Abstract

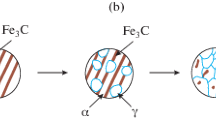

Welds in heavy haul rails are usually associated with accelerated wear and are a common source of defects, justifying a careful study of their characteristics. Heat-affected zones usually present hardness loss, corresponding to a spheroidized cementite region. The literature acknowledges that this is a consequence of the welding heat input but without further explanations. However, in order to control this loss, the mechanisms of microstructural changes need to be fully understood. This paper clarifies the mechanisms for the formation of the spheroidized region in the heat-affected zone of pearlitic welded rails, using as an example a flash butt-welded rail. The weld surroundings had its microstructure characterized and the correspondent hardness measured. Those microstructures were then simulated using a quenching dilatometer for three different rails. The results make it clear that the spheroidized microstructure is a consequence of the divorced eutectoid transformation, which is at a maximum at the end of the eutectoid gap.

Similar content being viewed by others

References

G. Girsch, J. Keichel, R. Gehrmann, A. Zlatnik, and N. Frank, in IHHA Conference, Shanghai

P. Mutton, J. Cookson, C. Qiu, and D. Welsby, Wear 366, 368 (2016).

K. Saita, K. Karimine, M. Ueda, K. Iwano, T. Yamamoto, and K. Hiroguchi, Nippon Steel Sumitomo Met. Tech. Rep. 105, 84 (2013).

M.J.M.M. Steenbergen and R.W. Van Bezooijen, in Wheel–Rail Interface Handbook (Elsevier, Amsterdam, 2009), p. 377

G. Krauss, Steels: Processing, Structure, and Performance (ASM International, Almere, 2015)

M. Fujii, H. Nakanowatari, and K. Nariai, JFE Tech. Rep. 20, 159 (2015).

P. Payson, W. L. Hodapp, and J. Leeder, Trans. Am. Soc. Met. 28, 306 (1940).

T. Oyama, O. D. Sherby, J. Wadsworth, and B. Walser, Scr. Metall. 18, 799 (1984).

J. D. Verhoeven and E. D. Gibson, Metall. Mater. Trans. A 29, 1181 (1998).

K. Ankit, R. Mukherjee, and B. Nestler, Acta Mater. 97, 316 (2015).

A.P. Tschiptschin, in 36 Congresso Anual da Associação Brasileira de Metais, Rio de Janeiro

K. Honda and S. Saito, J. Iron Steel Inst. 102, 261 (1920).

G. Speich and A. Szirmae, Trans. Met. Soc. AIME 245, 1063 (1969).

J. Cunningham, D. Medlin, and G. Krauss, J. Mater. Eng. Perform. 8, 401 (1999).

T. Nakano, H. Kawatani, and S. Kinoshita, Trans. Iron Steel Inst. Jpn. 17, 110 (1977).

G.-H. Zhang, J.-Y. Chae, K.-H. Kim, and D. W. Suh, Mater. Charact. 81, 56 (2013).

G. Molinder, Acta Metall. 4, 565 (1956).

M. Hillert, K. Nilsson, and L.-E. Törndahl, J. Iron Steel Inst. 209, 49 (1971).

M. Gouné, P. Maugis, and J. Drillet, J. Mater. Sci. Technol. 28, 728 (2012).

N. V. Luzginova, L. Zhao, and J. Sietsma, Metall. Mater. Trans. A 39, 513 (2008).

A.S. Pandit and H.K.D.H. Bhadeshia, in Proc. R. Soc. A, vol. 468 (The Royal Society), p. 2767.

D. Tawfik, P.J. Mutton, and W.K. Chiu, J. Mater. Process. Technol., 196, 279 (2008).

C.-M. Li, F. Sommer, and E.J. Mittemeijer, Z. Metallkd., 92, 32 (2001).

R.R. Porcaro, D.A.P. Lima, G.L. Faria, L.B. Godefroid, and L.C. Cândido, Soldagem Inspeção 22, 59 (2017)

M. Ueda, K. Mastushita, K. Iwano, A. Kobayashi, T. Yamamoto, T. Miyazaki, J. Takahashi, and Y. Kobayashi, Nippon Steel Sumitomo Met. Tech. Rep. 105, 63 (2013).

Acknowledgements

The authors are grateful for discussions with Amilton Sinátora, André Paulo Tschitschin and Luiz Henrique Dias Alves, for the help of Dany Michell Andrade Centeno on obtaining SEM images and Vale (Wheel-Rail Chair), CAPES and CNPq for financially supporting this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nishikawa, L.P., Goldenstein, H. Divorced Eutectoid on Heat-Affected Zone of Welded Pearlitic Rails. JOM 71, 815–823 (2019). https://doi.org/10.1007/s11837-018-3213-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3213-5