Abstract

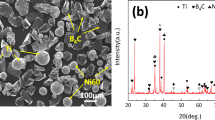

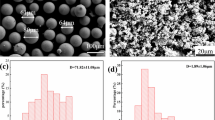

In order to solve the problems of low hardness and poor wear resistance of titanium alloy, laser cladding technology was used to prepare NiCrBSi coatings with different amounts of B4C on the surface of Ti-6Al-4V alloy. The effects of B4C content on the microstructure evolution, hardness, fracture toughness, and wear resistance of NiCrBSi coatings were investigated. The results showed that with an increase of B4C addition, the size and number of ceramic phases TiB2, TiC, and CrB in the coating increased, and the ceramic phases were dispersed in the coating. The average microhardness of the coating with 9 wt.% B4C addition was the highest, reaching 1250.3 HV0.2, which is 15% higher than that of the coating without B4C addition. After adding B4C, the fracture toughness of the coating increased. When the addition of B4C was 3 wt.%, the fracture toughness of the coating was the highest, reaching 1.42 MPa m1/2, which is 178.4% higher than that of the coating without B4C. With the increase of the addition of B4C, the wear loss of the coating decreased and the wear resistance increased.

Similar content being viewed by others

References

R. Sahoo, B.B. Jha, T.K. Sahoo, and D. Sahoo, J. Mater. Eng. Perform. 23, 2092. https://doi.org/10.1007/s11665-014-0987-7 (2014).

H. Dong and T. Bell, Wear 238, 131. https://doi.org/10.1016/S0043-1648(99)00359-2 (2000).

R. Srinivasan, M. Kamaraj, D. Rajeev, S. Ravi, and N. Senthilkumar, Silicon 14, 8629. https://doi.org/10.1007/s12633-022-01657-z (2022).

A. Vadiraj and M. Kamaraj, Mater. Sci. Forum 681, 539. https://doi.org/10.4028/www.scientific.net/MSF.539-543.681 (2007).

Y. Luo, S. Ge, Z. **, and J. Fisher, P I Mech. Eng. J-J Eng. Tribol. 223, 311. https://doi.org/10.1243/13506501JET488 (2009).

S. Mukherjee, S. Dhara, and P. Saha, J. Manuf. Process. 65, 119. https://doi.org/10.1016/j.jmapro.2021.03.023 (2021).

H.X. Zhang, H.J. Yu, and C.Z. Chen, Sci. Eng. Compos. Mater. 24, 541. https://doi.org/10.1515/secm-2015-0032 (2017).

Y. Zhu, X.B. Liu, Y.F. Liu, G. Wang, Y. Wang, Y. Meng, and J. Liang, Surf. Coat. Technol. 424, 127664. https://doi.org/10.1016/j.surfcoat.2021.127664 (2021).

Z.Y. Zhou, X.B. Liu, S.G. Zhuang, X.H. Yang, M. Wang, and C.F. Sun, Appl. Surf. Sci. 481, 209. https://doi.org/10.1016/j.apsusc.2019.03.092 (2019).

W.L. Li, R.F. Di, R.W. Yuan, H.Y. Song, and J.B. Lei, J. Manuf. Process. 74, 413. https://doi.org/10.1016/j.jmapro.2021.12.045 (2022).

Y.L. **a, H.N. Chen, X.D. Liang, and J.B. Lei, J. Manuf. Process. 68, 1694. https://doi.org/10.1016/j.jmapro.2021.06.074 (2021).

N.S. Karthiselva and S.R. Bakshi, Mater. Sci. Eng. A. 663, 38. https://doi.org/10.1016/j.msea.2016.03.098 (2016).

Y.H. Liu, Study on Fabrication and Reinforcement Mechanism of Ni-based Composite Laser Cladding Coating on Ti6Al4V Alloy. East China University of Science and Technology, 2015 (in Chinese).

L.L. Bai, J. Li, J.L. Chen, R. Song, J.Z. Shao, and C.C. Qu, Opt. Laser Technol. 76, 33. https://doi.org/10.1016/j.optlastec.2015.07.010 (2016).

Y. Diao and K. Zhang, Appl. Surf. Sci. 352, 163. https://doi.org/10.1016/j.apsusc.2015.04.030 (2015).

M.G. Krukovich, B.A. Prusakov, and I.G. Sizov, The formation conditions for boride and boronized layers and their influence on the layers’ plasticity. in Plasticity of Boronized Layers, vol 237 (Cham, Springer Series in Materials Science, 2016) pp. 81–110. https://doi.org/10.1007/978-3-319-40012-9_7.

Q.W. Meng, L. Geng, and B.Y. Zhang, Surf. Coat. Technol. 200, 4923. https://doi.org/10.1016/j.surfcoat.2005.04.059 (2006).

X.H. Fan, L. Geng, B. Xu, and J. Li, Adv. Mater. Res. 79, 473. https://doi.org/10.4028/www.scientific.net/AMR.79-82.473 (2009).

Y.L. Liang, H.G. Fu, Z.G. **ng, X.Y. Guo, and J. Lin, J. Mater. Eng. Perform. 31, 5189. https://doi.org/10.1007/s11665-022-06604-y (2022).

M. Masanta, S.M. Shariff, and A.R. Choudhury, Mater. Sci. Eng. A 528, 5327. https://doi.org/10.1016/j.msea.2011.03.057 (2011).

W.G. Li, J. Li, and Y.S. Xu, Coatings 11, 960. https://doi.org/10.3390/coatings11080960 (2021).

C.C. Qu, J. Li, L.L. Bai, J.Z. Shao, R. Song, and J.L. Chen, J. Alloys Compd. 644, 450. https://doi.org/10.1016/j.jallcom.2015.05.081 (2015).

J.M. Drezet, S. Pellerin, C. Bezençon, and S. Mokadem, J. Phys. IV 120, 299. https://doi.org/10.1051/jp4:2004120034 (2004).

J. Li, X.J. Zhang, H.P. Wang, and M.P. Li, Int. J. Min. Met. Mater. 20, 57. https://doi.org/10.1007/s12613-013-0693-8 (2013).

T. Chen, W.P. Li, D.F. Liu, Y. **ong, and X.C. Zhu, Ceram. Int. 47, 755. https://doi.org/10.1016/j.ceramint.2020.08.186 (2020).

E.B. Jacob and P. Garik, Nature 343, 523. (1990).

A. Faye, V. Paramesw, and S. Basu, Mech. Mater. 94, 156. https://doi.org/10.1016/j.mechmat.2015.12.002 (2016).

Q. Chang, D.L. Chen, H.Q. Ru, X.Y. Yue, L. Yu, and C.P. Zhang, Biomaterials 31, 1493. https://doi.org/10.1016/j.biomaterials.2009.11.046 (2010).

J.D. Hogan, L. Farbaniec, T. Sano, M. Shaeffer, and K.T. Ramesh, Acta Mater. 102, 263. https://doi.org/10.1016/j.actamat.2015.09.028 (2016).

Acknowledgements

The authors would like to thank R&D Program of Bei**g Municipal Education Commission (KZ202210005004) for financial support for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, H., Liang, Y. & Fu, H. Effect of B4C Addition on Microstructure and Wear Resistance of Laser Cladding NiCrBSi Coatings. JOM 75, 515–525 (2023). https://doi.org/10.1007/s11837-022-05610-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05610-8