Abstract

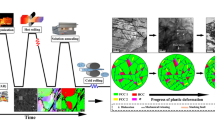

Single FCC CoCrFeMnNi with a mass of 1 kg was fabricated by vacuum levitation melting + casting. Lattice distortion caused by cold-rolling (CR) increases with thickness reduction ratio R (20%, 40%, 60% and 80%) and decreases in subsequent annealing. The recovery at 923–1023 K and grain growth at 1073–1273 K is systematically investigated. Nonlinear fitting methods are applied to study the recovery and grain growth kinetics, in which the equilibrium microhardness at a definite recovery temperature and initial grain size before the onset of grain growth are required to be fitted. The recovery activation energies of 60% and 80% CRed alloys are 148.91 kJ/mol and 155.1 kJ/mol, respectively, while the fitted equilibrium microhardness decreases with increasing T. Although satisfactory nonlinear fitted results of dn ~ 1/T curves, where d is grain size, can be obtained for both n = 2 and 3, the classic mechanism with n = 2 and lower activation energy (254 kJ/mol) are mainly responsible for grain growth. In all, the recovery at 923–1023 K is caused by dislocation (viscous) slide while the grain growth at 1073–1273 K can be mainly controlled by GB migration.

Similar content being viewed by others

Data Availability

The data used in this study are available from the authors on request.

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299 https://doi.org/10.1002/adem.200300567 (2004).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213. https://doi.org/10.1016/j.msea.2003.10.257 (2004).

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, and R.O. Ritchie, Science 345, 1153. https://doi.org/10.1126/science.1254581 (2014).

Z.F. Lei, X.J. Liu, Y. Wu, H. Wang, S.H. Jiang, S.D. Wang, X.D. Hui, Y.D. Wu, B. Gault, P. Kontis, D. Raabe, L. Gu, Q.H. Zhang, H.W. Chen, H.T. Wang, J.B. Liu, K. An, Q.S. Zeng, T.G. Nieh, and Z.P. Lu, Nature 563, 546. https://doi.org/10.1038/s41586-018-0834-3 (2018).

T.K. Tsao, A.C. Yeh, C.M. Kuo, K. Kakehi, H. Murakami, J.W. Yeh, and S.R. Jian, Sci. Rep. 7, 12658. https://doi.org/10.1038/s41598-017-13026-7 (2017).

Z.J. Zhang, M.M. Mao, J.W. Wang, B. Gludovatz, Z. Zhang, S.X. Mao, E.P. George, Q. Yu, and R.O. Ritchie, Nat. Commun. 6, 10143. https://doi.org/10.1038/ncomms10143 (2015).

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, and E.P. George, Acta mater. 61, 5743. https://doi.org/10.1016/j.actamat.2013.06.018 (2013).

E.P. George, D. Raabe, and R.O. Ritchie, Nat. Rev. Mater. 4, 515. https://doi.org/10.1038/s41578-019-0121-4 (2019).

L. Rogal, D. Kalita, and L. Litynska-Dobrzynska, Intermetallics 86, 104. https://doi.org/10.1016/j.intermet.2017.03.019 (2017).

B. Li, B. Qian, Y. Xu, Z.Y. Liu, and F.Z. Xuan, Mater. Letters 252, 88. https://doi.org/10.1016/j.matlet.2019.05.108 (2019).

J. Gu, S. Ni, Y. Liu, and M. Song, Mater. Sci. Eng. A 755, 289. https://doi.org/10.1016/j.msea.2019.04.025 (2019).

Q.F. Ye, K. Feng, Z.G. Li, F.G. Lu, R.F. Li, J. Huang, and Y.X. Wu, Appl. Surf. Sci. 396, 1420. https://doi.org/10.1016/j.apsusc.2016.11.176 (2017).

Z.L. Xu, H. Zhang, X.J. Du, Y.Z. He, H. Luo, G.S. Song, L. Mao, T.W. Zhou, and L.L. Wang, Corros. Sci. 177, 108954. https://doi.org/10.1016/j.corsci.2020.108954 (2020).

F. Otto, A. Dlouhy, K.G. Pradeep, M. Kubenova, D. Raabe, G. Eggeler, and E.P. George, Acta Mater. 112, 40. https://doi.org/10.1016/j.actamat.2016.04.005 (2016).

W.H. Liu, Y. Wu, J.Y. He, T.G. Nieh, and Z.P. Lu, Scripta Mater. 68, 526. https://doi.org/10.1016/j.scriptamat.2012.12.002 (2013).

P.P. Bhattacharjee, G.D. Sathiaraj, M. Zaid, J.R. Gatti, C. Lee, C.W. Tsai, and J.W. Yeh, J. Alloys Compd. 587, 544. https://doi.org/10.1016/j.jallcom.2013.10.237 (2014).

F. Otto, N.L. Hanold, and E.P. George, Intermetallics 54, 39. https://doi.org/10.1016/j.intermet.2014.05.014 (2014).

M. Vaidya, A. Anupam, J.V. Bharadwaj, C. Srivastava, and B.S. Murty, J. Alloys Compd. 791, 1114. https://doi.org/10.1016/j.jallcom.2019.03.341 (2019).

C.H. Song, G.J. Li, G. Li, G.P. Zhang, and B. Cai, Micron 150, 103144. https://doi.org/10.1016/j.micron.2021.103144 (2021).

J.B. Nelson, and D. Riley, Proc. Phys. Soc. 57, 160. https://doi.org/10.1088/0959-5309/57/3/302 (1945).

S. Varalakshmi, M. Kamaraj, and B.S. Murty, J. Alloys Compd. 460, 253. https://doi.org/10.1016/j.jallcom.2007.05.104 (2008).

K.J. Lu, A. Chauhan, D. Litvinov, M. Walter, A.S. Tirunilai, J. Freudenberger, A. Kauffmann, M. Heilmaier, and J. Aktaa, Mater. Sci. Eng. A 791, 139781. https://doi.org/10.1016/j.msea.2020.139781 (2020).

M. Vaidya, K.G. Pradeep, B.S. Murty, G. Wilde, and S.V. Divinski, Acta Mater. 146, 211. https://doi.org/10.1016/j.actamat.2017.12.052 (2018).

F.J. Humphreys, and M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd edn. (Elsevier, Oxford, 2004), pp 333–378.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11974316 and U2004167). We really appreciate the Center of Advanced Analysis & Gene Sequencing, Zhengzhou University for its equipment support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, G., Lu, F., Li, G. et al. Recovery and Grain Growth Behavior of CoCrFeMnNi High Entropy Alloy. JOM 74, 4271–4279 (2022). https://doi.org/10.1007/s11837-022-05436-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05436-4