition of oats suggests that more water is needed for wheat protein hydration and gluten formation. This result might be related to the presence of oat fiber and its higher water absorption capacity (Hemdane et al., 2016; Sivam et al., 2010). At the same time, the presence of fiber in the dough is responsible for the longer mixing time (Fig. 3b) needed to form a fully developed dough (that in the case of the Farinograph test corresponds to 500 FU). The impact of fiber on dough mixing properties has been reported by several studies, as recently reviewed by Foschia et al. (2013). In relation to the role of β-glucans, this fiber fraction is known to increase dough water absorption and decrease dough stability (de Erive et al., 2020; Mohebbi et al., 2018). However, the increase in dough resistance to mixing (evaluated as “stability” by the device; Fig. 3c) should not be read as a strengthening of the protein network but it could be indeed related to a kind of rigidity of the dough given by the fiber. In addition, the presence of fiber impacts on protein conformation, shifting from β-spirals to more ordered β-sheets structures (Bock et al., 2013).

Sprouting affected water uptake only at high replacement levels (20% and 30%) and for prolonged sprouting time (i.e., 72 h), suggesting the need to use less water than both wheat dough and unsprouted oat-enriched doughs to achieve the target torque (i.e., 500 FU), considered optimal for dough making (Fig. 3a). The molecular changes occurring during sprouting (e.g., protein and fiber hydrolysis) might have also affected their ability to absorb and hold water at room temperature. This is supported by previous studies on other sprouted grains, including sorghum (Cardone et al., 2021; Lorenz et al., 1981). In the case of oats, the hydroxyl groups of oat β-glucans can bind significant amounts of water through hydrogen bonds (Londono et al., 2015). Likely, a reduction in β-glucan content due to germination (Hübner et al., 2010) has led to a decreased water absorption, especially when using oats sprouted for 72 h.

Despite what was discussed for unsprouted oats, the partial substitution of wheat with sprouted oats (both for 48 h and 72 h) did not significantly affect the time requested for dough formation (i.e., dough development time; Fig. 3b). This result likely suggests sprouting (at least in the conditions of the present study) mitigated the effect of oat addition on gluten formation. Indeed, considering that previous studies have reported a decrease in total fiber upon oat sprouting (Kaur & Gill, 2020), as well as sprouting might have promoted a breakage in particle size of the bran fraction (Cardone et al., 2020), protein-fiber interactions could have been changed upon sprouting, favoring protein aggregation, as also shown by the GlutoPeak energy values of unsprouted oat dough compared with 48 h-sprouted oat dough (Fig. 2c).

The impact on dough resistance to prolonged mixing (i.e., dough stability; Fig. 3c) of wheat dough resulted to be significant only in the case of oats sprouted for 48 h. Specifically, the index followed the order: unsprouted oats > 48 h-sprouted oats > 72 h-sprouted oats = wheat. This result confirmed what recently reported by Cao et al. (2023): 72 h-sprouted oats improved the weakening degree of wheat dough, suggesting that properly sprouted oat flour may be helpful to improve the bread-making performance of oat-enriched dough. The decrease in stability upon sprouting and sprouting time could be related to the protease activities that might impact on gluten strength—by acting on wheat proteins—during the test. Further studies are needed from a molecular standpoint to evaluate the protein hydrolysis during mixing.

Overall, our results partially agree with those recently reported by Cao et al. (2023): an increase in water absorption and a decrease in dough development time and stability were indeed observed upon sprouting time (from 24 to 120 h). Differences in the results might be related to several factors, including the sprouting conditions (in terms of relative humidity and temperature), oats variety, as well as the wheat flour used for preparing the doughs. For example, in our study, a medium-weak flour for biscuit production was used, while Cao et al. (2023) used a strong flour for bread production.

Extensibility Properties of Oat-Wheat Blends

The three-dimensional extensional properties, that were assessed by the Alveograph test, are shown in Fig. 4. The test provides information on the ability of dough to withstand air pressure, which wants to mimic the pressure to which the dough is subjected during leavening. As expected, the wheat flour selected for cookie production was characterized by low tenacity (Fig. 4a), extensibility (Fig. 4b), and strength (Fig. 4c). Such characteristics are typical of weak flours that are used in those applications (such as cookies) where a strong gluten is not required.

Extensibility properties of wheat flour (WF) and oat blends. a Tenacity. b Extensibility. c Strength. Blends were prepared replacing WF with 10, 20, and 30% of unsprouted oat (USO) and sprouted oat for 48 h (SO48) and 72 h (SO72). Different letters indicate significant differences among samples (one-way ANOVA; Tukey HSD test; p ≤ 0.05)

Adding oats to dough promoted a significant decrease in extensibility (Fig. 4b), suggesting the formation of a more compact/rigid structure (thus less extensible) likely due to the presence of fiber and its detrimental effect on the gluten network. The decrease in extensibility of oat dough would likely indicate a less resistance to extension since during the alveograph test the air bubble burst earlier in oat-enriched doughs than control (i.e., wheat dough). The weakening effect of oat addition on gluten properties is clear not only during mixing/dough formation (as discussed in the previous section) but also when the dough is subjected to the stress of air pressure. Dough weakening was also confirmed by the decrease in alveograph W (i.e., the strength index; Fig. 4c). Tenacity (P value; Fig. 4a) decreased at 10% oat enrichment level, but no differences between wheat dough and oat doughs were observed when oat was added at 20% and 30%. Overall, rigidity (expressed as the ratio between tenacity and extensibility; P/L) proportionally increased with the addition of oats, going from 0.7 (wheat dough) to 0.9, 1.6, and 2.1 when oat was added at 10, 20, and 30%, respectively.

Also, in the study of Tamba-Berehoiu et al. (2019), it was shown an increase in dough resistance (P) and a decrease in mechanical work (W) and extensibility (L), that affected the P/L value.

Using sprouted oats (48 h or 72 h) instead of unsprouted oat did not further decrease the extensibility of the dough (Fig. 4b). On the contrary, sprouting impacted more on tenacity: as the sprouting time increased, dough tenacity decreased, regardless of the oat level (Fig. 4a). Specifically, tenacity decreased by up to 25% for dough with oats sprouted for 48 h and up to 40% when oats sprouted for 72 h was included in the formulation. Thus, also dough strength decreased in the presence of sprouted oats: a 10% enrichment level was enough to highly impact on dough strength, with further weakening at 20% level; on the contrary, no further detrimental effect was observed by increasing the level of oats from 20 to 30% (Fig. 4c). Compared to unsprouted oat-enriched doughs, the decrease in both dough tenacity and strength that was observed in the case of sprouted oats might be related to the protease activity developed during sprouting that might have been acted on gluten proteins during mixing and during the resting period during the analysis. The lack of studies investigating the effect of sprouting on dough extensibility makes the discussion and comparison of the results difficult. In a previous study, Mäkinen and Arendt (2012) investigated the role of oat malt in bread-making. Although malt (coming from 5 days germination) cannot be compared to the sprouted oats produced in the present study, a decrease in resistance to extension and an increase in extensibility was shown when oat malt was added to 5%.

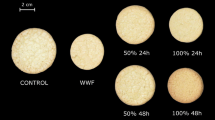

Biscuit Characteristics

Taking into consideration the rheological properties described above, blends at 20% enrichment level were selected for biscuit production. Indeed, most of the rheological indices (e.g., dough stability to mixing, extensibility) did not further changed with the increase in oat level, passing from 20 to 30%. Thus, a 20% replacement level could represent a good balance between the beneficial effects of using oats and the detrimental effect of its addition on the gluten matrix. The quality indices of biscuits are presented in Table 2.

Although the statistical analysis highlighted significant differences in the geometric indices (thickness, width, and length) among the samples, such differences were of about 1 mm, thus it is reasonable to state that they would not impact on packaging and/or consumer perception. At the same time, neither sprouting nor its duration affected the product volume. In a previous study, it was shown that replacing wheat flour with 50% of sprouted whole wheat promoted a slight decrease in both width and spread, as an effect of the enhancement in the hydration capacity of the dough upon sprouting (Jribi et al., 2020).

Replacing wheat with either unsprouted or sprouted oats significantly decreased both the hardness and the toughness of biscuits. The greatest effect was measured when 72 h-sprouted oat was used in the formulation. The observed reduction in hardness and toughness could be attributed to the structural degradation of starch and protein that was promoted by sprouting and that could have played a key role in the formation of a less strong/cohesive matrix within the biscuits (Chung et al., 2014). This structure could have contributed to the formation of a softer texture which, for biscuits, is usually associated with a better consumer acceptability (Laguna et al., 2013).

The impact of sprouted grain on biscuit texture might depend on several factors, including the type of grains, the sprouting conditions, and the formulation (e.g., the enrichment level and/or the presence of other ingredients). Indeed, contrasting results were found in literature. For example, no changes in biscuit texture were observed when 48 h-sprouted brown rice was used up to 50%, whereas a decrease in hardness was found at 70% enrichment level (Chung et al., 2014). Moreover, an increase in biscuit hardness was measured when 48 h-sprouted wheat was added to 50% to wheat flour (Jribi et al., 2020), whereas no changes were observed when using 48 h-sprouted chenopodium (Jan et al., 2016).

Conclusion

The results of this study suggest that when reformulating baked products with oats some changes in dough properties and biscuit texture are expected, despite the overall enrichment in specific components. Such changes concern the amount of water to be added to form a cohesive dough and/or the mixing time, as well as dough resistance to overmixing and air pressure. Some of these changes depend on sprouting time, others on the enrichment level. For example, adding sprouted oats instead of unsprouted grains significantly decreased the dough development time, mixing stability, dough tenacity, and strength but the development time was not affected by the sprouting time and only the enrichment level impacted on dough strength and extensibility, with no differences between 20 and 30%. Finally, using oats improved the texture of the biscuits, especially when 72 h-sprouted grains were used. Further studies will assess the effect of using sprouted oat on consumer acceptability, as well as its impact on the quality of other baked goods.

Data Availability

No datasets were generated or analysed during the current study.

References

AACC. (2001). Approved Methods of Analysis (eleventh). Cereals & Grains Association.

Agrahar-Murugkar, D., Gulati, P., Kotwaliwale, N., & Gupta, C. (2015). Evaluation of nutritional, textural and particle size characteristics of dough and biscuits made from composite flours containing sprouted and malted ingredients. Journal of Food Science and Technology, 52, 5129–5137.

Alemayehu, G. F., Forsido, S. F., Tola, Y. B., & Amare, E. (2023). Nutritional and phytochemical composition and associated health benefits of oat (Avena sativa) grains and oat-based fermented food products. The Scientific World Journal, 2023. https://doi.org/10.1155/2023/2730175

Biel, W., Bobko, K., & Maciorowski, R. (2009). Chemical composition and nutritive value of husked and naked oats grain. Journal of Cereal Science, 49(3), 413–418. https://doi.org/10.1016/j.jcs.2009.01.009

Bock, J. E., Connelly, R. K., & Damodaran, S. (2013). Impact of bran addition on water properties and gluten secondary structure in wheat flour doughs studied by attenuated total reflectance Fourier transform infrared spectroscopy. Cereal Chemistry, 90(4), 377–386. https://doi.org/10.1094/CCHEM-01-13-0008-FI

Cao, H., Gao, F., Shen, H., Su, Q., Guan, X., Sun, Z., & Yu, Z. (2023). Influence of partial substitution of wheat flour with sprouted oat flours on physicochemical and textural characteristics of wheat bread. Journal of Cereal Science, 110, 103649. https://doi.org/10.1016/j.jcs.2023.103649

Cardone, G., D’Incecco, P., Pagani, M. A., & Marti, A. (2020). Sprouting improves the bread‐making performance of whole wheat flour (Triticum aestivum L.). Journal of the Science of Food and Agriculture, 100(6), 2453–2459. https://doi.org/10.1002/jsfa.10264

Cardone, G., Rumler, R., Speranza, S., Marti, A., & Schönlechner, R. (2021). Sprouting time affects sorghum (Sorghum bicolor [L.] Moench) functionality and bread-baking performance. Foods, 10(10), 2285. https://doi.org/10.3390/foods10102285

Chung, H. J., Cho, A., & Lim, S. T. (2014). Utilization of germinated and heat-moisture treated brown rices in sugar-snap cookies. LWT-Food Science and Technology, 57(1), 260–266. https://doi.org/10.1016/j.lwt.2014.01.018

Daou, C., & Zhang, H. (2012). Oat beta-glucan: Its role in health promotion and prevention of diseases. Comprehensive Reviews in Food Science and Food Safety, 11(4), 355–365. https://doi.org/10.1111/j.1541-4337.2012.00189.x

de Erive, M. O., He, F., Wang, T., & Chen, G. (2020). Development of β-glucan enriched wheat bread using soluble oat fiber. Journal of Cereal Science, 95, 103051. https://doi.org/10.1016/j.jcs.2020.103051

EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). (2009). Scientific Opinion on the substantiation of health claims related to beta glucans and maintenance of normal blood cholesterol concentrations (ID 754, 755, 757, 801, 1465, 2934) and maintenance or achievement of a normal body weight (ID 820, 823) pursuant to Article 13 (1) of Regulation (EC) No 1924/2006. EFSA Journal, 7(10), 1254. https://doi.org/10.2903/j.efsa.2009.1254

FAO. (2021). https://www.fao.org/faostat/en/#search/Oats

Foschia, M., Peressini, D., Sensidoni, A., & Brennan, C. S. (2013). The effects of dietary fibre addition on the quality of common cereal products. Journal of Cereal Science, 58(2), 216–227. https://doi.org/10.1016/j.jcs.2013.05.010

Gangopadhyay, N., Hossain, M. B., Rai, D. K., & Brunton, N. P. (2015). A review of extraction and analysis of bioactives in oat and barley and scope for use of novel food processing technologies. Molecules, 20(6), 10884–10909. https://doi.org/10.3390/molecules200610884

Güçbilmez, Ç. M., Şahin, M., Akçacık, A. G., Aydoğan, S., Demir, B., Hamzaoğlu, S., Gür, S., & Yakışır, E. (2019). Evaluation of GlutoPeak test for prediction of bread wheat flour quality, rheological properties and baking performance. Journal of Cereal Science, 90, 102827. https://doi.org/10.1016/j.jcs.2019.102827

He, Li., & X., Chen, D., Huang, S., & Tao, N. (2023). Effect on bread properties of partial substitution of wheat flour with oat flour and flour from oat grain germinated in the light or dark. International Journal of Food Science & Technology, 58(4), 1979–1986. https://doi.org/10.1111/ijfs.16352

Heiniö, R. L., Lehtinen, P., Oksman-Caldentey, K. M., & Poutanen, K. (2002). Differences between sensory profiles and development of rancidity during long-term storage of native and processed oat. Cereal Chemistry, 79(3), 367–375. https://doi.org/10.1094/CCHEM.2002.79.3.367

Heiniö, R. L., Oksman-Caldentey, K. M., Latva-Kala, K., Lehtinen, P., & Poutanen, K. (2001). Effect of drying treatment conditions on sensory profile of germinated oat. Cereal Chemistry, 78(6), 707–714. https://doi.org/10.1094/CCHEM.2001.78.6.707

Hemdane, S., Jacobs, P. J., Dornez, E., Verspreet, J., Delcour, J. A., & Courtin, C. M. (2016). Wheat (Triticum aestivum L.) bran in bread making: A critical review. Comprehensive Reviews in Food Science and Food Safety, 15(1), 28–42. https://doi.org/10.1111/1541-4337.12176

Hübner, F., & Arendt, E. K. (2010). Studies on the influence of germination conditions on protein breakdown in buckwheat and oats. Journal of the Institute of Brewing, 116(1), 3–13. https://doi.org/10.1002/j.2050-0416.2010.tb00392.x

Hübner, F., & Arendt, E. K. (2013). Germination of cereal grains as a way to improve the nutritional value: A review. Critical Reviews in Food Science and Nutrition, 53(8), 853–861. https://doi.org/10.1080/10408398.2011.562060

Hübner, F., O’Neil, T., Cashman, K. D., & Arendt, E. K. (2010). The influence of germination conditions on beta-glucan, dietary fibre and phytate during the germination of oats and barley. European Food Research and Technology, 231, 27–35. https://doi.org/10.1007/s00217-010-1247-1

Jan, R., Saxena, D. C., & Singh, S. (2016). Physico-chemical, textural, sensory and antioxidant characteristics of gluten–Free cookies made from raw and germinated Chenopodium (Chenopodium album) flour. LWT-Food Science and Technology, 71, 281–287. https://doi.org/10.1016/j.lwt.2016.04.001

Jribi, S., Sahagún, M., Belorio, M., Debbabi, H., & Gomez, M. (2020). Effect of sprouting time on dough and cookies properties. Journal of Food Measurement and Characterization, 14, 1595–1600. https://doi.org/10.1007/s11694-020-00407-2

Kaur, H., & Gill, B. S. (2020). Comparative evaluation of physicochemical, nutritional and molecular interactions of flours from different cereals as affected by germination duration. Journal of Food Measurement and Characterization, 14(3), 1147–1157. https://doi.org/10.1007/s11694-019-00364-5

Klose, C., & Arendt, E. K. (2012). Proteins in oats; their synthesis and changes during germination: A review. Critical Reviews in Food Science and Nutrition, 52(7), 629–639. https://doi.org/10.1080/10408398.2010.504902

Laguna, L., Varela, P., Salvador, A., & Fiszman, S. (2013). A new sensory tool to analyse the oral trajectory of biscuits with different fat and fibre contents. Food Research International, 51(2), 544–553. https://doi.org/10.1016/j.foodres.2013.01.003

Lemmens, E., Moroni, A. V., Pagand, J., Heirbaut, P., Ritala, A., Karlen, Y., Lê, K. A., Van den Broeck, H. C., Brouns, F. J., De Brier, N., & Delcour, J. A. (2019). Impact of cereal seed sprouting on its nutritional and technological properties: A critical review. Comprehensive Reviews in Food Science and Food Safety, 18(1), 305–328. https://doi.org/10.1111/1541-4337.12414

Leszczyńska, D., Wirkijowska, A., Gasiński, A., Średnicka-Tober, D., Trafiałek, J., & Kazimierczak, R. (2023). Oat and oat processed products—Technology, composition, nutritional value, and health. Applied Sciences, 13(20), 11267. https://doi.org/10.3390/app132011267

Londono, D. M., Gilissen, L. J., Visser, R. G., Smulders, M. J., & Hamer, R. J. (2015). Understanding the role of oat β-glucan in oat-based dough systems. Journal of Cereal Science, 62, 1–7. https://doi.org/10.1016/j.jcs.2014.12.003

Lorenz, K., Collins, F., & Kulp, K. (1981). Sprouting of cereal grains–Effects on starch characteristics. Starch-Stärke, 33(6), 183–187. https://doi.org/10.1002/star.19810330603

Mäkinen, O. E., & Arendt, E. K. (2012). Oat malt as a baking ingredient–A comparative study of the impact of oat, barley and wheat malts on bread and dough properties. Journal of Cereal Science, 56(3), 747–753.

Mao, H., Xu, M., Ji, J., Zhou, M., Li, H., Wen, Y., Wang, J., & Sun, B. (2022). The utilization of oat for the production of wholegrain foods: Processing technology and products. Food Frontiers, 3(1), 28–45. https://doi.org/10.1002/fft2.120

Marchini, M., Marti, A., Folli, C., Prandi, B., Ganino, T., Conte, P., Fadda, C., Mattarozzi, M., & Carini, E. (2021). Sprouting of sorghum (Sorghum bicolor [L.] Moench): Effect of drying treatment on protein and starch features. Foods, 10(2), 407. https://doi.org/10.3390/foods10020407

Marchini, M., Paciulli, M., Broccardo, L., Tuccio, M. G., Scazzina, F., Cirlini, M., & Carini, E. (2023). Towards sustainable and nutritionally enhanced flatbreads from sprouted sorghum, tapioca, and cowpea climate-resilient crops. Foods, 12(8), 1638. https://doi.org/10.3390/foods12081638

Marti, A., Augst, E., Cox, S., & Koehler, P. (2015). Correlations between gluten aggregation properties defined by the GlutoPeak test and content of quality-related protein fractions of winter wheat flour. Journal of Cereal Science, 66, 89–95. https://doi.org/10.1016/j.jcs.2015.10.010

Menon, R., Gonzalez, T., Ferruzzi, M., Jackson, E., Winderl, D., & Watson, J. (2016). Oats—From farm to fork. Advances in Food and Nutrition Research, 77, 1–55. https://doi.org/10.1016/bs.afnr.2015.12.001

Miller, S. S., Wood, P. J., Pietrzak, L. N., & Fulcher, R. G. (1993). Mixed linkage -Glucan, protein content, and kernel weight in Avena species. Cereal Chemistry, 70, 231–231.

Mohebbi, Z., Homayouni, A., Azizi, M. H., & Hosseini, S. J. (2018). Effects of beta-glucan and resistant starch on wheat dough and prebiotic bread properties. Journal of Food Science and Technology, 55, 101–110. https://doi.org/10.1007/s13197-017-2836-9

Olaerts, H., Roye, C., Derde, L. J., Sinnaeve, G., Meza, W. R., Bodson, B., & Courtin, C. M. (2016). Impact of preharvest sprouting of wheat (Triticum aestivum) in the field on starch, protein, and arabinoxylan properties. Journal of Agricultural and Food Chemistry, 64(44), 8324–8332. https://doi.org/10.1021/acs.jafc.6b03140

Rakita, S., Dokić, L., Dapčević Hadnađev, T., Hadnađev, M., & Torbica, A. (2018). Predicting rheological behavior and baking quality of wheat flour using a GlutoPeak test. Journal of Texture Studies, 49(3), 339–347. https://doi.org/10.1111/jtxs.12308

Rasane, P., Jha, A., Sabikhi, L., Kumar, A., & Unnikrishnan, V. S. (2015). Nutritional advantages of oats and opportunities for its processing as value added foods-A review. Journal of Food Science and Technology, 52, 662–675. https://doi.org/10.1007/s13197-013-1072-1

Rosa Perez-Gregorio, M., & Simal-Gandara, J. (2017). A critical review of the characterization of polyphenol-protein interactions and of their potential use for improving food quality. Current Pharmaceutical Design, 23(19), 2742–2753. https://doi.org/10.2174/1381612823666170202112530

Simsek, S., Ohm, J. B., Lu, H., Rugg, M., Berzonsky, W., Alamri, M. S., & Mergoum, M. (2014). Effect of pre-harvest sprouting on physicochemical properties of starch in wheat. Foods, 3(2), 194–207. https://doi.org/10.3390/foods3020194

Sivam, A. S., Sun-Waterhouse, D., Quek, S., & Perera, C. O. (2010). Properties of bread dough with added fiber polysaccharides and phenolic antioxidants: A review. Journal of Food Science, 75(8), 163–174. https://doi.org/10.1111/j.1750-3841.2010.01815.x

Suárez-Estrella, D., Bresciani, A., Iametti, S., Marengo, M., Pagani, M. A., & Marti, A. (2020). Effect of sprouting on proteins and starch in quinoa (Chenopodium quinoa Willd.). Plant Foods for Human Nutrition, 75(4), 635–641. https://doi.org/10.1007/s11130-020-00864-6

Suárez-Estrella, D., Cardone, G., Buratti, S., Pagani, M. A., & Marti, A. (2020). Sprouting as a pre-processing for producing quinoa-enriched bread. Journal of Cereal Science, 96, 103111. https://doi.org/10.1016/j.jcs.2020.103111

Tamba-Berehoiu, R. M., Cristea, S., Negoiţă, M. I. O. A. R. A., Popa, C. N., & Turtoi, M. O. (2019). Bread making potential assessment of wheat-oat composite flours. Romanian Biotechnological Letters, 24(3), 522–530.

Wang, Q., & Ellis, P. R. (2014). Oat β-glucan: Physico-chemical characteristics in relation to its blood-glucose and cholesterol-lowering properties. British Journal of Nutrition, 112(S2), S4–S13. https://doi.org/10.1017/S0007114514002256

Webster, F. (2016). World oat production, trade, and usage. In: Oats Chemistry and Technology, (1), 1–10.

Yang, Z., **e, C., Bao, Y., Liu, F., Wang, H., & Wang, Y. (2023). Oat: Current state and challenges in plant-based food applications. Trends in Food Science & Technology, 134, 56–71. https://doi.org/10.1016/j.tifs.2023.02.017

Zhang, K., Dong, R., Hu, X., Ren, C., & Li, Y. (2021). Oat-based foods: Chemical constituents, glycemic index, and the effect of processing. Foods, 10(6), 1304. https://doi.org/10.3390/foods10061304

Acknowledgements

A.S.’s scholarship is funded under PON: “National Research and Innovation Operational Program 2014-2020.”

Funding

Open access funding provided by Università degli Studi di Milano within the CRUI-CARE Agreement. This study was partially funded under the National Recovery and Resilience Plan (NRRP), Mission 4 Component 2 Investment 1.3—Call for proposals No. 341 of 15 March 2022 of the Italian Ministry of University and Research funded by the European Union—NextGenerationEU, Award Number: Project code PE00000003, Concession Decree No. 1550 of 11 October 2022 adopted by the Italian Ministry of University and Research, CUP D93C22000890001, Project title “ON Foods—Research and innovation network on food and nutrition Sustainability, Safety, and Security—Working ON Foods. All data generated or analyzed during this study are included in this published article and comply with research standards.

Author information

Authors and Affiliations

Contributions

Alessio Sergiacomo was responsible for formal analysis, investigation, writing—original draft preparation, and visualization. Andrea Bresciani was responsible for methodology, validation, resources, and writing—original draft preparation. Francesca Gallio was responsible for resources, writing—review and editing. Paolo Varetto was responsible for writing—review and editing, and project administration. Alessandra Marti was responsible for conceptualization, writing—review and editing, supervision, and project administration.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sergiacomo, A., Bresciani, A., Gallio, F. et al. Sprouted Oats (Avena sativa L.) in Baked Goods: From the Rheological Properties of Dough to the Physical Properties of Biscuits. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03362-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03362-8