Abstract

The basic step in beer production is mashing, during which insoluble starch chains, and to a lesser extent cell walls and proteins are broken down by enzymatic hydrolysis. Since the beginning of the modern brewing process there have been empirical studies into the optimum effective temperatures of the corresponding enzymes, and mashing has been carried out accordingly. The resulting resting temperatures of proteolysis, cytolysis and amylolysis with the maltose and saccharification rest, are now rarely changed, only being adapted to the properties of the raw materials used to a limited extent. New varieties of barley and other raw materials used in breweries, as well as modern processes in malting plants, ensure better enzyme potential and optimized malt gelatinization temperatures. The aim of this paper is to determine enzyme activity in barley malt during mashing. For this purpose, isothermal mashing was used, i.e., a mashing process with a constant resting temperature over the entire mashing period. The obtained worts were analyzed for the attributes of extract, final attenuation, β-glucan, total nitrogen, free amino nitrogen, viscosity, and pH as well as sugar composition and individual amino acids. The change in these attributes indicates the enzyme activity of the malt.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Mashing is the mixing of grist, mostly consisting of crushed malt or partially crude cereals, with water and is a fundamental step in beer production. During mashing, the ingredients of the malt are dissolved and further released with the aid of physical and enzymatic degradation processes (Back et al., 2008; Narziß et al., 2017). Long-chain starch molecules are broken down into sugars that can be fermented by the yeast, such as glucose, maltose, and maltotriose (Bamforth, 2003). The decisive factor is the action of enzymes present in malt. Their activity is divided into three degradation processes, namely proteolysis, cytolysis, and amylolysis. Proteolytic enzymes cleave proteins, cytolytic enzymes hydrolyze gums and hemicelluloses of the cell walls, and amylolytic enzymes release sugars that are fermentable by the yeast from long-chain carbohydrates (Bamforth, 2009).

All enzymes will act within a certain temperature range. Their enzymatic activity will be strongest at an optimum temperature within this range (Back et al., 2008). By using isothermal mashes, i.e., mashes with only one rest at constant temperature, it is possible to follow the activity of specific enzymes and to investigate their optimal temperatures (Evans, 2017). It may also be possible to determine whether it is necessary to maintain different rests during the mashing process when using modern barley cultivars. One reason why it may be possible to simplify mashing is the increased diastatic power of barley cultivars. The diastatic power of barley malt cultivars over the last 40 years was examined and a steady increase was determined in the amylolytic enzyme activity—mainly β-amylase (Braugersten-Jahrbuch, 1954–2008). Important enzymes in the mashing process are listed in Table 1 (Back et al., 2008; Kreisz, 2002; Sissons et al., 1995).

The two amylases in particular are crucial for the mashing process. β-amylase is more sensitive to temperature than α-amylase. However, for a short period both amylases are equally active at the same time (Narziß & Back, 2019). In a recent study by Henson and Duke (2016a, b), the activity of the amylases of two different malt varieties were investigated at different temperatures, different wort compositions, and added maltose. It was concluded that the β-amylase activity is highest at 63 °C and that the enzyme is relatively stable in the presence of maltose. At a temperature of 73 °C, β-amylase quickly loses its activity within 30 min. The α-amylase is heat stable and has a high activity at 73 °C for over 90 min. This was confirmed by Evans et al. (2017) in another study. The properties of the amylases as well as limit dextrinase were investigated at a temperature of 65 °C. At this temperature the α-amylase showed no loss of activity over 70 min and lost 20–40% of its activity rapidly at 74 °C. In contrast, the β-amylase activity had already declined at 65 °C. After 60 min at this temperature only about 40–60% of its original activity remained. At 74 °C hydrolysis stopped entirely. The activity of limit dextrinase increases in the first 20 min at 65 °C, and rapidly declines thereafter. At 74 °C its activity is around 15 to 30% of its original value. Another reason why the wort composition is important for the activity of enzymes is the stabilizing effect of sugars on proteins. Sugars and polyols increase the surface tension of water and hydrophobic interactions stabilize the structure of proteins, thus increasing the thermostability of enzymes in sugary solution (Back et al., 1979).

Technical enzymes, which are used for example for the degradation of celluloses and hemicelluloses (de Souza & Kawaguti, 2021), also exist natively in barley malt and can promote the degradation of β-glucans and ensure the filterability of the beer by maintaining specific temperatures.

By producing isothermal mashes, i.e., maintaining a rest at a constant temperature, the influence of temperature on the effect of relevant enzymes was investigated. The obtained worts were analyzed for the attributes of extract, final attenuation, β-glucan, total nitrogen, free amino nitrogen, viscosity, pH, sugar composition, and individual amino acids. The aim of this study is to investigate the degradation products of enzymes that are relevant to brewing. The change in concentration should allow conclusions to be drawn about the mode of action of these enzymes and enable the mashing processes to be optimized. The results obtained show that enzymes relevant to brewing have a broader spectrum of activity than is indicated in relevant literature. Enzymes are already active at low temperatures and exhibit thermostable properties. These results suggest improved mashing processes when modern malt varieties are used. The new temperature ranges compared to the ones according to literature for brewing relevant enzymes can be seen in Table 1.

Mashing represents a time-consuming procedure that can take up to three hours when using classic decoction processes, such as three-step decoction (Narziß & Back, 2009). Therefore, it is important to find out at which temperatures specific enzymes show high activity and whether it makes sense from an economic point of view to draw partial mashes and to run and maintain different temperature levels. Many studies have been carried out on other cereals and their suitability for malting and beer production. This has been done, for example, for teff (Gebremariam et al., 2013), for which the malting properties and their enzyme activity have been studied. In the case of barley malt, classical literature is still relied upon without taking into account modern cultivated varieties and their improved enzyme endowments. Thus, opening the possibility of improved mashing procedures. Greater understanding of the activity of malting enzymes, new barley varieties with improved enzyme equipment or low gelatinization temperature and optimized processes in malting plants could simplify and reduce mashing in the brewery. It is also possible to brew special beer such as low-alcohol beer according to the diastatic power of different barley malts and the different thermostability of relevant enzymes (Endres et al., 2022; Muslin et al., 2003).

The aim of this study is to determine enzyme activity in barley malt during mashing. Whether temperature ranges cited in relevant literature are still comparable to ranges of current barley breeds. According to newly acquired information temperature ranges of mashing procedures could be adjusted to these findings to be improved or shortened.

Material and Methods

Malt

Pilsner barley malt from the 2019 harvest of Malzfabrik Mich. Weyermann GmbH & Co. KG (Bamberg, Germany) was used for the isothermal mashing tests. This is ordinary Pilsner malt with the analytical data shown in Table 2. The gelatinization temperature of this Pilsner malt was determined to be at 64.9 °C ("Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Raw Materials 2016, chapter R-200.32.283, pp. 194–197," 2016a). With its peak at a temperature of 71.8 °C and an off –set temperature at about 80 °C. All analyses were conducted at the Research Center Weihenstephan for Food and Brewing Quality in Freising.

Brewing Equipment and Procedures

Grist Mill

The Pilsner malt was milled using a disk mill. This is a DFLU laboratory disk mill from Bühler AG (Uzwil, Switzerland). The upper disc is stationary, and the lower disc rotates at a speed of approx. 1500 rpm. For the isothermal mash tests, the coarse grist setting with a grinding gap of 1.0 mm was used. This is the recommendation of the Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Raw Materials R-205.00.004 (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Raw Materials 2016, chapter R-205.00.004, pp. 54–55," 2016b).

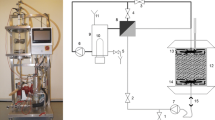

Mashing Apparatus

For mashing tests between 40 and 80 °C and at 20 °C, the mashing apparatus LP Electronic from Lochner Labor und Technik GmbH (Berching, Germany) was used. This machine operates in a temperature range of 20 °C to 92 °C, can work for 990 min per program step and has an accuracy of ± 0.1 °C. The mash unit has space for eight mash containers, which are made of stainless steel. Each container was used to produce 480 ml of mash. In addition, their contents were mixed using stainless steel stirrers. The agitator can be continuously adjusted within a speed range of 50 to 200 rpm.

Isothermal Mashing Process

The production of the wort took place in an isothermal mashing process. Mashes were prepared for each temperature in a range of 40 to 80 °C in 1 °C steps. Additionally, one mash was prepared at 20 °C. The mashing time was 90 min for each mash with an agitator speed of 100 rpm. Fully demineralized water was used to prepare the mashes. The water was preheated to the appropriate mashing temperature in a stainless steel mashing cup before the grist was added. At a liquor-to-grist ratio of 5:1, 80 g of the coarse grist was mashed into 400 g of the preheated, demineralized water.

After mashing, the cups were removed from the mashing apparatus and placed in a second water bath preheated to 96 °C for 10 min to deactivate the enzymes. The solid–liquid separation took place by transferring the mash into a folded filter with a pore size of 11 µm. The drained wort was again placed in the water bath at 96 °C for 10 min. To account for evaporated water, the obtained wort was filled up to a volume of 275 mL with demineralized water and then subsequently analyzed. In addition, a sample of each wort produced was frozen at 22 °C for subsequent analysis.

High-Short Infusion Procedure

A classic mashing process was carried out with Pilsner malt (Narziß & Back, 2009). This high-short infusion mashing process ran for 128 min, see Fig. 1. As with the isothermal processes, the liquor-to-grist ratio was 5 to 1, with 80 g of malt grist mixed with 400 g of demineralized water in each test. The malt was crushed, as described above, using a DFLU laboratory disk mill from Bühler AG with a grinding gap of 1.0 mm. The mashing-in temperature was 55 °C, at a heating rate of 1 K/min, the first rest was reached at 62 °C after 7 min. The maltose rest at this temperature was maintained for 25 min. After further heating for 3 min, another rest was held at 65 °C for 25 min. The mash was heated to 72 °C in 7 min and the temperature was held for 60 min. After the one-hour rest, the temperature was raised to 77 °C in 5 min. The temperature regime and duration of rests of the mashing process is shown graphically in Fig. 1. During the complete mashing period, the agitator speed of the mashing bath was set to 100 rpm. Like the isothermal mashes, the mash was heated to 96 °C and held for 10 min after the high-short infusion process. Spent grains were separated from the wort via a folded filter with a pore size of 11 µm. The wort obtained was heated again to 96 °C and held for 10 min. To account for evaporated water, the obtained wort was filled up to a volume of 275 mL with demineralized water and then subsequently analyzed. The results of the analysis, described below, for the high-short infusion procedure can be seen in Table 3.

Analysis Methods

The determination of the extract of the worts was carried out according to MEBAK: wort, beer, beer-based beverages 2.9.6.3 (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages 2012, chapter 2.9.6.3, pp. 150–151,” 2012d). A DMA 5000 M equipped with the module Alcolyzer Beer ME and an autosampler Xsample TM 520 from Anton Paar (Graz, Austria) was used for this analysis. The final degree of attenuation of the obtained worts was determined according to MEBAK: wort, beer, beer-based beverages 2.8.1 (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages 2012, chapter 2.8.1, pp. 127–129,” 2012c). The determination of the β-glucan concentration was carried out according to MEBAK regulation 2.5.1 (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages 2012, chapter 2.5.1, pp. 57–61,” 2012a). A Synergy 2 SLFP Multimode Microplate Reader by BioTek (Winooski, USA) was used for this analysis. The free amino nitrogen (FAN) was determined using the standard ninhydrin method according to MEBAK: wort, beer, beer-based beverages, chapter 2.6.4.1.1 (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages 2012, chapter 2.6.4.1.1, pp. 84–87,” 2012b). MEBAK: Raw Materials R-205.10.282 was applied to analyze viscosity (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Raw Materials 2016, chapter R-205.10.282, pp. 213–233,” 2016c). The apparatus used was a rolling-ball viscometer Lovis 2000 M/ME by Anton Paar (Graz, Austria).

The sugar composition of the produced worts was analyzed according to the MEBAK: wort, beer, beer-based beverages method 2.7.1 (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages, chapter 2.7.1, pp. 110–112,” 2012f) using high performance liquid chromatography. The worts were analyzed for their fructose, glucose, sucrose, maltose and maltotriose concentrations. The system used was a Thermo Fisher UltiMate 3000 (Waltham, USA) with a MN 250–4 Nucleodur NH2-RP 100–5 (Düren, Germany) column. The detector was an evaporative light scattering detector of the type Varian ELSD 385-LC (Palo Alto, USA). The eluent was acetonitrile. For calibration, D-glucose (Sigma G8270), maltose (Aplichem 141,797.1208), sucrose (Sigma 16,104-100G), fructose (Sigma F0127), and maltotriose (AlfaAesar J66491) were used.

The concentration of different amino acids in the worts was determined by high performance liquid chromatography according to MEBAK: wort, beer, beer-based beverages chapter 2.6.4.1.2 (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages, chapter 2.6.4.1.2, pp. 89–95,” 2012e) The produced worts were analyzed for their concentration of the amino acids aspartic acid, glutamic acid, asparagine, serine, histidine, glutamine, glycine, threonine, arginine, alanine, gamma-aminobutyric acid, tyrosine, valine, methionine, tryptophan, isoleucine, phenylalanine, leucine, and lysine. The same system was used to analyze the amino acids as for the sugar analysis. The column was a Bischoff Chromatography (Leonberg, Germany) 150 × 3 mm2 ProntoSIL Spheribond 80–3 ODS2. A Thermo Fisher FLD 3000 fluorescence detector was used to detect the amino acids. Acetonitrile with tetrahydrofuran and phosphate buffer and acetonitrile with phosphate buffer were used as the eluent. For calibration Thermo Scientific (Waltham, USA) Amino Acid Standard H and Laborservice Onken (Gründau, Germany) AS-Kalibrierstandard physiologisch 5.403.151 were used.

Every analysis, with the exception of the sugar and amino acid concentrations analysis, was performed in triplicate and a Welch-ANOVA was conducted with IBM SPSS software. The Pearson correlation coefficients were calculated using OriginLab OriginPro 2020 software. The α level was set at 0.05, and P < 0.05 was considered statistically significant. The sugars and amino acids were only analyzed once. Table 4 shows the results with p values and Table 5 presents the correlation coefficients.

Results and Discussion

Extract

The extract of the isothermal mashes can be seen in Fig. 2 and Table 4, along with its p value (< 0.001). The extract of all mashes did not fall below 13°P. As can be seen in Table 6, the 20 °C cold extract had an extract of 3.75°P, suggesting there was an influence of heat and enzymes on solubility and lower temperatures in which relevant enzymes are active. The mean values of the triplicate samples varied within a range of 13.17°P at mash temperature of 40 °C and 15.03°P at 74 °C. The difference can be attributed mainly to the activity of the amylases. Within the range of the temperature optima of β-amylase (60–65 °C) and of α-amylase (65–75 °C), in particular, the extract of the wort was higher on average at temperatures from 60 to 75 °C with an extract of 14.45°P. In comparison, at lower temperatures (40–59 °C), the extract was only 13.86°P on average and above the range of optimum temperatures (76–80 °C) it was 14.39°P. Here, the higher extract at increasing temperatures was due to better solubility in warmer media together with the effect of α-amylase, which was only deactivated at 80 °C (Kühbeck et al., 2005). This can also be seen in the 80 °C mash, which only had an average extract of 14.07°P and a low final degree of attenuation.

Cytolysis and proteolysis also play a role in the hydrolysis of the starch granules by the amylases. In a temperature range of 40–45 °C, both endo-1,3-β-glucanase and endo-1,4-β-glucanase, a non-specific endo-1,3–1,4-β-glucanase and an exo-glucanase are active (Kreisz, 2002). Low-molecular-mass β-glucans are formed, as well as the disaccharides laminaribiose and cellobiose. The enzymes laminaribiase and cellobiase, which have low temperature optima but are active up to 50 and 55 °C, respectively, can cleave these disaccharides into two glucose units each. This can be seen by the slight increase in extract up to 45 °C. The decrease at 46 °C of the extract can be attributed to the reduced activity of the glucanases. The increase after 46 °C was due to proteolysis. Peptidases, such as endopeptidase, started to be active and dissolution of the protein matrix between the starch granules began. It is assumed the mixture of the protein fractions commonly found in barley, mainly hordein and globulin, act as α-amylase inhibitors. Binding interactions occur between amylase and these two protein fractions, which hinder the enzyme’s activity (Yu et al., 2018, 2020). The activity of endoproteases, which degrade hordeins and globulins, promote the activity of β-amylase and limit dextrinase. Thus, the extract of the wort increases (Yu et al., 2020).

Another inhibitor protein of α-amylase is the barley α-amylase/subtilisin inhibitor (BASI). Depending on the temperature, BASI inhibits the amylase to different degrees. A linear decrease in inhibition from 50 to 70 °C can be observed. At 70 °C, the inhibitor was inactivated after 15 min. BASI thus played a role in the activity of α-amylase, which only reached its optimum effect at higher temperatures (Munck et al., 1984).

Limit dextrinase is also inhibited by two barley-specific inhibitors, which were identified with a low isoelectric point of 6.7 and a high one of 7.2. They consist of a single amino acid chain around 114 residues long (Macgregor, 2004). These proteins bind to the limit dextrinase and thus impedes its activity. Approximately 20% of the total limit dextrinase is present in free form in the mash, while the inhibitors inhibit 60–70% of the limit dextrinase. The action of proteinases can break the binding of the inhibitors to the limit dextrinase and improve its action in the mash (Jones & Marinac, 1999; Macgregor et al., 1999). The temperature optima of the various proteinases in malt are 45–50 °C, while the optimum temperature of limit dextrinase is 55–60 °C and can go up to 65 °C (Stenholm & Home, 1999). This enzyme is unstable at a temperature above 65 °C and has lost more than half of its activity at this temperature after 15 min (Sissons et al., 1995). Limit dextrinase is also inhibited by starch degradation products, such as maltotriose and maltodextrins with up to seven glucose units. This means that higher activity of the other amylases at higher temperatures, reduces the activity of limit dextrinase (Macgregor et al., 2002).

A strong increase in the extract at a temperature of 46 °C to 47 °C can be seen. This could be due to the action of the proteinases on the inhibitors of the limit dextrinase. Despite the optimum temperature of 55–60 °C for the limit dextrinase, it also acted at lower temperatures, which is supported by the activity of the proteinases.

It should be noted that the results fluctuated strongly, especially in a range of 47–57 °C. At rest temperatures between 64 and 67 °C both α- and β-amylase were active, albeit to a limited extent. No abnormalities in extract were observed here, but the extract was close to the average value for the 60–75 °C temperature range. The extract of the high-short infusion process was slightly higher at 14.63°P. This can be explained by the adherence to optimized rests for the amylases, the overall longer mashing time, more advanced gelatinization and a reduction of BASI activity (Munck et al., 1984).

The high extract value at 74 °C can be attributed to the higher solubility of substances at higher temperatures and the activity of enzymes. This might suggest higher thermostability of certain enzymes as well as the activity of β-glucan-solubilase as a carboxypeptidase.

As already assumed, the extract correlated strongly with the maltose and the maltotriose concentrations with a correlation coefficient of r = 0.85189 and r = 0.82395, respectively.

Final Degree of Attenuation

The final degree of attenuation indicates the amount of the theoretically possible fermentable portion of the extract as a percentage of the total dissolved components in the wort (Narziß et al., 2017). The degree of attenuation is therefore a good indicator of the intensity of the mashing process. Long-chain starch molecules in the form of amylopectin and amylose are cleaved by the amylolytic enzymes α- and β-amylase, and to a lesser extent by limit dextrinase, to form simple glucose molecules, maltose, maltotriose, and dextrins (Narziß & Back, 2019). Figures 3 and 6 show that the increase in the final degree of attenuation was accompanied by a decrease in viscosity. This was confirmed by a negative correlation (r = − 0.77184) of these two attributes. Like the extract, the final degree of attenuation correlated strongly with the maltose (r = 0.89139) and the maltotriose concentration (r = 0.92288).

The longer and more intense a mashing process is, the greater the action of amylolytic enzymes, releasing fermentable sugars and increasing the final degree of attenuation. The most important influencing variables are the resting temperature, the resting duration and the pH value of the wort (Back et al., 2008). The pH value and the resting time were not changed in any of the isothermal mashing trials. The resting time was 90 min for each mash. The pH value changed depending on the temperature and the effect of different enzymes. It fluctuated in a range of 5.42 to 5.79. As could be assumed, the proportion of fermentable extract was greatest at the overlap of the optimal ranges of activity of the amylolytic enzymes α- and β-amylase. The wort obtained the highest final degree of attenuation at this point. Figure 3 and Table 4 show the course of the apparent final degree of attenuation and its p value. Starting at a temperature of 56 °C, a sharp increase in the final degree of attenuation was observed, which rose steeply up to a temperature of 65 °C and reached the highest final degree of attenuation of 92%. At these temperatures, the amylases and the limit dextrinase were most active and starch was degraded into fermentable sugars. The optimal temperature of 65 °C in terms of final degree of attenuation is confirmed by the work of Evans et al. (Evans et al., 2005).

Along with the extract (Fig. 2), the final degree of attenuation increased slightly between 40 °C and 45 °C. This was due to the action of laminaribiase and cellobiase in combination with the endogenous glucanases and the consequent release of glucose (Kreisz, 2002). The action of the protein-degrading enzymes was also evident here at 45 °C. The final degree of attenuation initially increased slightly due to reduced protein binding to starch granules and the decreasing inhibitory effect of hordein on amylases and the reduced efficiency of limit dextrinase inhibitors. The sharp drop from 47 °C, as can also be seen in the course of the extract, was due to the reduced effect of the glucanases (Kühbeck et al., 2005).

As the temperatures of the isothermal mashes rose, the final degree of fermentation dropped again slowly and reached a value of 71% at 80 °C. From 65 °C onwards, β-amylase lost 70–90% of its original activity at the beginning of mashing, after only approx. 20 min. This can be seen by the decrease in the final degree of attenuation. However, the α-amylase was able to hydrolyze at these temperatures, which meant that it decreased slowly. For α-amylase, the activity decreased from a temperature of 78 °C and was deactivated after approx. 30 min (Henson et al., 2014). But even this reduced activity of the α-amylase lead to a final degree of attenuation of 71%.

The very intense high-short infusion mashing process achieved a degree of attenuation of 89% in comparison. This value was only reached for isothermal mashes at rest temperatures of 62 to 67 °C and confirmed the activity of the two amylases and their joint activity in this range.

The cold extract had a final degree of attenuation of 45% and, as expected, was lower than any other wort analyzed. As can be seen from the sugar analysis, amylolytic enzymes were active to a low degree even at low temperatures, which explains the value of the cold extract along with the pre-solution during malting.

It was noticed that the enzymes relevant for the release, i.e., α- and β-amylases, limit dextrinase, as well as invertase and maltase, had a wider range of action with respect to temperature than indicated in relevant literature. These enzymes are also more thermostable than previously found and needed a higher inactivation temperature. This is listed in Table 8.

β-Glucan

Figure 4 and Table 4 show the course of the β-glucan concentration of all the isothermal mashes produced. In general, the course fluctuated a lot, but a trend for the concentration could be identified. In a range of 40–51 °C, the β-glucan concentration was at its lowest at 17.53 mg/L on average. This very low value was due to the action of endo- and exo-glucanases, which were active at this temperature range (Osman et al., 2002). Solubilase, on the other hand, had little or no effect in this range and had no influence on the concentration. In a temperature range of 40–45 °C, both endo-1,3-β-glucanase and endo-1,4-β-glucanase, a non-specific endo-1,3–1,4-β-glucanase and an exo-glucanase were active. Low-molecular-mass β-glucans were formed, as well as the disaccharides laminaribiose and cellobiose. The enzymes laminaribiase and cellobiase, which have low temperature optima but are active to above 50 and 55 °C, respectively, can cleave these disaccharides into two glucose units each (Kreisz, 2002).

An increasing trend can be seen from 52 to 59 °C. The effect of the β-glucan degrading enzymes decreased due to the increased temperature and the glucan passed from the malt into the wort almost unchanged. A dip in the value can be seen starting at 59 °C. Only β-glucans with a mass of more than 10 kDa were measured, as only these are relevant for the brewing process and can hinder filtration. Smaller molecules were not measured (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages 2012, chapter 2.5.1, pp. 57–61,” 2012b). The dip could be explained by the increase in β-glucans with smaller molecular mass and were therefore not measured. A steep increase in β-glucan can be observed at 62 °C. At this point, the optimal temperature of the β-glucan solubilase was reached and bound β-glucan was increasingly converted into soluble form.

It is possible that other solubilases act at temperatures 70 °C and 75 °C, reaching their optimum temperature of action here. This could explain the minima and maxima in the 65–80 °C range. Microflora could bring β-glucan solubilases with other temperature optima into the wort explaining these trends (Yin et al., 1989).

The concentration in the cold extract was less than 15 mg/L. The classic high-short infusion mashing process, with an average of 75 mg/L, delivered a comparatively high value. However, none of the prepared worts reached a value of more than 100 mg/L. This indicated a sufficiently dissolved malt and is a good value for further wort processing.

Free Amino Nitrogen (FAN)

The free amino nitrogen concentration (Fig. 5 and Table 4) tended to be highest in a temperature range of 43 to 57 °C. On average, the FAN levels were about 258 mg/L. This was caused by the action of endopeptidase and carboxypeptidase, which operated in this range and hydrolyzes amino acids from proteins and peptides (Jones & Marinac, 2002). At higher temperatures, from 58 °C and upwards, there was a decreasing trend in the FAN concentration. This indicated reduced enzyme efficiency. At 70 °C and above, the concentration of FAN reached its lowest levels, averaging 196 mg/L and was even lower than the concentration of the cold extract at 224 mg/L. At a concentration of 177 mg/L, the FAN was lowest at 78 °C. This could be a response to the inactivation temperature of the endo- and carboxypeptidase, which is 70 °C, and may show that these enzymes were already active at very low temperatures. Aminopeptidase and dipeptidase only had a slight influence on the FAN concentration, since their optimum pH is in quite a high range and their inactivation temperature is already reached at 55 °C and 50 °C respectively (Narziß & Back, 2019).

It is assumed that the β-glucan solubilase also acts as a carboxypeptidase and cleaves amino acids from the carboxy end of proteins (Bamforth & Martin, 1981). The optimal temperature range of this solubilase is between 60 °C and 65 °C, explaining the increase in FAN concentration in this regime.

As can also be seen from the β-glucan concentration curve, the FAN concentration increased slightly at 69 °C. It is possible that other β-glucan-solubilases, which might come from microflora on the malt, may be active here, which also act as carboxypeptidases and cellulases in this higher temperature regime (Yin et al., 1989).

Viscosity

The viscosity primarily allows conclusions to be drawn about the cytolytic and amylolytic solution of the malt. The viscosity of the wort is strongly related to the enzymatic activity. It can be seen in Figs. 6 and 3 that the final degree of attenuation and the viscosity display inversely proportional behavior. While the final degree of attenuation increased with increased action of the amylolytic enzymes, the viscosity decreased. This is due to the cleavage of long-chain starch molecules into shorter dextrins, tri-, di- and monosaccharides. The results of the viscosity analyses, along with its p-value can be seen in Table 4. There was a sharp drop in viscosity from 57 °C onwards. At lower temperature, the viscosity had an average value of 1.8 mPas, which is a high value for wort. Viscosity reached its lowest value of 1.66 mPas at a temperature of 62 °C. The lower values of viscosity were observed in the range of the optimal temperature for β- and α-amylase, and therefore at temperatures at which the enzymatic degradation of starch into low molecular mass sugars takes place and starch gelatinization is well advanced. Viscosity increased again with increasing temperature as the efficiency of the amylolytic enzymes decreased. In particular, a strong, almost linear increase in viscosity can be seen from 72 °C onwards. This was due to the inactivation of β- and α-amylase, which was reached at 70 and 80 °C, respectively. In addition, no cytolytic degradation processes took place at these temperatures and β-glucan passed unchanged into the wort. Also at these higher temperatures, a β-glucan-solubilase was active, releasing matrix-bound β-glucan, further increasing viscosity without β-glucan being degraded. In general, mash had its highest viscosity when the gelatinization temperature of the malt was reached, and enzymatic degradation of the starch was not yet far advanced. As can be seen in Fig. 6, the viscosity was lowest at a temperature of 62 °C. Here, gelatinization appeared to be well advanced, and the gelatinized starch was easily attacked by the enzymes. At higher temperatures, the starch was also gelatinized, but enzyme activity was limited or no longer present due to the heat, and the viscosity therefore increased sharply (Kühbeck et al., 2005).

The sharp decrease in viscosity in a temperature range of 40–45 °C was due to the activity of β-glucanases. Both endo-1,3-β-glucanase and endo-1,4-β-glucanase have their optimal range of activity here. The nonspecific endo-1,3-β-glucanase, and the exo-glucanase, have their optima of action at a temperature of 40 °C, but continue to be active beyond this temperature, providing a decrease in viscosity in a low temperature range. The increased viscosity from 43 °C was due to a reduction in the glucanase activity.

Sugar Composition

The sugar composition of the worts obtained was determined by LS-HPLC (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages, chapter 2.7.1, pp. 110–112,” 2012f). The quantitative composition of the wort was analyzed for the yeast-fermentable sugars fructose, glucose, sucrose, maltose, and maltotriose. The disaccharide sucrose occurs natively in malt as well as monosaccharide fructose. Fructose can also be released by hydrolysis of sucrose by the enzyme invertase along with glucose (Briggs et al., 2004).

The sugar concentrations were not determined for every isothermal mash, but the analyses were performed for every other mash prepared, starting at 41 °C. The sugar analysis was only carried out once, as the results within the experimental setup, such as the final degree of attenuation and the extract, are consistent with each other. Figure 7 shows the sugar compositions at the different temperature levels.

In isothermal mashing, the optimum action of various enzymes is achieved at certain temperatures. This can be seen from the curves of the different sugar concentrations. The course of the maltose concentration followed the optimum temperature of the α- and β-amylases. The concentration of maltose increased continuously in a temperature range from 41 to 57 °C until it reached a relatively constant peak of 73.06 g/L of between 59 and 71 °C on average. This reflects the enzymatic action of α- and β-amylases on amylose and amylopectin. The temperature optima of these two enzymes, according to literature, are at 65–75 °C and 60–65 °C, respectively (Back et al., 2008; Henson et al., 2014). The inactivation temperatures of α- and β-amylases are at 80 and 70 °C, respectively, and explained the decrease in maltose concentration over 71 °C.

Gelatinization of the malt starch slowly began at a temperature of 55 °C, which made it more accessible to enzymes and accounted for the sharp increase in maltose concentration (Kessler et al., 2005; Macgregor et al., 2012; Narziß & Back, 2009). Another reason for this increase from 53 °C was hydrolysis by limit dextrinase, which has an optimum temperature activity of 55–60 °C (Back et al., 2008). At a temperature of 65 °C the activity of limit dextrinase still remains at 60% of its original activity for 60 min (Stenholm & Home, 1999). This enzyme cleaves α-1,6-bonds, increasing the quantity of starch chains that can be utilized by β- and α-amylase (Macgregor et al., 2002).

There was already a large difference in maltose concentrations between the cold extract of the malt and the isothermal mash at 41 °C. The cold extract had a concentration of 3.8 g/L, while the isothermal mash at 41 °C showed a concentration of 42.7 g/L. Gelatinization does not take place at these low temperatures, or only to a very small extent, which means that hydrolysis by amylolytic enzymes, apart from invertase, cannot take place or can only take place to a very limited extent. At these temperatures, however, starch granules had already swelled with this swelling advancing further over a mashing period of 90 min (Narziß & Back, 2009). The α- and β-amylases were less active at low temperatures outside their optimum range, but they did not lose their activity entirely and can hydrolyze released amylose and amylopectin chains over the entire mashing period (Henson et al., 2020). The activity of amylases was highest at their optimum effective temperatures. However, they are already rapidly damaged at these temperatures. The β-amylase activity decreases by 90% after just 10 min at 65 °C, while α-amylase can lose much of its activity at 70 °C (). Such a loss of activity does not occur at lower temperatures, but amylolysis proceeds more slowly.

The plateau and slight increase in sugars at temperature range of 47 °C to 53 °C was due to the starch gelatinization that had not yet advanced. Enzymes of amylolysis require gelatinization of the starch chains in order to be able to cleave them. However, it is possible that in this range maltase acts on the first starch molecules that have already been gelatinized. Although the activity of this enzyme decreased from 40 °C, it still had a high affinity for maltose at 45 °C and cleaved it into two glucose molecules (Narziß et al., 2017). This was also confirmed by an increase in the glucose concentration in this range.

Glucose is formed mainly by chance during mashing from the combined action of α- and β-amylases (Narziß & Back, 2009). In addition, maltase is also present, which cleaves maltose, an invertase, also called saccharase, an α-glucosidase, as well as laminaribiase and cellobiase.

Maltase has an optimal temperature range of 35 to 40 °C (Back et al., 2008), which is outside the selected temperatures for these isothermal mashes. The glucose concentration increased consistently starting at 41 °C and reaching its maximum at 57 °C with 14.9 g/L before decreasing again. The effect of maltase can also be seen in comparison with the glucose concentration of the cold extract. The glucose concentration of the cold extract was 4.9 g/L. The difference in concentration of 3.9 g/L compared to the isothermal wort of the 41 °C mash was also due to the maltase. Also, α-glucosidase played a minor role in hydrolyzing smaller dextrins into single glucose molecules. α-Glucosidase cleaves α-1,4-glycosidic bonds starting at the terminal non-reducing ends of dextrins. This enzyme denatures at a relatively low temperature of 45 to 48 °C and had a minor role in the increase of the glucose concentration of the mash up to around 48 °C (Muslin et al., 2000, 2003; Zhang & Li, 2010).

Amylases, which also split glucose from the amylose and amylopectin chains as a random product, can also act here (Narziß & Back, 2009). At elevated temperatures from 75 °C, the concentration again approached that of the cold extract, which indicated enzyme inactivation. In addition to the activity of maltase, laminaribiase, and cellobiase also play a role in the formation of glucose in a low temperature range. Laminaribiose and cellobiose, which consist of two β-1,4- and β-1,3-glycosically bound glucose units, respectively, are degradation products from cytolysis and are hydrolyzed by these two enzymes. The effect of these enzymes can be confirmed by the curves of extract, final degree of attenuation and β-glucan. Their optimum effective temperature is at about 40 °C, but they can be active up to 55 °C. It is therefore reasonable to assume that, in addition to maltase, the glucose increase above 40 °C was due to these enzymes. In addition, laminaribiase and cellobiase are independent of the gelatinization temperature being reached since glucose is released from β-glucan-derived disaccharides.

The effect of invertase is also independent of the gelatinization of the malt starch. The substrate that is cleaved by the enzyme is sucrose and is already present in small quantities natively in malt (Briggs et al., 2004). In the cold extract at 20 °C, it had a concentration of 5.0 g/L. It was therefore lower than the sucrose concentration at higher temperatures of the isothermal mash tests. This may show that invertase was active at this low temperature. Its effect results in one glucose and one fructose molecule from each sucrose molecule. According to the literature, this enzyme is stable up to 50 °C and is inactivated rapidly at a temperature above 55 °C (Bassetti et al., 2000). An increase in glucose concentration can be seen up to 57 °C and might be due to this enzyme. Confirmation could be the relatively constant sucrose concentration up to 57 °C, which was 4.08 g/L on average. From 59 °C, the sucrose concentration increased constantly and had its highest concentration at 73 °C and 79 °C at a value of 8.0 g/L. This indicated a decrease in invertase activity.

Likewise, the course of the fructose concentration indicates the activity of invertase. The concentration of fructose increased up to a temperature of 57 °C, which corresponded to the glucose development and comes from the cleavage of sucrose. At a temperature higher than 57 °C, the concentration decreased again, indicating the decrease in invertase activity, and fructose, with the exception of sucrose, only occurs natively in malt in small amounts. Fructose reached its peak at 57 °C, with a concentration of 3.9 g/L. At higher temperatures of 65 °C and above, the value levelled off at approx. 0.66 g/L.

The duration of action of the invertase can be seen clearly with the aid of the cold extract. As already mentioned, no gelatinization of the starch is required for hydrolysis by invertase, since sucrose is already freely present in the malt (Briggs et al., 2004). Invertase is active already at a relatively low temperature and may cleave sucrose. This was also the reason for the slightly higher initial concentration of fructose and glucose and the somewhat lower sucrose concentration of the cold extract. The sucrose in the cold extract had a concentration of 5.0 g/L. At the start of the isothermal mash, for sugar analysis at a temperature of 41 °C, the concentration was already significantly reduced and levelled at 3.8 g/L. This indicated the activity of invertase, which remained relatively constant up to 47 °C and then decreased from 49 °C, as evidenced by an increase in sucrose concentration. According to the literature, the optimum temperature for invertase is 50 °C (Narziß & Back, 2009). This cannot be confirmed based on our isothermal mashes. With a rise in temperature, the sucrose concentration increased almost linearly. This also contradicted the inactivation temperature of 55 °C, reported in the literature (Narziß & Back, 2009). Invertase did not seem to lose its activity abruptly, but decreased consistently until it lost activity from about 65 °C onwards (Manoochehri et al., 2020). The hydrolysis at low temperatures catalyzed by invertase can be seen from the difference in concentration between the cold extract and the concentration at higher temperatures. The sucrose concentration of the cold extract was lower than the concentration at a temperature of 59 °C and above. This was confirmed by the fructose concentration, which reflected the trend of sucrose. Fructose initially rose, only to fall again from a temperature of approx. 57 °C. At 65 °C and above, invertase activity no longer seemed to prevail and the fructose concentration levelled off at the level occurring natively in malt, which is approx. 1% of the dry matter of the malt (Briggs et al., 2004).

The trisaccharide maltotriose, consisting of three glucose units bound by α-1,4-glycosidic bonds, is another fermentable sugar that is mainly formed during mashing (Stewart, 2006). Maltotriose is formed here by the interaction of α- and β-amylases or from the hydrolysis of starch from molecules of odd chain length (Narziß & Back, 2009). The course of the maltotriose concentration mirrored the concentration course of the maltose, as can be seen in Fig. 7 and is confirmed by their correlation (r = 0.95075). In a range below the temperature optima of the amylases, the maltotriose concentration was relatively constant or increased only slightly. On average, the concentration was 12.98 g/L in a temperature range from 41 to 55 °C. When the optimum temperature of action of the amylases was reached, the concentration of maltotriose increased sharply. The maximum value was reached at temperatures of 61 and 67 °C and had a value of 20.9 g/L. As can also be seen from the maltose concentration curve, the maltotriose concentration decreased when the inactivation temperature of the amylases was reached. There was also a negative correlation of viscosity with maltose (r = − 0.71234) and maltotriose (r = − 0.76400).

The enzymatic action of β-amylase is already severely impacted at temperatures above 60 °C and shows barely any activity at 70 °C. A recent study by De Schepper et al. (De Schepper & Courtin, 2021) suggests that β-amylase is still active at 70 °C for up to 10 min. α-Amylase has an inactivation temperature of 80 °C and begins to be affected at 70 °C. This was confirmed by the decreasing concentration of maltotriose from temperatures higher than 67 °C.

Amino Acids

In addition to sugar composition, amino acids were also analyzed using LS-HPLC (“Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages, chapter 2.6.4.1.2, pp. 89–95,” 2012e) as can be seen in Table 7. The enzymes carboxypeptidase, aminopeptidase and dipeptidase are exoenzymes in malt, which cleave amino acids from proteins and peptides. Carboxypeptidase, in particular, plays a prominent role in mash production, as it has an optimum effective temperature of 50 °C and an optimum pH of 4.8–5.6. Endopeptidases are also present, which cleave proteins and peptides from within (Back et al., 2008).

With the exception of glutamic acid and tryptophan, an increase in the concentration in the range of the effective temperature of the carboxypeptidase and endopeptidase could be detected for all amino acids. The concentration of the individual amino acids increased up to a temperature of 53 °C and decreased steadily from a temperature of 55 °C or remained constant. Glutamic acid behaved in the opposite way to the other amino acids. Its concentration remained constant up to a temperature of 53 °C and then increased almost linearly. The amino acid tryptophan had a constant concentration of 2.20 mg/100 ml up to 59 °C and remained at about this level from 71 °C upwards. In the range between these two temperatures, the tryptophan concentration formed an elevated plateau with an average concentration of 2.82 mg/100 ml. As already mentioned, β-glucan-solubilase is also a carboxypeptidase and it is possible that different solubilases are active at different temperatures in mash. Due to the higher temperature range of solubilases from microflora and malt kernels single amino acids were cleaved at temperatures above 60 °C.

Conclusion

From the analyses of the various isothermal worts, it is possible to conclude the effective temperatures and their optima of the relevant enzymes, which can be seen in Table 8. It is clear from the results that cytolysis already takes place in the malting plant and well-dissolved malts are processed in breweries. This can be seen especially in the β-glucan content of the worts. None of the 41 isothermal worts, as well as the cold extract exceed 100 mg/l, which means a very good content for the subsequent process steps.

Amylolytic enzymes, here especially α- and β-amylase, limit dextrinase, maltase, and invertase, play an important role on the attributes extract, degree of final fermentation, viscosity and sugar composition. The two most meaningful attributes for the progress of amylolysis are the final degree of attenuation and the sugar composition. Based on the sugar composition, it can be seen that a temperature of 61 °C releases the highest amount of fermentable sugars. It was noticed that the enzymes relevant for the release, i.e., α- and β-amylases, limit dextrinase, as well as invertase and maltase, have a wider range of action with respect to temperature than is indicated in relevant literature. These enzymes are also more thermostable than previously found and need a higher inactivation temperature.

The proteolytic work is also sufficiently given with an isothermal mashing process. The free amino nitrogen content of all the worts produced is in a range that is sufficient for the subsequent proliferation and fermentation phase.

With regard to all attributes investigated, resting temperatures in a range between about 60 °C and 70 °C seem to represent a wort very well suited for beer production. Using well-dissolved malts of modern cultivars, it is not necessary to maintain rests at different temperature levels in view of the examined attributes.

Availability of Data and Materials

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Back, J. F., Oakenfull, D., & Smith, M. B. (1979). Increased thermal stability of proteins in the presence of sugars and polyols. Biochemistry, 18, 5191–5196. https://doi.org/10.1021/bi00590a025

Back, W., Gastl, M., Krottenthaler, M., Narziß, L., & Zarnkow, M. (2008). Ausgewählte Kapitel der Brauereitechnologie (2 edn.). Fachverlag Hans Carl GmbH.

Bamforth, C. W. (2003). Barley and Malt Starch in Brewing: A General Review. Master Brewers Association of the Americas - Technical Quarterly, 40(2), 89–97.

Bamforth, C. W. (2009). Current perspectives on the role of enzymes in brewing. Journal of Cereal Science, 50(3), 353–357. https://doi.org/10.1016/j.jcs.2009.03.001

Bamforth, C. W., & Martin, H. L. (1981). The Development of β-Glucan-Solubilase During Barley Germination. Journal of the Institue of Brewing, 87(2), 81–84. https://doi.org/10.1002/j.2050-0416.1981.tb03991.x

Bassetti, F. J., Bergamasco, R., Moraes, F. F., & Zanin, G. M. (2000). Thermal stability and deactivation energy of free and immobilized invertase. Brazilian Journal of Chemical Engineering 17(4–7). https://doi.org/10.1590/S0104-66322000000400050

Arbeitsgemeinschaft zur Förderung des Qualitätsgerstenanbaues im Bundesgebiet e. V. (eds) (2008): Braugerstenjahrbuch 1954-2008, Fachverlag Hans Carl GmbH

Briggs, D. E., Boulton, C. A. B., Peter, A., & Stevens, R. (2004). Brewing: Science and Practice. Woodhead Publishing Limited.

De Schepper, C., & Courtin, C. (2021). Thermal stability of α-amylase and β-amylase throughout the mashing process. Paper presented at the 14th International Trends in Brewing, KU Leuven, Leuven, 18 October 2018.

de Souza, T. S. P., & Kawaguti, H. Y. (2021). Cellulases, Hemicellulases, and Pectinases: Applications in the Food and Beverage Industry. Food and Bioprocess Technology, 14(8), 1446–1477. https://doi.org/10.1007/s11947-021-02678-z

Endres, F., Prowald, A., Fittschen, U. E. A., Hampel, S., Oppermann, S., Jacob, F., Hutzler, M., Laus, A., Methner, Y., & Zarnkow, M. (2022). Constant temperature mashing at 72 °C for the production of beers with a reduced alcohol content in micro brewing systems. European Food Research and Technology. https://doi.org/10.1007/s00217-022-03968-2

Evans, D. E. (2017). Comparison of Diastatic Power Enzyme Release and Persistence During Modified Institue of Brewing 65 °C and Congress Programmed Mashes. Journal of the American Society of Brewing Chemists, 75(4), 302–311. https://doi.org/10.1094/ASBCJ-2017-4707-01

Evans, E., Collins, H., Eglinton, J., & Wilhelmson, A. (2005). Assessing the impact of the level of diastatic power enzymes and their thermostability on the hydrolysis of starch during wort production to predict malt fermmentability. Journal of the American Society of Brewing Chemists, 63(4), 185–198. https://doi.org/10.1094/ASBCJ-63-0185

Gebremariam, M. M., Zarnkow, M., & Becker, T. (2013). Effect of dyring temperature and time on alpha-amylase, beta-amylase, limit dextrinase activities and dimethyl sulphide level of teff (Eragrostis tef) malt. Food and Bioprocess Technology, 6(12), 3462–3472. https://doi.org/10.1007/s11947-012-1025-0

Henson, C. A., & Duke, S. H. (2016a). Maltose effects in barley malt diastatic power enzyme activity and thermostability at high isothermal mashing temperatures: I. beta-Amylase. Journal of the American Society of Brewing Chemists, 74(2), 100–112. https://doi.org/10.1094/ASBCJ-2016-2734-01

Henson, C. A., & Duke, S. H. (2016b). Maltose effects in barley malt diastatic power enzyme activity and thermostability at high isothermal mashing temperatures: II. alpha-Amylase. Journal of the American Society of Brewing Chemists, 74(2), 113–126. https://doi.org/10.1094/ASBCJ-2016-2746-01

Henson, C. A., Duke, S. H., & Vinje, M. A. (2014). A comparison of barley malt amylolytic enzyme thermostabilities and wort sugars produced during mashing. Journal of the American Society of Brewing Chemists, 72(1), 51–65.

Henson, C. A., Vinje, M. A., & Duke, S. H. (2020). Maltose effects on barley malt beta-amylase activity and thermostability at low isothermal mashing temperatures. Journal of the American Society of Brewing Chemists, 78(3), 207–2018. https://doi.org/10.1080/03610470.2020.1738811

Jones, B. L., & Marinac, L. A. (1999). Endogenous Inhibitors of the Endoproteinases and Other Enzymes of Barley. 2nd European Symposium on Enzymes in Grain Processing, Helsinki.

Jones, B. L., & Marinac, L. A. (2002). The effect of mashing on malt endoproteolytic activities. Journal of Agricultural and Food Chemistry, 50, 858–864. https://doi.org/10.1021/jf0109672

Kessler, M. T., Zarnkow, M., Kreisz, S., & Back, W. (2005). Gelatinisation properties of different cereals and pseudocereals. Monatsschrift Für Brauwissenschaft, 9(10), 82–88.

Kreisz, S. (2002). Der Einfluss von Polysacchariden aus Malz, Hefe und Bakterien auf die Filtrierbarkeit von Würze und Bier [Dissertation, Technische Universität München]. Munich.

Kühbeck, F., Dickel, T., Krottenthaler, M., Back, W., Mitzscherling, M., Delgado, A., & Becker, T. (2005). Effects of mashing parameters on mash β-Glucan, FAN and soluble extract levels. Journal of the Institue of Brewing, 111(3), 316–327. https://doi.org/10.1002/j.2050-0416.2005.tb00690.x

Macgregor, A. W., Bazin, S. J., & Izydorczyk, M. S. (2012). Gelatinisation characteristics and enzyme susceptibility of different types of barley starch in the temperature range 48–72 °C. Journal of the Institue of Brewing, 108(1), 43–47. https://doi.org/10.1002/j.2050-0416.2002.tb00121.x

Macgregor, A. W., Bazin, S. J., Macri, L. J., & Babb, J. C. (1999). Modelling the contribution of alpha-amylase, beta-amylase and limit dextrinase to starch degradation during mashing. Journal of Cereal Science, 29, 161–169. https://doi.org/10.1006/jcrs.1998.0233

Macgregor, A. W., Bazin, S. J., & Schroeder, S. W. (2002). Effect of starch hydrolysis products on the determination of limit dextrinase and limit dextrinase inhibitors in barley and malt. Journal of Cereal Science, 35(1), 17–28. https://doi.org/10.1006/jcrs.2001.0408

Macgregor, E. W. (2004). The proteinaceous inhibitor of limit dextrinase in barley and malt. Biochimica et Biophysica Acta (BBA) - Proteins and Proteomics, 1696(2), 165–170. https://doi.org/10.1016/j.bbapap.2003.09.018

Manoochehri, H., Hosseini, N. F., Saidijam, M., Taheri, M., Rezaee, H., & Nouri, F. (2020). A review on invertase: Its potentials and applications. Biocatalysis and Agricultural Biotechnology, 25, 1–11. https://doi.org/10.1016/j.bcab.2020.101599

Jacob, F. (ed) (2016) Verkleisterungstemperatur (Malz) - Viskosimetrische Methode In: Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Raw Materials, Weihenstephan, p 194–197

Jacob, F. (ed) (2016) Schrotung (EBC-Methode) In: Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Raw Materials, Weihenstephan, p 203–208

Jacob, F. (ed) (2016) Viskosität - Mikroviskosimeter der Fa. Anton Paar In: Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Raw Materials, Weihenstephan, p 236-238

Jacob, F. (ed) (2016) Enzymatische Methode In: Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages, Weihenstephan, p 57–61

Jacob, F. (ed) (2016) Ninhydrin-Methode (photometrisch, EBC) In: Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages, Weihenstephan, p 84-87

Jacob, F. (ed) (2016) Endvergärungsgrad der Würze (Gärrohrmethode) In: Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages, Weihenstephan, p 127-129

Jacob, F. (ed) (2016) Biegeschwinger und NIR Messung In: Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages, Weihenstephan, p 57–61 150-152

Jacob, F. (ed) (2016) Bestimmung von Aminosäuren in Würze und Bier In: Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages, Weihenstephan, p 87-93

Jacob, F. (ed) (2016) Zuckerspektrum In: Mitteleuropäische Brautechnische Analysenkommission (MEBAK): Wort, Beer, Beer-based beverages, Weihenstephan, p 107-109

Munck, L., Mundy, J., & Vaag, P. (1984). Characterization of Enzyme Inhibitors in Barley and Their Tentative Role in Malting and Brewing. Journal of the American Society of Brewing Chemists, 43(1), 35–38. https://doi.org/10.1094/ASBCJ-43-0035

Muslin, E. H., Kanikula, A. M., Clark, S. E., & Henson, C. A. (2000). Overexpression, purification, and characterization of a barley alpha-glucosidase secreted by Pichia pastoris. Protein Expression and Purification, 18(1), 20–26. https://doi.org/10.1006/prep.1999.1160

Muslin, E. H., Karpelenia, C. B., & Henson, C. A. (2003). The impact of thermostable α-glucosidase on the production of fermentable sugars during mashing. Journal of the American Society of Brewing Chemists, 61(3), 142–145. https://doi.org/10.1094/ASBCJ-61-0142

Narziß, L., & Back, W. (2009). Die Bierbrauerei - Band 2: Die Technologie der Würzebereitung (8 ed.). Wiley-VCH Verlag GmbH & Co. KGaA.

Narziß, L., & Back, W. (2019). Die Bierbrauerei: Band 1 - Die Technologie der Malzbereitung (8 ed.). John Wiley and Sons.

Narziß, L., Back, W., Gastl, M., & Zarnkow, M. (2017). Abriss der Bierbrauerei (8. vollständig überarbeitete und erweiterte Auflage ed.). Wiley-VCH Verlag GmbH & Co.

Osman, A. M., Coverdale, S. M., Cole, N., Hamilton, S. E., de Jersey, J., & Inkerman, P. A. (2002). Characterisation and assessent of the role of barley malt endoproteases during malting and mashing. Journal of the Institue of Brewing, 108(1), 62–67. https://doi.org/10.1002/j.2050-0416.2002.tb00125.x

Sissons, M., Taylor, M., & Proudlove, M. (1995). Barley malt limit dextrinase: its extraction, heat stability, and activity during malting and mashing. Journal of the American Society of Brewing Chemists, 53(3), 104–110. https://doi.org/10.1094/ASBCJ-53-0104

Stenholm, K., & Home, S. (1999). A new approach to limit dextrinase and its role in mashing. Journal of the Institue of Brewing, 105(4), 205–210. https://doi.org/10.1002/j.2050-0416.1999.tb00020.x

Stewart, G. G. (2006). Studies on the uptake and metabolism of wort sugars during brewing fermentations. Master Brew. Ass. Am. Tech. Quart., 43, 265–269.

Yin, X. S., Macgregor, A. W., & Clear, R. M. (1989). Field fungi and β-glucan solubilase in barley kernels. Journal of the Institue of Brewing, 95(3), 195–198. https://doi.org/10.1002/j.2050-0416.1989.tb04626.x

Yu, W., Gilbert, G. R., & Fox, G. (2020). Malt protein inhibition of β-amylase alters starch molecular structure during barley mashing. Food Hydrocolloids, 100. https://doi.org/10.1016/j.foodhyd.2019.105423

Yu, W., Zou, W., Dhital, S., Wu, P., Gidley, M. J., Fox, G., & Gilbert, G. R. (2018). The adsorption of α-amylase on barley proteins affects the in vitro digestion of starch in barley flour. Food Chemistry, 241, 493–501. https://doi.org/10.1016/j.foodchem.2017.09.021

Zhang, G., & Li, C. (Eds.). (2010). Genetics and Improvement of Barley Malt Quality (1 ed.). Springer-Verlag. https://doi.org/10.1007/978-3-642-01279-2

Funding

Open Access funding enabled and organized by Projekt DEAL. This work was not financially supported.

Author information

Authors and Affiliations

Contributions

Andreas Laus wrote the manuscript, conceived and designed the research and analyzed the data. Frank Endres conducted additional experiments. Martin Zarnkow, Mathias Hutzler, and Fritz Jacob supervised and administrated the project. All authors reviewed, read, and approved the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Laus, A., Endres, F., Hutzler, M. et al. Isothermal Mashing of Barley Malt: New Insights into Wort Composition and Enzyme Temperature Ranges. Food Bioprocess Technol 15, 2294–2312 (2022). https://doi.org/10.1007/s11947-022-02885-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02885-2